BH79A277H01

•

MITSUBISHI

....

ELECTRIC

MITSUBISHI ELECTRIC Package Air-Conditioner Grille {Optional Part)

Automatic Filter Elevation Panel Installation Manual (PLP-6EAJ I

PLP-6EAJE (with "i-see Sensor"))

•11,4;,,~)k4!i!iit·

1

it'I

•

Before

installation,

make

sure

to

read

all

the

"Safety

precautions

that

must

be

followed"

and

perform

it

accurately.

•

The

precautions

herein

provide

very

important

points

regarding

safety

.

Make

sure

you

follow

them

.

•

Symbols

used

in

this

manual

are

categorized

as

follows

according

to

the

degree

of

risk

when

used

improperly:

~

Warning

Describes

warnings

that

must

be

observed

to

prevent

serious

consequences,

such

as

serious

injury

or

death

of

the

user.

Lt,Caution

Describes

precautions

that

must

be

observed

to

prevent

damage

to

the

unit.

•

After

installation,

describe

the

user

"Safety

Precautions

",

how

to

use,

and

how

to

care

for

and

clean

the

unit

following

the

operation

manual

,

and

test

run

the

unit

to

check

whether

there

are

any

problems.

In

addition,

direct

the

user

to

keep

this

installation

manual

together

with

the

operation

manual,

and,

should

the

users

change,

to

give

the

manuals

to

the

new

user.

~Warning

Wiring

must

be

done properly using specific cables and fixed

so

Do not mixsubstances otherthan the designated refrigerant

in

that external pressurefrom the cable will not transmitto

the

the refrigerant cycle when installing and/or moving the unit.

terminal area. Neversplice the cables

for

wiring. •

If

air

or

other substances

mix

in, abnormal high-pressure will occur

in

•

If

the connection and/orfixation are notdone properly,

or

if

the cables the refrigerant cycle, which may cause explosion.

are spliced, heat

or

fire may result.

The

unit

must not

be

moved

or

reinstalled by the user.

Never makealterations

to

the

unit.

•

If

the unit

is

installed improperly, water leakage, electric shock

or

fire

• Consult with a dealer

for

repairs.

If

alterations

are

doneon the unit

or

may result.

Ask

the

dealer

or

an authorized company to do so.

the unit

is

repaired improperly, waterleakage, electric shock

or

fire

Use genuine Mitsubishi parts such as humidifierand high

may result. performancefilters (sold separately).

Ask

the dealer or an authorized technician to install the unit. •

Ask

an authorized company

to

install.

If

the unit is installed by the

user improperly, waterleakage, electric shock

or

fire may result.

•

If

the unitis installed improperly by the user, water leakage, electric

shock

or

fire

may

result. Terminal board cover (panel)

of

the indoor/outdoorunitmustbe

Installation must be properly donefollowing this installation manual. inSialled properly.

•

If

the unitis installed improperly, water leakage, electric shock

or

fire • Ifthe terminal board cover (panel)

is

installed improperly, fire

or

It electric shock may result due to dust

or

water.

;:=

m=a=y=r=e=s=u=·

=========================================:

;:

================================================

='.

Installation

must

be done in proper order in case

of

strongwind Make sure the refrigerant has not leaked after installation.

such as storms and earthquakes. •

In

case the refrigerant leaks into the room and comes in contactwith

•

If

the unit is installed improperly, there

is

a riskthat a fall may result. a fan heater, heater,

or

stove burner, noxious fumes maybe produced.

The unitmust be securely installed on a surface that

is

able

to

support

the

weight ofthe unit.

•

If

the surface does nothave sufficientstrength, accidents may result

dueto falling

of

the unit.

If

the unit

Is

to

be Installed In a small room, takemeasures to

prevent exceeding the concentration limit

of

refrigerant in the

case

of

refrigerant leakage.

•

Ask

a dealeraboutmeasures

to

prevent the exceeding the

concentration limit.

If

there is anychance

of

refrigerant leakage and

its concentration exceedsthe limit,

it

may result in lack

of

oxygen.

Before installation(Environment)

Electrical work must

be

done by an authorized engineerfollowing

"Technical standards for electrical equipment", "Extension Code"

and this installation manual and using dedicated communication

circuit and rated powervoltage/circuit breakers.

• Ifthe electrical circuit does not have sufficient capacity

or

if

the unit is

installed improperly, electricshock

or

fire may result.

Turn

off

the main power before

the

installation work.

• Otherwise, injury

or

electricshock may result.

Ventilate the room

if

refrigerant leaks outduring installation.

• When refrigerant comes in contact with fire, noxious fumes may be

produced.

J

~Caution

Do not usethe unit in unusual environment. The unitmust not

be

used

for

special purposes such as

•

If

used in

an

environmentwith a large amount

of

volatile oil

(including mechanical oil), steam,

or

sulfidizing

gas

or

where it is high

in salt content such as a seashorewhere

the

outdoor unit may

become blocked bysnow, performance

may

dropsignificantly

or

parts

may become damaged.

the

storage

of

precision apparatuses, food, animals and plants,

and

art

objects.

•

It

may cause deterioration in quality

of

the objects.

Do not Install the

unit

above objects that should not getwet.

Do not Install

the

unit

In

an area where flammable

gas

may be

generated, flow in, be retained or leaked.

• In case gas leaks around the unit, fire or explosion may result.

•

In

case humidityexceeds 80%

or

the drain outlet is blocked, dew

may

fall from the indoor unit. When the heating function is on, waterleaks

from the outdoor unit; intensive drain work

may

be done to the

outdoorunit as needed.

If

the unit

Is

Installed

In

a hospital or telecommunlcatlons office, preparation

for

noise

must

be adequately completed.

• The effect

of

inverterequipment, private power generators, high-frequency medical devices and radio communication devices may result in

malfunctions and/ordamage

of

the air-conditioner. Air-conditioners may affectmedical devices

or

telecommunications devicesto interfere with

medical treatment

or

cause adverse effects such as disturbance

of

broadcasting and/or noise bursts.

1.

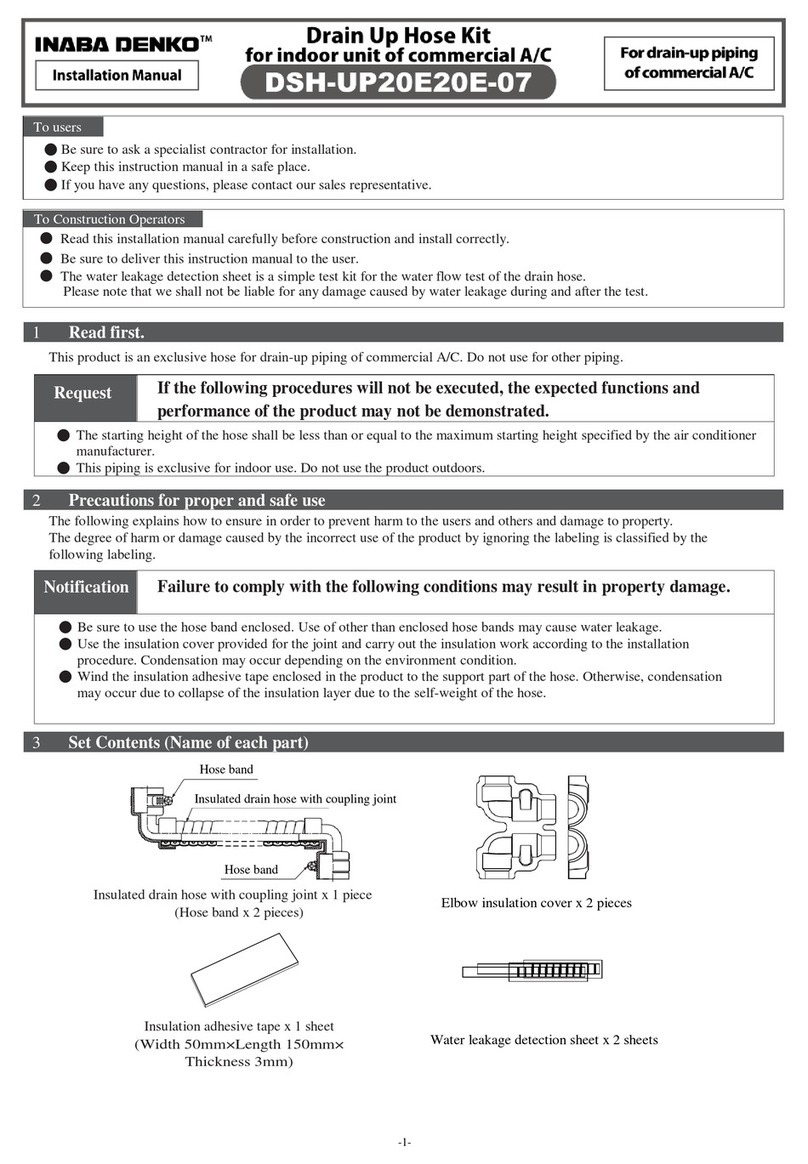

IIncluded partsI(This manual and following parts are included.)

Standard grille

Part

Number/ 0 Grille

Name

Quantity

Shapes/

Sizes

Grille with i-see Sensor

@ Installation gauge @Tag Wireless remote

© controller forAutomatic @ Battery

FilterElevation Panel

0

Lithium battery

CR2025

3V

Remote

@controller

holder ©

screw

2

@

Screw

®i-see Sensorcorner panel Note: Neverforce pressure on thevane,

it

may result in damage.

Parts

G)

to

(J)

above and

...!J

4><16

L!J

jf"

0 :i

·~

,.

-~"fl

Neverforce pressureon the lens

of

!@

I-see Sensor cornerpanel,

it

may result in damage.

' Ceiling surface

Main unit

,,

2,

IPreparation before installing the grille I

I

Confirming

the

location

of

the

main

unit

I

•Check

whetherthe opening holes

of

the ceiling are within

the

following range:

860

><

860

to 910

><910

Measurement

@Installation gauge

of

opening holes

(Insert into the main unit)

of

the ceiling

•Using

included installation gauge@, locatethe ceiling surface and the main unit.

If location

of

the ceiling s

urf

a

ce

and the main unit does not match, wind leakage,

dewfail

or

damage

of

the vane

may

result. Note:

The

ga

mustbe in the ran e

of

17 to

22

.

Ifit exceeds

or

fails below

the

range,

•Turn

off

the main power(short circuit breaker).

~

Turn

off

the

main

ower.

~

Warning

•If

the main poweris notturned

off

,

injury

or

electric shockmay result.

[Remarks]

The

grille

must

not

be

painted

by

the

user.

•Itmay result extreme malfunction

or

the damage

of

parts.

Ask

the

dealer

or

an authorized technician

to

aint.

I

Installing

the

wired

remote

controller

I

•The

intake grille elevation function can be controlled with the wired remote controller. There are 2 methods

for controlling

the

intake grille elevation function: Use the elevation function

for

all

the

main units which are

controlled by the remote controller

at

once, and use the elevation function for each main unit individually.

(Please refer to

the

oper

ation manual

for

the operation method.)

Install

the

remote controller

in

a place where you can observe all the indoor units managed with it.

Otherwise,

the

lowering grille may hit people

or

objects and cause damage

to

them.

I

Installing

the

remote

controller

holder

(For Automatic Filter Elevation Pane

l)

I

•The

remote controller holder

is

included. Use the holderto prevent losing

the

wireless remote controller.

•In

stall

the

wir

eless remote controllerfor Automatic FilterElevation Panel

in

the following locations.

• Locations that

ar

e notexposed to dire

ct

sunlight • Locations

in

which

it

is

ea

sy tooperate the

• Locations that are not ne

ar

sources

of

heat remote controller and see its display

• Locations

th

at are not exposed to

co

ld

air

(hotair) • Locations thatare

out

of

the reach

of

children

being blown from

the

indoorunit • Locations that are

not

exposed to oilysmoke, and so on

•To

install

the

wireless r

em

o

te

controller for Automatic Filter Elevation Panel, secure the remote controller holder

to a wail using the included screws, a

nd

then

fit

the wireless remote controller

for

Automatic Filler Elevation

Panel into the holder.

I

Removing

the

intake

grille!

•Remove

the tape that secures the intake grilleand remove the intake grille from t

he

grille.

Not

e: You will find the limit switch for storing and

det

ecting intake grille shown

in

the

right figure.

Make sure you do not damage the limitswitch when operating.

I

Removing

the

corner

panel

I

~

lScrew

-r

~~

lo

se-

up

• Loose the 4 screws on the corner,

I..':&>!

slide the corner panel in the

dir

ection

LI

~c

rew

of

the

arrow

(1)

in

the

figure and

A:f

¥ ~

remove the corner panel. Cornerpanel

@Wireless remote

controller for Automatic

Filter Elevation Panel

!ID

Remote controller holder

--

----

-

---------

~

---------

~

3,

ISelection

of

airoutlets I

•You can sele

ct

11

differe

nt

patterns

of

air

outlet directions on this grille.

•Sel

ect

a pa

tt

ern

of

air outlet directions.

More than two directions must be selected.

Notes 1. When

ch

anging the number

of

directions, you need an air

outlet shutter plate, which is optional part. An air outlet shutter

plate will be

att

ached to the indoor unit; configurati

on

must be

done before attaching the grille on

the

main unit.

2. Do notselect 2 directions in a hotand humid environment.

(Dew

formation

or

dew drop may r

es

ult.)

4 dir

ec

tions 3

dir

ections 2 directions

§ ( 1 pattern ) ( 4 patterns ) ( 6 patterns )

'fl

Initial setting Block 1

of

the

air

outlets on Block 2 of the air outlets on

~

the main unitwith shutter the ma

in

unitwith s

hutt

er

'5

❖

·-o

'¢.oo.

~

V

c>~~

~

0

"'

i

CL

Before installation(Relocation)

~Caution

Do

not neglect damaged platforms.

•

If

leftdamaged, the unitmayfail and result in injury.

Transport

of

the product must be done carefully.

•

In

principle, products over 20

kg

must be carried

by

two

or

more

people. Make sure you move the product holding onlythe designated

handle but nota PP band and such. Use protectors to prevent injury;

do not touch the fins

or

the

edge

of

part

with your bare hands.

Appropriately dispose

of

packages.

• Packaging may contain metal objects such as "nails" and wood chips.

So injury may result ifdisposal is neglected.

Make sure that

the

joints are locked securely and they

do

not

come

off

from all

of

4 holes.

• Otherwise,

the

intake grille may drop

off

and cause an injury

or

a

failure.

Before electrical work

Do notwash the air-conditioner.

• Doing

so

maycause electric shock. J

Drain piping must be done properly according tothe installation

manual

to

drain

water

and

must

be

heat Insulated to prevent bedewlng.

•

If

piping is notproperlyinstalled, waterleakage mayresult, which will

make the ceilings, floors

or

otherhousehold Items wet.

Make sure heat insulation

for

refrigerant piping

is

properly

installed to prevent bedewing.

•

If

heat insulation is not done properly, bedewing

of

the surfaces such

as piping mayresult, which will make the ceilings, floors,

or

other

valuable items wet.

• Insulation forthe

joint

part must be done afteran

air

tightness test.

Make sure

to

hang the safety strap

of

the intake grille while

temporarily installing the grille.

• Otherwise, the intake grille may drop

off

and cause an injury

or

a failure.

~Caution

Makesure to install a short circuit breakerto the power. Unit must be grounded.

•

If

a

short

circuit breakeris not installed, electric shock mayresult.

Use properelectrical cables to meet the standard for current

capacity.

• Do notconnectthe ground wires with ground wires for gas pipes,

waterpipes, conductor rods,

or

telephones.

If

the unit is notproperly

grounded, electric shock may result.

•

If

improperelectrical cables are used, shortcircuit, heat,

or

fire may

result. Use fuses with appropriate capacity such as short circuit breaker,

hand switch (switch +type B fuse), and circuit breakers forwiring

devices.

Electrical wiring must be done without tension.

•

If

there istension

on

the cables, wire disconnection, electric shock,

or

fire may resuIt.

•

If

fuses, wires, and copper wires with larger capacities are used,

damage

or

fire may result.

Start

the

electrical work after turning

off

the main power.

• Otherwise, electric shock, damage,

or

failure may result.

Before test runs

~Caution

Do not operate the unitwithout the grille

or

guard. Do nottouch refrigerant piping when operating with bare hands.

•

If

you touch rotating, hot

or

high-voltage parts

of

the equipment,

injury may result from being snagged or burnt,

or

from electric shock. • Refrigerant piping when operating becomes cold and hot, depending

on the condition

of

the flowing refrigerant.

If

touched with bare

ha

nds,

frostbite

or

burns may result.

Do

notoperatethe unitwith wet hands. Do notturn

the

unit

off

soon after operation stops.

• Electricshock may result.

Turn It on more than 12 hours before operation.

• Make sure you wait

for

more than 5 minutes.

If

it is turned

off

too

soon, water leakage

or

damage may result.

Do notoperate the unit without

air

filters.

•

If

operation starts as soon as the unit

is

turned on, damage may

result. Do not turn it

off

during the season. • Dirt mayget clogged inside and may result in damage.

3,ISelection

of

airoutlets I(continued from the previous page)

•Change

the settings depending on the number

of

air

outlets and the ceiling heightwhere the main unitis installed.

If

not changed, failure may result

or

users mayfeel discomfort.

Note: Do not

set

up for lowceilings

in

a hotand humid environment. (Dew drop may result.)

I

When

used

in

combination

with

PLA-EA

I

Configuration will be done on the remote controller. Refer

to

the section "Function Se

tt

ing" in the installation manual

of

the

remote controller

or

the section "Function Setting on the Remote Controller" in the installation manual

of

the main unit.

I

When

used

in

combination

with

PLFY-EM

I

Set up the switches on controller board

of

the main unit as shown in the following table.

<Ceiling

height

and

number

of

air

outlets>

Main unitType 20

to80

Type

Low ceiling Standard High ceiling Low ceiling 100to 125Type

Standard High ceiling

sw21-1

l

sw21-2

sw21-1lsw21-2

sw21-1

l

sw21-2

sw21-1

lsw21-2

sw21-1

I

sw21-2

sw21-1

lsw21-2

OFF I ON OFF I

OFF

ON I OFF OFF I ON

OFF

I OFF ON I OFF

4 directions SW21-3 OFF 2.5m 2.7m 3.5m 2.7m 3.2m 4.5m

SW21-4 ON

3 directions SW21-3 OFF 2.7m 3.0m 3.5m 3.0m 3.6m 4.5m

SW21•4 OFF

2 directions SW21-3 ON 3.0m 3.3m 3.5m 3.3m 4.0m 4.5m

SW21-4 OFF

Note: Swit

ch

setting is necessary exceptfor the column highlighted in gray. (Column highlighted in

gr

ay is the initial setting).

4.1

Installing grilleI <Hook is in the raised position>

1)

Preparations

Make

sur

e

to

flip 2 hookson the grille up.

2)

Temporary

installation

of

grille

Join t

he

corner

of

drain pipe on the main unitwith

the cornerwith hole on the grille and putthem

togethertemporarily

by

hanging the hook

of

the

grille

to

the claw

of

the main unit.

•Make

sure the lead wires

of

the grille do not

get

caught between the main unit and the grille.

•Never

force pressure on

the

grillewhile the

tempora

ry

installation. It may result in accident

and damage.

3)

Fixing

the

grille

•By

tightening the pre-installed screws,

fix

the grille onto the main unit.

Note: Make sure there is

no

gap between

the

main unitand the grille

or

between the grille and the ceiling surface.

r !~~

~·

'"

C

·1·

c::::

rf

\

eI

Ing su ace Grille

•If

there is a gap between the grille and

the ceiling: With the grille a

tt

ached, slightly

adjust the installation height

of

the main unit

and clear the ga

p.

[Remarks] When tightening the screw, make sure that

the tightening torque is 2.8N• m

to

3.6N · m.

Neveruse an impact screw driver.

• It may result in parts damage.

Lead wires of

the grille

4)

Wiring

conn

e

ctions

r

..l!L

~

+-

--1

--ir-

CNV connector

I

Wiring

connections

for

van

e

motor

I

1.

Loose the 2 screws fixing the electrical box cover on the main unit, and slide the coverto open.

2. Make sure to connect a connec

tor

forvane motor(white, 20 poles) to

CNV

connector(white)

on the controller board

of

the main unit.

3. Lead wires thatlead

off

the

grille must be held togetherwithoutslackusing a clamp into the

electrical box. /'ii

Note: Lead wires

of

thegrille must be held together using a clamp on the main unit

so

Electri

ca

l box ·,

that

th

ey do notcont

ac

t the strings of elevation machine motor box.

!Wiring

connections

for

elevation

machine

I

4. Ro

ule

the lead wires (blue, 4 poles)

of

the elevation m

ac

hine of the grille from the side of the

electrical box on the main unit.

5. Make sure to connect them

to

CN4G (blue) on the controller bo

ar

d

of

the main unit.

6. Earth wires

of

the grille must be fixed with the included

sc

rews in the el

ec

trical box

of

the main unit.

Indoor

unit

must

be grounded.

~Caution

• Do notconn

ec

t

th

e ground wires with ground wires for gas pipes,

water pip

es

, conduct

or

rods, or telephon

es

.

If

the indoor unit is

no

t

prope

rl

y grounded, electric shock may result.

Ground wire

fixing position

7. Lead wires for elevation machine

of

the grille mustbe fixed with the cable band without sla

ck

inside the electrical box.

on the

co

ntroller

board

Cl

amp

Continued to the next page