Printed in Japan

Mitutoyo Corporation, 1-20-1 Sakado, Takatsu-ku, Kawasaki City, Kanagawa 213-8533, Japan

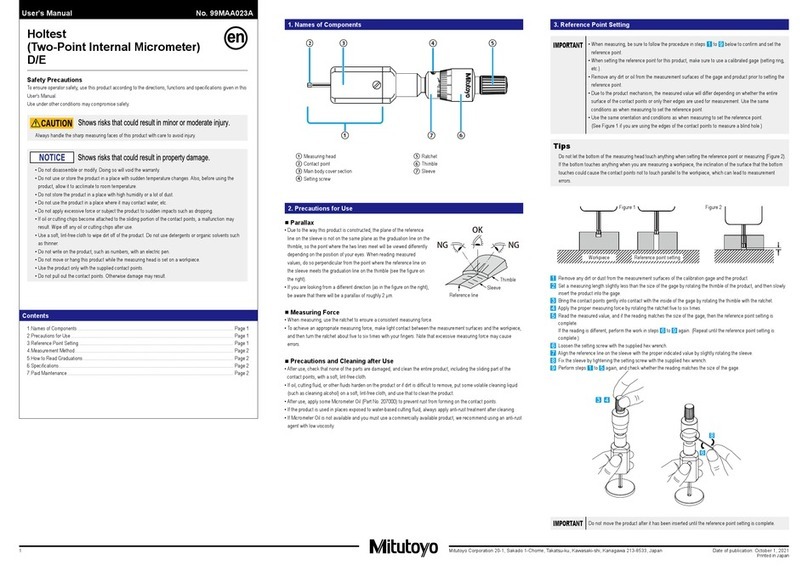

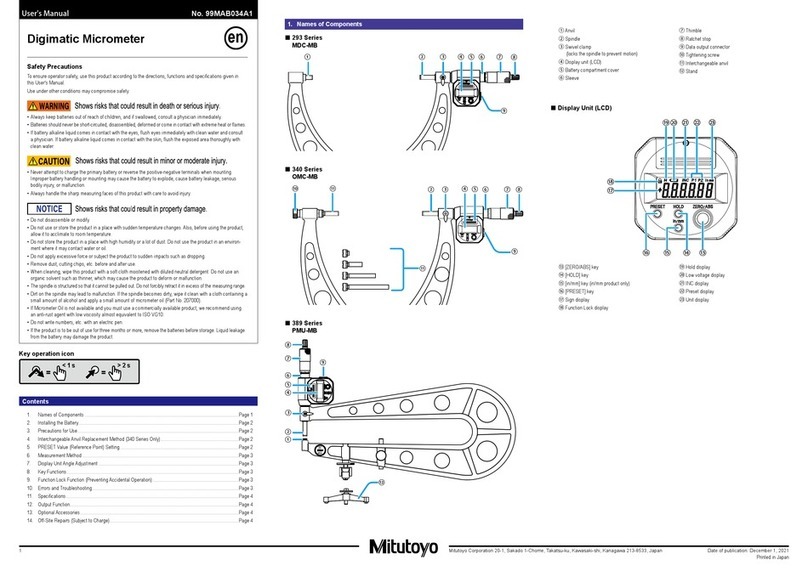

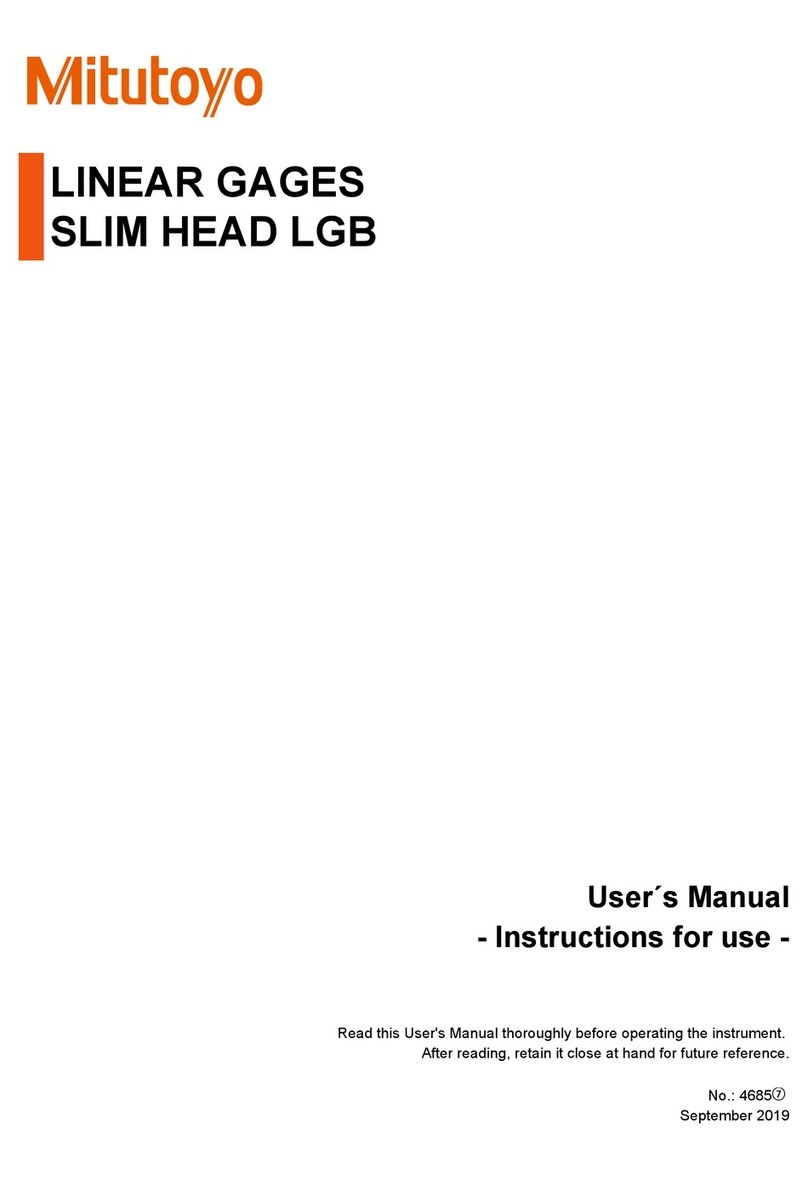

1. Names and Dimensions of Components

① ②

③

④

⑤

⑥

⑦

⑧

⑨

⑩

⑪

①Output connector (with cap)

②Battery cap

③[+/-] key

④Display (LCD)

⑤[ON/OFF] key

⑥[ORIGIN] key

⑦[in/mm] key (Code No. 575-122,

575-123 only)

⑧

Release mounting hole (with rubber cap)

⑨Stem

⑩Spindle

⑪Contact point

■Display (LCD)

①

⑤

④

③ ②

①Unit display

②Measured value display

③Sign display

④Low battery voltage display

⑤Reverse count display

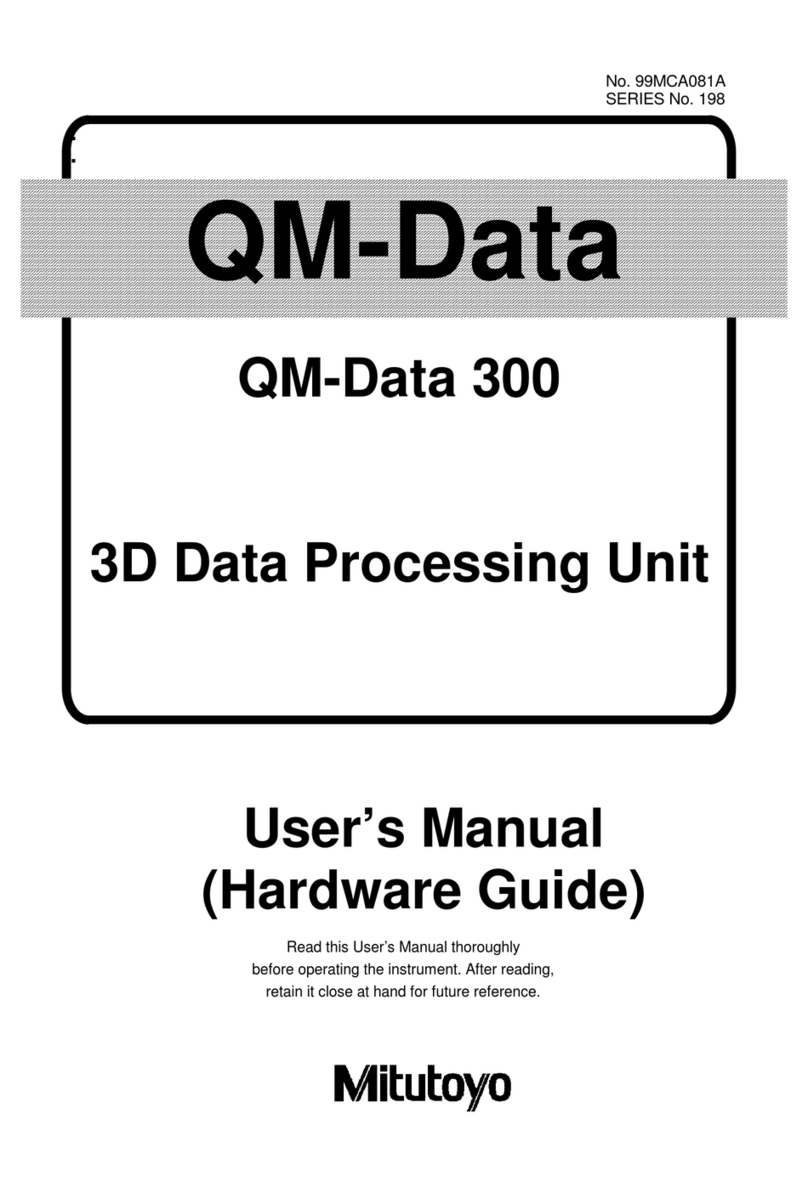

2. Installing (Replacing) the Battery

• Be sure to use SR44 (silver oxide button battery, part No. 938882) for the battery.

• The product may display an error or malfunction if the battery cap is not mounted correctly.

• If the product will be out of use for 3 months or more, remove the battery and store it separately,

to prevent damage to the product due to battery fluid leakage.

21

3

4 5

SR44

ORIGIN

1Insert a coin or similar into the battery cap groove and rotate the cap to remove it.

2If replacing an existing battery, remove the old battery.

3Insert a new battery with the "+" symbol facing the display (LCD).

4Rotate the battery cap to mount it.

5Press the [ORIGIN] key for 1 second or more.

Tips

• If no value is displayed even when a battery is installed, reinstall the battery.

• Although the display may show garbled text or [E] for minimum digits just after installing the

battery, this is not abnormal. Perform reference point setting as is (refer to "5. ORIGIN Setting

(Reference Point Setting").

• Reference point settings are cleared when the battery is removed. Perform reference point

setting again after installing the battery.

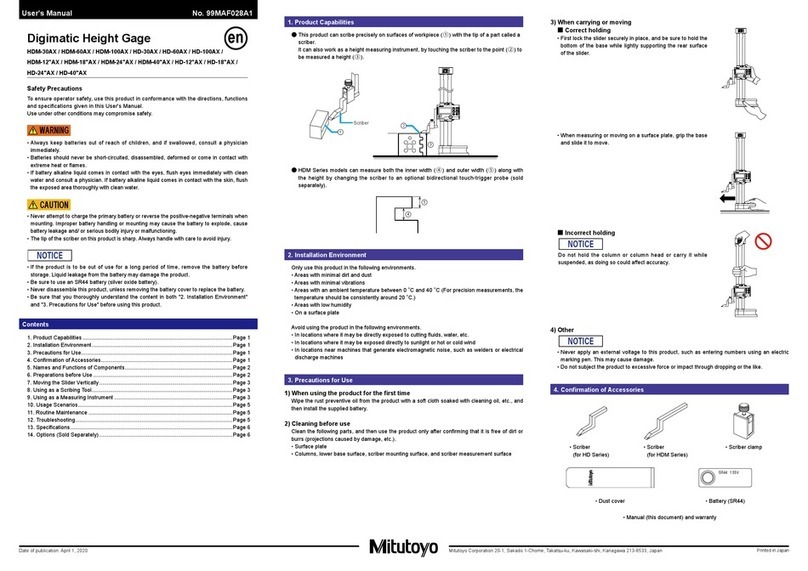

3. Setup

1) Mounting to a stand, jig, etc.

• Whenever possible, avoid fixing the stem directly with a set screw, etc.

•

The spindle may not be able to move smoothly if the screw is tightened with a tightening torque of

150 cN・m or more to secure the stem.

Stem

ø8 mm

+0.0 2

+0.0 0 5

ø9.52 (3/8 in)

mm

+0.0 2

+0.0 0 5

Tips

When mounting the product to a stand or jig,

use the stem. If using the stem, use a slotted

holder with a ø8 mm (ID-U1025, ID-U1025M) or

ø9.52 mm hole with G7 (+0.005 mm to +0.02

mm) (ID-U1025E).

Safety Precautions

To ensure operator safety, use this product in conformance with the directions, functions

and specifications given in this User's Manual.

Use under other conditions may compromise safety.

•

Always keep batteries out of reach of children. If swallowed, consult a physician immediately.

• Batteries should never be short-circuited, disassembled, deformed or come in contact with

extreme heat or flames.

• If battery alkaline liquid comes in contact with the eyes, flush eyes immediately with clean

water and consult a physician. If battery alkaline liquid comes in contact with the skin,

flush the exposed area thoroughly with clean water.

Never attempt to charge the primary battery. Never reverse the positive-negative terminals

when mounting. Improper battery handling or mounting may cause the battery to explode,

cause battery leakage and/ or serious bodily injury or malfunctioning.

• Do not disassemble or modify. This may cause damage.

• Do not use or store the product in a place with sudden temperature changes. Adapt the

product to ambient temperature before use.

• Do not store the product in a place with high humidity or a lot of dust. Also, avoid usage in

places exposed to splashes of water or coolant.

• Do not apply excessive force or subject to sudden impacts such as dropping.

• Be sure to perform reference point setting before measurement.

• Remove dust, cutting chips, etc. before and after use.

• Do not write numbers, etc. with an electric pen. This may cause damage.

• Do not operate the keys with a pointed object (such as a screwdriver or ballpoint pen).

•

Avoid loads in the vertical direction relative to the spindle or usage involving torsion to the spindle.

• This product is shipped without a battery. Install a battery before use.

• The battery supplied is for confirming the functions and performance of the product. Note

that this battery may not fulfill the expected life.

• When disposing of batteries, follow local laws, regulations, etc.

• Malfunction or damage due to depleted batteries, etc. is not covered by the warranty.

ABS Digimatic Indicator ID-U

User's Manual No. 99MAH003A2

Date of publication: November 1, 2020

Contents

1. Names and Dimensions of Components .......................................................................Page 1

2. Installing (Replacing) the Battery...................................................................................Page 1

3. Setup .............................................................................................................................Page 1

4. Power ON/OFF..............................................................................................................Page 2

5. ORIGIN Setting (Reference Point Setting) ....................................................................Page 2

6. Measurement Method....................................................................................................Page 2

7. Precautions after Use ....................................................................................................Page 3

8. Errors and Troubleshooting ...........................................................................................Page 3

9. Output Function .............................................................................................................Page 3

10. Specifications.................................................................................................................Page 3

11. Accessories (Optional)................................................................................................... Page 3

12. Off-Site Repairs (Subject to Charge) .............................................................................Page 3

Key icon operation

=

> 2 s

=

< 1 s

Unit: mm