1Date of publication: May 1, 2023

Printed in Japan

Mitutoyo Corporation 20-1, Sakado 1-Chome, Takatsu-ku, Kawasaki-shi, Kanagawa

213-8533, Japan

■

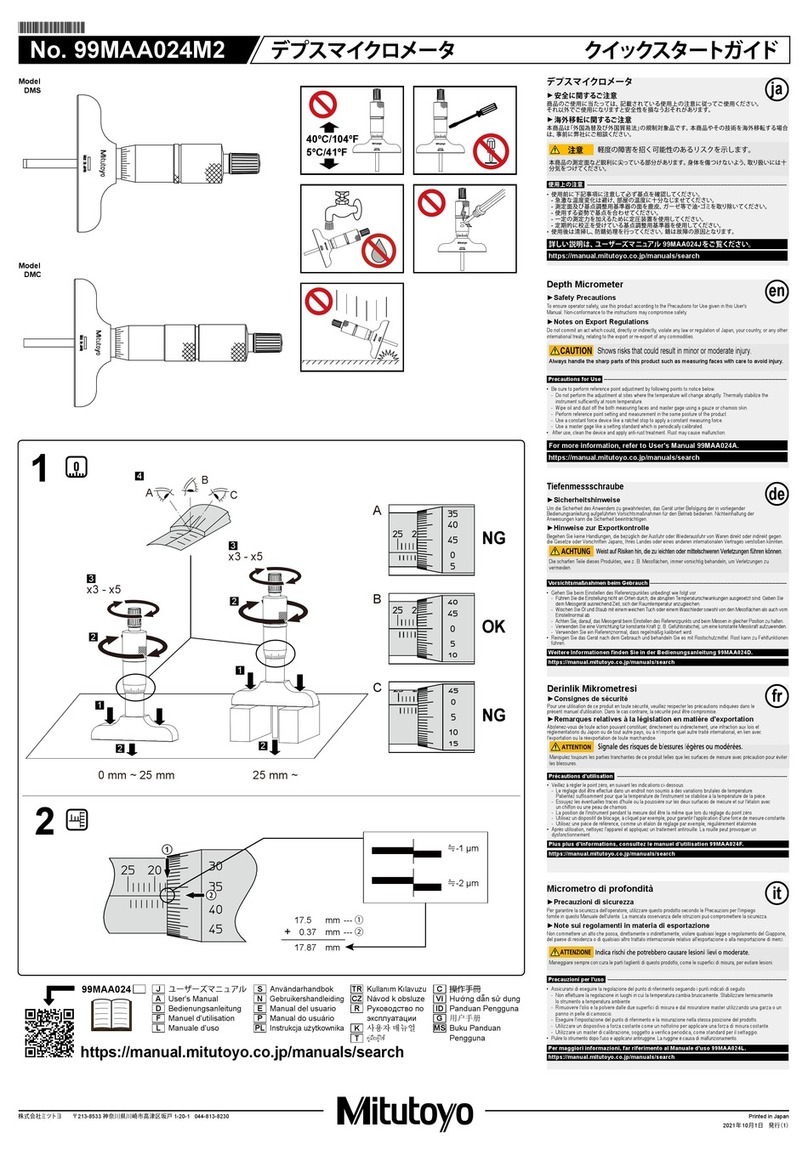

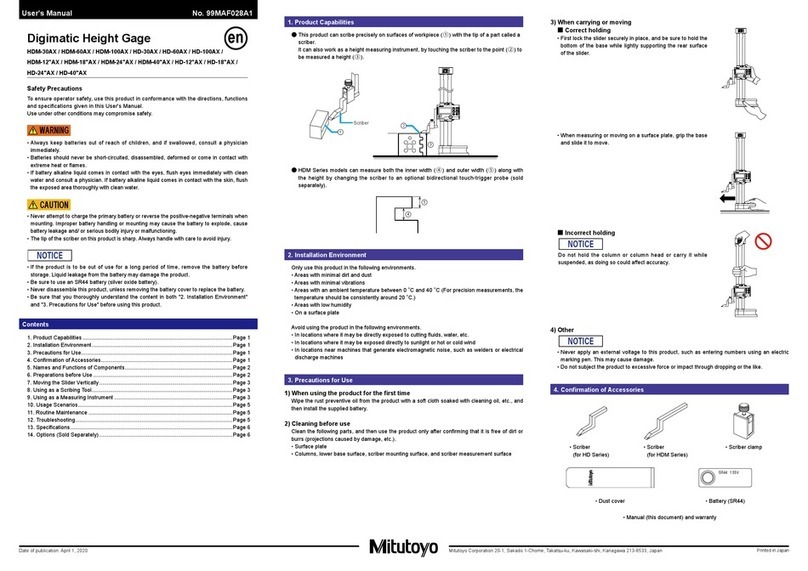

129Series

DMC

⑩

⑥

⑦

⑪

①Spindle

②Base

③Sleeve

④Thimble

⑤Ratchet stop

⑥Spindle clamp

⑦Key wrench

⑧Rod

⑨Thimble cap

⑩Hex wrench

⑪Wrench

2. PrecautionsforUse

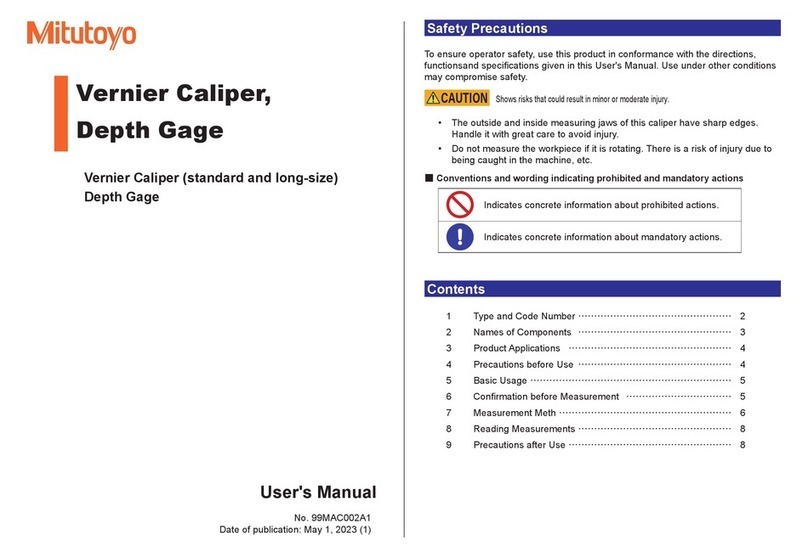

■Parallax

• Because of the structure of the product, the reference line surface on

the sleeve and the graduation line surface on the thimble are not on

the same plane, so the point where the two lines meet will deviate

depending on the position of your eyes. When reading measured

values, do so with reference to the gure at right, perpendicular from

the point where the reference line on the sleeve is aligned with the

graduation line on the thimble.

• If looking from a different direction (as in the gure at right), there will

be a parallax of approximately 2 μm.

■MeasuringForce

• Use the ratchet stop to ensure consistent measuring force.

• The appropriate measuring force is about three to ve turns of the ratchet

stop with ngers after the measuring surface lightly contacts the

workpiece. Note that excessive measuring force may cause measurement

error.

■PrecautionsandCleaningafterUse

• After use, check each part for damage and clean the entire spindle, rod, and base with a soft lint-free cloth.

• When oil, cutting uid, or liquid itself is adhered, or when very dirty, clean with a soft lint-free cloth impregnated with a

volatile solvent (cleaning alcohol, etc.).

• After use, apply anti-rust treatment to the spindle, rod, and base using Micrometer Oil (Part No. 207000).

• If using in places exposed to water-based cutting uid, always apply anti-rust treatment after cleaning.

• If Micrometer Oil is unavailable and the only option is a commercial product, we recommend low-viscosity anti-rust oil

of ISO VG10 or so.

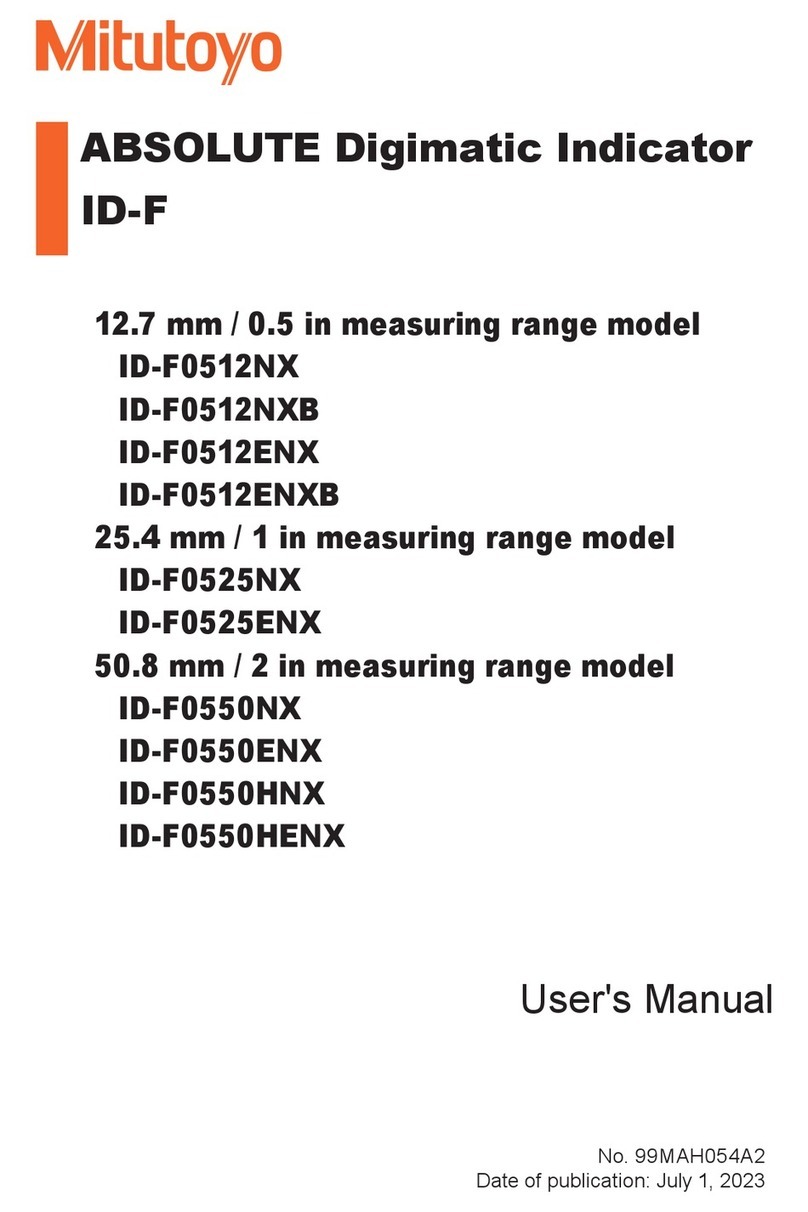

3. ReferencePointSetting

Important

• Be sure to follow the procedure below to conrm and adjust the reference point prior to measuring.

• Reference point setting for this product should be performed on a at surface such as a precision surface plate.

• When setting the reference point for this product, make sure to use a calibrated gage (gauge block, etc.).

• Remove any dirt or oil from the measuring surfaces of the gages and product prior to setting the reference point.

• Use the same orientation and conditions when measuring and setting the reference point.

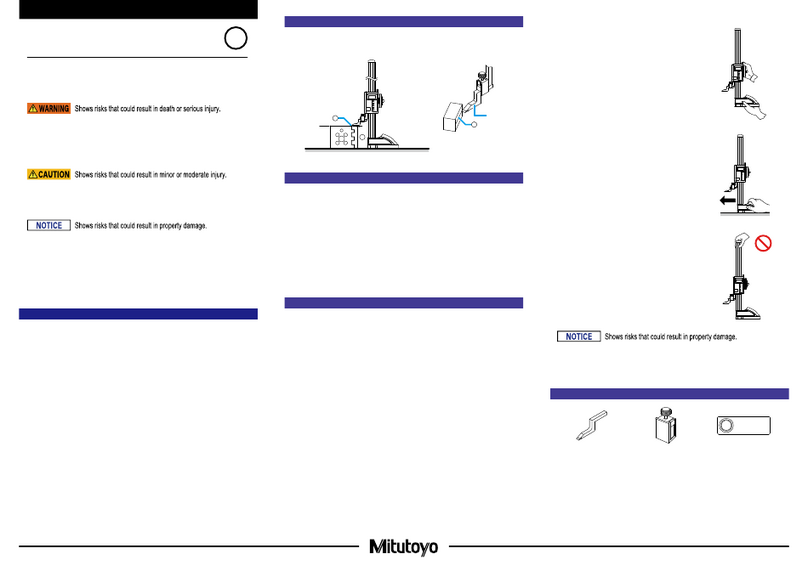

• When setting the reference point, press the base rmly against the reference surface as shown in the gure below.

■ReferencePointConrmation

1Remove any dirt or dust from the measuring surfaces of the gages and the product.

2Rotate the thimble and bring the measuring surface gently into contact with the precision surface plate.

3 Apply the prescribed measuring force by turning the ratchet stop three to ve times.

4 Read the scale, and if the reading does not match the zero point or the gage dimensions, adjust the reference point

in accordance with the following procedure.

■ReferencePointAdjustment

●128Series

• If the reference point difference is ±0.01 mm or less

1 With the reference point conrmed, x the spindle with the spindle clamp.

2Insert the supplied key wrench into the hole on the rear of the reference line on the sleeve, and then rotate the

sleeve until the reference line is aligned with the zero graduation line on the thimble.

• If the reference point difference is approximately ±0.01 mm or more

1 With the reference point conrmed, x the spindle with the spindle

clamp.

2 While holding the thimble in place with your ngers to prevent it

from turning, insert the supplied key wrench into the hole on the

side of the ratchet stop and loosen the ratchet stop.

3Rotate the thimble while pushing it toward the ratchet stop and

align the thimble's gradations with the sleeve's reference line.

4Tighten the ratchet stop with the key wrench while gently pushing

the thimble in the direction of the sleeve, being careful not to allow

the thimble to rotate.

5Loosen the spindle clamp.

SafetyPrecautions

To ensure operator safety, use this product according to the directions, functions and specications given in this

User's Manual. Use under other conditions may compromise safety.

Always handle the sharp parts of this product such as measuring faces with care to avoid injury.

• Do not use this product for purposes other than measurement.

• Do not disassemble or modify. Doing so will void the warranty.

• Do not use or store the product in a place with sudden temperature changes. Adapt the product to

ambient temperature before use.

• Do not store the product in a place with high humidity or a lot of dust.

• Do not use the product in a place where it may contact water, etc.

• Apply anti-rust treatment after use if the product is used in a place where it is directly exposed to

splashes of coolant, etc. Rust may cause malfunction.

• Do not apply excessive force or subject to sudden impacts such as dropping.

• Remove dust, cutting chips, etc. and apply anti-rust oil after use.

• Remove any dirt on the product by wiping gently with a soft non-linty cloth. Do not use organic solvents

such as cleaning agents or thinner.

• Do not write numbers, etc. with an electric pen.

DepthMicrometer

User's ManualNo.99MAA024A

Contents

1. Names of Components ........................................................................................... Page 1

2. Precautions for Use................................................................................................. Page 1

3. Reference Point Setting .......................................................................................... Page 1

4. Changing the Measurement Range ........................................................................ Page 2

5. How to Read Graduations....................................................................................... Page 2

6. Specications.......................................................................................................... Page 2

7. Paid Maintenance ................................................................................................... Page 2

1. NamesofComponents

■

128Series

DMS

⑦

NG

OK

NG

Reference line

Sleeve

Thimble

For 0 to 25 mm measurement range

For measurement range greater than 25 mm

2

Thimble

Ratchet stop

Key wrench

Rotate about three to ve times

Base

Reference surface

Precision surface plate

en