8 PZ 70 en 7

Clean the packing counterbore.

Push the new packing rings (28) one by one into the

counterbore with the gland (6). Position the cut ends

of the rings at a 90° angle to each other and at a 45°

angle to the flow port.

Push the outer ring (34) and gland (6) into place and

tighten the nuts (17) lightly.

Fasten tight the tilting device nuts (18) and then the

nuts (17) and install the cap (53). See Section 4.7.2.

Always check the seal of the gland packings after

installation.

4.3 Bearings (5, 22)

The ball stem bearing is located in the bonnet (8) under the

gland packing rings (28). The bearing is maintenance free. It

is recommended to be dismantled only when the whole

valve is dismantled.

The purpose of the bearing at the rear end of the ball, i.e.

the support (38), is to keep the ball at the valve center line

during operation, allowing a free up-and-down movement.

Normally, the support does not need to be inspected or

replaced.

4.4 Body joint

If the body joint leaks, tighten nuts (16) as shown in Table 1.

If the leak continues after the tightening, the valve must be

dismantled. Inspect the seating surface and ensure that the

body joint plane is level. Then replace the body gasket (26).

See Section 4.7.2.

4.5 Ball and seating

If the valve leaks, the probable cause is chips between the ball

and the seat. Before adjusting lifting springs (20), wash and

pool the ball surface with a water jet when valve partly open.

Operate the valve 2-3 times and retest.

If washing does not help, the valve must be dismantled and

cleaned.

If the ball surface is damaged for some reason and causes

leakage, the ball can be turned 180° provided that the ball

seat is not damaged. A damaged ball seat will destroy the

ball surface in a short time. The valve must be dismantled

for inspection before turning the ball.

4.6 Dismantling the valve

It is best to dismantle the valve for servicing when it is

detached from the digester. The lower body half can alter-

natively be left mounted on the digester. Use the loops

delivered with the valve for lifting.

Dismantle the valve on a clean, level cardboard or wooden

underlay.

Lower the valve onto the underlay if you have

removed the whole valve from the digester.

Turn the ball to the closed position.

Detach the actuator using the extractor, see

Chapter 6.

Dismantle the upper body half (1).

Fasten the lifting strap through the ball and keep it

adequately tightened.

Remove caps (53) and the tilting device nuts (18),

disc springs (20) and screws (13).

Detach the actuator console (7).

Remove the bonnet with gland packings (28) and

bearings (5, 22).

Remove the support (38) with extractor screws.

Lift the ball out of the body; take care not to damage

the seating surfaces or the stem.

Clean all dismantled parts carefully and replace worn

or damaged parts as necessary.

4.6.1 The ball

After lifting the ball from the body, place it on a clean, soft

surface for cleaning. Take special care to clean the ball seat-

ing surfaces and the gland packing area. Grind any minor

scratches on the ball and packing with 28/20 μm grinding

paste and finish with 7/5 μm paste. Scratches and burrs in

the stem can be ground with fine abrasive cloth of grade

400. If there are deeper scratches in the ball or it is mis-

shapen, send it to the manufacturer for repair.

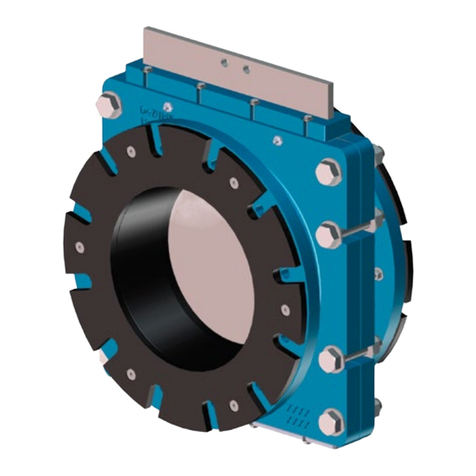

4.6.2 Ball seat

The seat (4) is locked in its groove. If the seat is in order and

there is no reason to suspect the condition of the seal (25),

the seat need not be dismantled for servicing.

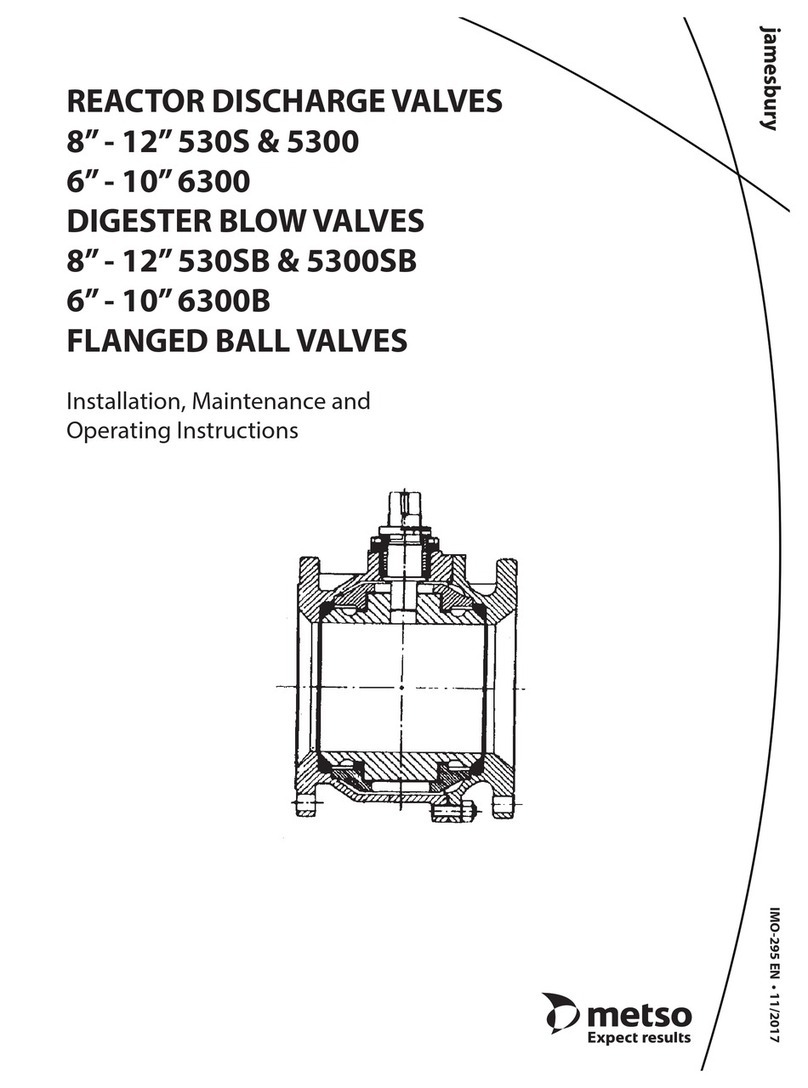

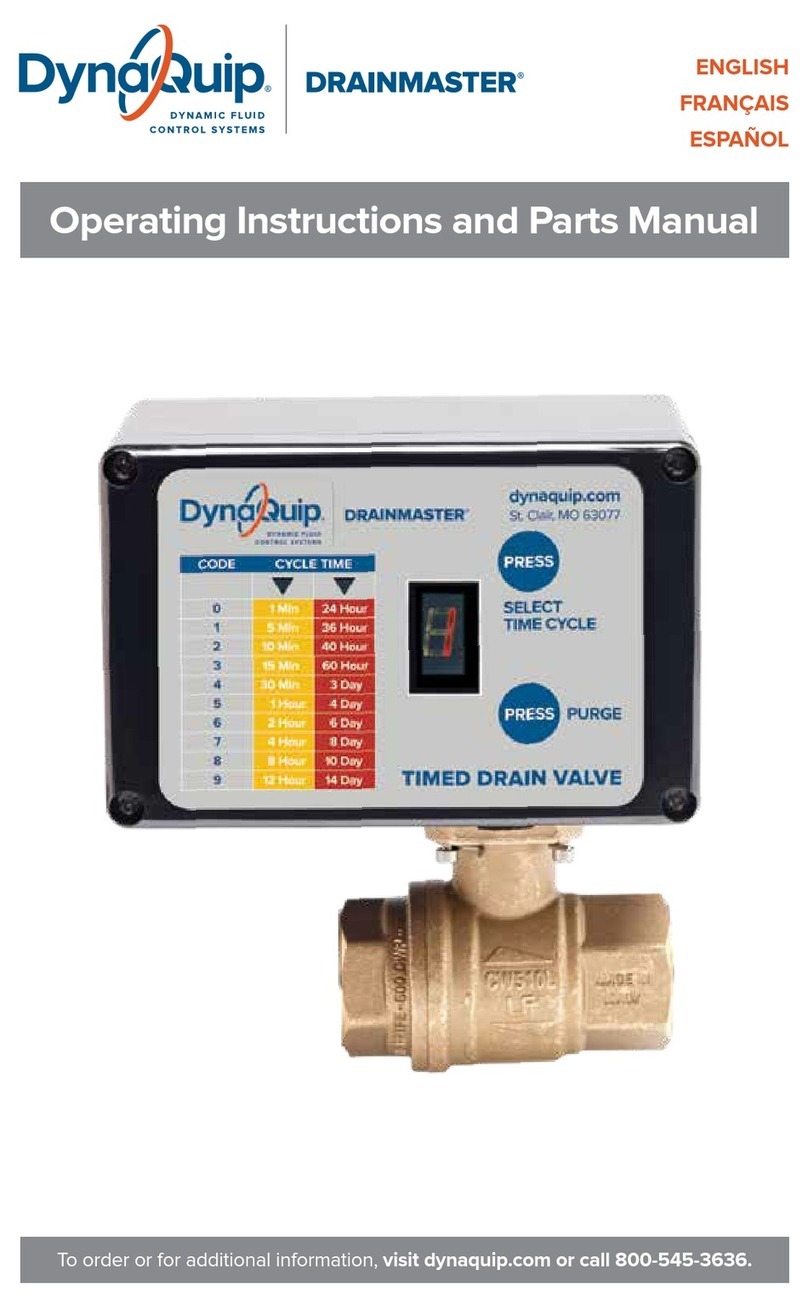

Remove the seat as follows:

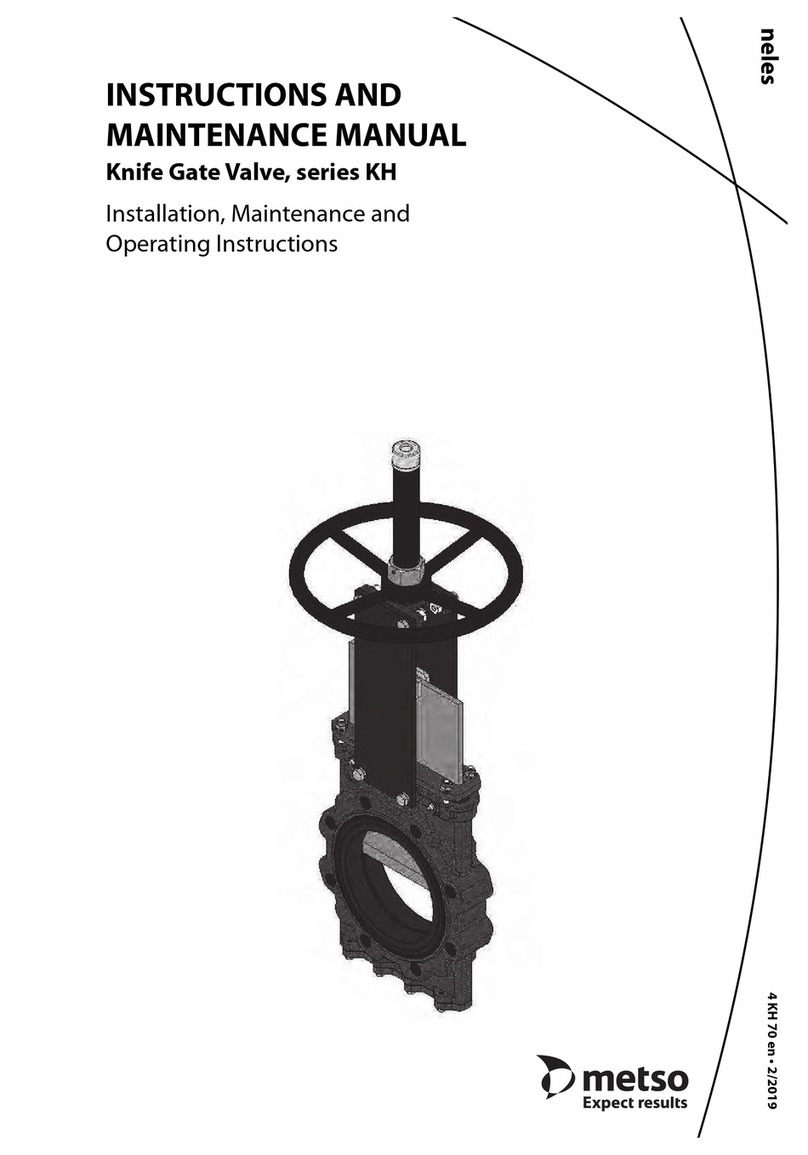

First grind down the locking points with a grinder,

see Fig. 9.

Open the locking points with a sharp chisel to facili-

tate removal, see Fig. 10.

Make sure that the seat slides freely in the groove.

Turn the body half upside down and knock it lightly

near the seating edge to make the seat drop out of

the groove on the underlay.

4.6.3 The body

Clean the body halves carefully and check all seating sur-

faces.

The body gasket (26) must be replaced each time the valve

is dismantled.

NOTE:

Lifting springs are factory preset and excessive tightening

might damage the ball surface. See Section 4.7.2, Table 2.

CAUTION:

Do not dismantle or remove the valve when it is pres-

surized!

Fig. 9 Grinding the seat locking