TOC - IV 750 FEEDER MANAGEMENT RELAY – INSTRUCTION MANUAL

TABLE OF CONTENTS TOC

S5 PROTECTION ................................................................................................................................ 5-44

OVERVIEW ............................................................................................................................ 5-44

TIME OVERCURRENT CURVE CHARACTERISTICS .............................................................. 5-45

PHASE CURRENT .................................................................................................................. 5-49

NEUTRAL CURRENT ............................................................................................................. 5-57

GROUND CURRENT ............................................................................................................. 5-63

SENSITIVE GROUND ............................................................................................................ 5-67

NEGATIVE SEQUENCE .......................................................................................................... 5-75

VOLTAGE ...............................................................................................................................5-81

FREQUENCY .......................................................................................................................... 5-86

BREAKER FAILURE ............................................................................................................... 5-89

REVERSE POWER ................................................................................................................. 5-91

S6 MONITORING ............................................................................................................................... 5-93

CURRENT LEVEL ................................................................................................................... 5-93

POWER FACTOR ................................................................................................................... 5-94

FAULT LOCATOR .................................................................................................................. 5-96

DEMAND ...............................................................................................................................5-98

ANALOG INPUT .................................................................................................................... 5-105

ANALOG OUTPUTS .............................................................................................................. 5-109

OVERFREQUENCY ................................................................................................................. 5-112

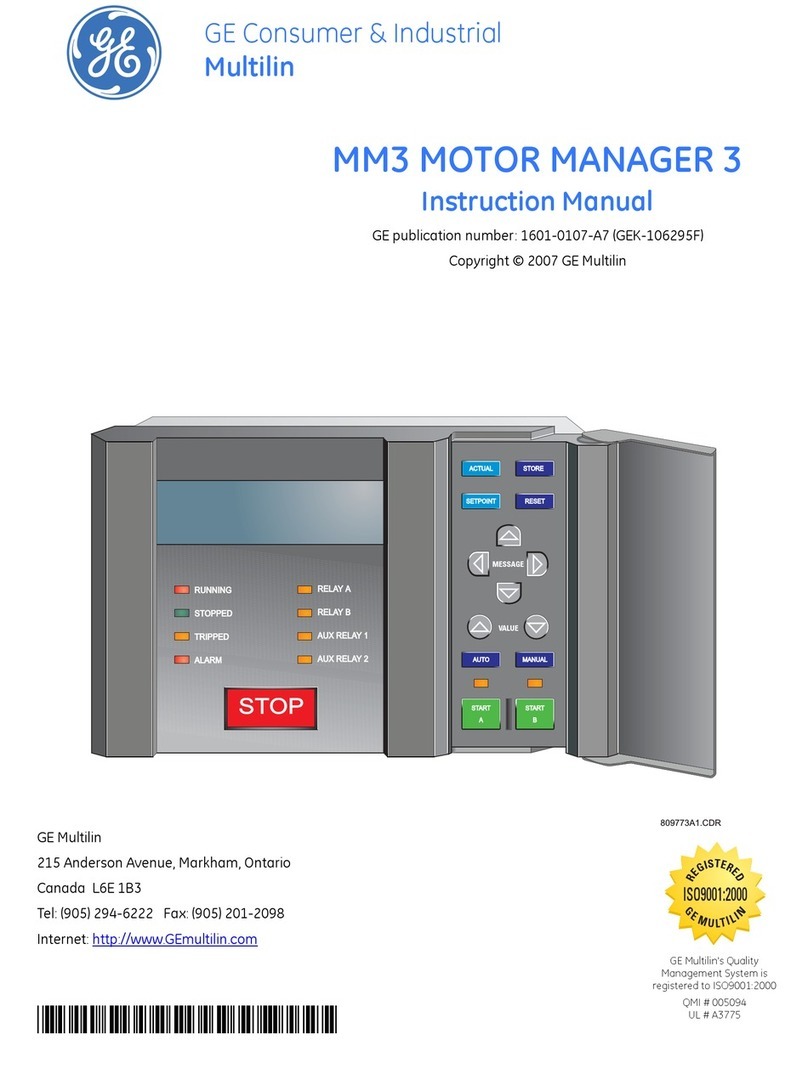

EQUIPMENT ........................................................................................................................... 5-113

PULSE OUTPUT .................................................................................................................... 5-120

S7 CONTROL ...................................................................................................................................... 5-122

SETPOINT GROUPS .............................................................................................................. 5-122

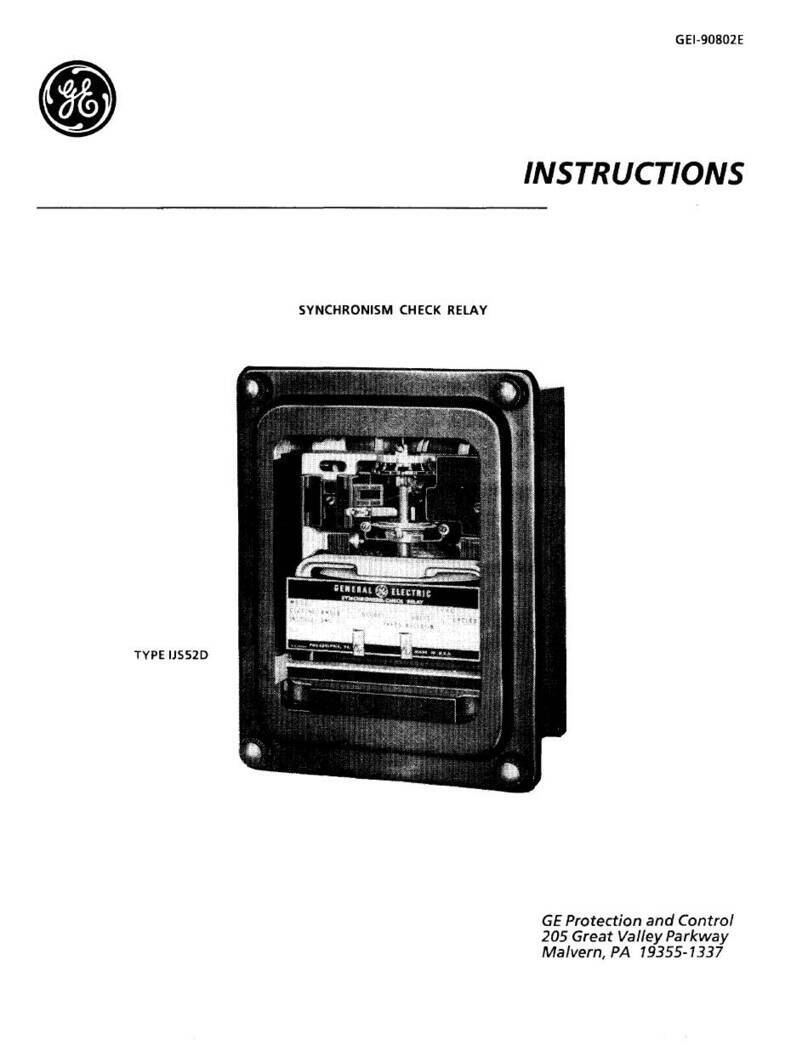

SYNCHROCHECK .................................................................................................................. 5-126

MANUAL CLOSE BLOCKING ............................................................................................... 5-128

COLD LOAD PICKUP ............................................................................................................ 5-130

UNDERVOLTAGE RESTORATION ......................................................................................... 5-132

UNDERFREQUENCY RESTORE ............................................................................................. 5-133

TRANSFER SCHEME ............................................................................................................. 5-135

AUTORECLOSE (760 ONLY) ................................................................................................ 5-155

S8 TESTING ......................................................................................................................................... 5-168

OUTPUT RELAYS .................................................................................................................. 5-168

PICKUP TEST ......................................................................................................................... 5-169

ANALOG OUTPUTS .............................................................................................................. 5-169

SIMULATION ......................................................................................................................... 5-170

FACTORY SERVICE ................................................................................................................ 5-174

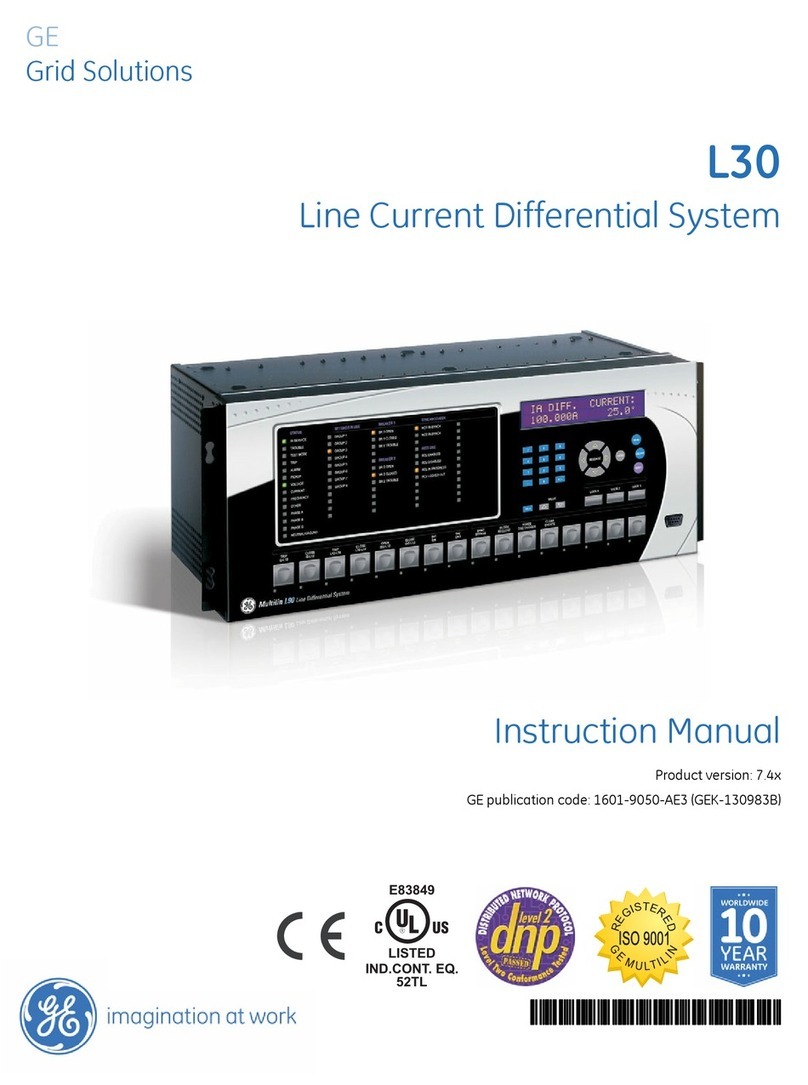

6: ACTUAL VALUES OVERVIEW ........................................................................................................................................... 6-1

ACTUAL VALUES MAIN MENU ........................................................................................... 6-1

A1 STATUS ........................................................................................................................................... 6-6

VIRTUAL INPUTS ................................................................................................................... 6-6

HARDWARE INPUTS ............................................................................................................. 6-6

LAST TRIP DATA ................................................................................................................... 6-7

FAULT LOCATIONS ............................................................................................................... 6-8

CLOCK ................................................................................................................................... 6-8

AUTORECLOSE (760 ONLY) ................................................................................................ 6-8

A2 METERING ..................................................................................................................................... 6-10

METERING CONVENTIONS .................................................................................................. 6-10

CURRENT ...............................................................................................................................6-11

VOLTAGE ...............................................................................................................................6-12

FREQUENCY .......................................................................................................................... 6-13

SYNCHRONIZING VOLTAGE ................................................................................................. 6-14