Jun. 2023

03

Version

ØD

Metric

Unit : mm

SAE Accuracy : C.W.±4%

# Matt finish # Shinny finish

1/4”

3/8”

3/8”

1/2”

1/2”

3/4”

3/4”

3/4”

1”

1 in.lb

0.5 ft.lb

1 ft.lb

1 ft.lb

2.5 ft.lb

1 ft.lb

2.5 ft.lb

35 -200 in.lb

15-80 ft.lb

30-150 ft.lb

50-250 ft.lb

50-300 ft.lb

100-600 ft.lb

100-700 ft.lb

0.56

0.84

1.34

2.38

3.68

5.70

6.00

T-200i

T-80F

T-150F

T-250F

T-300F

T-600F

T-700F

W

28.7

36.5

46.6

47.7

71.6

71.6

71.6

H

29.0

29.0

30.6

38.6

38.6

42.6

42.6

KG

A

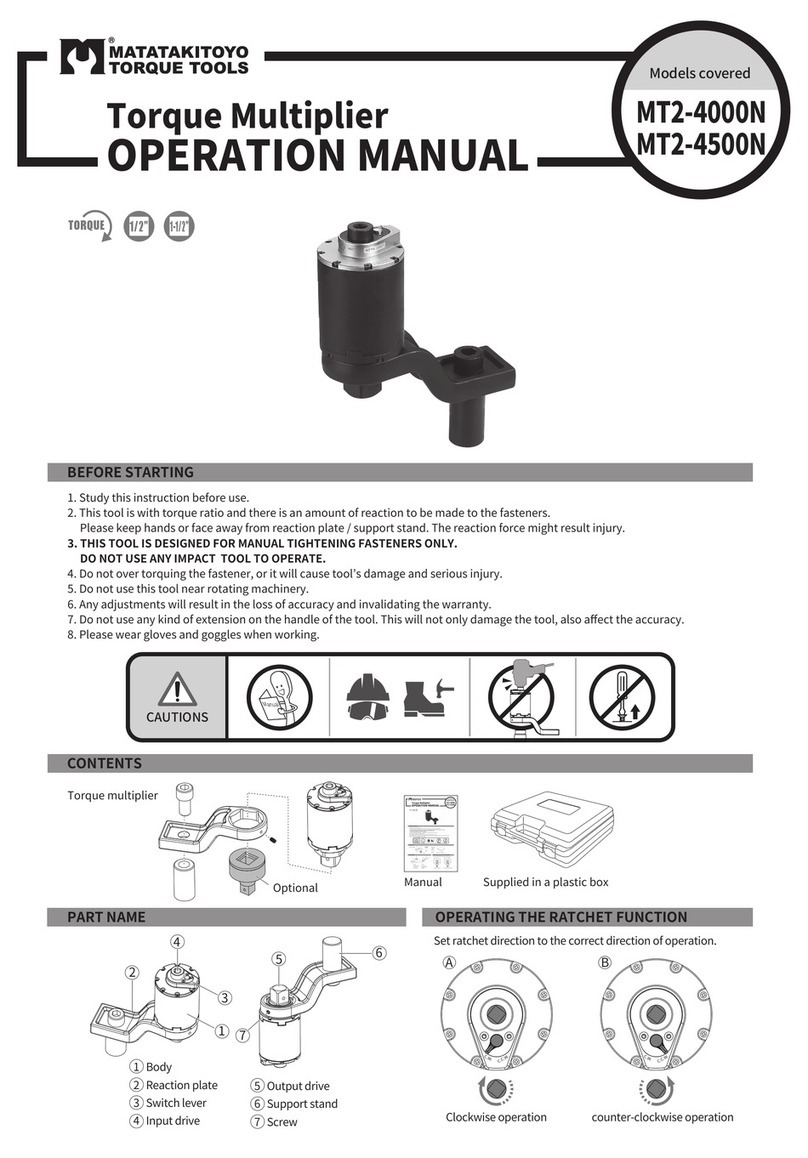

ITEM NO. Range ITEM NO. Range

1/4”

3/8”

3/8”

1/2”

1/2”

3/4”

3/4”

3/4”

1”

0.1 Nm

0.5 Nm

1 Nm

1 Nm

1 Nm

2.5 Nm

3.5 Nm

5-25 Nm

20-110 Nm

42-210 Nm

70-350 Nm

65-450 Nm

140-700 Nm

140-980 Nm

0.56

0.84

1.34

2.38

3.68

5.70

6.00

T-25N

T-110N

T-210N

T-350N

T-450N

T-700N

T-980N

L

280

360

470

630

850

1078

1222

L

280

360

470

630

850

1078

1222

W

28.7

36.5

46.6

47.7

71.6

71.6

71.6

H

20.3

23.6

27.8

33.2

37.1

51.5

51.5

51.5

57.0

20.3

23.6

27.8

33.2

37.1

51.5

51.5

51.5

57.0

29.0

29.0

30.6

38.6

38.6

42.6

42.6

KG

AØD ØD

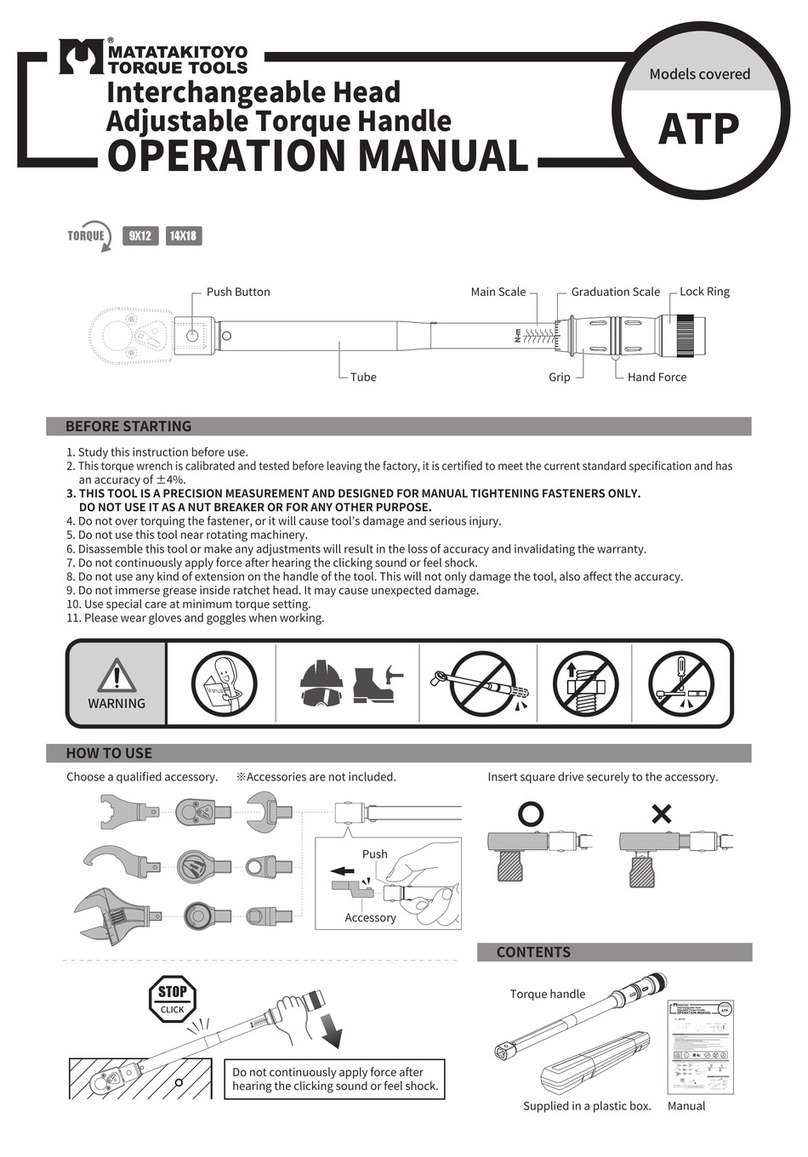

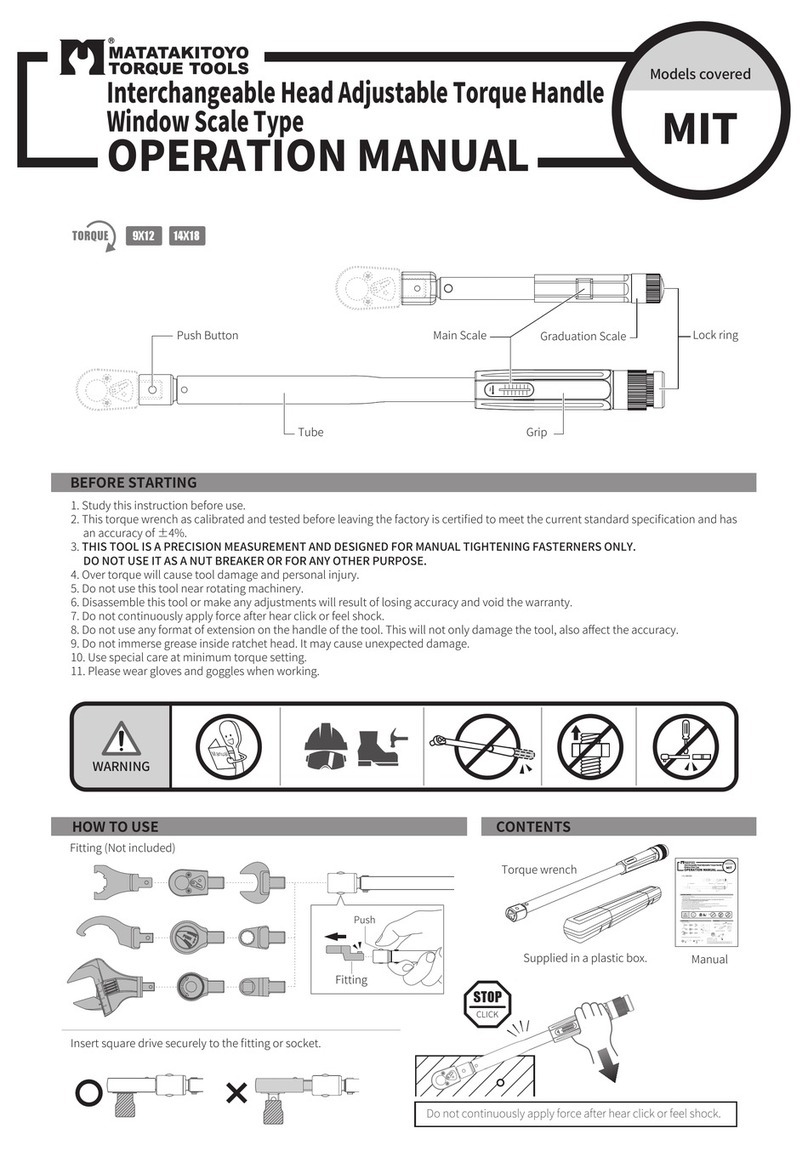

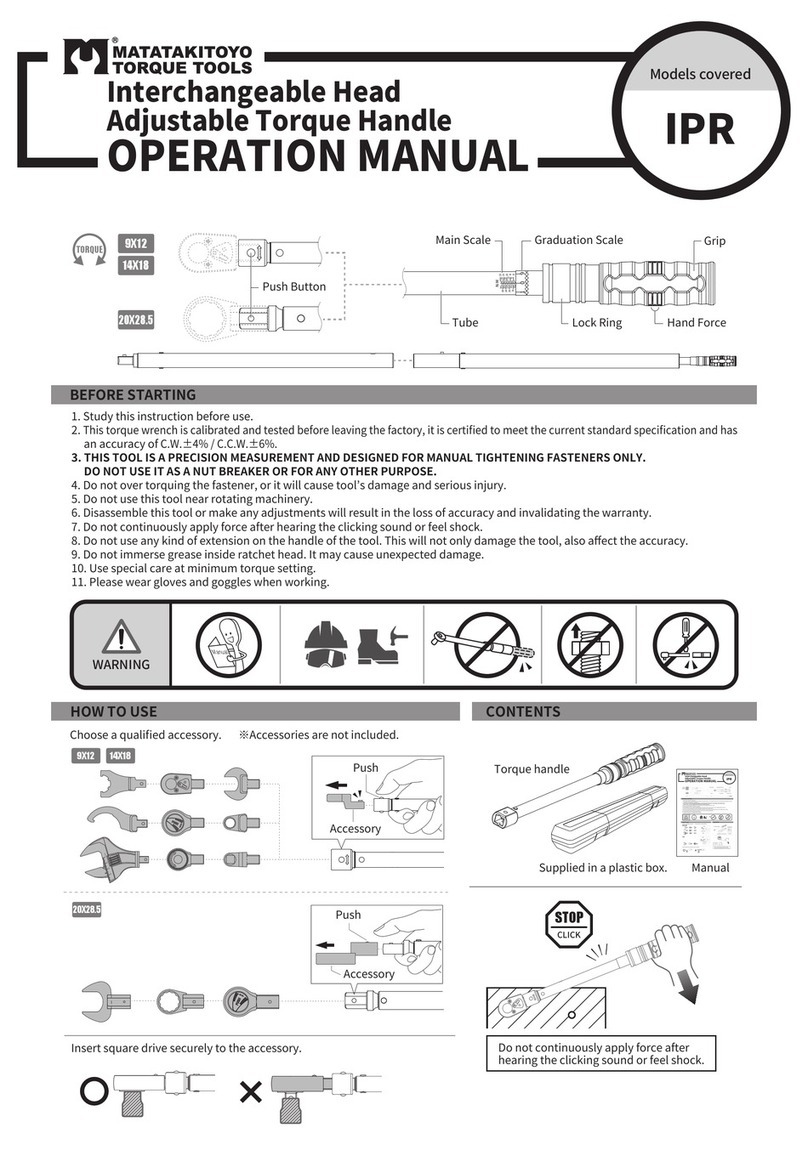

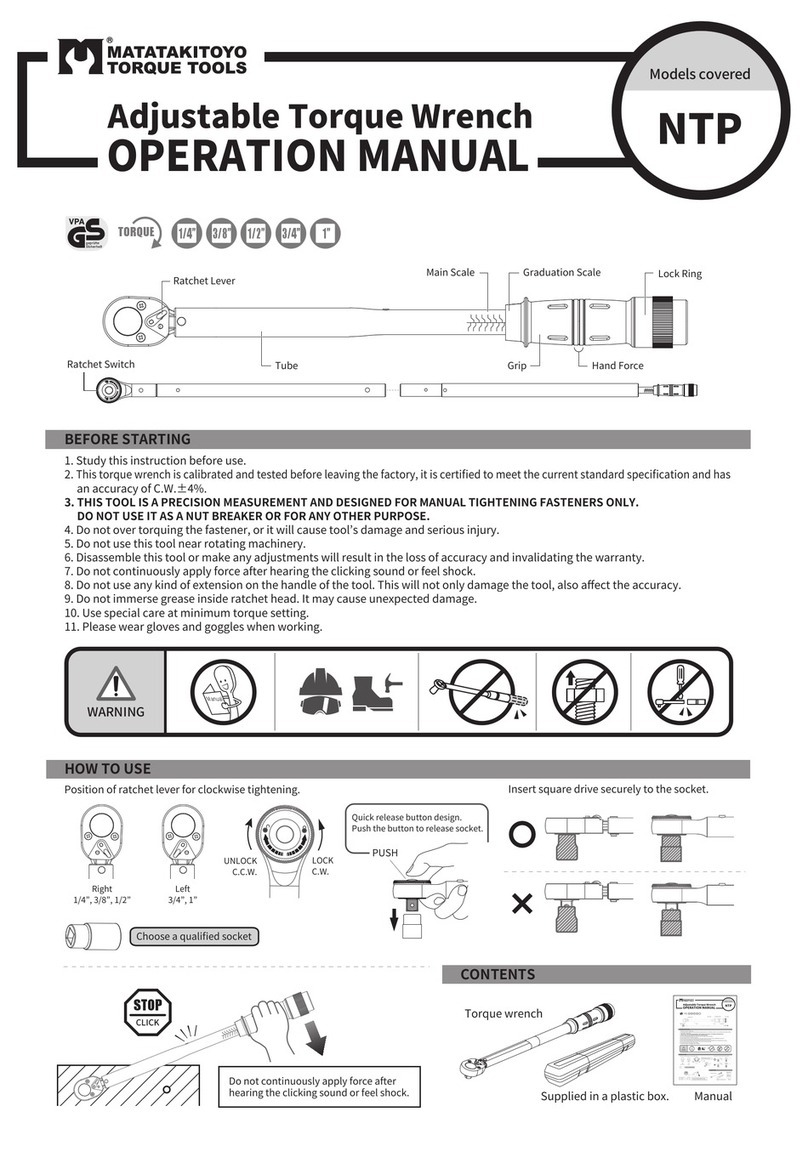

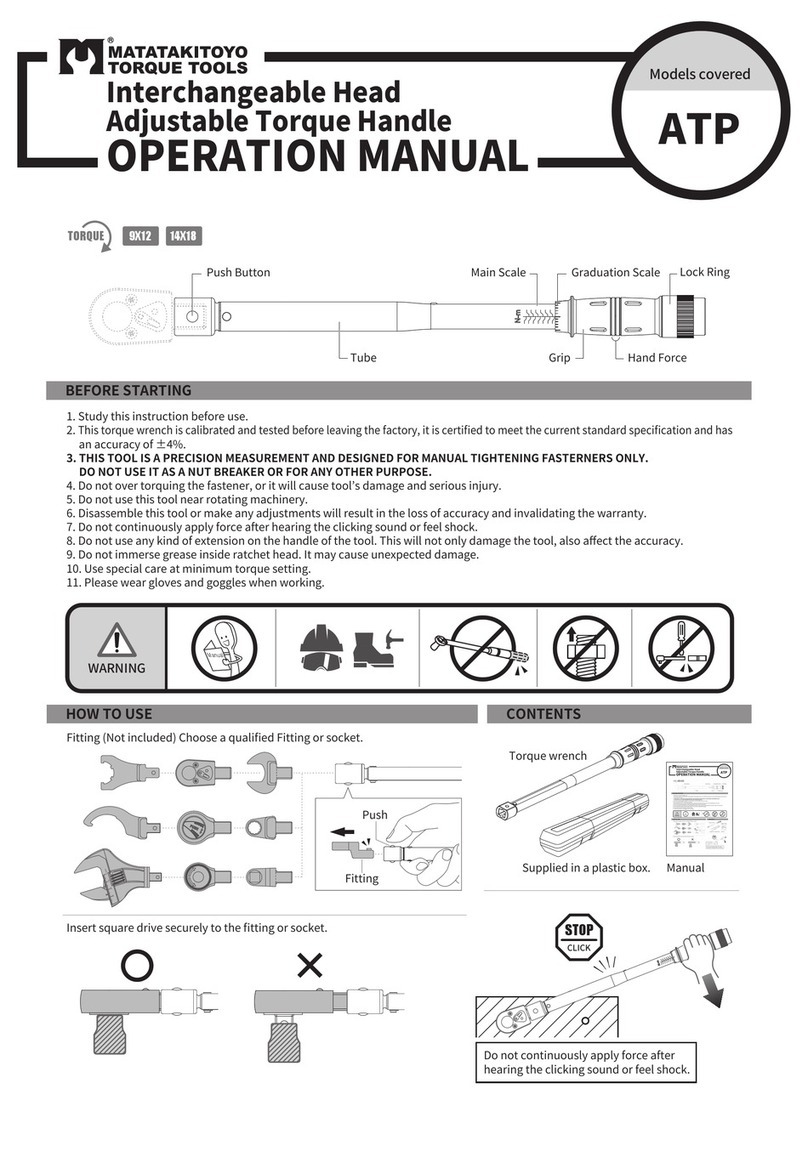

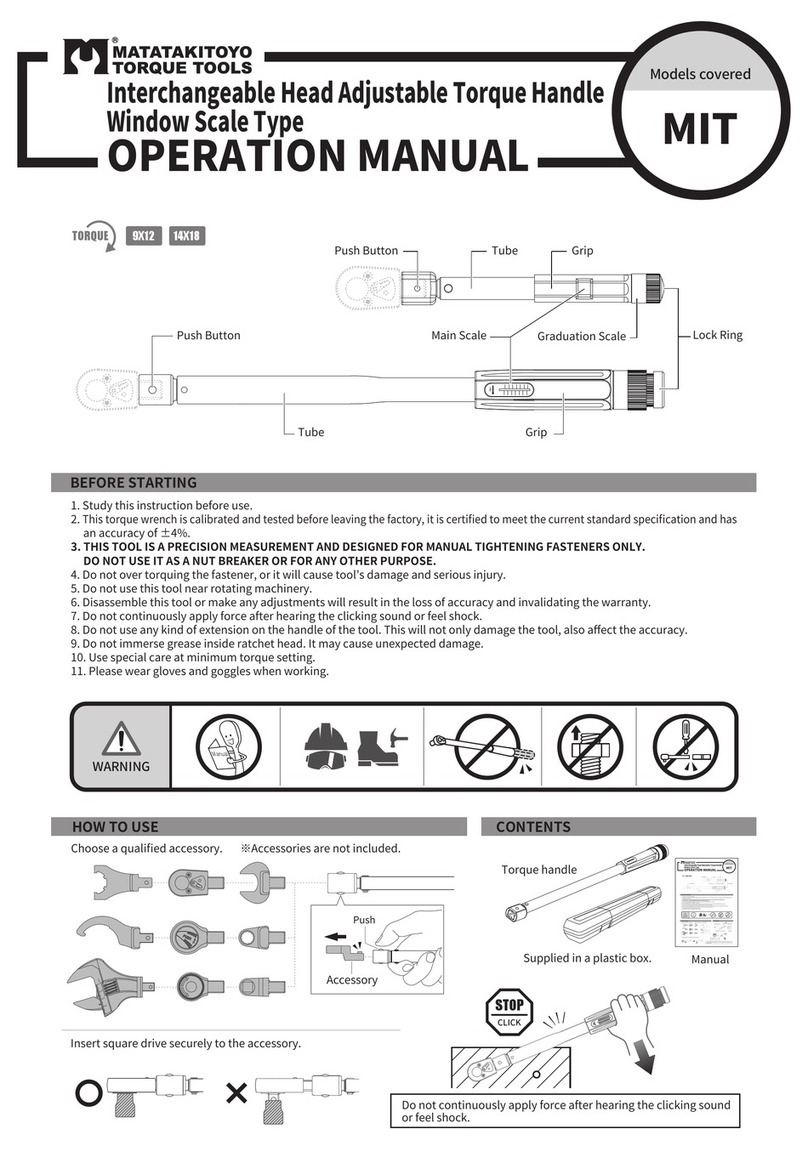

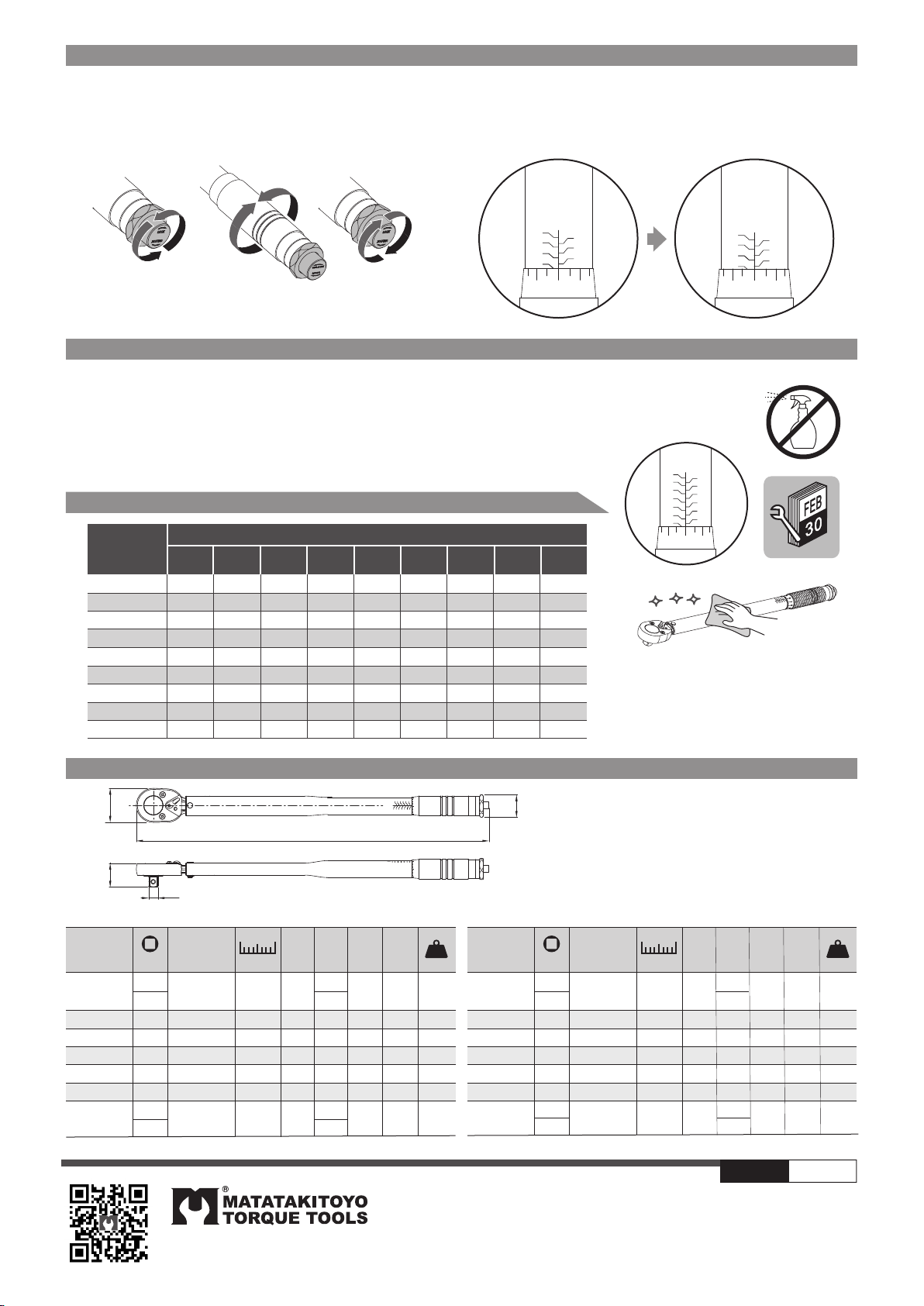

1. Turn the lock counter-clockwise to unlocked.

2. Turn the knurled handle clockwise or counter-clockwise

(Right or left) to set the desired torque.

3. Turn the lock clockwise to set finished.

For example : ITEM No. T-210N to set torque to 135 Nm.

Firstly turn the lock counter-clockwise and turn the knurled handle

clockwise until the upper edge to 130 Nm (see A) and the reading “5”

on the long tube must align with the center line of scale vertically so

as to acquire 130+5=135 Nm. (see B)

0

N-m

12

1

210 196

182

154

130

168

140

N-m

53

7

210 196

182

154 168

140

A

1 2 3 B

L

H W

N-m

A

Set Lock

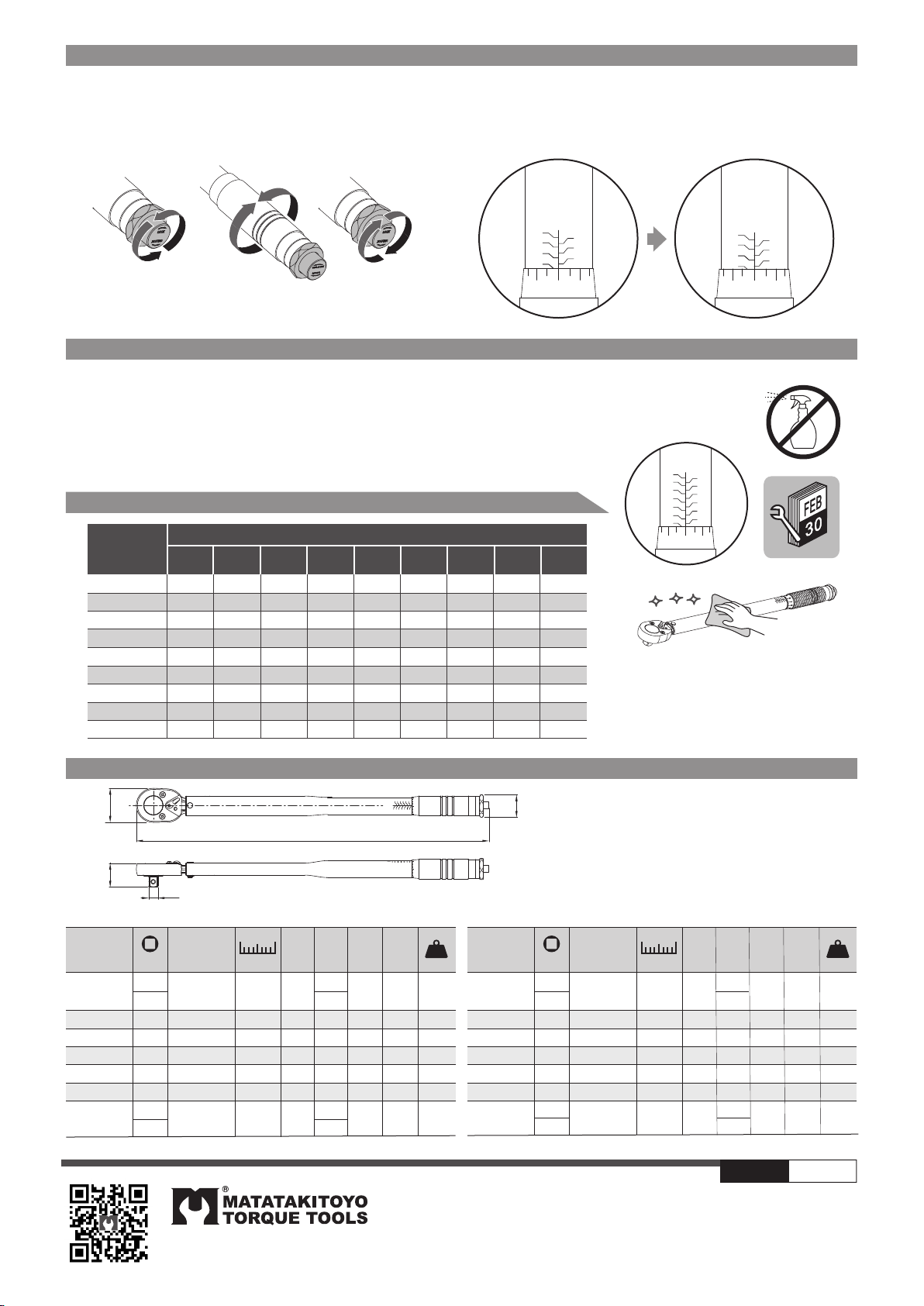

Unlock

Units to be

converted

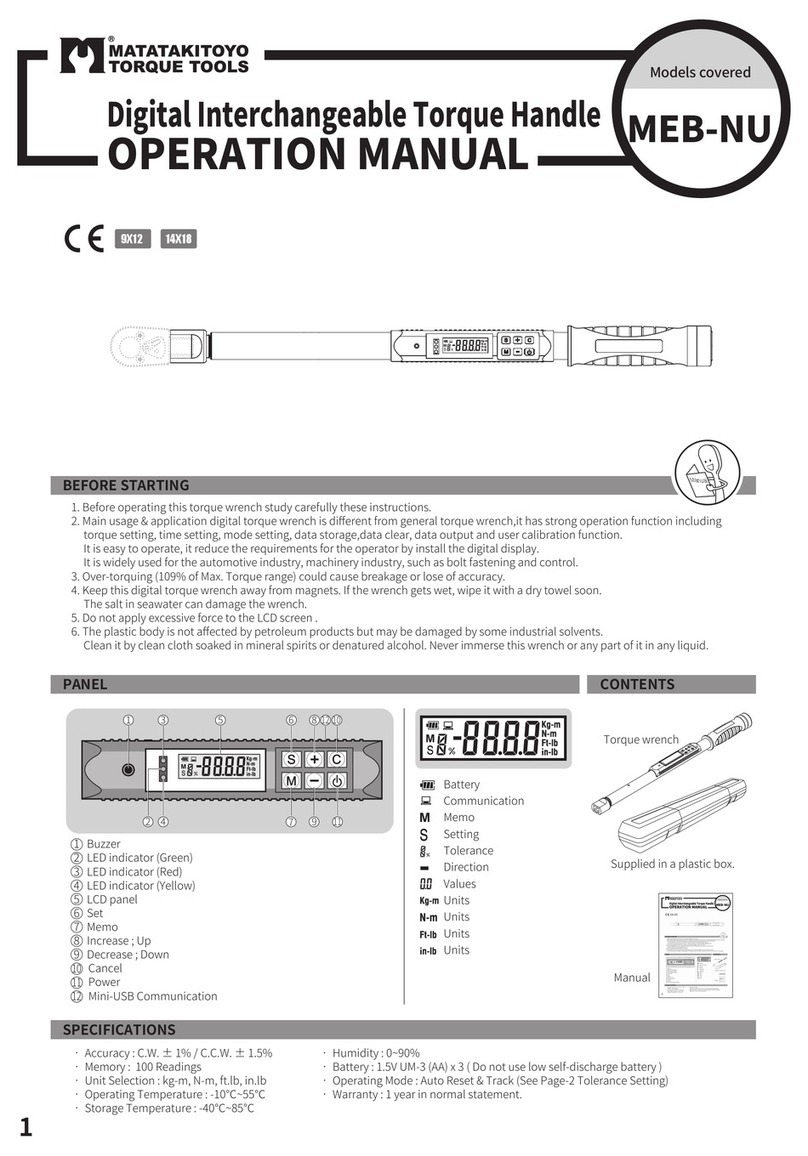

1 mN.m

1 cN.m

1 N.m

1 ozf.in

1 lbf.in

1 lbf.ft

1 gf.cm

1 kgf.cm(kp.cm)

1 kgf.m(kp.m)

1

10

1000

7.062

113

1356

0.098

98.07

9807

0.1

1

100

0.706

11.3

135.6

0.01

9.807

980.7

0.001

0.01

1

0.007

0.113

1.356

0.0001

0.098

9.807

0.142

1.416

141.6

1

16

192

0.014

13.89

1389

0.009

0.088

8.851

0.0625

1

12

0.0009

0.868

86.8

0.0007

0.007

0.738

0.005

0.083

1

0.00007

0.072

7.233

10.2

102

10197

72

1152.1

13826

1

1000

100000

0.01

0.102

10.2

0.072

1.152

13.83

0.001

1

100

0.0001

0.001

0.102

0.0007

0.0115

0.138

0.00001

0.01

1

=mN.m =cN.m =N.m =ozf.in =lbf.in =lbf.ft =gf.cm =kgf.cm

(kp.cm)

=kgf.m

(kp.m)

Corresponding unit

TORQUE CONVERSION FACTORS

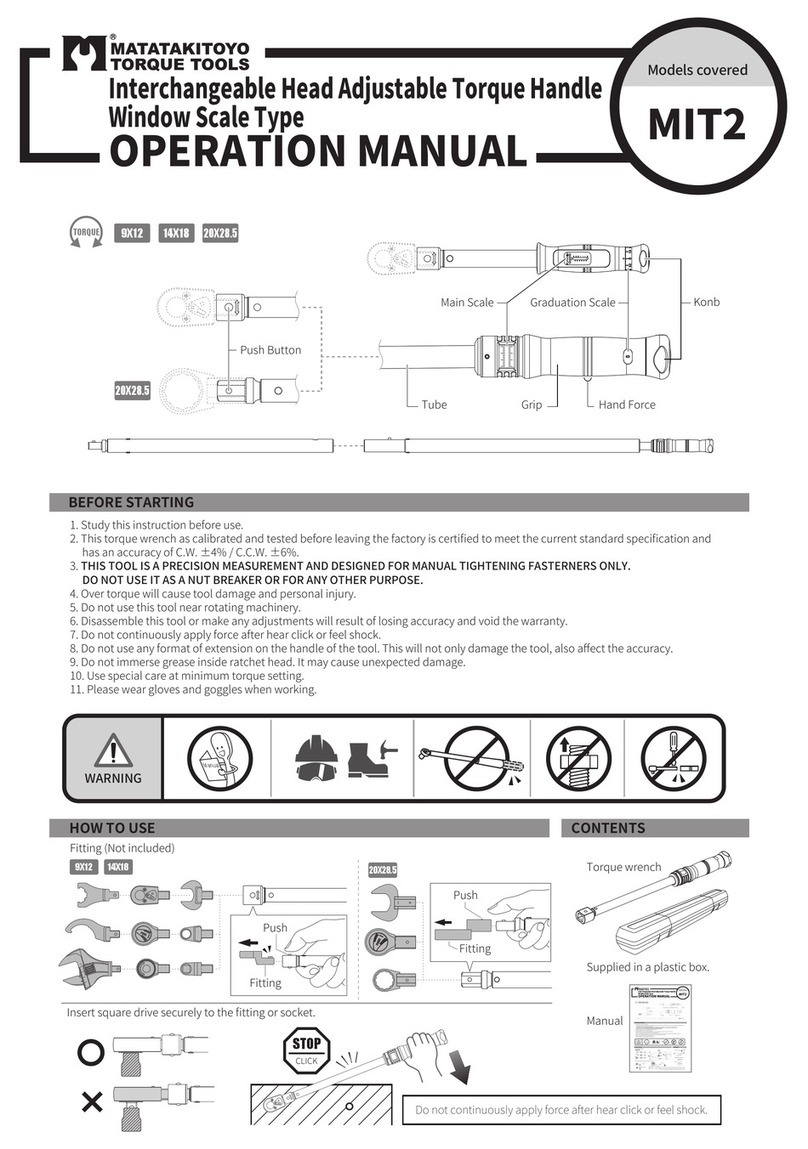

MAINTENANCE AND STORAGE

HOW TO SET TORQUE VALUE

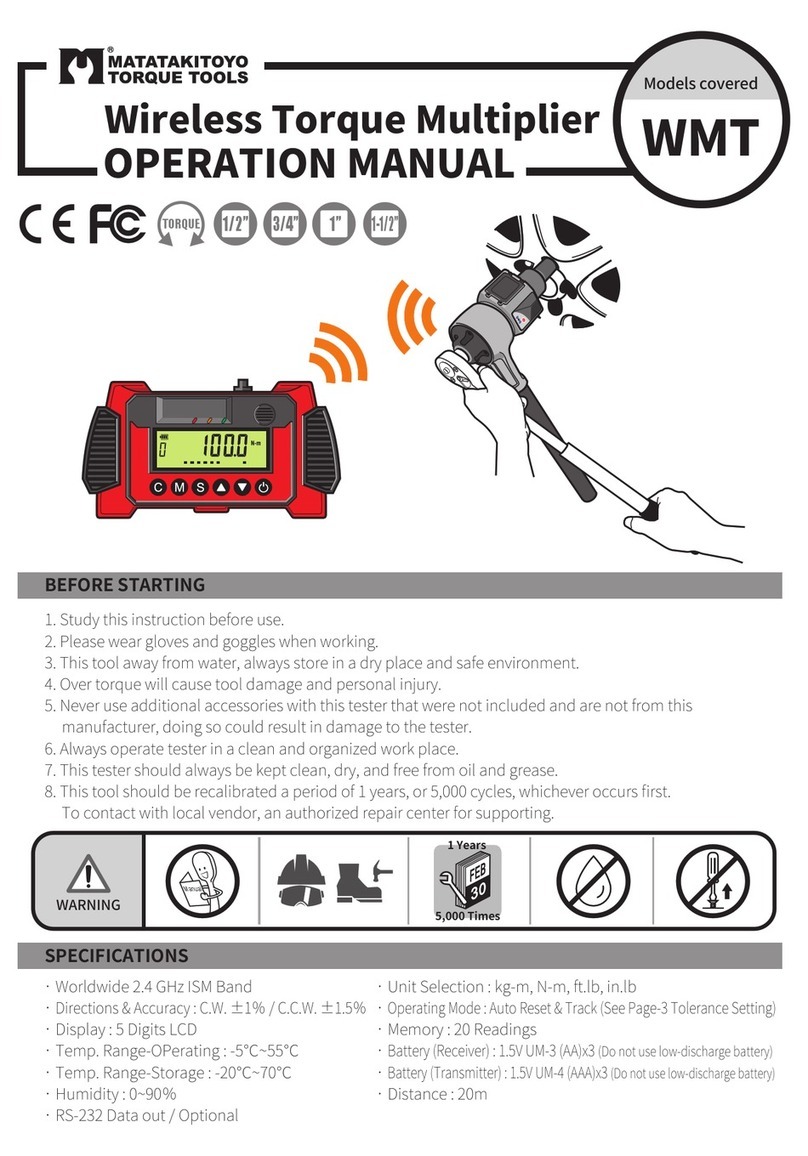

SPECIFICATION

Conversion-formula :

Units to be converted × Factor = Corresponding unit

Example : Convert 5 lbf . ft into cN . m

Solution : 5 × 135,6 = 678 cN . m

1. Please return torque value to the lowest reading when not in use. (see C) Do not turn below the lowest reading.

2. If this tool has not been used for a period of time, it shall be preloaded several times at its

maximum torque setting. This will allow internal lubricant to recoat.

3. Clean this tool by wiping with a clean cloth after operation and storage in a dry environment.

Do not dip any type of liquid in this tool. This may damage the internal of this tool.

4. This tool should be recalibrated a period of 12 months, or 5,000 cycles, whichever occurs first.

To contact with local vendor or an authorized repair center for supporting.

N-m

012

1

210 196

182

154

126

98

70

42

168

140

112

84

56

C

12 months

5000 cycles

www.matatakitoyo.com Made in Taiwan

MATATAKITOYO TOOL CO., LTD.

No. 63, Ln. 493, Sec. 3, Zhongshan Rd., Tanzi Dist.,

Taichung City 42754, Taiwan

TEL : 886-4-2533 5893

Manufacturer