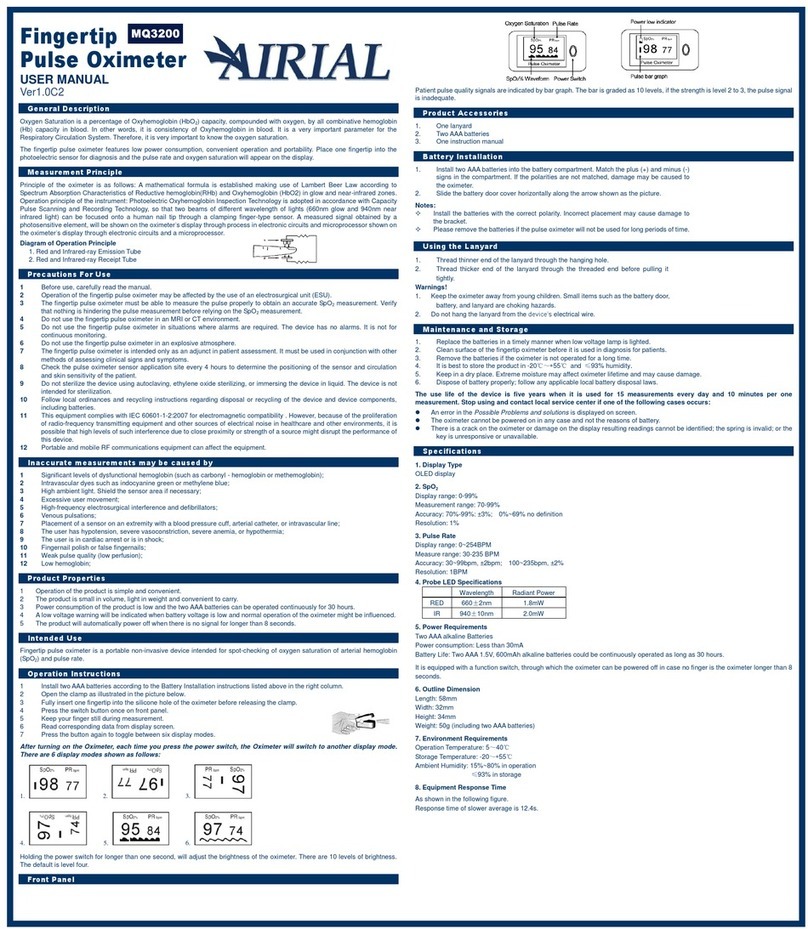

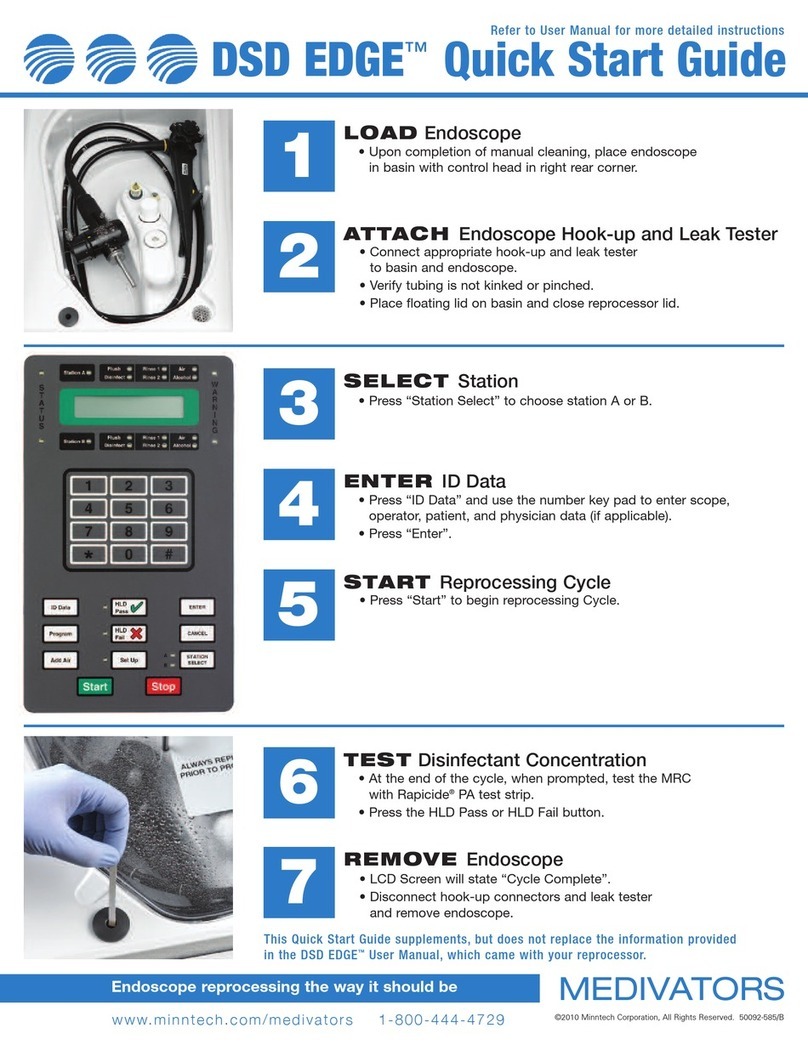

Medivators DSD EDGE User manual

Other manuals for DSD EDGE

1

Other Medivators Medical Equipment manuals

Medivators

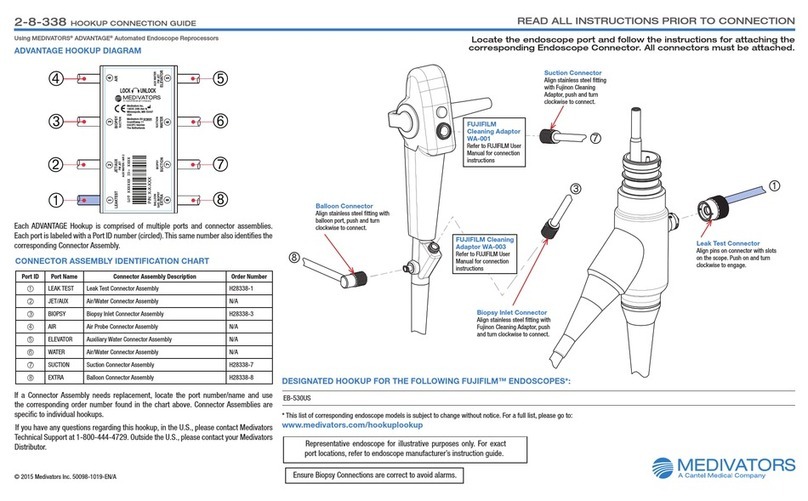

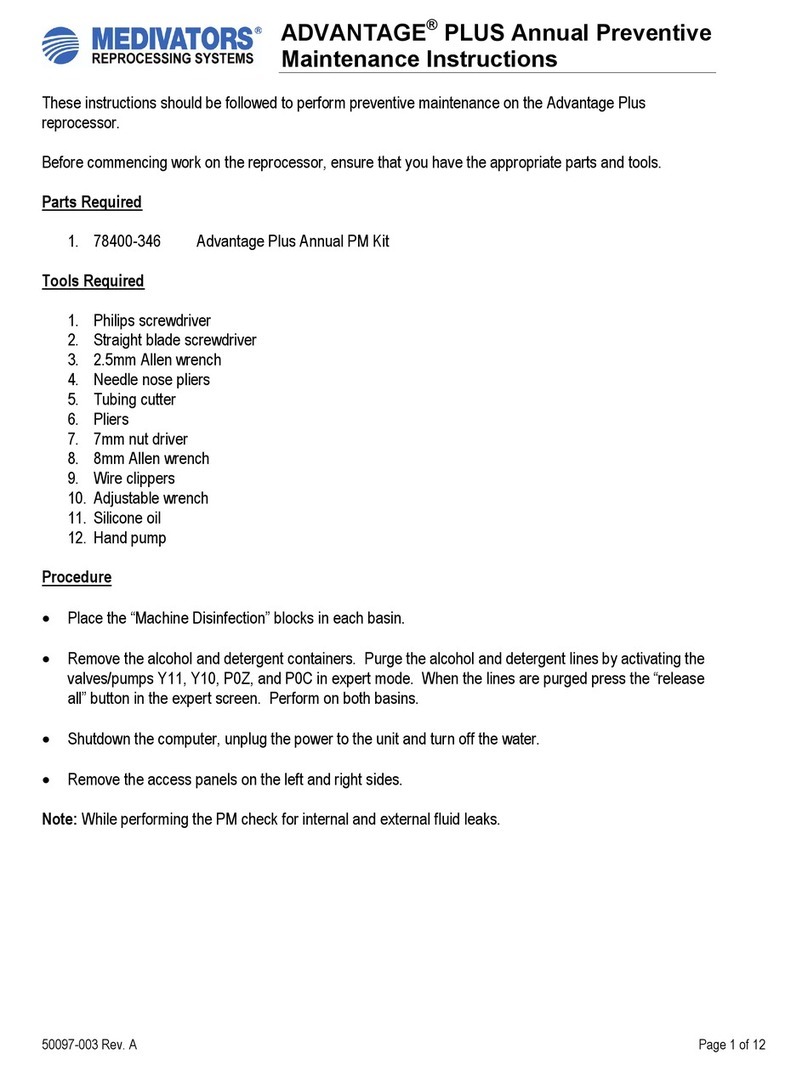

Medivators ADVANTAGE PLUS Operating instructions

Medivators

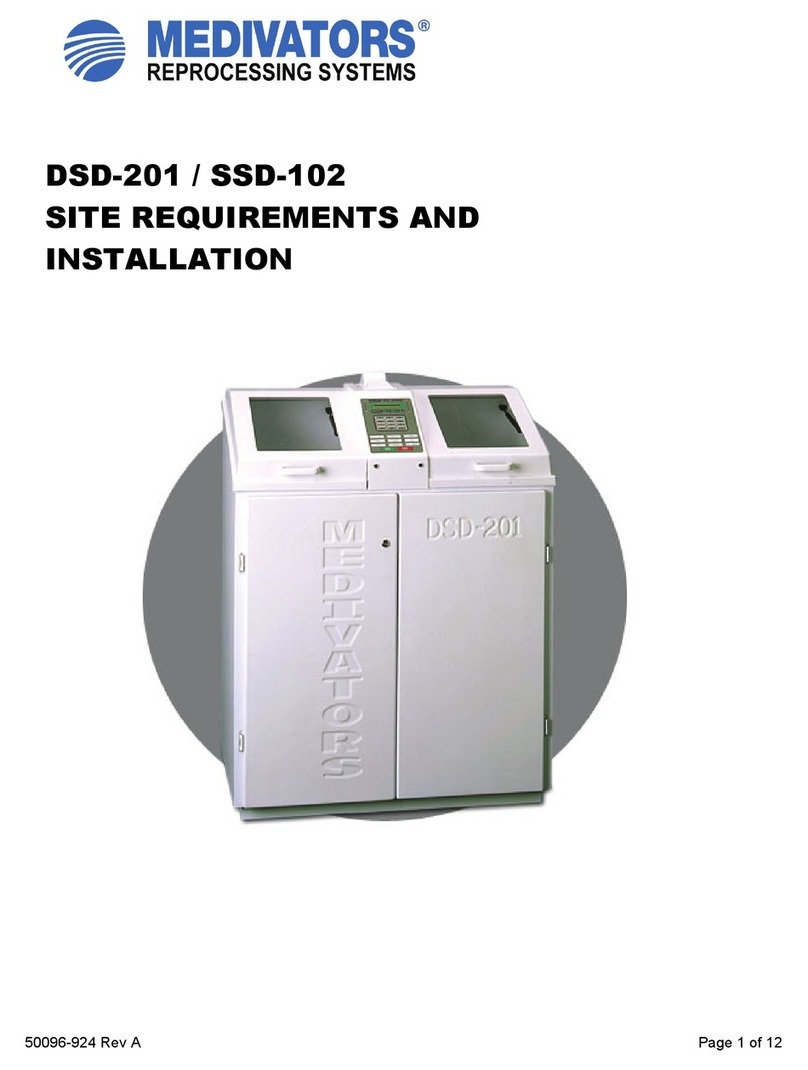

Medivators DSD-201 User manual

Medivators

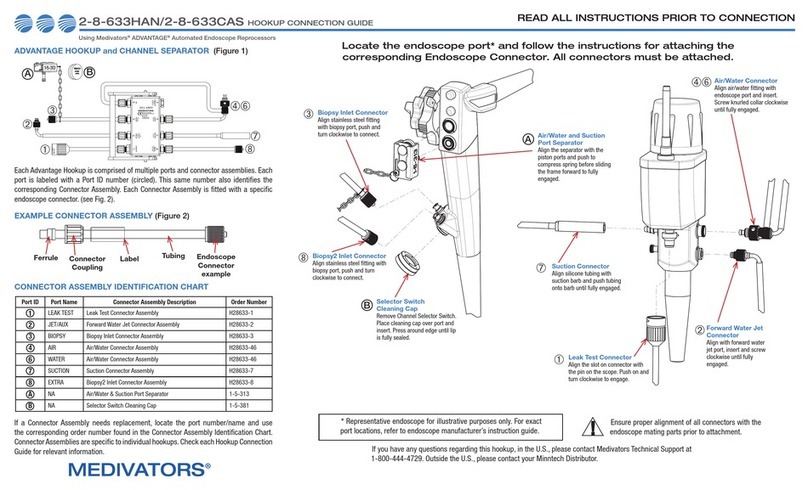

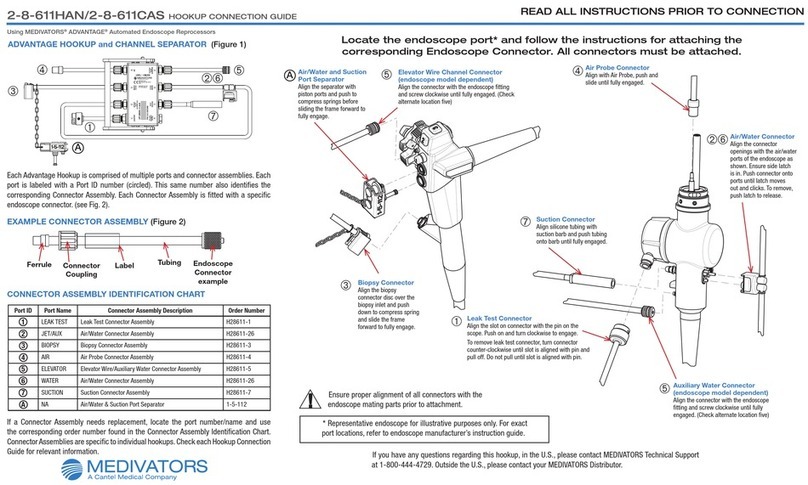

Medivators 2-8-611HAN Instruction Manual

Medivators

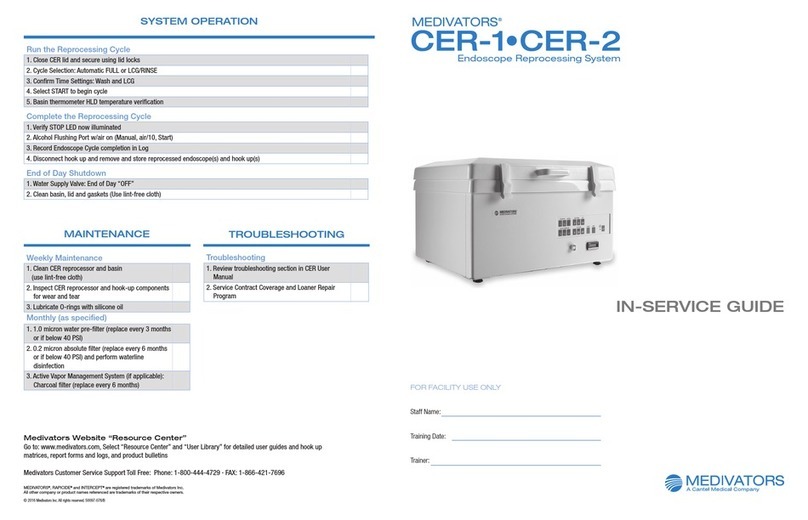

Medivators CER-1 User manual

Medivators

Medivators DSD EDGE User manual

Medivators

Medivators DSD-201 User manual

Medivators

Medivators Advantage Instruction Manual

Medivators

Medivators ADVANTAGE PLUS Technical specifications

Medivators

Medivators ADVANTAGE PLUS User manual

Medivators

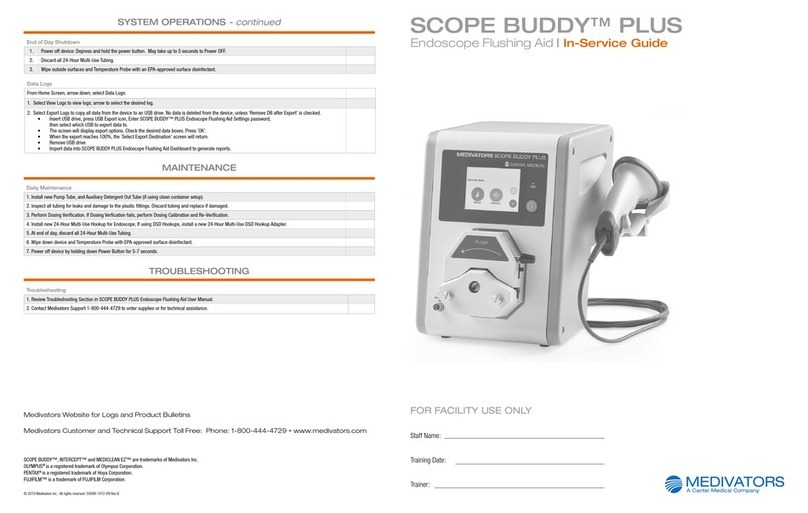

Medivators SCOPE BUDDY User manual

Popular Medical Equipment manuals by other brands

Launch

Launch CRP123 user manual

Smiths Medical

Smiths Medical CADD-Solis Quick reference card

MyDiagnostick

MyDiagnostick 1001R manual

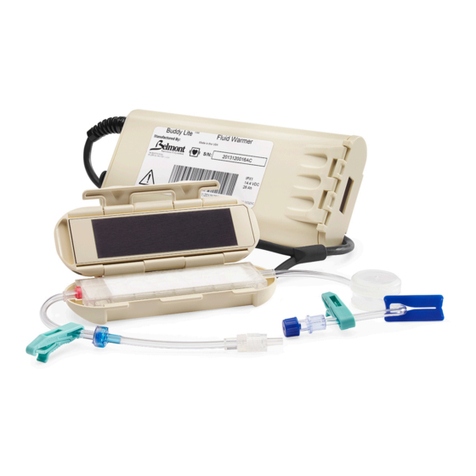

Belmont

Belmont buddy lite Operator's manual

Boston Scientific

Boston Scientific LATITUDE 6288 Patient manual

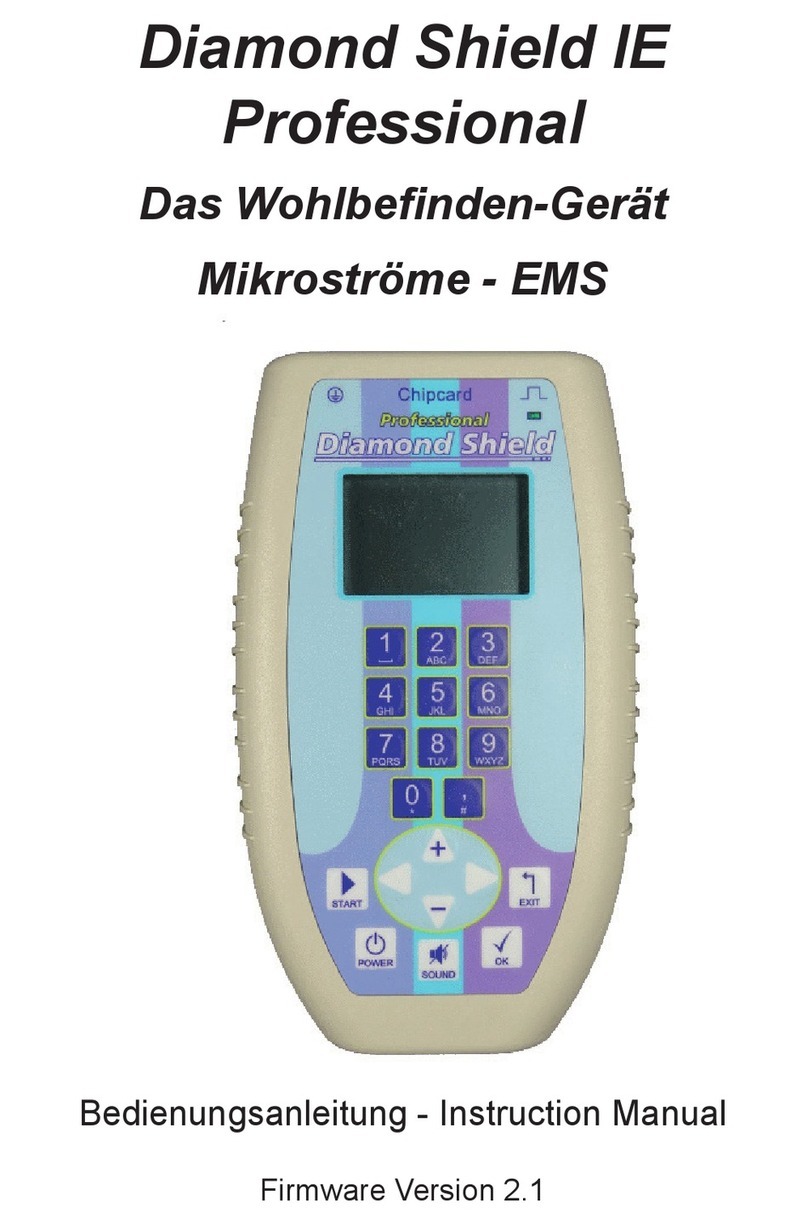

DERMAVIT

DERMAVIT Diamond Shield IEProfessional instruction manual

Skytron

Skytron F-ABSS Instructions for use

Orliman

Orliman Lumbitron Elite Use and maintenance instructions

Braun

Braun Aesculap Eccos Instructions for use/Technical description

Ortho8

Ortho8 vera one 08-0042 Instructions for use

natus

natus XLTEK EMU128 User and service manual

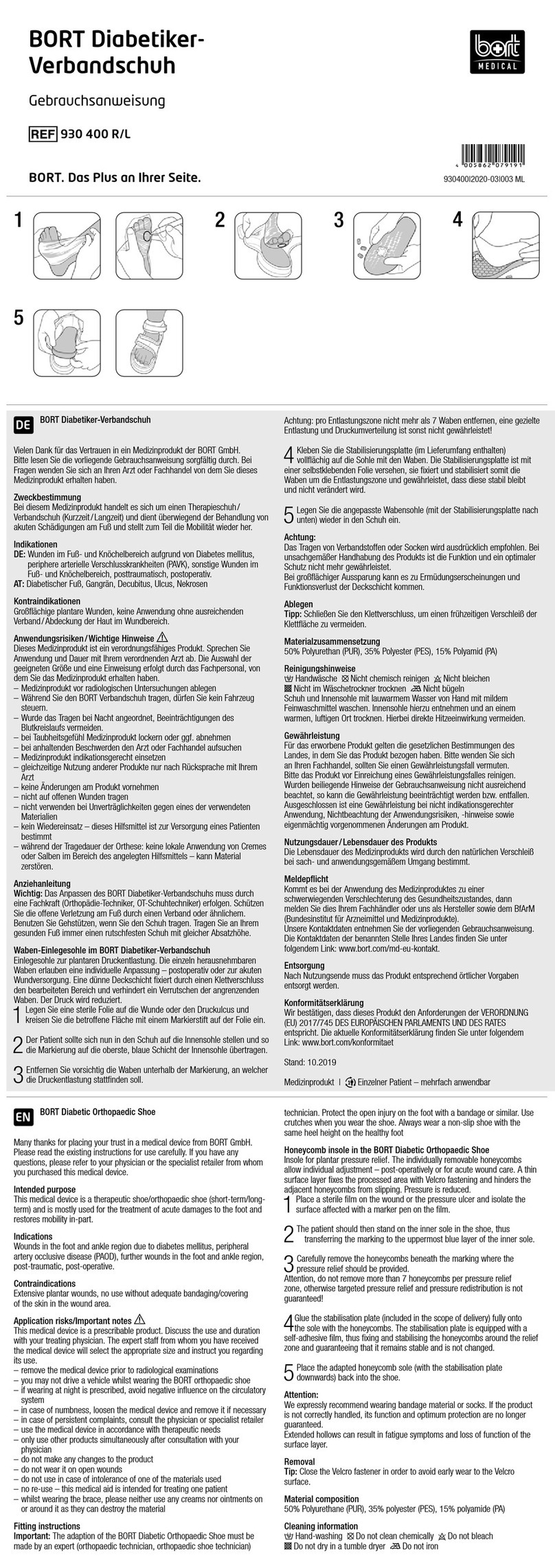

bort medical

bort medical 930 400 R quick guide