2.6 Connection to input/output terminal block

The input/output terminal blocks of the products which have -TS at the end of

their model name conform to spring clamp terminal block.

For details, refer to MELSEC iQ-F FX5UC User’s Manual (Hardware).

1) Wire size

2) Treatment of wire ends

When not using a ferrule, strip the cable about 10 mm from the tip and connect

it as a strand wire so that the wires do not separate.

When using a ferrule,

strip the cable about 10 mm from the tip to connect a wire ferrule at the

striped area.

Failure to do so may result in electric shock or short circuit

between adjacent terminals because the conductive part. If the wire strip length

is too short, it may result in the poor contact to the spring clamp terminal part.

When using a wire ferrule with an insulating sleeve, choose a wire with

proper cable sheath referring to the above outside dimensions, otherwise

the wire cannot be inserted easily.

The following table shows wire ferrules and tools for wire ferrules

compatible with the terminal block. Use of items other than these may

result in not being able to remove the wire ferrule, so carefully check that

the wire ferrule can be unplugged.

<Reference product>

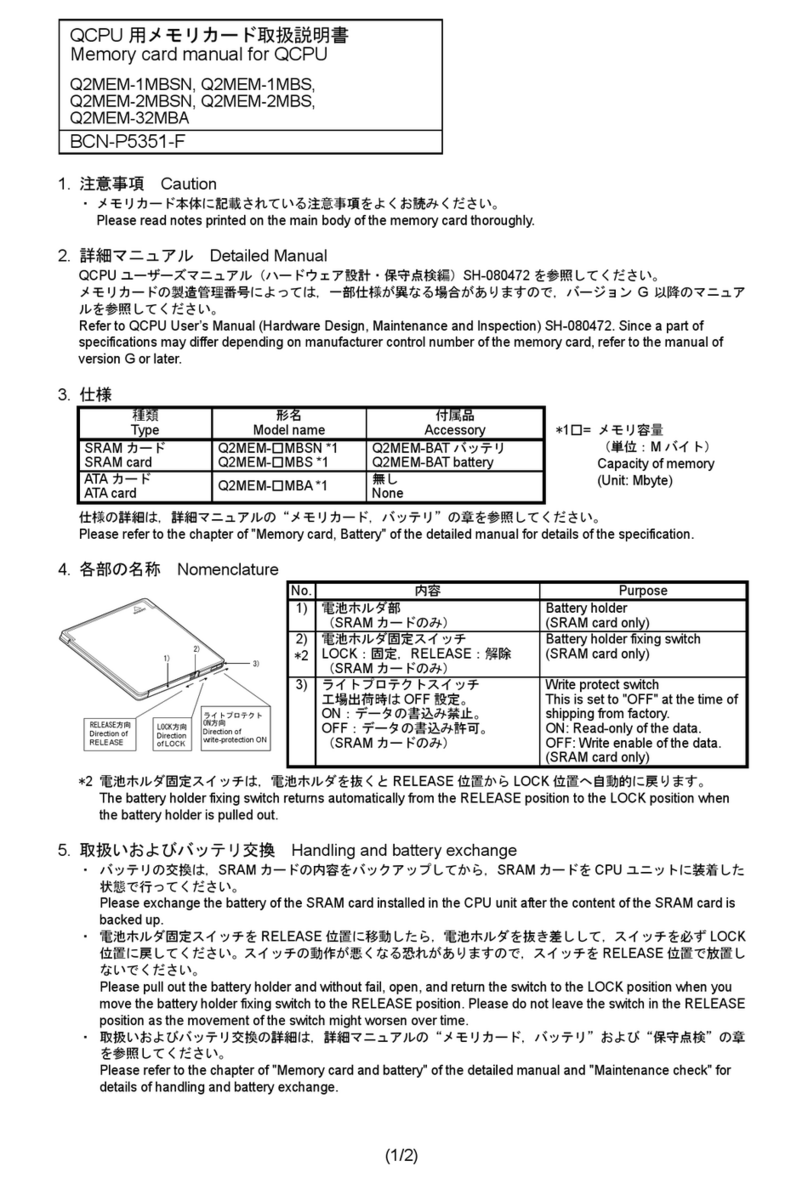

3) Connection and disconnection of the cable

Spring clamp terminal block is the push-in type, therefore, wiring without a

tool is possible only by inserting the connecting terminal to the terminal

block. However, the stranded wire does not comply with the push-in type,

and a tool is required for connecting cables.

•Connection of the cable

Fully insert a cable or bar solderless terminal whose end has been

properly processed into the wire insertion opening.

If the cable or bar solderless terminal cannot be inserted with this

procedure, fully insert the cable or bar solderless terminal while pushing

the open/close button with a flathead screwdriver having a tip width of

2.0 to 2.5 mm. After fully inserting the cable, remove the screwdriver.

Do not tighten terminal screws exceeding the specified torque range.

Otherwise it may cause equipment failure or malfunction.

When wiring with the thick electric wire, make sure to prevent the

conductive parts from protruding to the front of the terminal block.

<Reference>

•Disconnection of the cable

While pushing the open/close button with a flathead screwdriver having a

tip width of 2.0 to 2.5 mm, disconnect the cable or bar solderless terminal.

2.7 Connection to built-in RS-485 Communication

terminal block

The built-in RS-485 Communication terminal block conform to terminal block

(European type).

For details, refer to MELSEC iQ-F FX5UC User’s Manual (Hardware).

1) Wire size

2) Treatment of wire ends

Strip the coating of strand wire and twist the cable core before connecting

it, or strip the coating of single wire before connecting it. An alternative

connection is to use a ferrule with insulating sleeve.

When using a wire ferrule with an insulating sleeve, choose a wire with

proper cable sheath referring to the above outside dimensions, otherwise

the wire cannot be inserted easily.

Tighten the screws to a torque of 0.22 to 0.25 N⋅m.

Do not tighten terminal screws with a torque outside the above-mentioned

range.

Failure to do so may cause equipment failures or malfunctions.

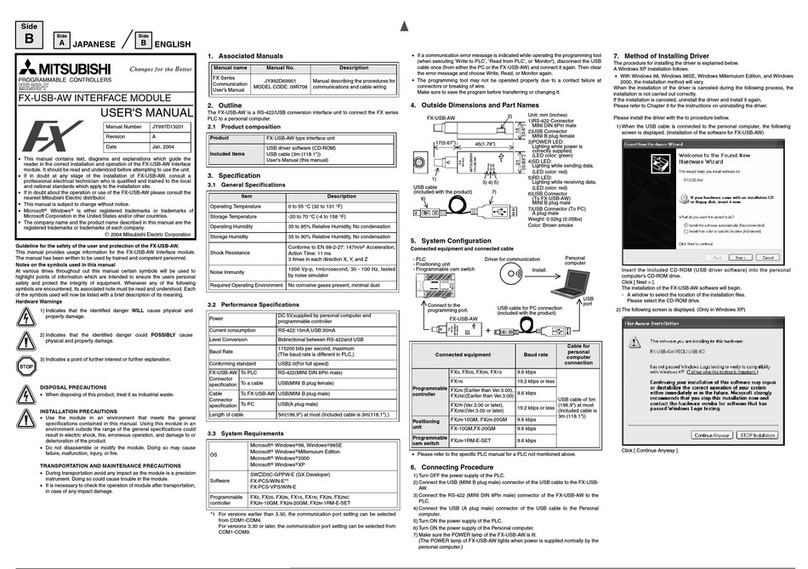

3) Tool

For tightening the terminal, use a

commercially available small

screwdriver having a straight form

that is not widened toward the end

as shown right.

Note:

If the diameter of screwdriver grip

is too small, tightening torque may

not be achieved. To achieve the appropriate tightening torque shown in the

table above, use the following screwdriver or appropriate replacement (grip

diameter: approximately 25 mm).

3. Specifications and examples of external wiring

As for the details of the power supply wiring and input/output wiring, refer to

MELSEC iQ-F FX5UC User's Manual (Hardware)..

No. of wire

per terminal

Wire size

Single wire/Strand

wire

Ferrules with

insulation sleeve

Ferrules without

insulation sleeve

One wire AWG24 to 16 AWG23 to 19 AWG23 to 16

Manufacturer Model Wire size Crimp tool

PHOENIX CONTACT

GmbH & Co. KG

AI 0.5-10 WH 0.5 mm2

CRIMPFOX 6

AI 0.75-10 GY 0.75 mm2

A 1.0-10 1.0 mm2

A 1.5-10 1.5 mm2

Manufacturer Model

PHOENIX CONTACT GmbH & Co. KG SZS 0.4×2.5 VDE

No. of wire

per terminal

Wire size

Solid wire/Stranded

wire

Ferrules with insulating

sleeve

1 AWG22 to 20 AWG22 to 20

2AWG22

10 mm

Contact area

(Crimp area)

16 to 18 mm

2 to 2.8 mm

Insulation sleeve

- Ferrule with insulation sleeve

10 mm

- Strand wire/single wire

Manufacturer Model Caulking tool

PHOENIX CONTACT GmbH & Co. KG AI 0.5-6WH CRIMPFOX 6

Manufacturer Model names

PHOENIX CONTACT GmbH & Co. KG SZS 0.4 × 2.5

DESIGN PRECAUTIONS

•Make sure to set up the following safety circuits outside the PLC to ensure

safe system operation even during external power supply problems or

PLC failure. Otherwise, malfunctions may cause serious accidents.

- Most importantly, set up the following: an emergency stop circuit, a

protection circuit, an interlock circuit for opposite movements (such as

normal vs. reverse rotation), and an interlock circuit (to prevent

damage to the equipment at the upper and lower positioning limits).

- Note that when the CPU module detects an error, such as a watchdog

timer error, during self-diagnosis, all outputs are turned off. Also, when

an error that cannot be detected by the CPU module occurs in an input/

output control block, output control may be disabled.

External circuits and mechanisms should be designed to ensure safe

machinery operation in such a case.

- Note that when an error occurs in a relay, transistor or triac of an output

circuit, the output might stay on or off. For output signals that may lead

to serious accidents, external circuits and mechanisms should be

designed to ensure safe machinery operation in such a case.

•Construct an interlock circuit in the program so that the whole system

always operates on the safe side before executing the control (for data

change) of the PLC in operation. Read the manual thoroughly and ensure

complete safety before executing other controls (for program change,

parameter change, forcible output and operation status change) of the

PLC in operation. Otherwise, the machine may be damaged and

accidents may occur due to erroneous operations.

WIRING PRECAUTIONS

•Make sure to cut off all phases of the power supply externally before

attempting installation or wiring work.

Failure to do so may cause electric shock or damage to the product.

•Make sure to attach the terminal cover, provided as an accessory, before

turning on the power or initiating operation after installation or wiring work.

Failure to do so may cause electric shock.

•The rating temperature of the cable should be 80or more.

9 mm

- Strand wire/single wire

8 mm

14 mm

2.6 mm

Insulating sleeve Contact area

(Crimp area)

- Ferrule with insulation sleeve

0.4 mm 2.5 mm

With

straight tip

3.1 Power supply specifications and external wiring

3.1.1 Power supply specifications [CPU module]

*1 This item shows value when only the CPU module is used.

The value in [ ] is the value in the maximum configuration connectable to

the CPU module. (The value does not include the external 24 V DC

power supply of extension devices)

3.1.2 Example of external wiring

24 V DC power is supplied to the CPU module. CPU module supplies power

through dedicated power connector.

For the details, refer to the MELSEC iQ-F FX5UC User's Manual (Hardware).

*1 Class D grounding

See section 3.3 for details.

3.2 Grounding

Ground the PLC as stated below.

•Perform class D grounding. (Grounding resistance: 100 Ωor less)

•Ground the PLC independently if possible.

If it cannot be grounded independently, ground it jointly as shown below.

•Bring the grounding point close to the PLC as much as possible so that the

ground cable can be shortened.

3.3 Input specifications and external wiring

3.3.1 Input specifications [24 V DC input type]

WIRING PRECAUTIONS

•Please separate the AC power supply from the AC commercial power

supply network with an insulation transformer when connecting to AC

input module or AC output module.

•Make sure to properly wire to the terminal block (European type) in

accordance with the following precautions.

Failure to do so may cause electric shock, equipment failures, a short-

circuit, wire breakage, malfunctions, or damage to the product.

- The disposal size of the cable end should follow the dimensions

described in the manual.

- Tightening torque should follow the specifications in the manual.

- Twist the ends of stranded wires and make sure that there are no loose wires.

- Do not solder-plate the electric wire ends.

- Do not connect more than the specified number of wires or electric

wires of unspecified size.

- Affix the electric wires so that neither the terminal block nor the

connected parts are directly stressed.

•Make sure to properly wire to the spring clamp terminal block in

accordance with the following precautions.

Failure to do so may cause electric shock, equipment failures, a short-

circuit, wire breakage, malfunctions, or damage to the product.

- The disposal size of the cable end should follow the dimensions

described in the manual.

- Twist the ends of stranded wires and make sure that there are no loose wires.

- Do not solder-plate the electric wire ends.

- Do not connect more than the specified number of wires or electric

wires of unspecified size.

- Affix the electric wires so that neither the terminal block nor the

connected parts are directly stressed.

WIRING PRECAUTIONS

•

Perform class D grounding (grounding resistance: 100

Ω

or less) of the grounding

terminal on the CPU module and extension modules with a wire 2 mm

2

or thicker.

Do not use common grounding with heavy electrical systems (refer to

section 3.3).

•When drilling screw holes or wiring, make sure that cutting or wiring debris

do not enter the ventilation slits of the PLC.

Failure to do so may cause fire, equipment failures or malfunctions.

•Connect the power supply wiring to the dedicated terminals described in

this manual. If an AC power supply is connected to a DC input/output

terminal or DC power supply terminal, the PLC will burn out.

•

Do not wire vacant terminals externally. Doing so may damage the product.

•Make sure to observe the following precautions in order to prevent any

damage to the machinery or accidents due to malfunction of the PLC

caused by abnormal data written to the PLC due to the effects of noise.

- Do not bundle the power line, control line and communication cables

together with or lay them close to the main circuit, high-voltage line,

load line or power line. As a guideline, lay the power line, control line

and communication cables at least 100 mm away from the main circuit,

high-voltage line, load line or power line.

- Ground the shield of the shielded wire or shielded cable at one point on

the PLC. However, do not use common grounding with heavy electrical

systems.

Item Specification

Power supply voltage 24 V DC

Voltage fluctuation range +20%, -15%

Allowable instantaneous

power failure time

Operation can be continued upon occurrence

of instantaneous power failure for 5 ms or less.

Power fuse 125 V 3.15 A Time-lag Fuse

Rush

current

FX5UC-32M/35 A max. 0.5 ms or less/24 V DC

FX5UC-64MT/

FX5UC-96MT/40 A max. 0.5 ms or less/24 V DC

Power

consumption

*1

FX5UC-32M/5 W/24 V DC [30 W/24 V DC +20%, -15%]

FX5UC-64MT/8 W/24 V DC [33 W/24 V DC +20%, -15%]

FX5UC-96MT/11 W/24 V DC [36 W/24 V DC +20%, -15%]

24 V DC built-in power supply

capacity 500 mA

5 V DC built-in power supply

capacity 720 mA

Item Specification

Input signal voltage 24 V DC +20%, -15%

Input

impedance

CPU

module

X0 to X17 4.3 kΩ

X20 and

subsequent 5.6 kΩ

I/O module 5.6 kΩ

Input

signal

current

CPU

module

X0 to X17 5.3 mA/24 V DC

X20 and

subsequent 4.0 mA/24 V DC

I/O module 4.0 mA/24 V DC

ON input

sensitivity

current

CPU

module

X0 to X17 3.5 mA or more

X20 and

subsequent 3.0 mA or more

I/O module 3.0 mA or more

OFF input sensitivity current 1.5 mA or less

Input response time Refer to MELSEC iQ-F FX5UC

User's Manual (Hardware)

Input

signal

form

(Input

sensor

form)

FX5UC-MT/D

FX5-CEX/D

FX5-C32ET/D

•No-voltage contact input

•NPN open collector transistor

FX5UC-MT/DSS

FX5UC-32M/-TS

FX5-CEX/DS

FX5-C32EX/DS-TS

FX5-C32ET/DSS

FX5-C32ET/DS(S)-TS

•Sink input:

- No-voltage contact input

- NPN open collector transistor

•Source input:

- No-voltage contact input

- PNP open collector transistor

Input operation display LED on panel turns on when input.

(DISP switch IN side.)

24 V DC

Breaker,

Circuit protector,

Fuse etc. Power

on

Emergency

stop

Power supply for loads connected to CPU module output terminals

MC

PL

CPU module

Fuse

*1

PLC Other

equipment PLC Other

equipment PLC Other

equipment

Shared grounding

(Good condition)

Common grounding

(Not allowed)

Independent grounding

(Best condition)