3

TABLE OF CONTENTS

CHAPTER 1

Using this manual ...................................................................................................................5

Safety ......................................................................................................................................6

Operator Safety .......................................................................................................................7

Installation and Maintenance ..................................................................................................9

Guidelines for Reliable Disinfection ....................................................................................10

Professional Guidelines ........................................................................................................12

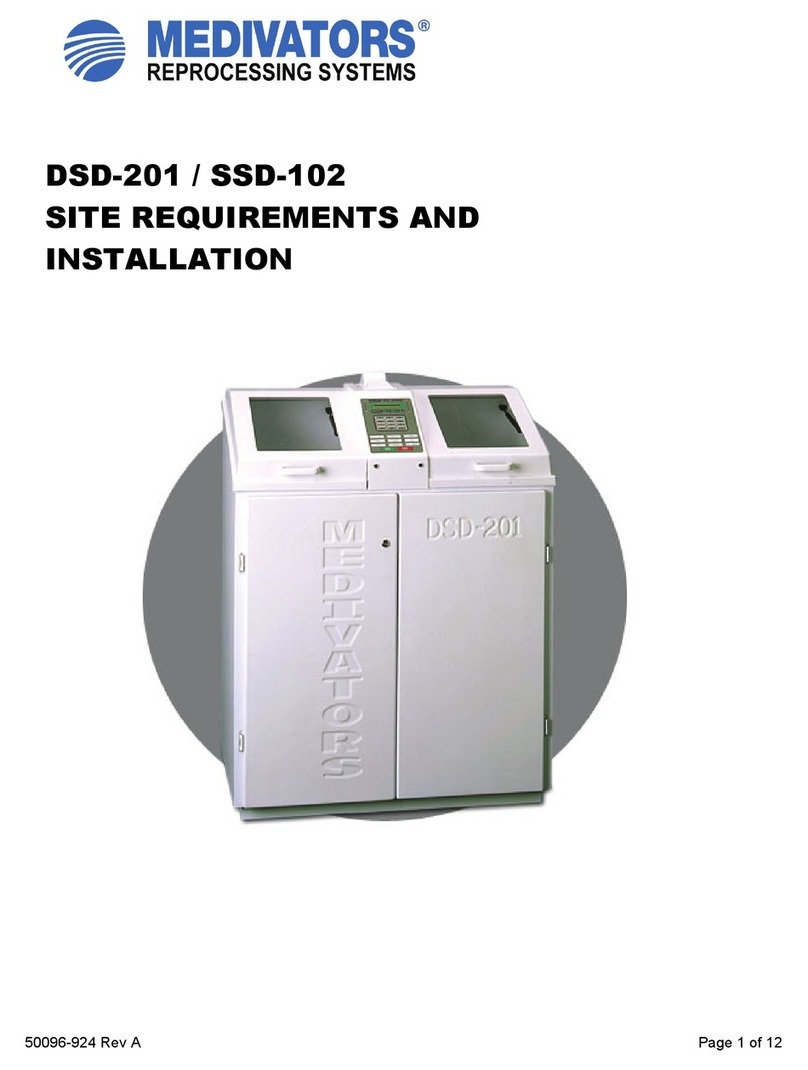

Reprocessor Specications ...................................................................................................13

Dimensions and Clearances ..................................................................................................14

Installation Specications .....................................................................................................15

Storage ..................................................................................................................................16

Transport ...............................................................................................................................16

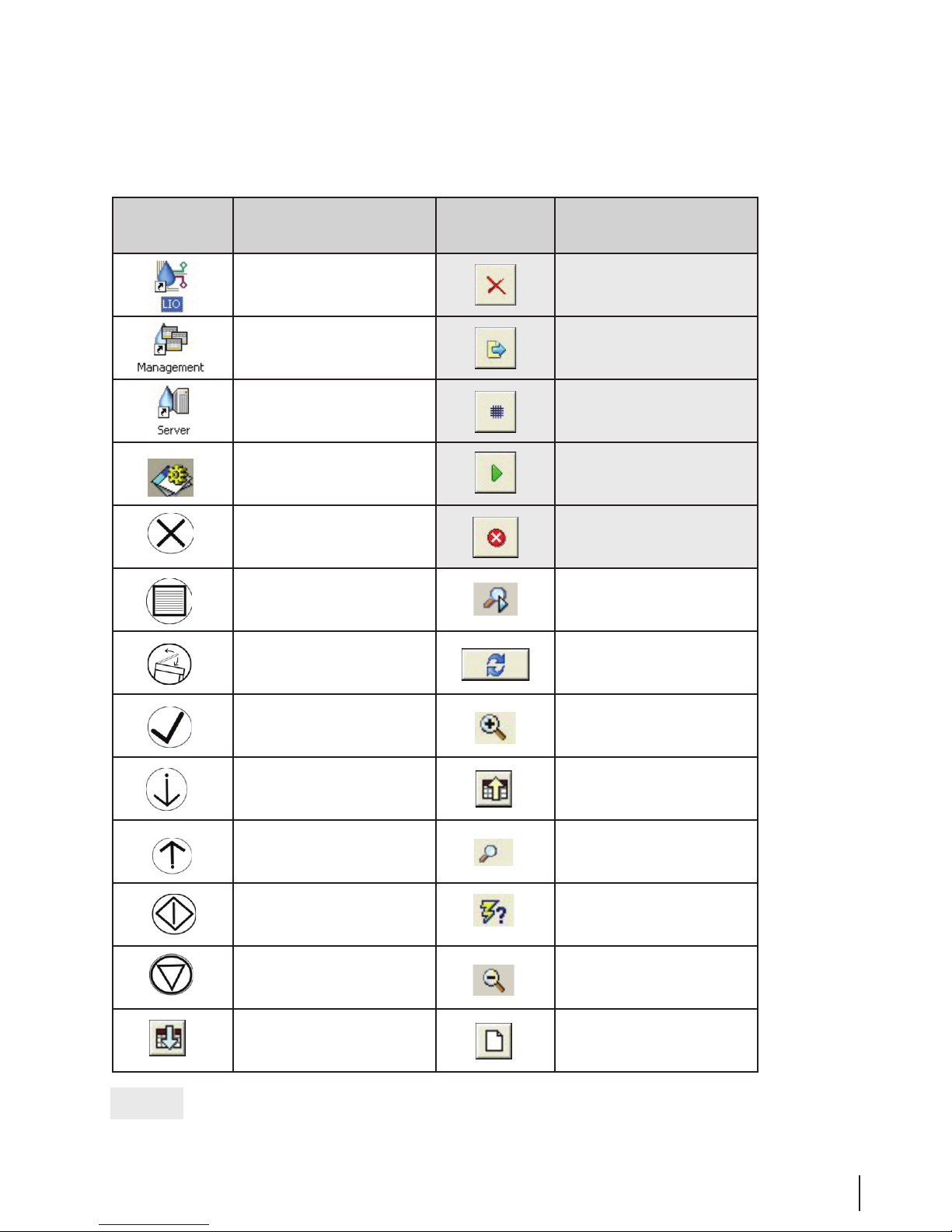

Symbols and Icons ................................................................................................................17

Warning Summary ................................................................................................................18

CHAPTER 2

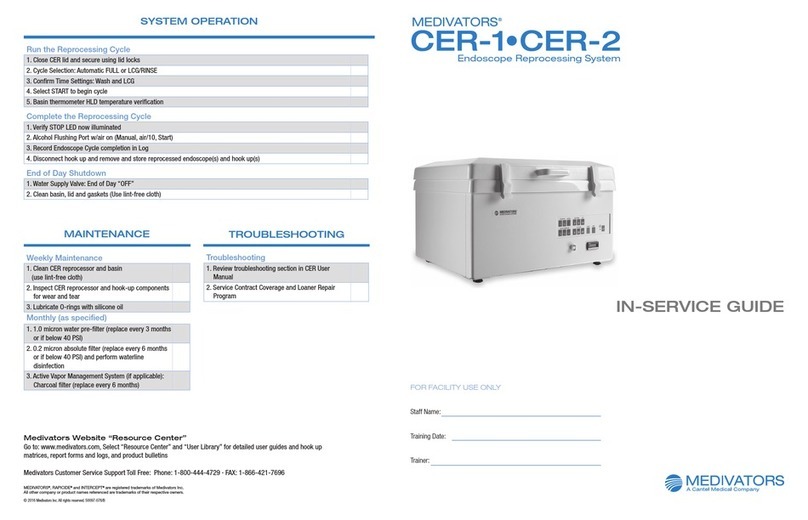

Main Components.................................................................................................................22

Software System ...................................................................................................................33

Printing ................................................................................................................................ 41

Backup ................................................................................................................................ 43

Fluid System .........................................................................................................................44

CHAPTER 3

System Startup ......................................................................................................................54

Daily Service.........................................................................................................................54

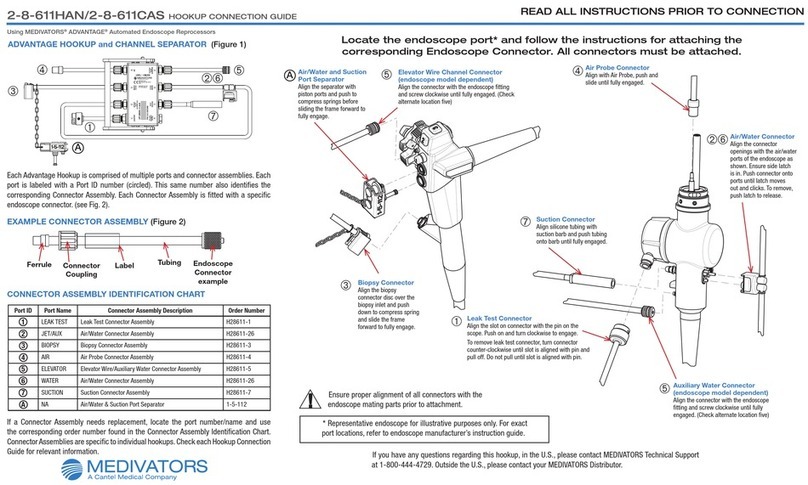

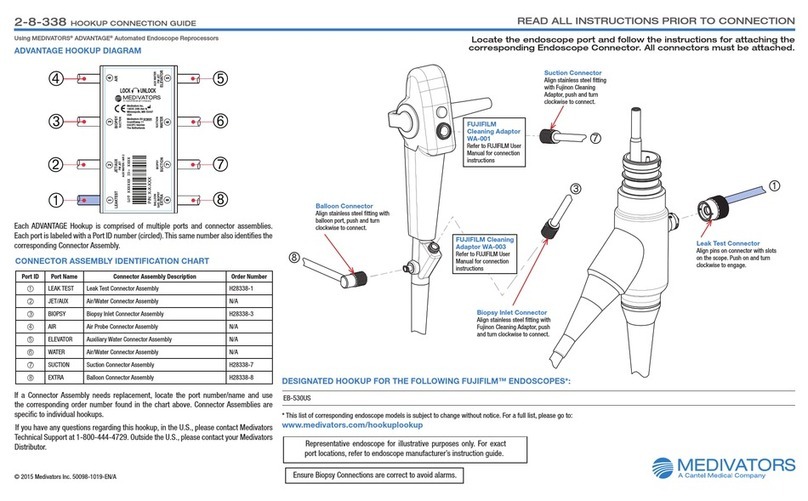

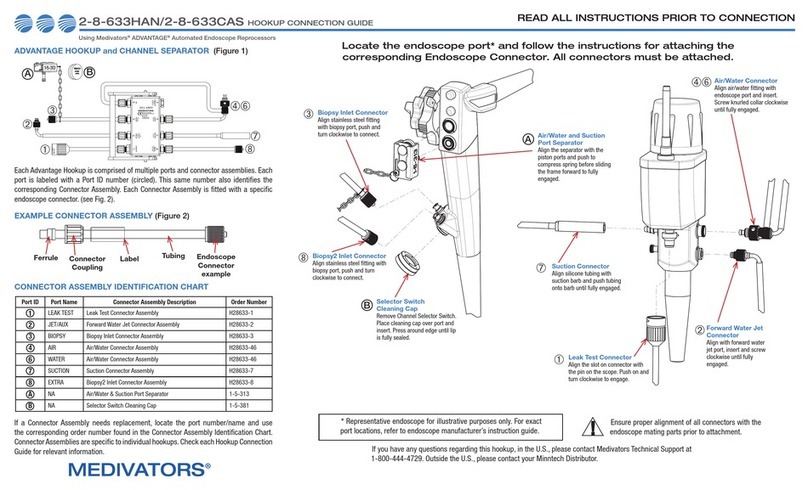

Prepare the Endoscope..........................................................................................................62

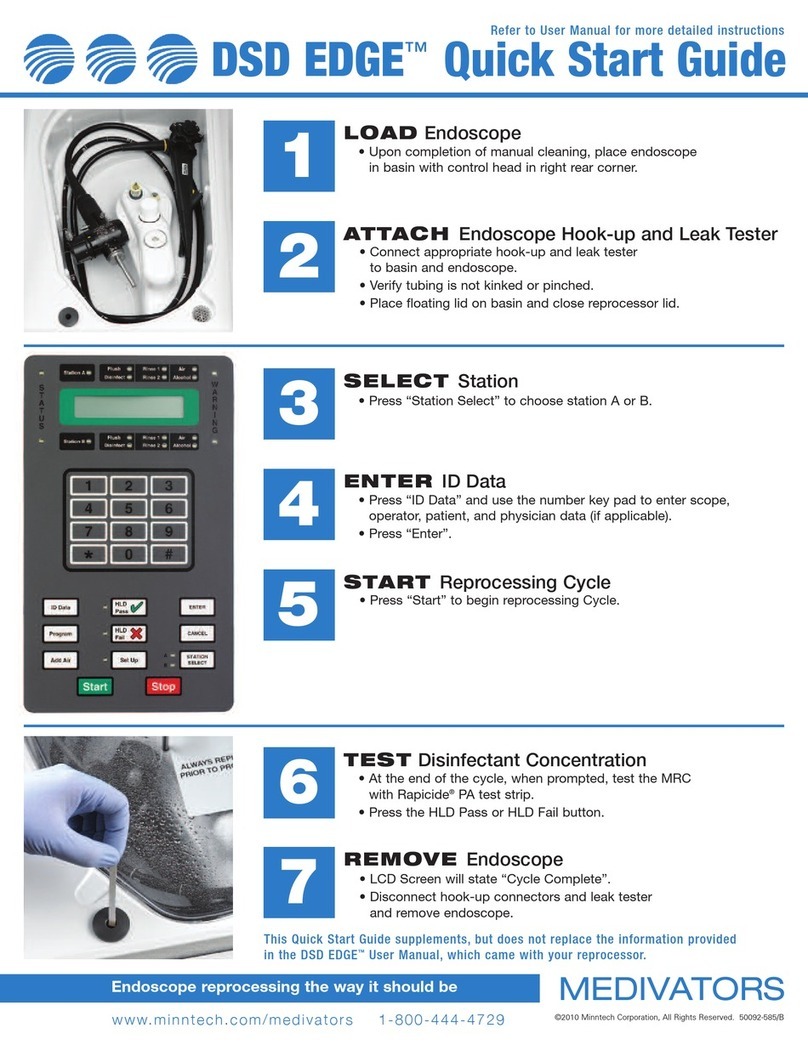

Disinfection Process Summary.............................................................................................68

Run the Disinfection Program ..............................................................................................69

Cycle Interruptions................................................................................................................74

Taking a Sample of Disinfectant – Check MRC...................................................................77

Complete the Disinfection Process .......................................................................................79

Reports ..................................................................................................................................81

Shutdown ..............................................................................................................................85

Procedure Summary..............................................................................................................86

Downtime..............................................................................................................................86

CHAPTER 4

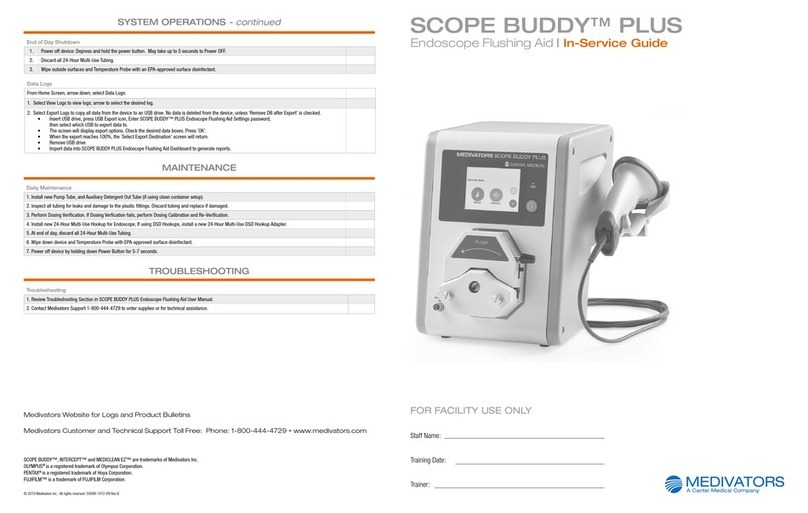

Daily Maintenance................................................................................................................88

Weekly Maintenance.............................................................................................................88

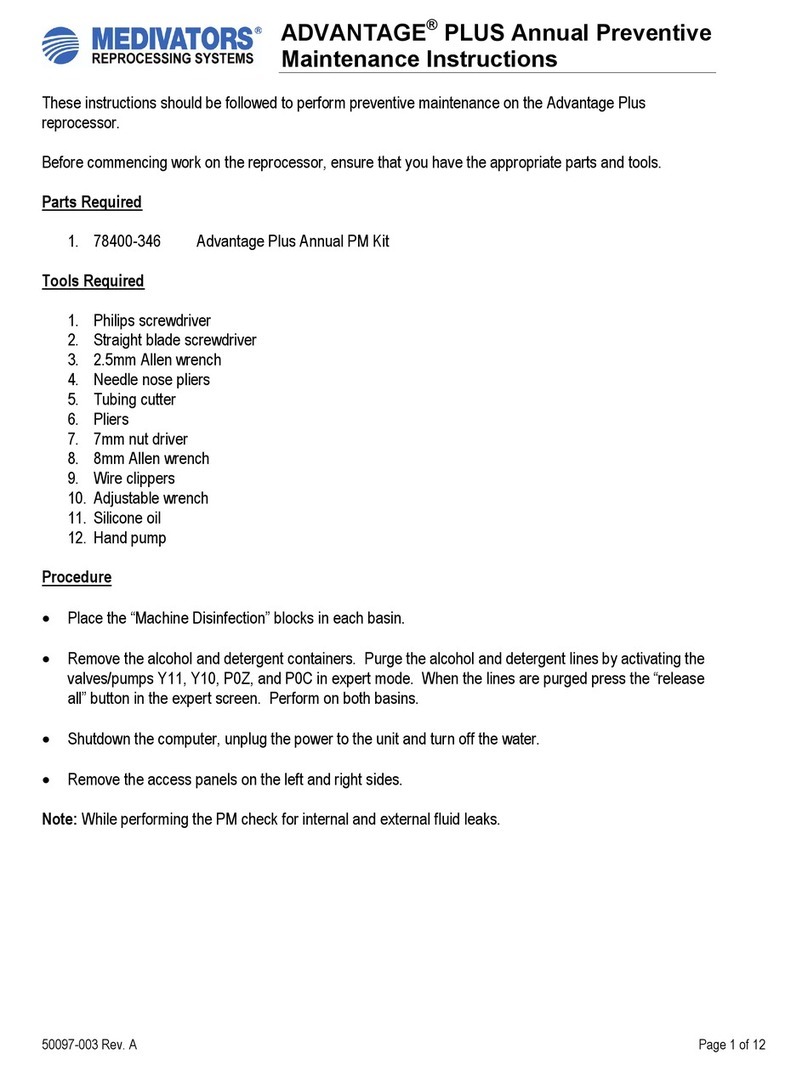

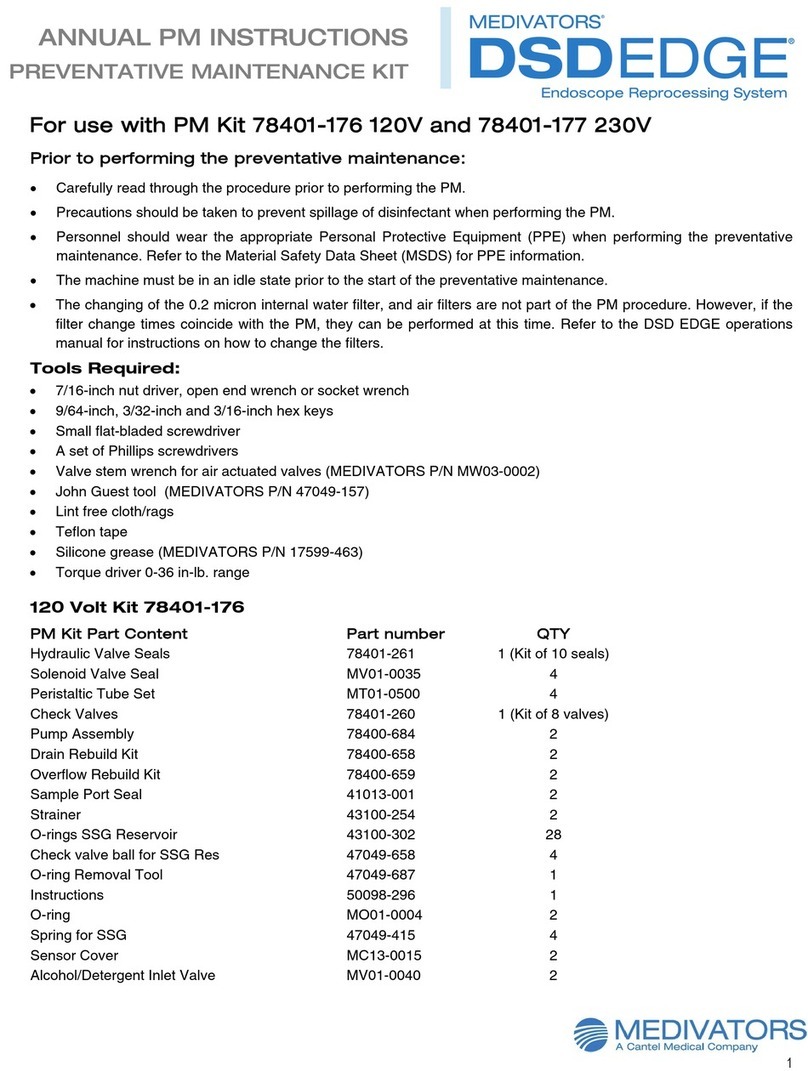

Monthly Maintenance ...........................................................................................................89

Air Filter Replacement..........................................................................................................89

Water Filter Replacement......................................................................................................92

CHAPTER 5

Introduction.........................................................................................................................100

Error Overview ...................................................................................................................104

System Errors......................................................................................................................109

Barcode Errors ....................................................................................................................113

Endoscope Errors................................................................................................................114