Installation and Operating Instructions for

EAS®-NC clutch Type 45_. _ _ _ . _ Sizes 02 and 03 (B.4.8.2.1.GB)

13/02/2009 TK/KR/GC Chr. Mayr GmbH + Co. KG Tel.: 08341 / 804-241

Eichenstraße 1 Fax: 08341 / 804-422

D-87665 Mauerstetten http://www.mayr.de

Page 5 of 10 Germany eMail: info@mayr.de

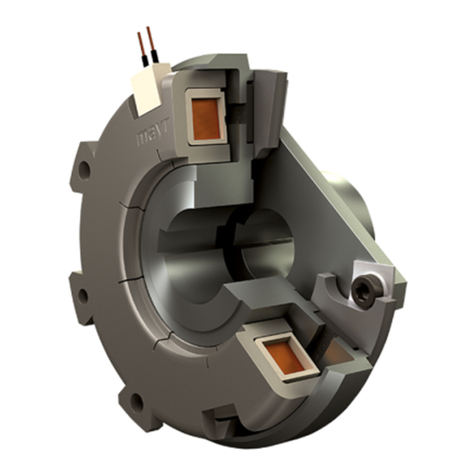

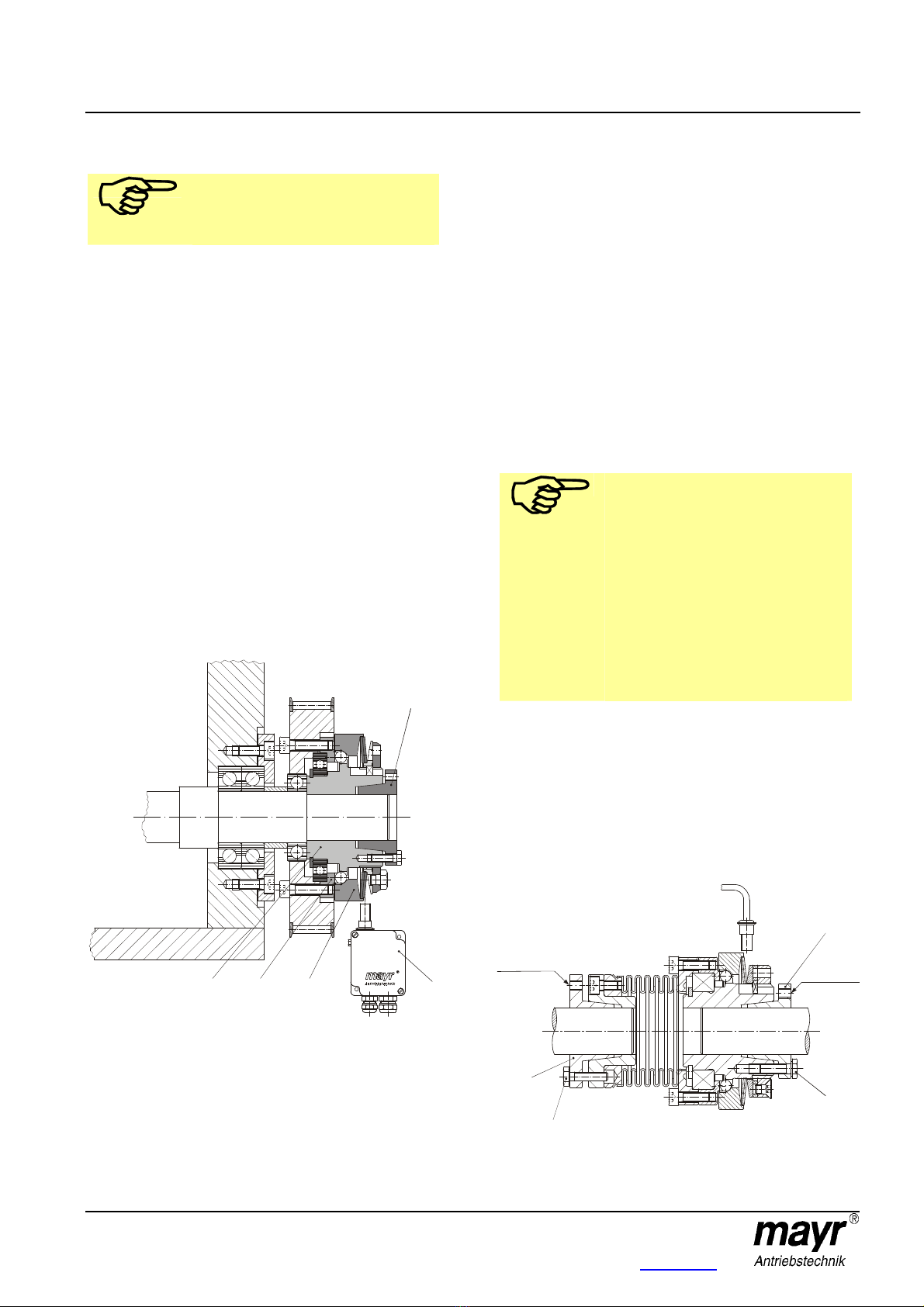

Assembly of the output elements (Figs. 1 and 3)

Please Observe!

Observe thread diameter and max. reach of

screw in the pressure flange (2) according

to Table 2.

In case of the EAS®-NC Type 450.- the output element is

located on the deep groove ball bearing (6) and screwed with the

pressure flange (2).

If the resulting radial force of the output element is nearly in the

centre of the ball bearing (7) an additional bearing of the output

element is not required.

In case of very wide output elements and a force application of

the resulting radial force outside the bearing centre, the output

element is additionally located on the shaft, Fig. 3.

Ensure that no significant axial forces (see Table 2) are

transmitted from the output element onto the pressure

flange (2) of the clutch.

For extremely wide output elements or for elements with a small

diameter, the EAS®-NC with long projecting hub is

recommended (Type 450._ _ _.1).

In the case of a very small diameter the output element is

attached to the pressure flange (2) of the clutch via an

intermediate adapter flange provided by the customer.

Ball bearings, needle bearings or bearing bushings are suitable

as bearing for the output element depending on the mounting

situation and installation facility.

Ensure that the bearing of the output element is designed as

location bearing (Fig. 3).

Fig. 3

Type 450.61_.0

Attachment onto the shaft

The EAS®-NC clutches are supplied with cone bushings or

keyways already fitted as standard.

Following points have to be noticed for the assembly of

cone bushings:

Shaft fits: h6 up to k6,

Surface of the shafts:

fine turned or ground (Ra = 0,8 µm)

Shaft material: yield point at least 400 N/mm2,

e.g. St 60, St 70, C 45, C 60.

Shafts and bores must be degreased or the preservation is to

be washed off before installation of the clutch or clutch hubs.

Greasy or oily bores or shafts do not transmit the torque

TRindicated in the order.

Push the clutch or clutch hub onto both shaft ends with a

suitable device and bring them to the correct position.

Uniformly tighten the clamping screws one after another (in 3

to max. 6 tightening circulations) using a torque wrench to the

torque indicated in Table 2.

Please Observe!

The clutch or clutch hub executes an axial

displacement in direction of the cone

bushing when tightening the cone bushing.

In case of the EAS®-NC clutch with steel

bellows (Type 453._ _ _.0) it must be

observed that at first only one cone bushing

is completely tightened (e.g. component

13/22), and then the other (steel bellows)

side (component 20/21, Fig. 5) because of

the above mentioned effect.

Additionally it must be observed when

assembling the Type 453._ _ _.0, that no

axial pressure is exerted on the steel

bellows (damage).

Disassembly

There are extractor threads beside of clamping screws

(13 and 20) in the cone bushings.

1) Release all clamping screws by several threads.

2) Unscrew the clamping screws located beside the extraction

threads and screw them into the extraction threads until

contact. Afterwards tighten these screws until the clamping

connection is released.

Fig. 5

2 3

21

thread

Extraction

thread