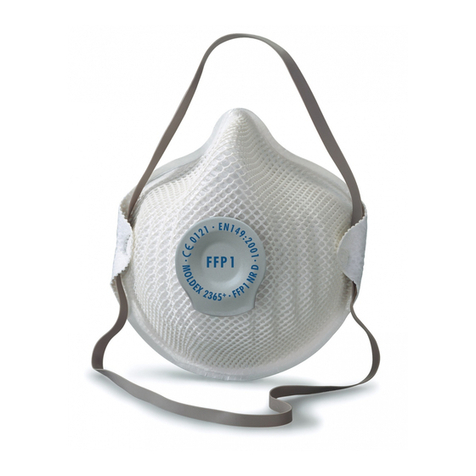

Characteristics

The "Classic+Series of FFP's" from Moldex first introduced the

patented DuraMesh®-Design and the Ventex®-Valve.

The DuraMesh®shell ensures optimum shape retention and durability,

and therefore protection, far superior to that of unsupported filtering

facepieces.

The Ventex®-Valve uses low pressure valve technology to optimise air

flow, reducing the temperature, moisture vapour and exhaled carbon

dioxide inside the mask.

Areas of use:

The Classic Series of FFP's.

Construction / Materials

The Moldex Classic+Series of FFP's have a common design based on

the DuraMesh®technologies.

The respirator is made of:

- Filter Layer = Polypropylene

- Inner Shell = Polypropylene

- DuraMesh®Shell = Polypropylene

- Head Strap = Natural Rubber

- Ventex®-Valve = Natural Rubber

Weight: 2360+= 12 g 2400+= 12 g

2365+= 16 g 2405+= 16 g

Testing

The Moldex Classic+Series of FFP respirators have been tested to

EN149: 2001 and fulfill all requirements of the relevant categories.

·Total inward leakage

Ten test subjects wearing respirators perform a variety of exercises on a

tread mill. During the exercises the amount of test aerosol that

penetrates the filter, face seal and valve (if provided) are sampled. In

the different categories the total inward leakage of 8 out of 10 test

subjects shall not exceed the following levels:

CATEGORY MAX. TOTAL INWARD LEAKAGE

FFP1D 22 %

FFP2D 8 %

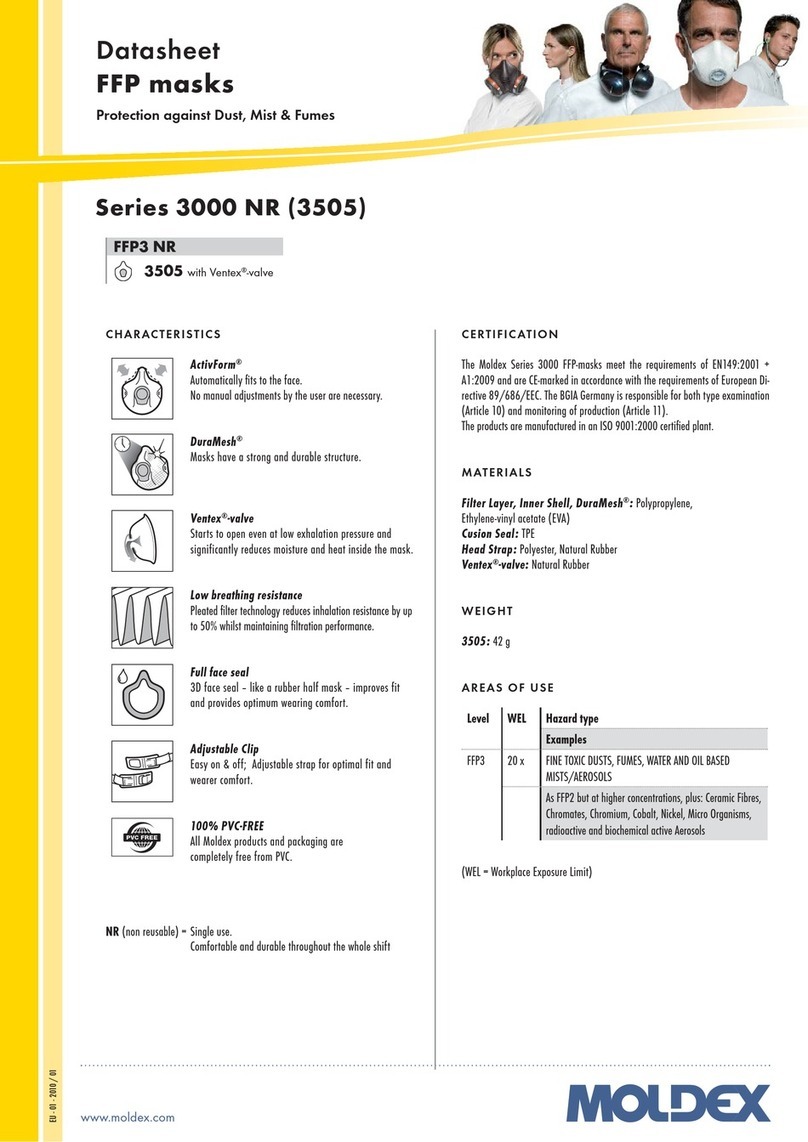

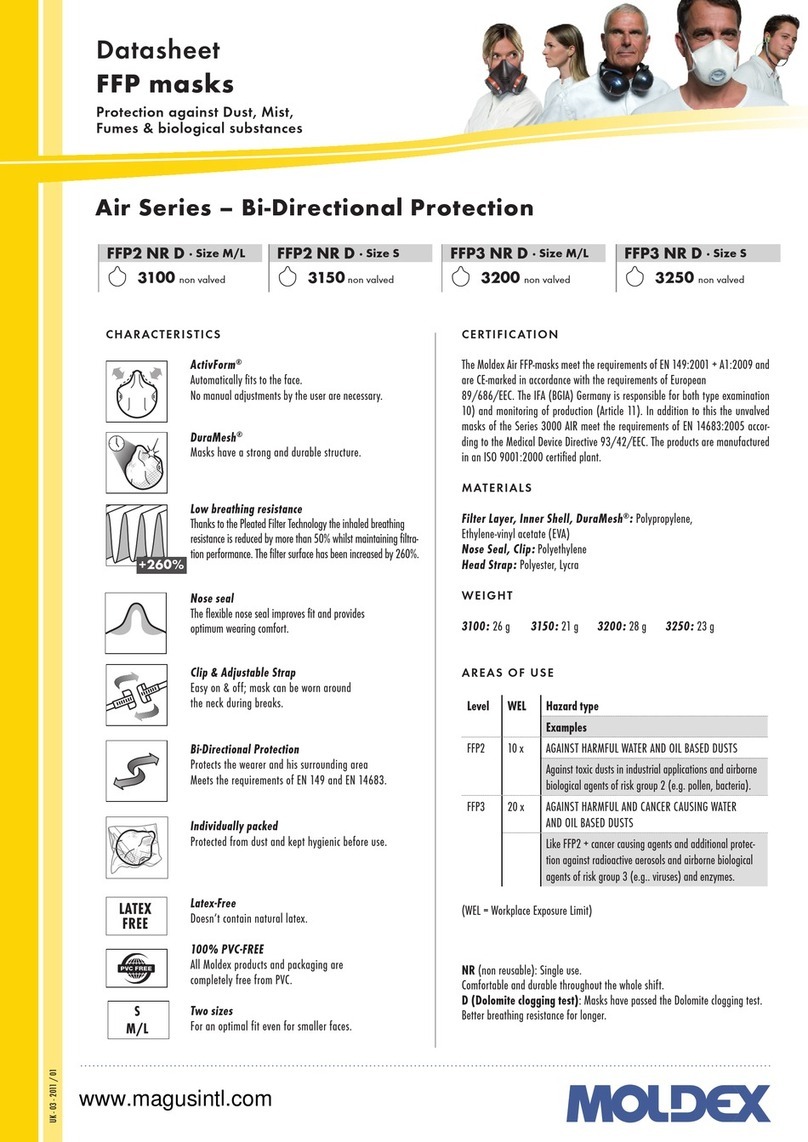

Certification

The Moldex Classic+Series of FFP's meet the requirements of

EN149: 2001 and are CE-Marked in accordance with the requirements

of European Directive 89/686/EEC. The Berufsgenossenschaftliche

Institut für Arbeitssicherheit (BGIA) in St. Augustin in Germany is the

body responsible for both type examination (Article 10) and

monitoring of production (Article 11).

The products are manufactured in an ISO 9001 certified plant.

FFP1D

·2360+(non valved)

·2365+with Ventex®-Valve

FFP2 D

·2400+(non valved)

·2405+with Ventex®-Valve

LEVEL OEL HAZARD TYPE

(MASK) (EXAMPLE)

FFP1D 4 x

(2360+)

(2365+)

FFP2D 10 x

(2400+)

(2405+)

(OEL = Occupational exposure limit)

Technical Data Sheet

RFFP+- EU / 03-2007

+

FINE DUSTS, FUMES, WATER AND OIL BASED

MISTS/AEROSOLS

(Against non-toxic dusts, e.g. Aluminium Oxide,

Bauxite, Borax, Brick Dust, Cellulose, Cement, Coal

Dust, Gypsum, Limestone, Plaster of Paris, Pollen,

Portland Cement, Sucrose, Sugar)

FINE TOXIC DUSTS, FUMES, WATER AND OIL

BASED MISTS/AEROSOLS

(e.g. As for FFP1 but at higher concentrations, plus:

Brake Dust, Calcium Oxide, China Clay, Concrete Dust,

Cotton Dust, Granite, Hay, Lead Dust and Fume,

Particulate Welding Fumes, Silica, Sodium Hydroxide,

Wood Dust, Zinc Oxide Fume)

·Filter Penetration

The filter efficiency of 12 respirators is tested. In EN149: 2001 both

Sodium Chloride and Paraffin Oil aerosols are tested. The following

filter penetration shall not be exceeded.

CATEGORY TEST AEROSOL MAX. FILTER

PENETRATION

FFP1D Sodium Chloride / Paraffin Oil 20 %

FFP2D Sodium Chloride / Paraffin Oil 6 %

This masks fulfil the additional 120 mg oil loading test.