3

INSTALLATION

‐Themachineissuppliedfactorylubricatedandreadytorun.Itshouldbepositionedonanysolid,

levelandnon‐skidworksurfacethatisnonflammable.Installinworkareawithadequatelightand

space.

‐ForSP‐22HAorSmallerCapacityModel,youmayplacethemixeronbenchwhichiscapableof

supportingaloadofmixer’sweight.Forsafety,themixershouldbeBOLTEDinpositionusingall

fourholeslocatedinthelegs, bolt size L50 mm 3/8".

‐DONOTattempttoliftthemixeralone.

‐Cleanthemixerbeforeuse.Itisnormalforthefactorytoapplya

generousamountofgreaseinandonthemachinebeforeinitialuse.

‐Duringthetransportationorfitting,pleasedonotleanover35degree

toavoidthegearoilleakingfromthegearoilcontainer.

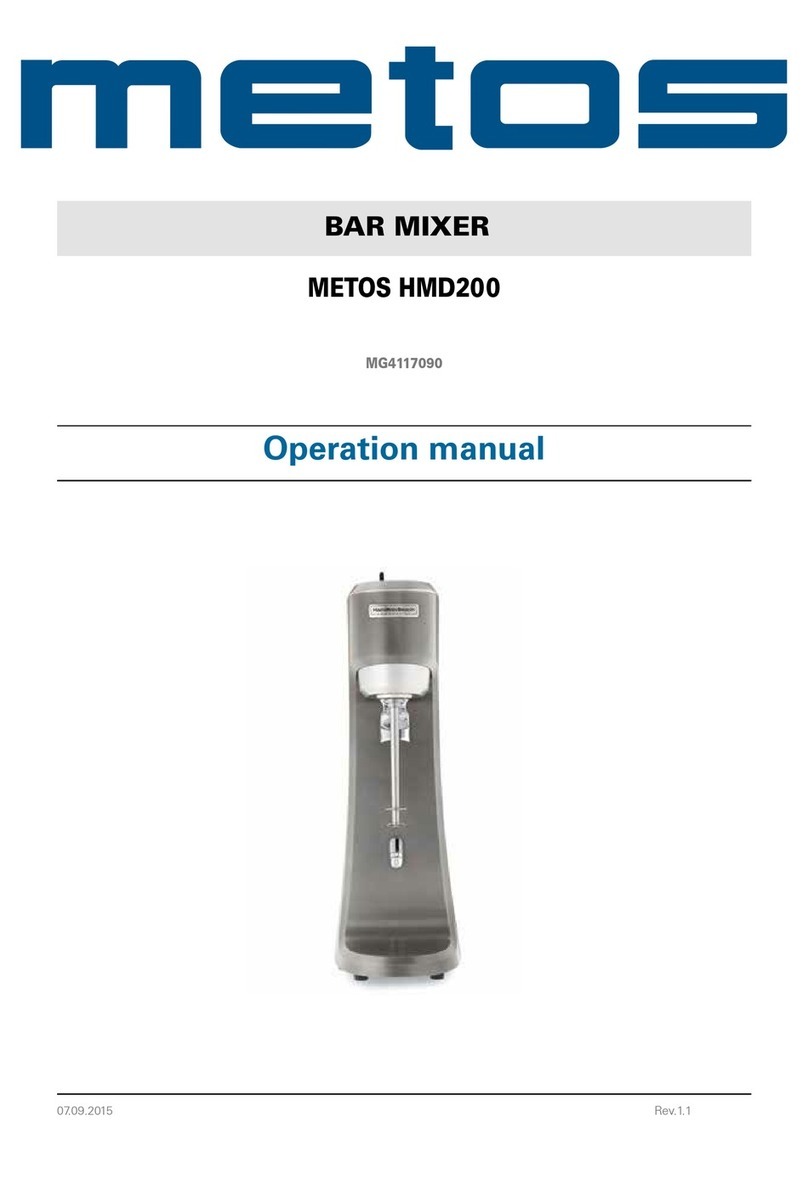

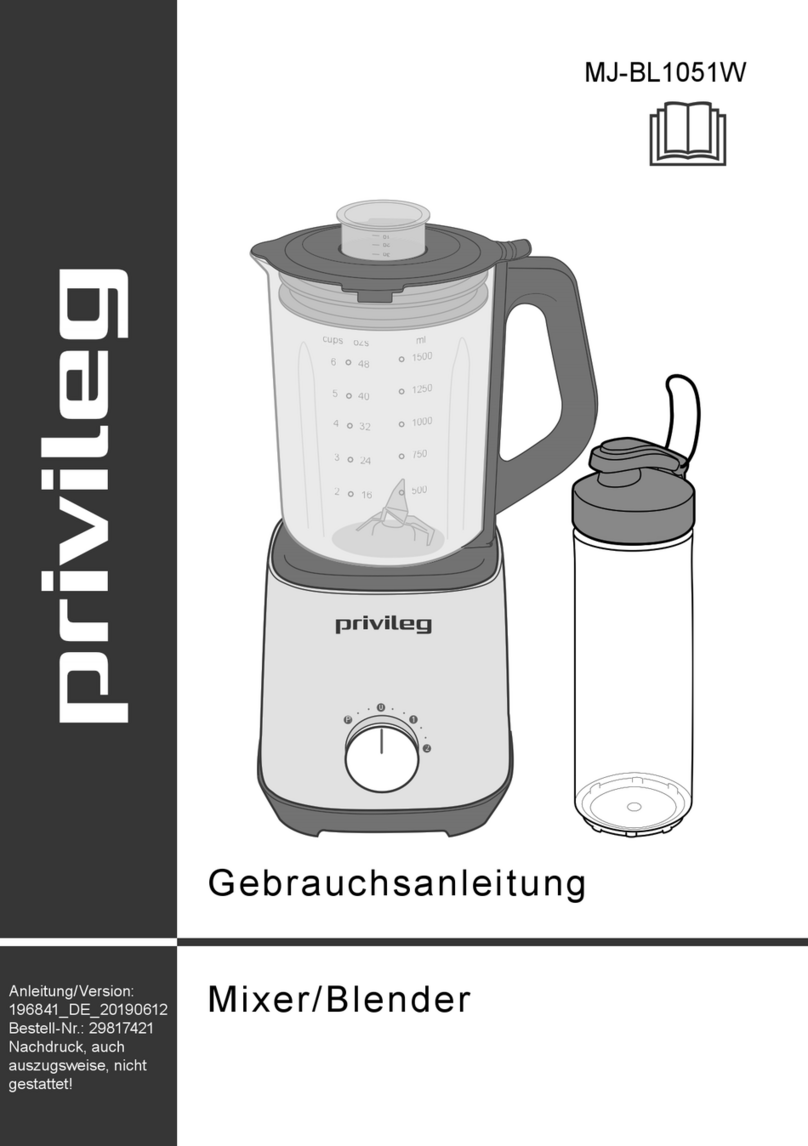

‐Pleaseuseforklifttotransporting.PleaserefertoFigure1.

ELECTRICAL CONNECTION

CAUTION:NEVERUSEEXTENSIONCORD.Lowampsupplycoulddamagethemixerorcauseafire.

CAUTION:Theusershouldinstallanover‐currentprotectiondevice(e.g.fuseorNFB)orResidual

CurrentDevice(GFCI)inthemachineincomingsitepowerlinestopreventafaultcurrentrisk.

CAUTION:ThemachineisdesignedforTNpowersystem.

Beforeconnectingthismachinetotheelectricalsupply,checkthatthedetailsontheratingplate

(locatedontherearofthemachine)correspondtothedetailsofyourelectricalconnection.

Themixerissuppliedwithatrailingleadfittedwithamoldedplug.Ifthestyleofplugisunsuitablefor

thesocketyouplantouse,theplugmustbecutoffandreplacedwithanappropriateplug.

Machinesarefittedwithacolorcodedthreecorecableasfollows:

(1) Brown:Live

(2) Blue:Neutral

(3) Green/Yellow:Earth

Asthecolorofthewiresmaynotcorrespondtothecoloredmarkingsidentifyingtheterminalsinyourplug,

youshouldproceedasfollows:

‐Thewirewhichiscoloredbluemustbeconnectedtotheterminalwhichismarkedwiththeletter

Norcoloredblack.

‐Thewirewhichiscoloredbrownmustbeconnectedtotheterminalwhichismarkedwiththe

letterLorcoloredred.

‐Thewirewhichiscoloredgreen/yellowmustbeconnectedtotheterminalwhichismarkedwith

theletterEorcoloredgreen.

NOTE:Intermsofthe3‐phase,whenthemixerislocatedandconnectedwiththeplug,pleasemakesure

thattheshaftgoesclockwise.(Samedirectionasthearrowstickerthatlocatedonthefrontofthemachine)

Iftheshaftgoescounterclockwise,pleasereplacethewires:R.S.T.(USA)L1,L2,L3,(Europe).Toreplacethe

wireseachotheruntiltheshaftgoesclockwise.

Themixershouldbepluggedintoaswitchedsocketwhichisolatesallpolesandhasaminimum

contactclearanceof3mmandlocatedclosetothemixerforuseinanemergencyandtofacilitateservicing.

Themachinemustbeincorporatedintoapotentialequalizationsystem.

Theleakagecurrentforthisapplianceisnogreaterthan1mA/KW.

Iftheelectricalsupplycabletothemachinebecomesdamaged,itmustbereplacedbyaspecification

orhigherandsuitablefortheMixer’smotorload.

Thegroundwireisfixedtothemachineandthisconnectionmustbekeptintact.

CAUTION:ThemixerMUSTbegrounded.

InstallationInstructions

Figure1