X9751122-A010014MSC

English

MICRO-EPSILON

Contents

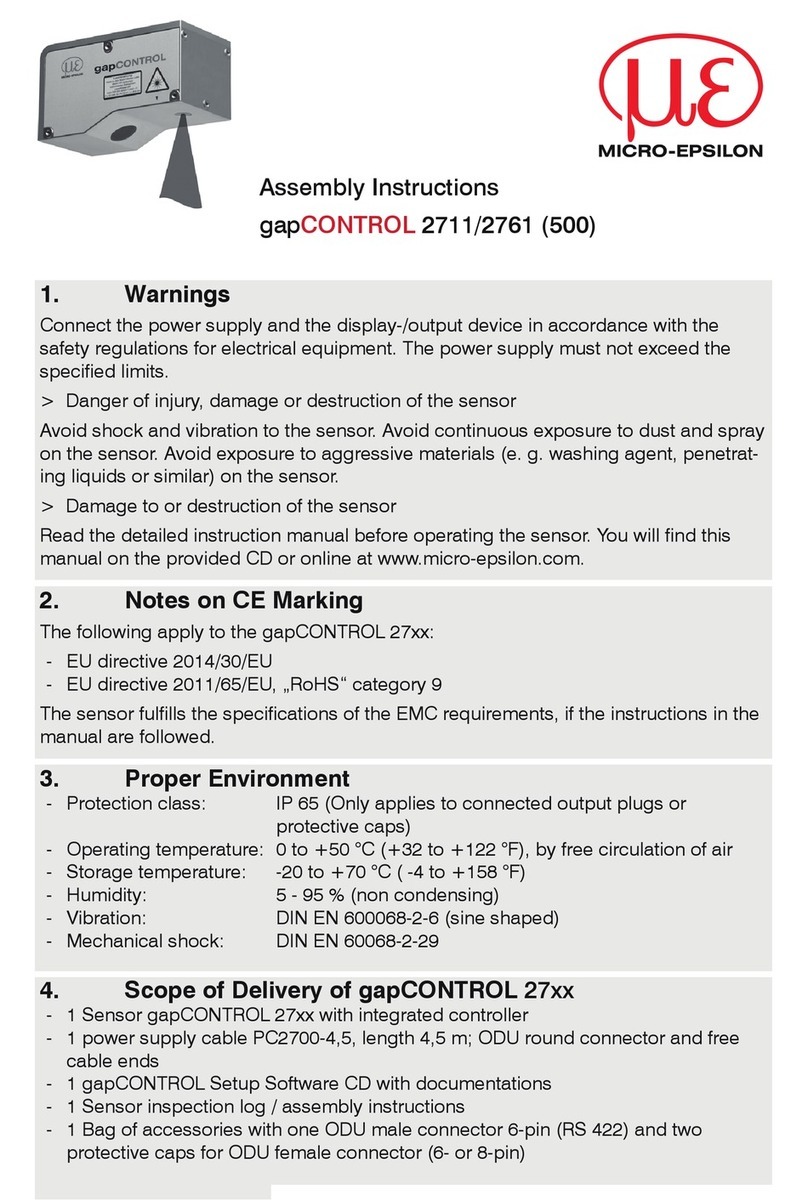

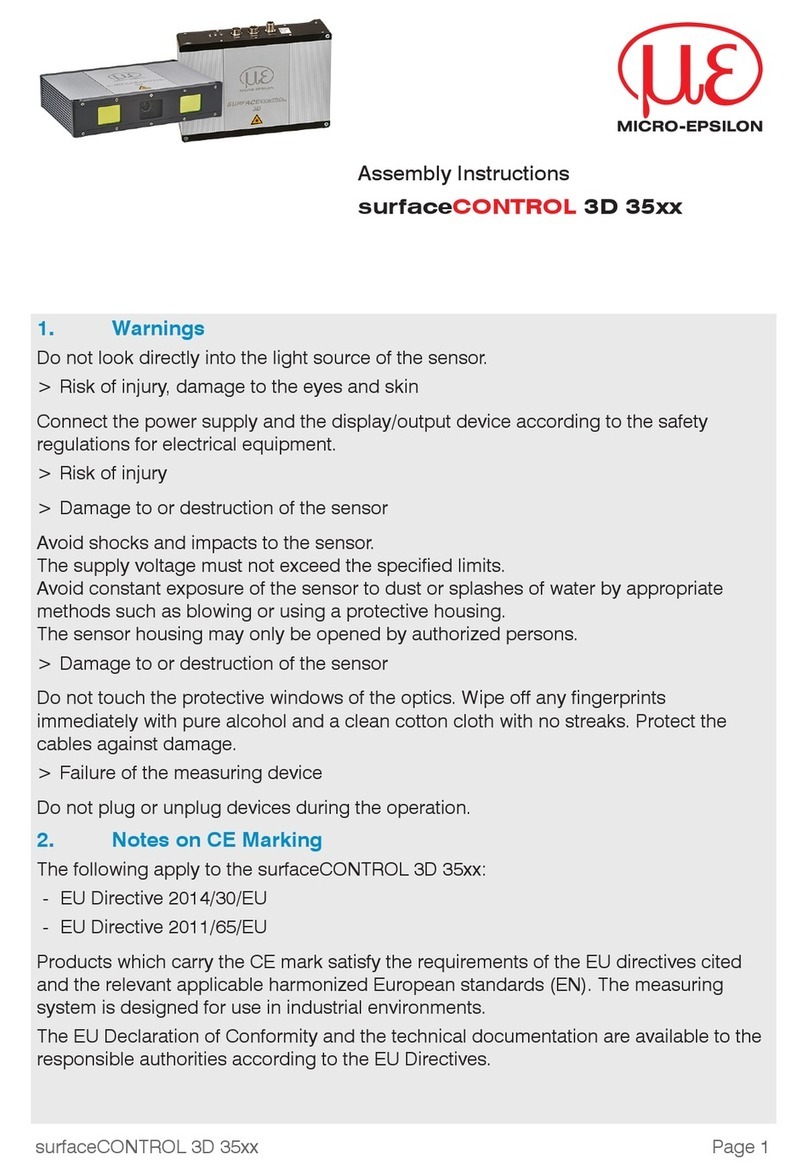

1. Safety ........................................................................................................... 23

1.1 Symbols Used.................................................................................................................23

1.2 Warnings ......................................................................................................................... 23

1.3 Notes on CE-Identification .............................................................................................. 24

1.4 Proper Use ...................................................................................................................... 25

1.5 Proper Environment ........................................................................................................ 25

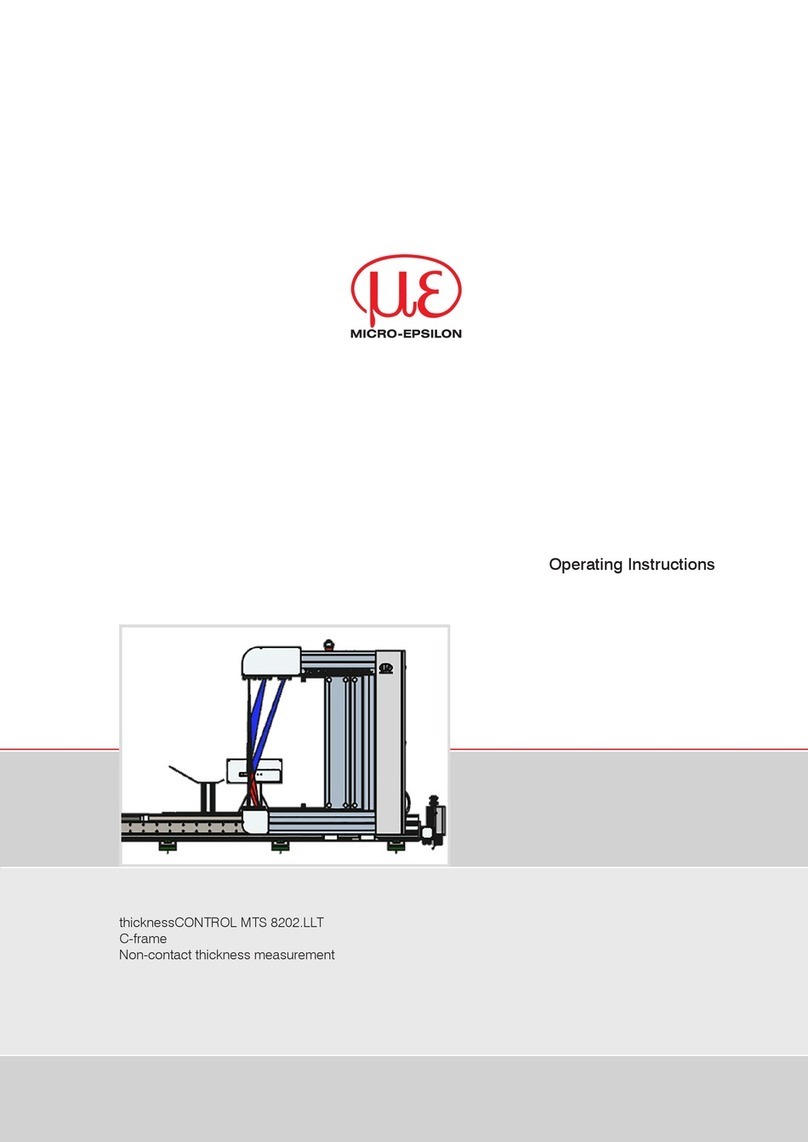

2. Functional Principle, Technical Data.......................................................... 26

2.1 Measuring Principle ......................................................................................................... 26

2.2 Structure.......................................................................................................................... 27

2.2.1 Controller ........................................................................................................................ 27

2.2.2 Sensors ........................................................................................................................... 28

2.3 Technical Data ................................................................................................................. 28

3. Delivery ....................................................................................................... 30

3.1 Unpacking....................................................................................................................... 30

3.2 Storage ........................................................................................................................... 30

4. Installation and Assembly .......................................................................... 31

4.1 Precautionary Measures .................................................................................................. 31

4.2 Sensor ............................................................................................................................. 31

4.3 Electronics, Ground Connection, Earthing ..................................................................... 33

4.4 Signal Output .................................................................................................................. 33