5

Note

Not required for wall-surface installation

Shielded cable

CVVS, MVVS: 1.25 mm²~2 mm² (AWG16~14)

CPEVS: Ø1.2 mm~Ø1.6 mm (AWG16~14 or their equivalents)

Qty.

1

As appropriate

As appropriate

As appropriate

Parts

Triple electric box

Thin metal conduit

Lock nut and bushing

M-NET cable

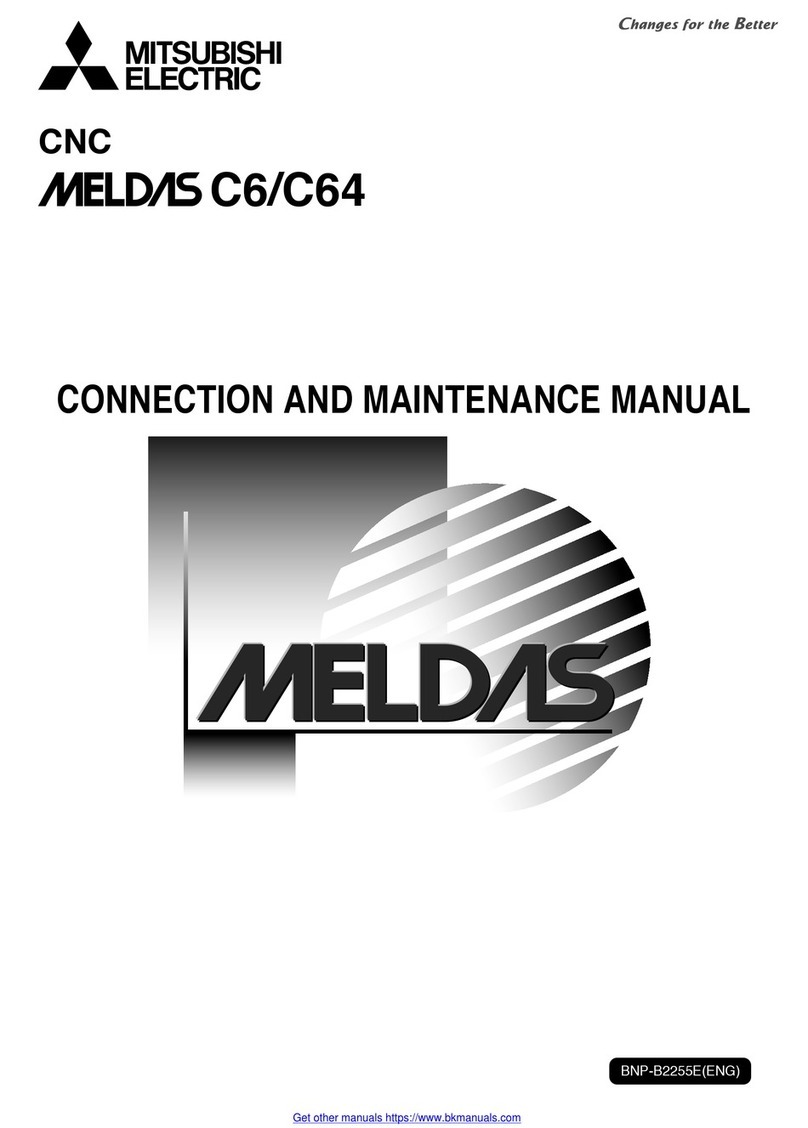

The figure below shows the M-NET transmission wiring diagram for City Multi air conditioners.

The maximum length of centralized control M-NET transmission line and the indoor-outdoor transmission line per system can be

expressed in the following formulas. Labels "a through g" represent the sections of wiring in the system in the figure below. These

limits ensure normal signal communication over the M-NET transmission line.

If the line length exceeds the maximum length, M-NET signal attenuation can occur, rendering normal communication and control

impossible.

a+b+d+e(f) ≤ 500 m (1640 ft) a+b+c+g ≤ 500 m (1640 ft) e(f)+d+c+g ≤ 500 m (1640 ft)

The maximum length of local remote controller cable is 10 m (32 ft). The length that exceeds 10 m (32 ft) must be included in the

maximum total line length 500 m (1640 ft).

ac

edb

f

g

Outdoor

unit

Outdoor

unit

Indoor unit Indoor unit

Indoor unit

Indoor unit Indoor unit

Power supply

unit for transmission

cable

System

controller

Indoor-outdoor

transmission line

10 m (32 ft)

Centralized controller

transmission line

M-NET

remote

controller

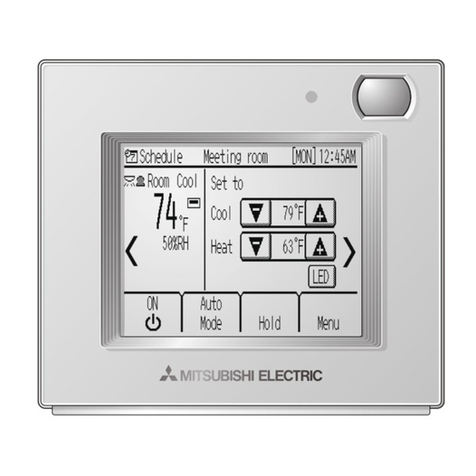

5 Installation

1. Field-supplied parts

The following parts are required to install the controller.

2. Required tools

•A knife or nippers •Crosshead driver

3. Installation methods

Follow the instructions provided for the selected installation option.

(a) Wall-embedded installation using an electric box

(b) Wall-surface installation

(b-1) To route the cable through the wall

(b-2) To route the cable along the wall surface

4. Preparation

(1) Install a breaker on the power supply unit side before installing the controller.

(2) Select an installation site for the Touch Controller.

• Install the controller at the user's eye level for easy operation.

• Ensure there is enough clearance space as shown in the figure at right.

• Ensure there is enough clearance space to allow for easy access to the panel and the

buttons.

(3) Bring the cable end up to the controller.

Ensure the M-NET transmission cables and external input/output cables are long enough to

reach the controller. Have extra cables to extend these cables as necessary.

• To install the controller according to the instructions provided in sections (a) and (b-1) above

Include an extra 30 cm (12 in) of cable to provide adequate slack in the cable.

Remove the sheath on the M-NET transmission cable up to 20 cm (8 in) from the end.

• To install the controller according to the instructions provided in section (b-2) above

Include an extra 15 cm (6 in) of cable to provide adequate slack in the cable.

Remove the sheath on the M-NET transmission cable up to 10 cm (4 in) from the end.

(4) Prepare the Touch Controller.

Unscrew the screw at the bottom of the

controller, and remove the cover.

To route the cable along the wall surface, cut

out the rectangle knockout hole (18 mm (W)

x 9 mm (D)) at the top of the controller with a

knife or a nipper (shown as the shaded area

in the figure below at right).

30

(1.3/16)

30 (1.3/16)

50 (2)

Unit: mm (in)

Refer to section 6 "External input

output" for how to connect external

input/output signal cables.

Note

Do not push the shield wire into

or connect it to the TC-24A. Trim

the shield wire, cover it with vinyl

insulating tape, and leave it outside

the controller.

Note

30

(1.3/16)

Touch controller

outline

6

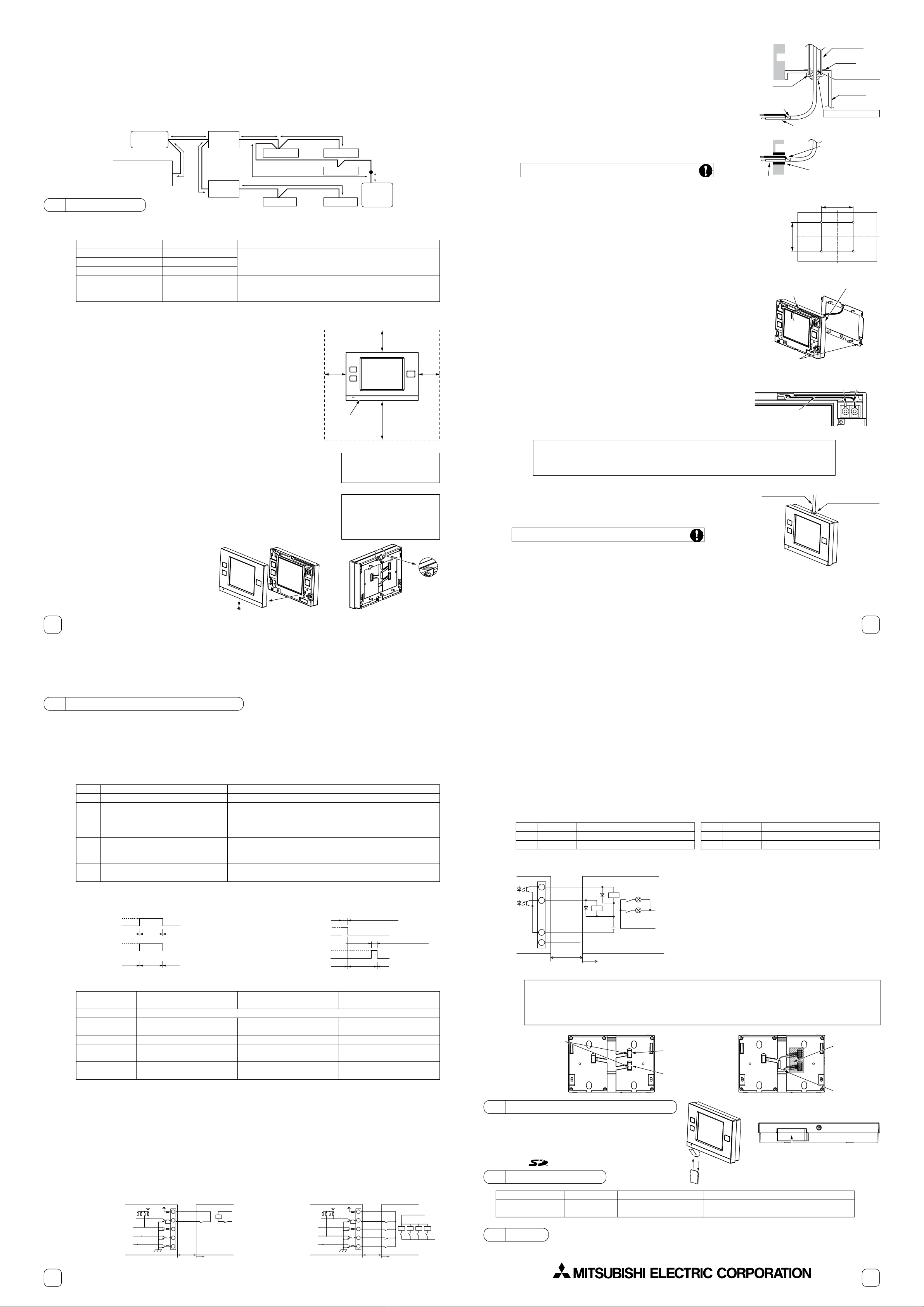

5. Installation steps

(1) Routing the cables

(a) Wall-embedded installation using an electric box

Pull the M-NET transmission cable through the hole on the wall and the electric

box, and seal the gap between the cable and the end of the conduit tube.

(b) Wall-surface installation

•To route the cable through the wall :

Drill a hole in the wall, push the M-NET transmission cable through the hole, and

seal the gap between the cable and the hole with putty.

•To route the cable along the wall surface :

It is approximately 10 cm (4 in) from the cable access hole on the back of TC-24A

to the M-NET terminal block. Trim off the excess transmission cable, if any.

(2) Attach the mounting bracket on the wall.

Attach the mounting bracket on the designated area on the wall using the supplied

screws.

The pitch for the mounting bracket is shown in the figure at right.

(3) Attach the controller to the mounting bracket.

After inserting the M-NET transmission cables (A and B) through the cable access hole

on the controller from the back, hang the controller on the hooks of the mounting

bracket.

Attach the controller to the mounting bracket using twenty M4 screws with spring

washers/washers.

(4) Connect the cables.

Connect the M-NET transmission cables (A and B) to the terminal block. M-NET

transmission cable is non-polarized.

Insert the cables in the groove on the controller so they will not be pinched when

the cover is installed.

(5) Replace the cover.

Snap the cover into place, and attach it to the controller with a screw at the bottom.

*Tighten the screw to a torque of 10 N·m or less.

*To route the cable along the wall surface

Secure the cables in place with a cable cover, and seal the gap between the cable cover

and the controller with putty.

• The M-NET terminal on the controller is only for connection to the M-NET cable.

Do not connect an AC power supply.

• Do not daisy-chain M-NET terminals.

Note

To reduce the risk of electric shock, malfunctions, or fire, seal the

gap between the cables and access holes with putty.

Wall Remove the sheath,

and insulate the

shield wire with vinyl tape.

M-NET transmission cable

A , B

Seal the gap with putty.

Cable access hole

Hang the controller on the

hooks of the mounting bracket.

Screw the controller

on the bracket.

Insert the cable into the groove.

M-NET transmission cable

(non-polarized)

A B

Use a cable cover.

Seal the gap with putty.

92 (3.5/8)

83.5 (3.5/16)

Unit: mm (in)

To reduce the risk of electric shock, malfunctions, or fire, seal the

gap between the cables and access holes with putty.

Conduit tube

Electric box

Bushing

M-NET transmission cable

A , B

Remove the sheath,

and insulate the

shield wire with

vinyl tape.

Locknut

Wall

Cable access hole

Seal the gap with putty.

7

Mode

1

2

3

4

External input signal setting

Do not use external input. (Factory setting)

Emergency stop/Normal operation signal

(level signal)

ON/OFF signal (level signal)

ON/OFF and Prohibit/Permit remote

controller operation signal (pulse signal)

Notes

-

When the units are not operating after receiving an emergency stop signal,

the ON/OFF operation from the local remote controller will not be allowed,

and the ON/OFF and Prohibit/Permit settings on the Touch Controller

cannot be changed. Timer operation will not function.

ON/OFF operation from the local remote controller will not be allowed, and

the ON/OFF and Prohibit/Permit settings on the Touch Controller cannot

be changed. Timer operation will not function.

The ON-signal pulse width should be set to a value between 0.2 and 1

seconds.

6 Usingexternal input/output

1. External signal input (CN2)

*To use external input, an external input/output adapter (PAC-YT41HAA; sold separately) is required.

(1) External input

Using external dry contact signals, the following operation of all air conditioning units can be controlled from the Touch Controller:

Emergency stop/Normal operation, ON/OFF, Permit/Prohibit local remote controller operation. These settings are made on the

External Input Settings on the Initial Settings screen that is accessible from the Service Menu screen. (Refer to Chapter 3 in the Initial

Setting Manual.)

(3) External input specifications

(A) Level signal

• tIf the type of signal assigned to the external input contact is "Emergency/Normal," the units in normal operation will stop when

the signal input changes from OFF to ON. Conversely, the units that are stopped will resume normal operation when the signal

changes from ON to OFF. After the emergency stop is reset, the original operating status of each air conditioning unit will not be

automatically restored. The air conditioning units must be started up manually.

• If the type of signal assigned to the external input contact is "ON/OFF," the units that are stopped will start operation after the

input signal changes from OFF to ON. Conversely, the units that are in operation will stop after the input signal changes from

ON to OFF.

(B) Pulse signal

• If the incoming signal is the same as the signal that is currently being received, no status change will occur.

• If local remote controller operation is prohibited, ON/OFF status, operation mode, or temperature setting cannot be changed and

filter sign cannot be reset from the remote controller.

• The ON-signal pulse width should be set to a value between 0.2 and 1 seconds.

(4) Sample circuit recommended

(A) Level signal (B) Pulse signal

(2) Level signal and pulse signal

CN2

1

2

3

4

5

Lead wire

Green

Yellow

Orange

Red

Brown

Emergency stop/Normal

operation signal (level signal)

Emergency stop/Normal

operation signal input

Not used

Not used

Not used

Built-in 5 VDC power for external input * Exclusively for use with external input. Not usable for other purposes.

ON/OFF level signal

ON/OFF signal input

Not used

Not used

Not used

ON/OFF, Prohibit/Permit remote

controller operation (pulse signal)

ON signal input

OFF signal input

Prohibit-local-remote-controller-

operation signal input

Permit-local-remote-controller-

operation signal input

(ex.)ON/OFF

Signal 1 (ON)

Signal 2 (OFF)

*Same for Prohibit/Permit remote controller operation.

OFF

Contact ON

Contact OFF OFFON

Normal

operation

Contact ON

Contact OFF

Normal

operation

Emergency

stop

Contact ON

Contact OFF

OFF

Contact ON

Contact OFF OFFON

0.2 to 1 seconds

0.2 to 1 seconds

(A) Level signal (B) Pulse signal

CN2

ON/OFF

or Emergency stop

Green

Yellow X1

Touch Controller

Maximum

10 m

(32 ft)

X1

X1 X2 Y1 Y2

1

2

3

4

5

ON

OFF Permit

Prohibit

CN2 Green

Yellow X1

Touch Controller

Maximum

10 m

(32 ft)

Orange X2

Red Y1

Y2

Brown

1

2

3

4

5

Field supplied Field supplied

8

•The relays and extension cables are field supplied.

•Use a no-voltage contact and minute load relay (minimum application load 5VDC-1mA).

•The length of the connection cable extension should not exceed 10 m (32 ft). (Use a cable of 0.3 mm² (22AWG) or thicker.)

•Insulate the area with vinyl tape where the controller cable and the extension cable are connected.

•Insulate the end of unused lead wires with tape.

2. External signal output

*To use external output, an external input/output adapter (PAC-YT41HAA; sold separately) is required.

Requires a separate external power source.

(1) External signal output (CN3)

Operation signal will be output when one or more air conditioning units are in operation, and error signal will be output when one or

more units are in error.

The On-signal will be output even during an error.

(2) External output specifications

(3) Sample circuit recommended

Relay-driven circuit

CN3

1

2

Lead wire

Brown

Red

Signal

ON/OFF

Error/Normal

CN3

3

4

Lead wire

Orange

Yellow

Signal

Ground for all external outputs

Not used

Parts

External input/output

adapter

Model

PAC-YT41HAA

Usage

Enables the use of external

input/output function

Note

Required to use the external input/output function

5-wire cable (input) , 4-wire cable (output)

CN3 Diode (*2)

Power source

(*1)

Z1

Z2

L1

L2

Red

Brown

Orange

Yellow

Touch Controller

2

1

3

4

Maximum

10 m

(32 ft)

Z2

Z1

L1 : Operation indicator

L2 : Error indicator

Use relays that meet the following specifications for relays indicated as Z1

and Z2 in the figure.

Operating coil

Rated voltage:12 VDC or 24 VDC

Power consumption: 0.9 W or below

(*1) Select a power supply suitable for the relays used. (12 VDC or 24 VDC)

(*2) Use a diode at each end of the relay coil.

• Each element will turn on when an error occurs during operation.

• The maximum length of extension cable is 10 m (32 ft). (Use a cable of

0.3 mm² (22AWG) or thicker.)

• Insulate the area with vinyl tape where the controller cable and the

extension cable are connected.

• Relays, lamps, diode, extension cables are field-supplied.

●To connect cables from an external input/output adapter to connectors CN2 and CN3 on the controller, cut out the appropriate

knockout holes on the controller with nippers.

After connecting the cables to the connectors, hold the cables in place with a piece of tape included with the external

input/output adapter (PAC-YT41HAA).

●Use caution not to damage the circuit board with the nippers or other tools when cutting out knockout holes.

Note

7 Usingan SD memorycard

8 Optional Parts

9 Note

■ A protective film is placed on the display.

Remove the protective film off the display before use.

HEAD OFFICE : TOKYO BLDG., 2-7-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

WT05821X01

Field supplied

The Touch Controller has a slot for an SD memory card at the

bottom that can be used to update software.

Refer to the Initial Setting Manual for the detailed information

about updates.

*Only the 1GB and 2GB SD memory cards by SanDisk are

supported.

Back of controller

Cut out the

knockout holes. CN2

External input connector

CN3

External output connector

Tape

External

input/output adapter

Bottom of controller

(a) Remove the SD memory card slot cover from the controller.

(b) Insert the SD memory card into the slot until it clicks.

(c) To remove the SD memory card, push it in until it clicks.

SD memory slot (for program updates)

“SD Logo is a trademark of SD-3C , LLC.”

(a)

(b) (c)