Medivators DSD-201 User manual

ac)

#

/00

POST

DSD™-201

Endoscope

Reprocessor

ervice

Manual

Software

Version

3.xx

0050

Listed

MM03-0047

Revision

D

©2008,

Medivators

Reprocessing

Systems

a

Minntech

Corporation

Business

Group.

All

rights

reserved.

This

publication

is

protected

by

copyright.

Copy-

ing,

disclosure

to

others,

or

the

use

of

this

publication

is

prohibited

without

the

express

written

consent

of

Medivators.

Medivators

reserves

the

right

to

make

changes

in

the

specifications

shown

herein

without

notice

or

obligation.

Contact

your

Medivators

representative

or

Medivators

customer

service

for

more

information.

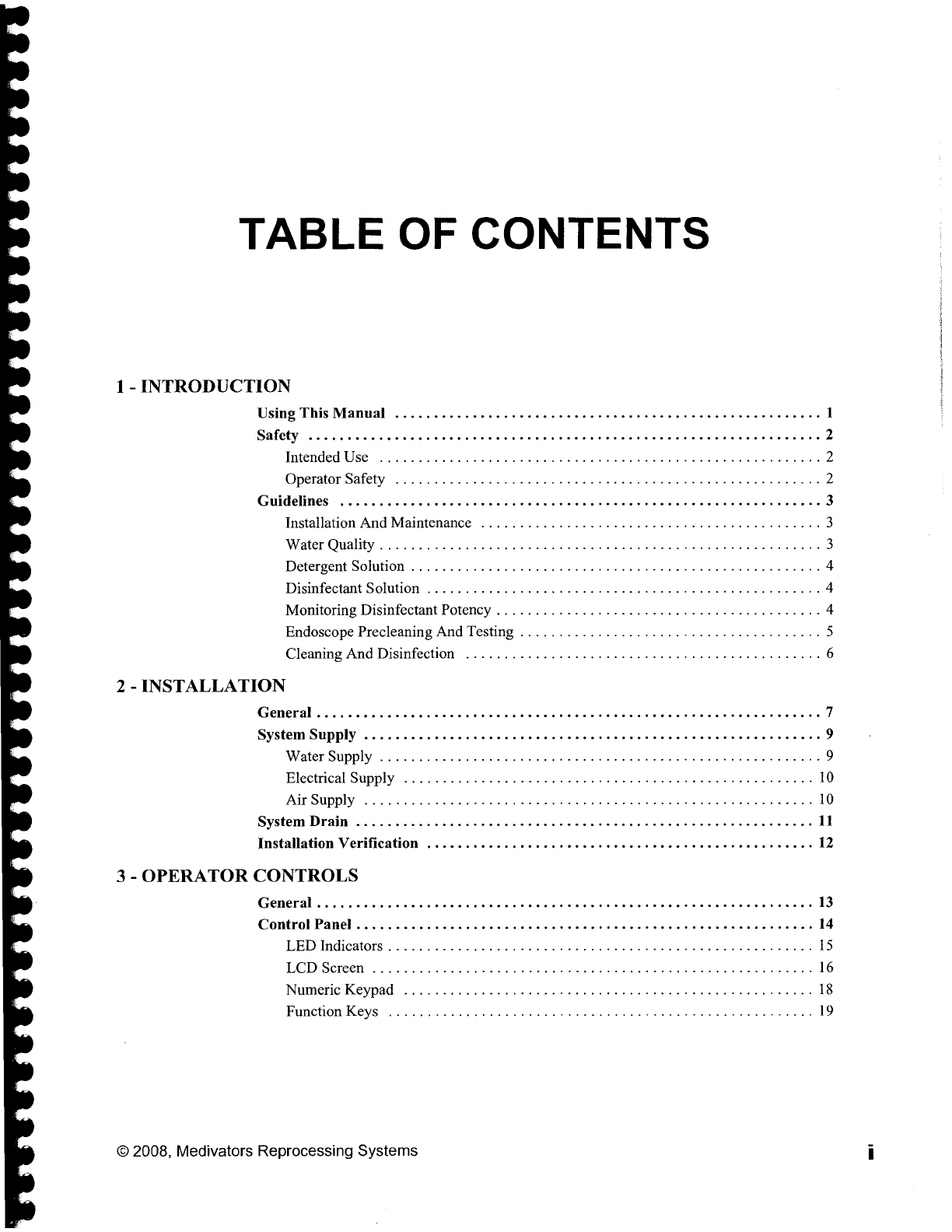

TABLE

OF

CONTENTS

1 -

INTRODUCTION

Using

This

Manual

...................

0.si

ως»

1

Μοτο

απο...

2

Intended

Use

......

ea

2

Operator

Safety

........................

ο ο

ον

ερ εν

νε

εννοω

ων

εν ων

νο

ο κ ο

ων

2

Guidelines

..................+444

40000000

k

K

rr

K

K

3

Installation

And

Maintenance

............................................

3

Water

Quality

ei

eee

3

Detergent

Solution

.............................................,.....2.

4

Disinfectant

Solution

,.........................,................,.......

4

Monitoring

Disinfectant

Potency

..........................................

4

Endoscope

Precleaning

And

Testing

.......................................

5

Cleaning

And

Disinfection

..............................................

6

2

-

INSTALLATION

General...............

-4.4444

400000006

K K K K

K

K

R

K

기

기이

에의

7

System

Supply

1

に に に に に に に

に

・

ト

に

トト トト

トト

トト

トト

トト

トト トト

て

し に

に に

て

た

し

に

で

くし

て

に

で

た

し で で

で

にし

K

K

9

Water

Supply

ké

9

Electrical

Supply

te

eee

eee

10

AirSupply

.....................

eee

10

System

Drain

0

ten

eee

S K

K

να

νο

ο

ο

ος

11

Installation

Verification

1 に

に

に

に

に

に

に

に

に

に に

に

に

に

トト

トト

トト

トト

トト

トト

ッッ

トト

ト に て

て

て

て

に

と

し

ゃ

し に

で

に

て

12

3

-

OPERATOR

CONTROLS

General

に

に

に

に

に に し に に

に

に に

トト

に

トト

スト

トト トト トト トト トト

トト

トト

トト

で

し て

た

て

に

で

た

た

て

に

に

に に

に

に

に

に

이

이이

13

Control

Panel

.................

4444444000000

k

K

K

K

K

K

O

K

시

아아

14

LED

Indicators

.......................................................

15

LCD

Screen

ε

νεο

νο νο

νε

ενω

aaa

16

Numeric

Keypad

.............

cece

eee

18

FuncüonKeys

..........................

eee

19

©

2008,

Medivators

Reprocessing

Systems

i

U)

REPROCESSING

SYSTEMS

Setting

Up

The

Reprocessor

..........................................s....

21

Load

Disinfectant

From

Basin

.....................................,.....

21

Load

Disinfectant

With

Internal

Pump

....................................

23

Automatic

Disinfectant

Dump

..

eee

24

Dump

Disinfectant

With

Internal

Pump

«νο

ν

ων

νεο

ν

ρω

ν

ων

νε

νε

κ

εν

κ

νεο

ον

26

SetTheDate............................

aran

28

Set

The

Time

are

30

Display

Software

Version

..............................................

32

Water

Line

SAnitize

.

τν

ε

ων

εν

οννωνονε

ορ

ω

νε ων

ε

ων εω

ών

κοκ

ε

κε

ε

ων ντ ον

34

Display

Log

rnknre

36

DisablelLog

................................

ete

ee

κ

ενω

νε

κ

εν

ων

38

Clearlog

........................

1...

een

40

Clear

Disinfectant€ycleCount.........................

ké

42

Programming

the

Reprocessor

1

に に

に

に

に

ュー に

ュー

トト

ーー

トー

トー

トード

ーー

トト

トト

トト

トト

トト

トット

ャ

こし

てこ

ここ

44

Input

Program

.........................

esse.

44

Disinfectant

Warning

Inhibit

............................................

50

Display

Temperatures

.......................................,..,.,....

52

Set

Heater-on

Time

........................................,.,.,....2.

54

Set

Heater-of

Time

εν

ον

ω

εν

ον

ον

εν νε

νε

κε

νε

νερο

εν

κ

των

56

Display

Disinfectant

Cycle

Count

............................,.....,.....

58

Display

Time

Remaining

し

し に

に

に

レー

レー

レー

に に

レレ

に

ーー

に

ーー

トー

トー

トー トト

ーー

トー

トー

バー

バー

60

Display

State

Tnme

. .

.

2

2

iile

62

Print

Entire

Log

..............................

иене

неее

нения

64

Print

Last

Run

にし

し

に

に

に

κοκ

ενω

εν

νοκ

εν εν κε

κ ο

ον

66

Set

Automatic

Printing

Enable

...................................

ーーーーー

68

Set

Delayed

Start

Date/time

.............................................

70

SetDelayedStartEnable

................................

iie

72

Enter

Diagnostics

.....................................................

74

4

-

DIAGNOSTICS

MENU

Imtroducton..............

00mm

77

Precautions

し

し

し

し

に

に に

세

9

과

세

세 사 셔

의

세 세

와와

에

에

세

에 에 에 에

이아

77

DiagnosticsFunctions

...................

e

seen

78

Function

0

—

Close

All

Valves

and

Turn

All

Pumps

Off......................

79

Function

|

—

Activate

Detergent

Valve

...................................

79

Function

2

—

Activate

Water

Valve

..................................,..

79

Function

3

—

Activate

Alcohol

Pump

....................................

79

Function

4

—

Activate

Air

System

.......................................

80

Function

5

—

Activate

Air

Valve

........................................

80

MM03-0047

Revision

D

DSD™-201

Endoscope

Reprocessor

Service

Manual

Function

6

—

Activate

Chamber

Valve

......................,............

80

Function

7

—

Activate

Disinfectant

Pump

.....................,............

80

Function

8

—

Activate

Disinfectant

Supply

Valve

..................,........

80

Function

9

—

ActivateDisinfectantOverflow

Valve

.........................

81

Function

10

—

Activate

Disinfectant

Return

Valve

.......,.....,.,..........

81

Functionll

—

ActivateDrainValve

................................

81

Function

12

—

Activate

Alcohol

Valve

......................,...,........

81

Function

13

—

ActivateRecirculationPump

...............................

82

Function

14

—

Activate

Water

Inlet

Valve

...........,......................

82

Function

15

—

Activate

Disinfectant

Inlet

Valve

.............................

82

Function

16

—

Activate

Recirculation

Inlet

Valve

............................

82

Function

17

—

Activate

Recirculation

Chamber

Valve

...............,........

82

Function

18

—

Activate

Valves

Incrementally

.............................

83

Function

19

—

Activate

Detergent

Pump

..............,....................

83

Function

20

—

Activate

Station

A

LED

.....................,.....,........

84

Function

21

—

Activate

Station

B

LED

........................,...,.......

85

Function

22

—

Activate

System

LEDs

...........,...................,.....

86

Function

23

—

Write

LCD

Test

Pattern

....................................

87

Function

24

—

Write

Counter

to

Display

.....................,.............

87

Function

25

—

Test

Keypad

...............................,.,...........

88

Function

26

—

Adjust

LCD

Contrast

.....................................,

89

Function

27

—

Adjust

Alarm

Volume

.....................................

89

Function

28

—

Lock Cover

(Optional)

..............,..,...............,..,

90

Function

29

—

Unlock

Cover

(Optional)

....................,..,,,.........

90

Function

31

—

Calibrate

Basin

Thermistor

..................................

91

Function

32

—

Calibrate

Reservoir

Thermistor

................,.......,.....

92

Function

40

—

Flow

Sense

Inhibit

...................................,....

93

Function

41

—

Cover

Sense

Inhibit

....................,..,...............

93

Function

42

—

Basin

Level Sense

Inhibit

...................,.,.............

94

Function

43

—

Reservoir

Low

Level

Sense

Inhibit

..........................,

95

Function

44

—

Reservoir

High

Level

Sense

Inhibit

...........................

95

Function

45

—

Sheath

Sense

Inhibit

....................,,.................

96

Function

46

—

Disinfectant

Warning

Acknowledge

................,.........

96

Function

47

—

Enable

Alcohol

Level

Sensor

................,............,..

97

Function

48

—

Enable

Detergent

Sensor

...................................

98

Function

49

—

Temperature

Monitoring

Enable

................,............

99

Function

50

—

Turn

Sheath

Test

Off

...........................,.........

100

Function

51 —

Activate

Sheath

Valve

....................................

100

©

2008,

Medivators

Reprocessing

Systems

REPROCESSING

SYSTEMS

NM

Function

52

—

Activate

Sheath

Test

Compressor

Valve

...................,.,

101

Function

53

—

Activate

Sheath

Test

Compressor

.........................,..

101

Function

54

—

Turn

Off

All

Valves

and

Reset

Latches

.......................

102

Function

55

—

Turn

Off

Sheath

Test

Compressor

...........................

102

Function

56

—

Activate

Sheath

Test

......................................

103

Function

57

—

Activate

Sheath

Hold

.....................................

103

Function

60

—

Set

Default

Program

......................................

104

Function

61

—

Set

Rinse

Drain

Time

and

Disinfectant

Drain

Time..............

104

Function

62

—

Set

Rinse

and

Disinfectant

Fill

Times

........................

105

Function

63

—

Set

Fluid

and

Air

Purge

Times

....................,.........

105

Function

64

—

Set

Disinfectant

Pulse

Time

................................

106

Function

65—SetAddAirTime...........................

0.

εν

106

Function

66

—

Set

Partial

Rinse

Fill

and

Drain

Times

........................

107

Function

67

—

Set

Rinse/Disinfectant

Top-Off

Times

........................

107

Function

69

—

Set

Water

Line

Disinfect

Hold

Time

.........................

108

Function

71

—

Set

Maximum

Disinfectant

Cycle

Count

......................

108

Function

72

—

Reset

Programs

..........................................

109

Function

73

—

Clear

Disinfectant

Counter

.................................

109

Function

74

—

Set

Maximum

Reservoir

Temperature

........................

110

Function

75

—

Set

Minimum

BasinTemperature............................

110

Function

79

—

Enable

All

Sensors

.......................................

111

Function

80

—

Set

Language

...........................................

111

Function

81 —

Set

Time

Limit

..........................................

112

Function

82

—

Set

Serial

Number

........................................

113

Function

83

—

Program

Low

Flash

......................................

113

Function

84

—

Program

High

Flash

......................................

114

Function

85

—

Program

Entire

Flash

......................,..............

114

Function

86

—

Initialize

NVRAM

...................,...................

115

Function

87

—

Disable

All

Sensors

..........,...........................

115

Function

88

—

Set

Options

.................,................,...........

115

Function

89

—

Set

Station

to

Idle

State

...................................

116

Function

90

—

Display

Inputs

...........................................

116

Function

91

—

Display

Cycle

Count

ενω

ων εν

νε

ρω

ενώ

νεο

εν

εκ

ων

εν

117

Function

93

—

Display

Temperatures

.....................................

117

Function

94

—

Test

Sensors

............................................

118

Function

95

—

Test

Sheath

Tester

.......................................

118

IV

MM03-0047

Revision

D

DSD™-201

Endoscope

Reprocessor

Service

Manual

5

-

OPERATION

Introducüon...............

002

119

Cycle

Operation

に

に に

に

に

に

に

に に

に に に

に

に に に

トト トト

トト

トト

トト

ト

トト トト

トト

トト

トト

トト

し

に

て

トト

て

トト

ここ

て

いこ

てこ

120

Startup

Phase

.......................................................

120

Wash

Phase

..

----,

120

Disinfectant

Phase

...........................................,......,

121

Rinse

1

Phase

renees

121

Rinse

2

Phase

.......................................................

121

Rinse

3

Phase

.......................................................

121

Alcohol

Phase

......................................................

121

Air

Phase

ーー

122

Pre-start

Inspection

......................,..,,.,..

esse.

123

StartUD

1

に

ュ

に

トト

トト

トト

トト

トト

トト

トト

トト

トト

トト

トト

トト

トド

トト

トト て

た

に

た

に

トト

し

に

し

に

に

に

に

に

に

し

に

に

K

124

Checking

the

Potency

Level

に

に に

に

に

に

に

に

に

に

に

に

に

に に

に

に

トト

トト

トト

トト

トト

トト

トー

トト

トト

トト

トト

ここ

トー

ここ

125

Overriding

the

Disinfectant

Warning

................................,...

126

Disinfecting

Endoscopes

........................,.......................

127

Preparing

the

Endoscope

........................................,.....

127

LeakTesting(Optional)...............................................

128

Running

the

Disinfection

Process

.......................................

129

Completing

the

Disinfection

Process

.....................................

130

Processlnterruption

..................

ösen

131

System

Interruption

cece

teen

nna

131

Operator

Initiated

Interruption

.................................,...,....

131

Shutdown

に

に

に

に に に に

に

に

に

に

に

に

トト

トト

トー

トト

トト

トト

トト

トト

トト

トト

トト

トト

に

で

に

に

に

に

に

に

で

し

で

し

で

て

た

ゃ

で と

くく

ここ

132

6

-

MAINTENANCE

General..............

eeose

133

Leveling

e

134

Collet

Coupling

Disconnection/connection

.......................,.,......

136

Disinfectant

Filter

Cartridge

—

Replace

...........................,.....,

138

Internal

Water

Filter

—

Remove

...............................,,,,.....

140

Internal

Water

Filter

一

Replace

νο

ων

ον

ενω

νο

νο

ον

142

Printer

Paper

—

Replace

..............................................

144

Printer

Ribbon

—

Replace

............................................0

146

Airfilter—Replace................................

aaa

148

3/4-inch

Solenoid

Valve

—

Clean/sealReplacement

........................

150

Flow

Sensor

—

Clean

......................................,,....,...

152

Removing

The

Disinfectant

Reservoir

...................................

154

©

2008,

Medivators

Reprocessing

Systems

v

REPROCESSING

SYSTEMS

Replacing

The

Fuses

..

ω

ων

ων

νε

ε

εκ

ενω

νο

νε

κ

νε

ων

εν ων

156

Leak

Tester

Option

—

Check

..................,...............,..,....

158

Draining

Condensation

From

Air

Chamber

................................

160

Manually

Unlocking

The

Lid

(Optional)

.......................,..........

162

7

-

TROUBLESHOOTING

(ο

μου.

165

Error

and

Warning

Messages

...........................................

170

8

-

APPENDIX

Error

Messages

..........................................

esse

R

K

A-2

Diagnostic

Messages

........................................s.s.sss..s

A-4

Log

Messages

に

に

に に

に

ュ

に

に

に に に

に

トー

トー

トー

トト

トト

トト

トト

トト

トー

て

トト

トト

トト

トト

トト

ャ

トト

トト

ャ

こし

て

て

て て

ここ

A-7

Glossaryoflerms....................

0.0

0

eee

A-9

Specifications

...................

00.00

eee

A-10

DisinfectionCyeleChart

...................

ömer

A-11

Custom

Program

Reference

Chart

...................

ören

A-19

FlowDiagram

............

cece

cee

ee

reece

eee

eee

ee

eee

nen

ew

eee

eens

A-20

Electrical

Block

Diagram

cece

cece

ee

cere

renee

cree

neces

A-22

See

A-24

Diagnostic

Menu

...................

-0444440000000

o

ee

n

A-25

MM03-0047

Revision

D

INTRODUCTION

Using

this

Manual

This

manual

describes

the

Medivators

Reprocessing

Systems

DSD

-201

endoscope

reproces-

sor.

It

also

describes

the

features

of

the

reprocessor,

how

to

setup

and

operate

the

reprocessor,

and

maintenance

and

troubleshooting

procedures

to

keep

the

reprocessor

in

good

operating

order.

Throughout

the

manual

are

notes,

service

notes,

cautions,

and

warnings.

These

provide

addi-

tional

important

information.

An

example

of

each

is

illustrated

below.

Note:

A

note

refers

to

relevant

information

not

covered

in

the

main

body

of

the

text.

Service:

A

service

note

refers

to

operations

or

repairs

only

a

trained

service

technician

may

perform.

Caution!

A

caution

describes

actions

and

conditions

that

may

cause

damage

to

or

destruction

of

the

equipment.

Warning!

A

warning

describes

actions

and

conditions

that

may

cause

severe

personal

injury

or

death

to

the

operator

or

patient.

>

>

@

>

©

2008,

Medivators

Reprocessing

Systems

m

Safety

This

section

outlines

general

safety

guidelines

for

proper

operation

and

service

of

the

reprocessor.

Failure

to

follow

these

guidelines

may

result

in

severe

injury

or

death

to

the

patient

and/or

opera-

tor.

Read

and

understand

all

operating

and

service

procedures

before

attempting

to

operate

the

reprocessor.

Intended

Use

Only

properly

trained

individuals

may

operate

or

service

the

reprocessor.

Never

use

the

reproces-

sor

for

any

purpose

other

than

the

manufacturer’s

specific

intended

purpose.

Operator

Safety

Avoid

biological

contamination

and

chemical

burns—always

wear

appropriate

personal

protective

equipment

when

handling

endoscopes

or

disinfectant

solutions.

Never

open

the

reprocessor

lid

or

remove

the

floating

basin

lid

during

operation.

For

disinfectant

handling

guidelines,

refer

to

the

American

National

Standard

recommended

prac-

tice

titled

“Safe

Use

and

Handling

of

Glutaraldehyde-based

Products

in

Health

Care

Facilities”

(AAMI/FDS

ST58,

1996-03-26).

The

document

is

available

from

the

Association

for

the

Advancement

of

Medical

Instrumentation.

MM03-0047

Revision

D

DSD™-201

Endoscope

Reprocessor

Service

Manual

INTRODUCTION

Guidelines

Guidelines

are

established

to

ensure

patient

safety,

operator

safety,

and

to

maintain

reliable

reprocessor

operation.

Installation

and

Maintenance

Proper

maintenance

will

ensure

effective

disinfection

and

prolong

the

life

of

the

reprocessor.

・

The

reprocessor

must

be

protectively

grounded.

*

The

system

default

is

factory-set

for

a

20

minute

disinfectant

immersion

period.

This

period

may

be

changed

in

the

custom

program

setting.

Verify

the

program

is

appro-

priate

for

the

disinfectant

used.

+

All

pressure

regulators

are

factory-preset.

Do

not

adjust

the

settings.

Contact

your

Technical

Support

representative

for

assistance.

・

Do

not

allow

the

sanitizing

solution

to

contact

metal

components.

*

Do

not

use

alcohol

or

alcohol-based

products

to

clean

the

reprocessor

cabinet

as

this

may

cause

crazing.

+

The

hook-ups

are

not

autoclavable

and

must

be

reprocessed

by

low

temperature

dis-

infection

only.

・

Replacement

parts

must

be

ordered from

the

manufacturer

to

maintain

the

warranty.

Water

Quality

Potable

water

is

the

minimum

standard.

Incoming

water

must

be

pre-filtered

to

minimum

of

0.45-microns.

*

The

high

performance

0.2-micron

water

filter

included

with

the

reprocessor

is

a

ster-

ilizing

grade

bioretentive

filter.

The

filter

removes

all

microorganisms

and

particles

greater

than

0.2-microns.

+

The

routine

maintenance

schedule

recommends

replacing

the

0.2-micron

water

filter

every

6

months

or

sooner,

depending

on

the

pre-filtration

system

and

the

quality

of

the

incoming

water.

©

2008,

Medivators

Reprocessing

Systems

3

REPROCESSING

SYSTEMS

Detergent

Solution

Medivators

recommends

the

use

of

a

detergent

solution

that

has

bacteriostatic

properties

to

inhibit

bacterial

growth

in

the

detergent

reservoir

and

detergent

line.

Caution!

Never

use

household

detergent

in

the

reprocessor.

Disinfectant

Solution

Select

a

low-foaming,

high

level

disinfectant

specifically

manufactured

for

high-level

medical

instrument

disinfection.

The

product

must

be

capable

of

destroying

M.

tuberculosis.

・

Consult

the

product

label

for

appropriate

contact

time

and

temperature

when

program-

ming

the

disinfection

cycle.

Monitoring

Disinfectant

Potency

The

efficacy

of

a

disinfection

procedure

is

directly

related

to

the

disinfectant

solution

used

and

the

amount

of

time

the

endoscope

is

exposed

to

that

solution.

・

Disinfectants

must

be

monitored

for

potency

on

a

daily

basis.

Consult

the

disinfectant

manufacturer

recommendations

for

monitoring

guidelines.

*

Use

the

manufacturer’s

test

strips

to

test

the

potency

of

the

solution

on

a

daily

basis.

If

the

potency

of

the

solution

is

below

its

minimum

recommended

concentration

(MRC),

discard

and

replace

it

with

fresh

solution.

*

Never

use

disinfectant

beyond

the

manufacturer’s

recommended

reuse

life,

even

if

the

potency

levels

are

acceptable.

+

Never

use

disinfectant

with

unacceptable

potency

levels,

even

if

the

reuse

date

is

unexpired.

MM03-0047

Revision

D

DSD™-201

Endoscope

Reprocessor

Service

Manual

INTRODUCTION

Endoscope

Precleaning

and

Testing

All

endoscopes

must

be

precleaned

prior

to

disinfection.

Follow

the

endoscope

manufacturer

instructions

and

established

professional

guidelines

to

properly

preclean

the

endoscope.

*

Endoscopes

with

elevator

wire

channels

require

additional

manual

cleaning

and

disinfection

steps.

‚

Leak

test

endoscopes

prior

to

disinfection

procedures.

©

2008,

Medivators

Reprocessing

Systems

5

la

REPROCESSING

SYSTEMS

Cleaning

and

Disinfection

Always

follow

established

professional

guidelines

while

cleaning

and

disinfecting

endoscopes.

The

following

organizations

have

published

recommended

guidelines.

Society

of

Gastroenterology

Nurses

and

Associates

401

North

Michigan

Ave.

Chicago,

IL

60611-4267

TEL:

(800)

245-7462

FAX:

(312)

321-5194

http://www.sgna.org/

American

Society

for

Gastrointestinal

Endoscopy

13

Elm

Street

P.

O.

Box

1565

Manchester,

MA

09144-1314

TEL:

(978)

526-8330

FAX:

(978)

526-4018

http://www.asge.org/

Association

of

Operating

Room

Nurses

2170

So.

Parker

Rd.,

Suite

300

Denver,

CO

80231-5711

TEL:

(303)

755-6304

FAX:

(303)

750-3462

http://www.aorn.org/

British

Society

of

Gastroenterology

3

St.

Andrews

Place

Regents

Park,

London

NW1

4LB

01144-171-387-3534

Association

for

Professionals

in

Infection

Control

and

Epidemiology,

Inc.

1275

K

Street,

NW,

Suite

1000

Washington,

DC

20005-4006

TEL:

(202)

789-1890

FAX:

(202)

789-1899

http://[email protected]

American

Society

for

Testing

and

Materials

100

Bar

Harbor

Drive

West

Conshohocken,

PA

19428-2959

TEL:

(610)

832-9585

FAX:

(610)

832-9555

http://www.astm.org/

Canadian

Society

of

Gastroenterology

Nurses

&

Associates

P.O.

Box

366

36

Adelaide

Street

East

Toronto,

Ontario

MSC

2J5

http://www.webray.com/csgna

MM03-0047

Revision

D

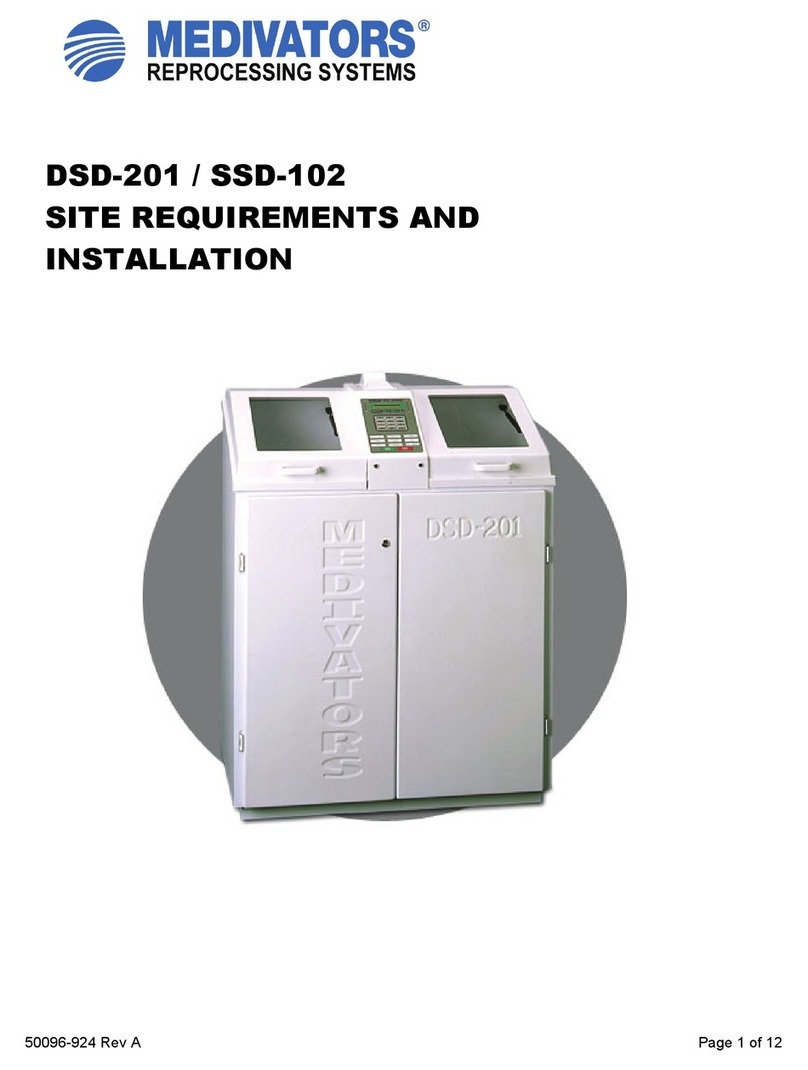

INSTALLATION

General

Move

the

reprocessor

to

the

installation

location

before

removing

the

protective

packaging

material.

If

this

is

not

possible,

use

a

hand

truck

or

moving

dolly

and

ensure

the

reprocessor

is

not

damaged.

During

installation,

be

sure

the

lower

reservoir

cover

is

in

place,

to

prevent

drill

shavings

and

chips

or

other debris

from

entering

the

reservoir.

The

reprocessor

must

be

installed

on

a

level

surface,

or

adjusted

to

level.

See

the

Leveling

pro-

cedure

in

the

Maintenance

chapter.

©

2008,

Medivators

Reprocessing

Systems

7

REPROCESSING

SYSTEMS

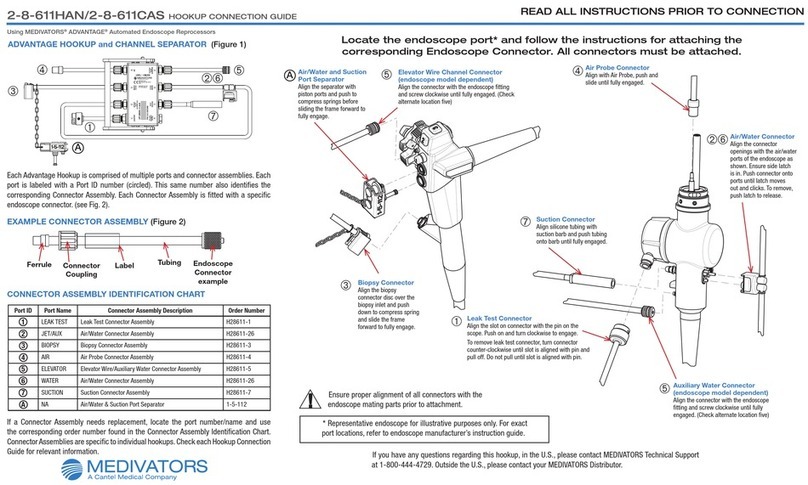

Conirol

Panel

Process

Indicators

Disinfectant

Return

Valve

Drain

Valve

Alcohol

Reservoir

Air

Valves

Reservoir

Cover

Disinfectant

Filter

Regulator

Disinfectant

Reservoir

Temperature

Control

Air

Compressor

Lid

Basin

Water

Filter

Bleeder

Valve

Drain

Line

af

(rear

side)

Detergent

Reservoir

Pump

Override

Switch

下

Incoming

Water

Water

Filter

Air

Filter

Disinfectant

Pump

Fig.

1.

DSD-201

Internal

components

MM03-0047

Revision

D

DSD™-201

Endoscope

Reprocessor

Service

Manual

INSTALLATION

System

Supply

Water

Supply

For

optimum

cycle

performance,

the

water

supplied

to

the

reprocessor

must

provide

a

flow

rate

of

3.2

gal/min

(12

liters/min),

at

35-40

psi

(2.4-2.75

bar).

The

incoming

water

line

must

be

a

minimum

1/2-inch

(13

mm).

Use

a

cold

water

supply

with

a

maximum

temperature

of

110°

F

(43°

C).

1.

Install

an

incoming

water

shut-off valve

before

the

pre-filter

system.

2.

Install

the

incoming

water

prefilter,

supplied

with

the

reprocessor.

*

Mount

the

incoming

water

filter

on

the

wall

where

it

can

be

periodically

checked

for

particle

saturation.

installation

requires

the

outlet

to

be on the

left

side,

remove

the

filtration

brackets

and

reinstall

on

the

opposite

side,

then

loosen

and

rotate

the

gauges

180°.

À

Note:

The

filter

is

provided

with

the

outlet

on

the

right

side.

If

the

filter

3.

Install

the

supplied

water

regulator

between

the

pre-filter

and

the

reprocessor

water

connection.

*

Incoming

water

pressure

to

the

regulator

must

be

less

than

100

psi

(6.8

bar).

・

Set

the

outgoing

water

pressure

between

35-40

psi

(2.4-2.75

bar).

©

2008,

Medivators

Reprocessing

Systems

9

10

MM03-0047

Revision

D

REPROCESSING

SYSTEMS

Electrical

Supply

Domestic

reprocessors

are

supplied

with

a

hospital

grade,

grounding

plug

that

can

be

connected

to

any

standard

110-130VAC

outlet.

International

reprocessors

are

supplied

with

a

standard

ground-

ing

European

plug

that

connects

to

220-240VAC

outlets.

We

recommend

surge

protectors

be

used

for

protection

against

power

spikes

and

surges.

The

reprocessor

must

be

plugged

into

or

connected

to

a

fused

branched

circuit.

Caution!

The

reprocessor

does

not

have

an

on/off

switch.

Be

sure

the

reprocessor

is

positioned

so

that

the

power

cord

or

main

circuit

breaker

is

accessible

at

all

times.

Warning!

The

reprocessor

must

be

protectively

grounded.

ας

Air

Supply

Compressed

air

is

required

(30

-

60

psi/2.1

-

4.1

bar).

If

you

did

not

purchase

the

air

compressor

option

with

the

reprocessor,

be

sure

to

make

the

compressed

air

connection

to

the

labeled

fitting

on

the

side

of

the

cabinet.

Warning!

This

air

must

be

supplied

from

an

oil

free

air

source.

DSD™-201

Endoscope

Reprocessor

Service

Manual

INSTALLATION

System

Drain

The

drain

tube

provided

with

the

reprocessor

consists

of

36

inches

of

1-inch

diameter

clear

tub-

ing.

The

drain

tube

must

have

3

inches

of

drop

(7.5

cm)

or

greater

over

the

36-inch

length.

Con-

sult

your

maintenance

department

for

multiple

reprocessor

installation.

Caution!

The

reprocessor

drain

relies

on

gravity

flow.

There

must

be

no

low

spots

in

the

drain

line.

Fluid

trapped

in

the

drain

line

will

interfere

with

free

drainage

and

reprocessor

function.

©.2008,

Medivators

Reprocessing

Systems

1

1

δα

“©

REPROCESSING

SYSTEMS

\

Installation

Verification

To

be

sure

that the

system

is

ready

to

operate,

perform

a

trial

run

with

water

as

outlined

below.

Use

scope

hook-up

to

simulate

an

endoscope.

might

blow

the

8-amp

slow

blow

fuse.

Operating

the

230VAC

reprocessor

without

a

hook-up

fitting

might

blow

the

4-amp

slow

blow

fuse.

1

Caution!

Operating

the

120VAC

reprocessor

without

a

hook-up

fitting

1.

Load

the

lower

reservoir

with

water.

Use

the

procedure

described

in

the

Operator

Con-

trols

Chapter

for

loading

disinfectant.

2.

Fill

the

alcohol

and

detergent

reservoirs,

then

prime

the

tubing.

・

Enter

the

Custom

Programs

menu.

*

Set

the

alcohol

and

detergent

inject

time

to

15

seconds.

3.

Close

the

lid,

then

press

the

START

button.

4.

Check

the

flow

through

the

tubing during

the

disinfect,

air,

and

rinse

cycles.

5.

Check

the

water

regulator

in

the

incoming

water

line.

*

Pressure

must

be

35

-

40

psi

(2.4

—

2.75

bar).

6.

Verify

the

cycle

completes

with

no

errors.

7.

Verify

there

are

no

leaks

in

the

reprocessor.

8.

Press

DISINFECT

DUMP

and

START

on

the

control

panel

to

run

a

dump

cycle.

Refer

to

the

“Disinfection

Dump”

procedure

in

the

Operation

Chapter

of

this

manual

9.

After

the

disinfectant

dump

cycle

is

complete,

program

the

disinfectant

soak,

etc.,

times

as

needed.

10.

Load

fresh

disinfectant

and

begin

to

operate

the

reprocessor.

Service:

__

If

the

reprocessor

cannot

be

verified,

contact

Medivators

Technical

Support

at:

1-800-444-4729

or

1-763-553-3300.

1

2

MM03-0047

Revision

D

Other manuals for DSD-201

4

Table of contents

Other Medivators Medical Equipment manuals

Medivators

Medivators SCOPE BUDDY Series User manual

Medivators

Medivators CER-1 User manual

Medivators

Medivators SCOPE BUDDY User manual

Medivators

Medivators CER-1 User manual

Medivators

Medivators DSD-201 User manual

Medivators

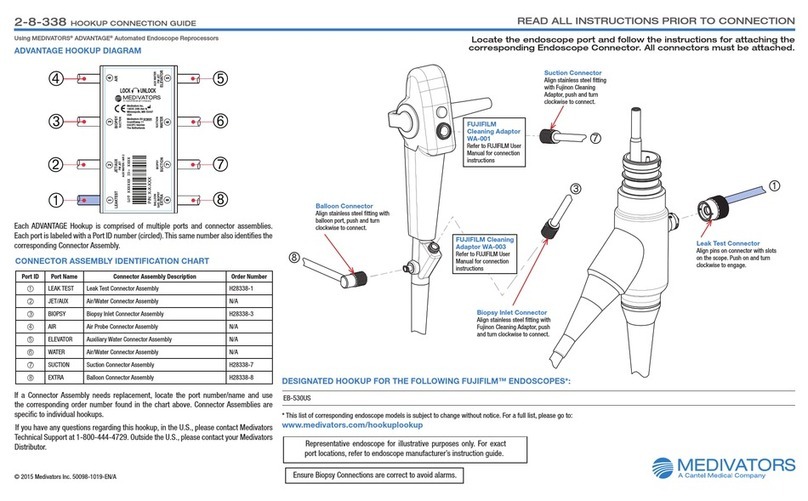

Medivators Advantage Instruction Manual

Medivators

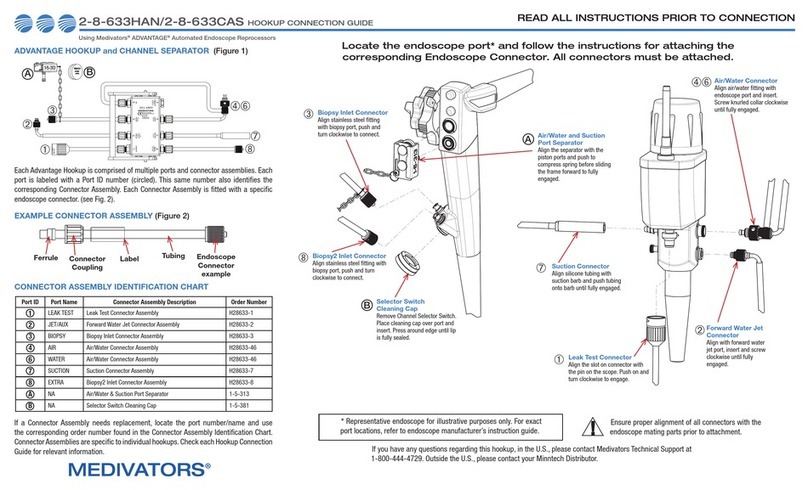

Medivators 2-8-633HAN Instruction Manual

Medivators

Medivators DSD EDGE User manual

Medivators

Medivators SCOPE BUDDY PLUS User manual

Medivators

Medivators DSD-201 Operating instructions