METHVEN Amio 01-4002 User manual

Other METHVEN Plumbing Product manuals

METHVEN

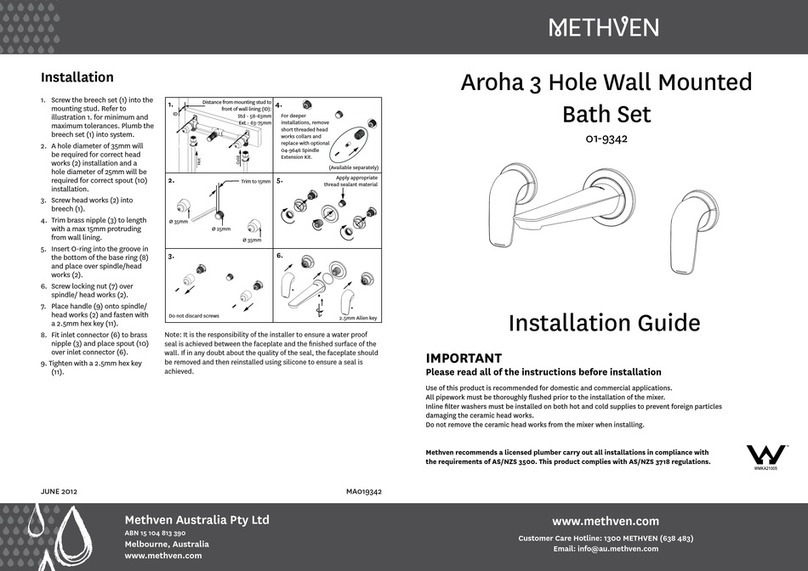

METHVEN Aroha 01-9342 User manual

METHVEN

METHVEN Amio Shower Mixer With Divertor User manual

METHVEN

METHVEN Kiri HOT 01-5795 User manual

METHVEN

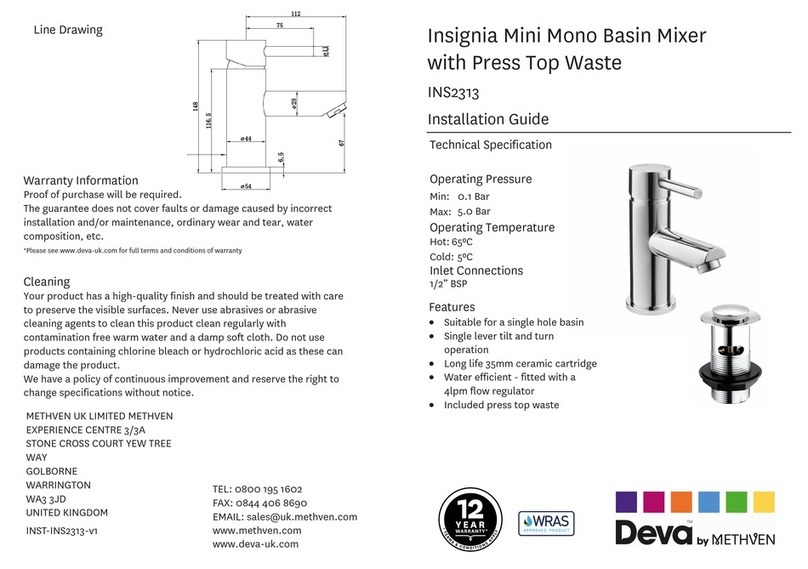

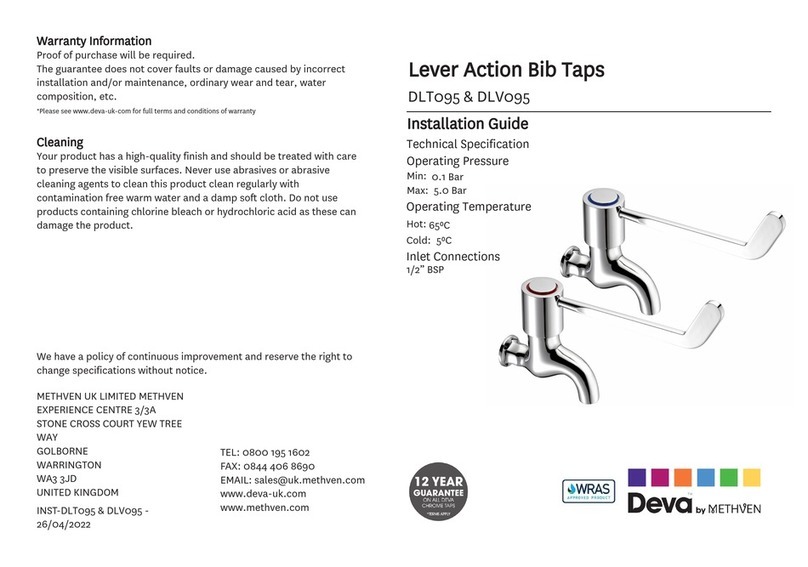

METHVEN Deva NCT002 User manual

METHVEN

METHVEN WAIPORI User manual

METHVEN

METHVEN 03-9470M User manual

METHVEN

METHVEN Kiri 3 Hole Wall Faucet User manual

METHVEN

METHVEN Kaha 01-7409 User manual

METHVEN

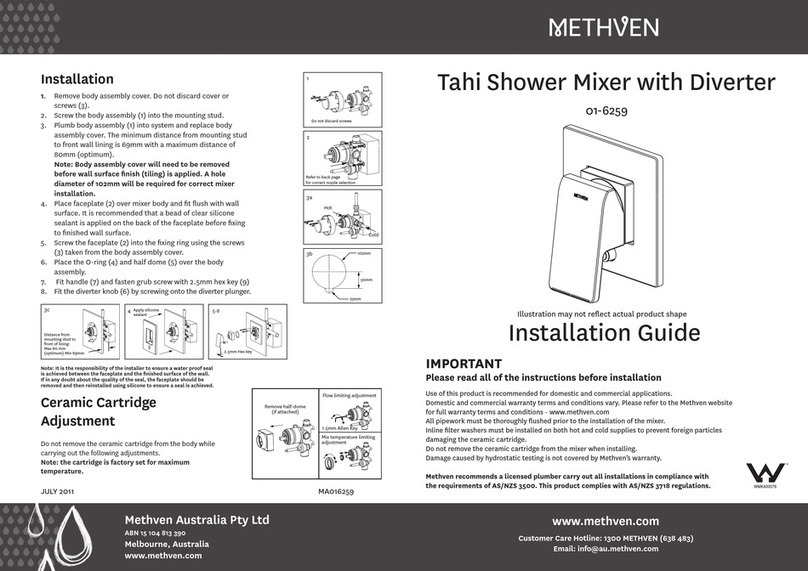

METHVEN 01-6259 User manual

METHVEN

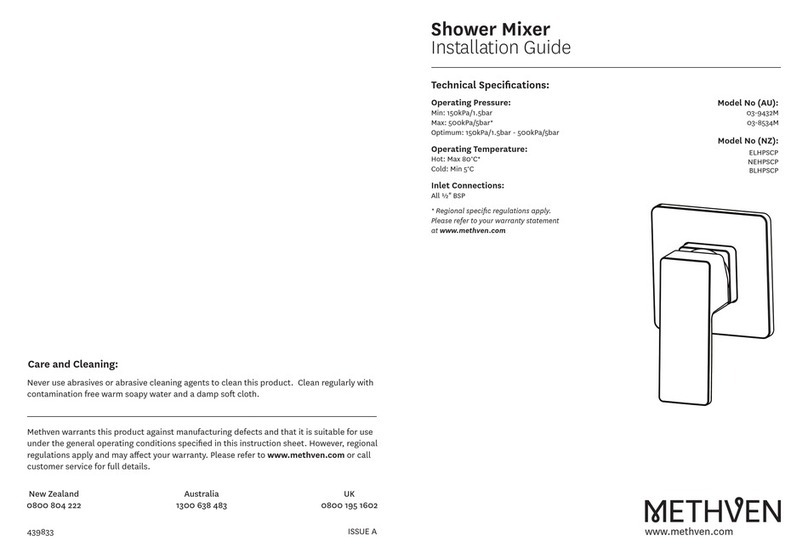

METHVEN 03-9432M User manual

METHVEN

METHVEN MINIMALIST MMSCP User manual

METHVEN

METHVEN echo Basin Mixer User manual

METHVEN

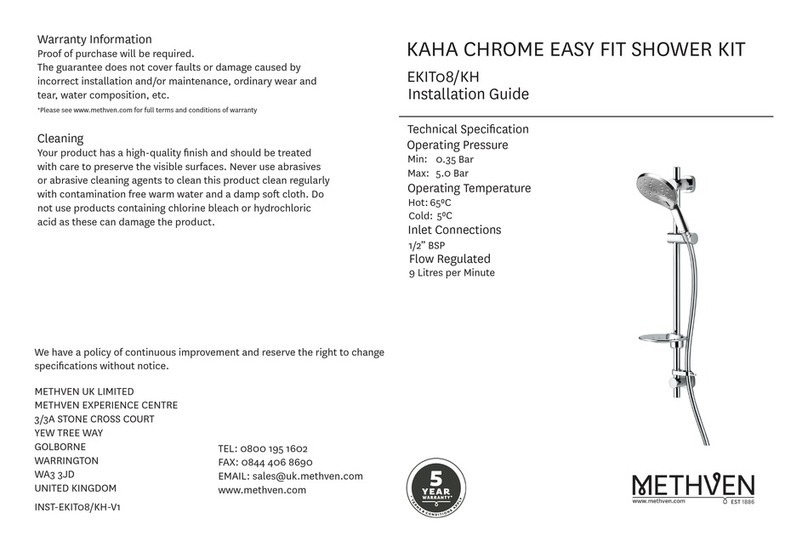

METHVEN KAHA EKIT08/KH User manual

METHVEN

METHVEN Promix Assembly instructions

METHVEN

METHVEN TUROA User manual

METHVEN

METHVEN Kaha 01-7508 User manual

METHVEN

METHVEN AROHA User manual

METHVEN

METHVEN Amio Shower Mixer User manual

METHVEN

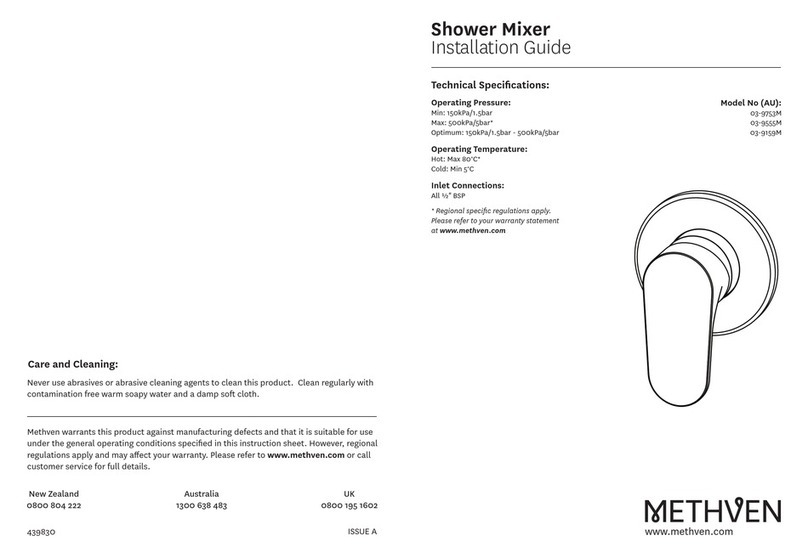

METHVEN 03-9753M User manual

METHVEN

METHVEN KOHA SHOWER MIXER WITH FASTFLOW II User manual

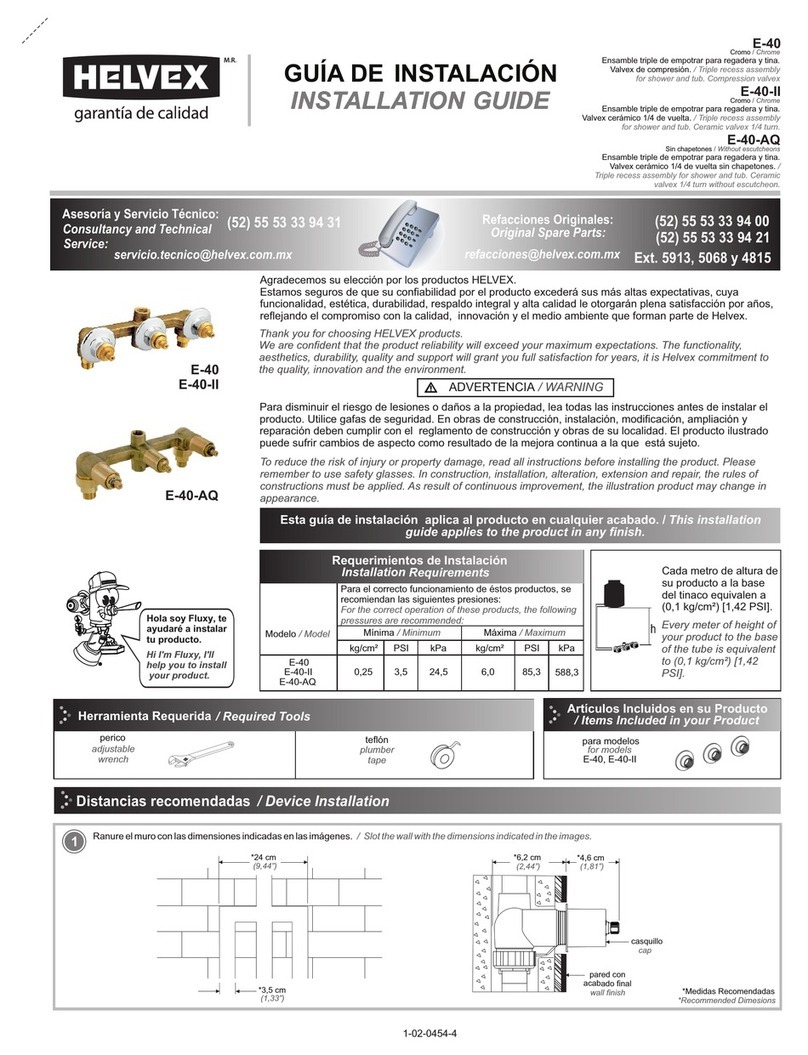

Popular Plumbing Product manuals by other brands

Haws

Haws 8320 Installation, operation & maintenance instructions

Spectrum Brands

Spectrum Brands Pfister Woodbury RT6-5WD Quick installation guide

Franke

Franke F5ET2006 Installation and operating instructions

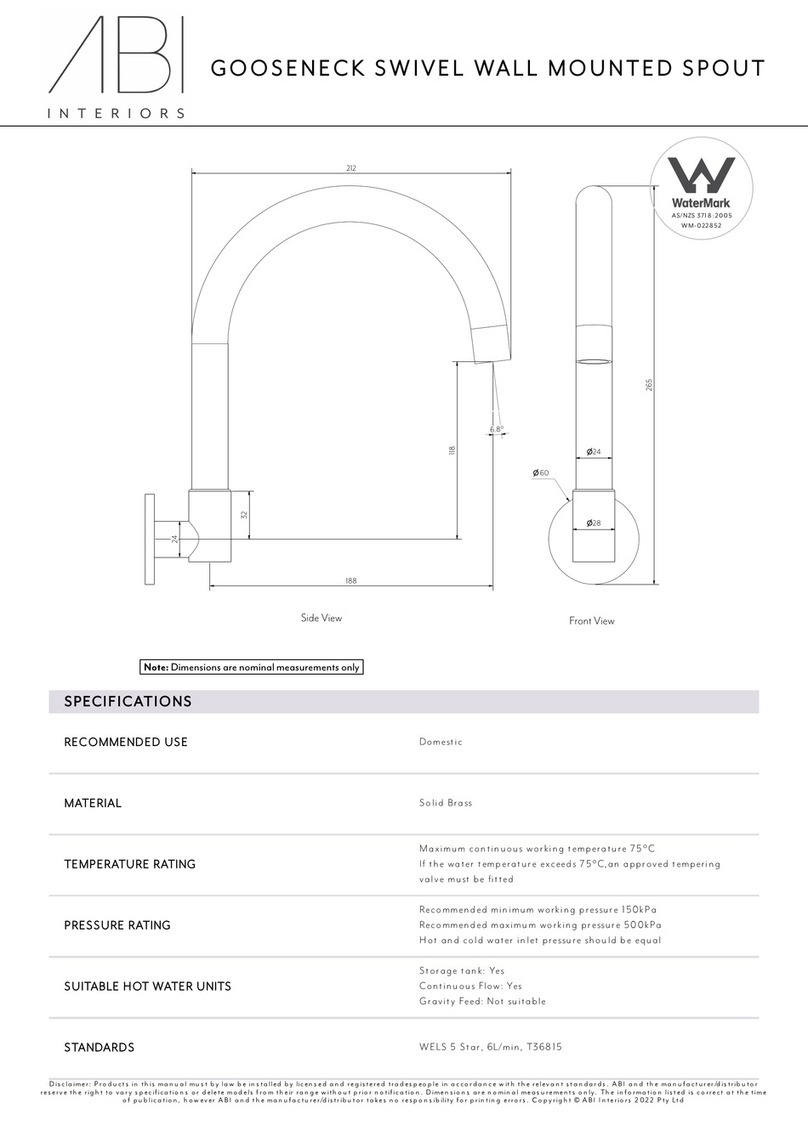

abi

abi GOOSENECK 11941 manual

Spectrum Brands

Spectrum Brands Pfister Courant LF-048-CO Quick installation guide

Grohe

Grohe Ladylux Plus 33 737 quick start guide