4

‐Theminimumrequirementforallelectricalequipmentiscorrectoperationbetweenairtemperature

of+5℃and+40℃.

‐Electricalequipmentiscapableofoperatingcorrectlywhentherelativehumiditydoesnotexceeding95%at

amaximumtemperatureof+40℃.

‐Electricalequipmentiscapableofoperatingcorrectlyataltitudeupto1000m.

‐Electricalequipmentisdesignedtowithstandtoprotectedagainsttheeffectsoftransportation,and

storagetemperaturewithinarangeof‐25℃to+55℃andforshortperiodsnotexceeding24hatup

to+70℃.

OperatingInstructions

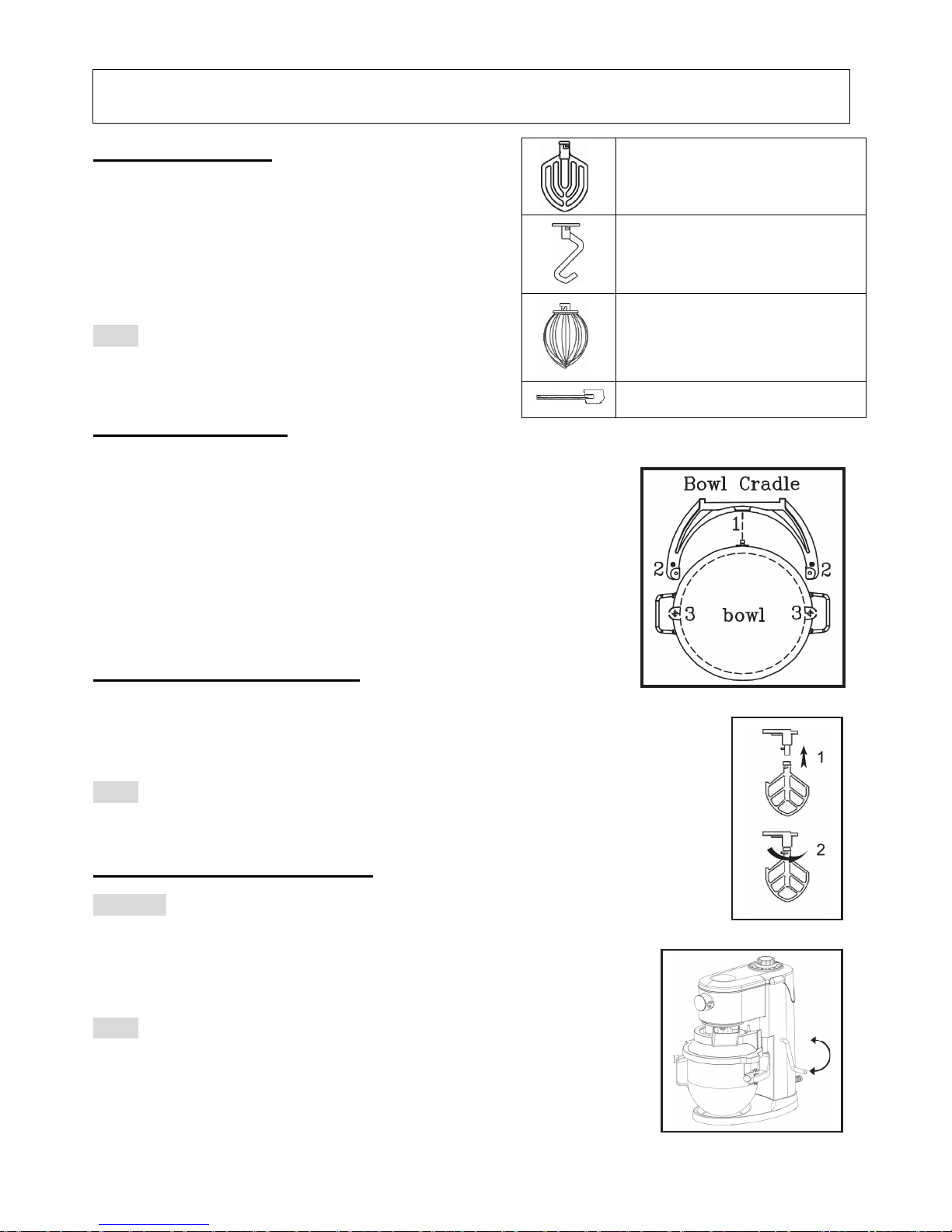

BEFORE USING THE MIXER

Beforeusingthemixer,ensurethatallusersarefamiliarwiththecorrectoperationofthemachine.In

particular,careshouldbetakentoensurethatthebowlandmixingtoolsarecorrectlyfittedandthatthe

bowlguardisinpositionpriortostartingthemachine.

SAFETY AT WORK

‐NEVERplaceyourhandoranykitchenutensilinthebowlwhilstthemixerisinoperation.

‐Keephands,hairandclothingawayfrommovingparts.

‐Isolatethemachinefromtheelectricalsupplybyremovingtheplugfromthesocketbefore

cleaning,servicingoradjustinganypartsorattachments.

‐Donotusethemachinewithanycoverorguardremoved.

‐Certainoperatornoticeadvisingaboutthesafeuseofthismixerisattachedtothemachine.

OFFICE, SHOPS AND RAILWAY PREMISES ACT, 1963

TheaboveActrequiresthatthismachineandattachmentsshallbeoperatedonlybyaproperly

instructedpersonorbyanemployeewhoisunderthesupervisionofaproperlyinstructedperson.The

instructionshallincludeindicationofthepossibledangersarisingandtheprecautionstobeobserved.The

Actalsorequiresthatnopersonundertheageof18shallcleanamachineifthisexposeshimtoriskof

injuryfromamovingpartofthatmachineoranyadjacentmachine.

CORRECT USE OF THE MIXER

‐Itistheresponsibilityoftheoperatorstousethemixercorrectlywithintherecommended

limitations.Alwaysfollowtheinstructionsonthesideofthemachinewhenchanginggear.Ifthe

motorlabors,pleasestopthemachineandreducethesizeofthemiximmediately.Damage

resultingfromimproperuseiswillvoidthewarranty.

‐Foroperatorsafety,themachineisfittedwithabowlguardwhichiselectricallyinterlockerto

ensurethatthemixercannotoperateunlesstheguardiscorrectlypositionedandthebowlis

raised.Excessiveforceusedtoopenandclosethebowlguardmaydamagetheelectrically

interlocker,andwillvoidthewarranty.

‐Foradditionalsafety,themixerhasanovoltreleasefeaturewhichmeansthatintheeventofa

powerfailure,themachinewillonlyrestartafterthecontrolhasbeenrestedtoOFF.This

arrangementensuresthatwhenthesupplyisrestored,themachinecannotrestartonitsown.

‐Carefulhandlingofbaggedproductsbyminimizingtheheightabovethebowlbasefromwhich

theyarepoured.

‐Carefulslittingofbagsinthelowerpartofthebowltoallowdustfreedischargeofflourasflouras

possible.

‐Usetemporarybowlcoverstominimizeopeningsthroughwhichflourmanyescape.

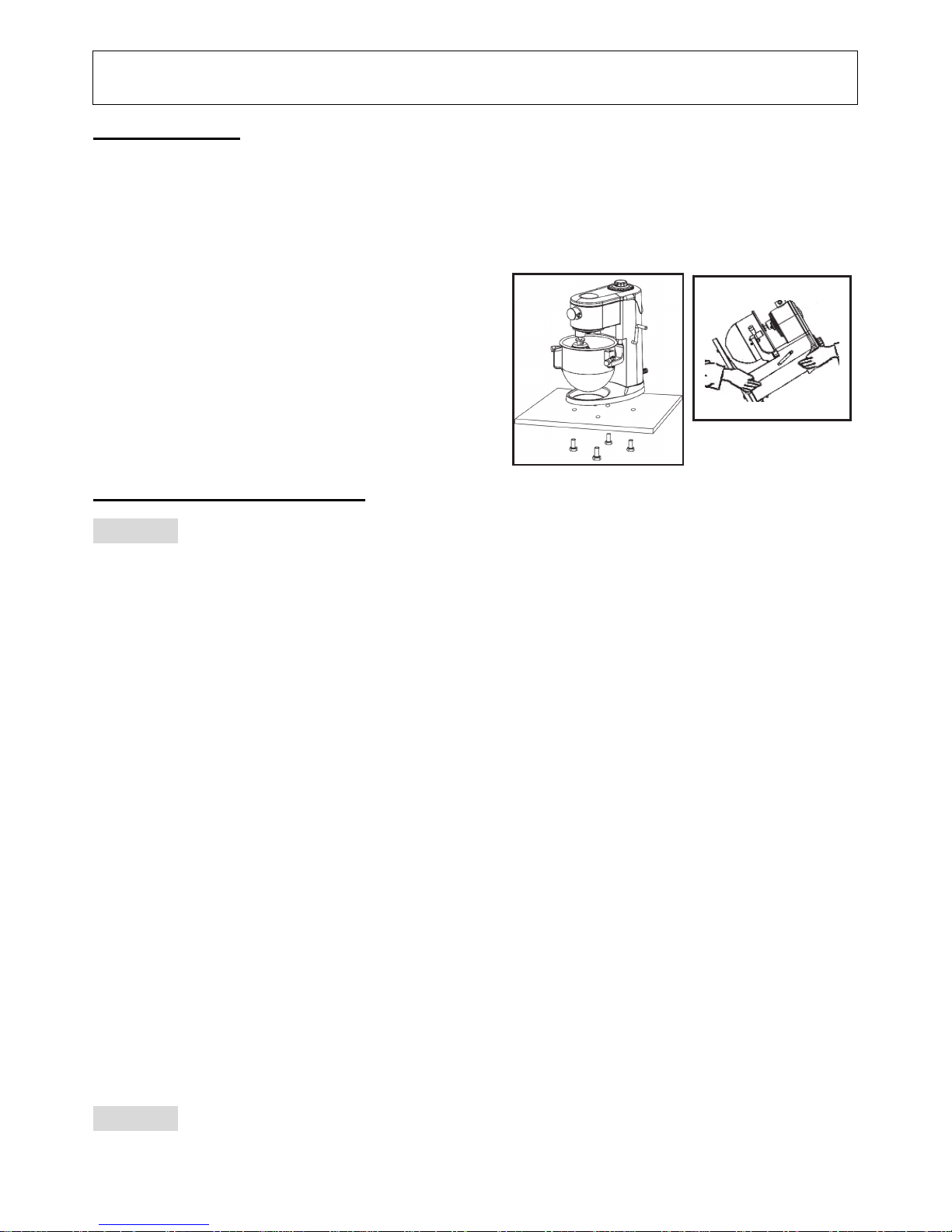

InstallationInstructions