12

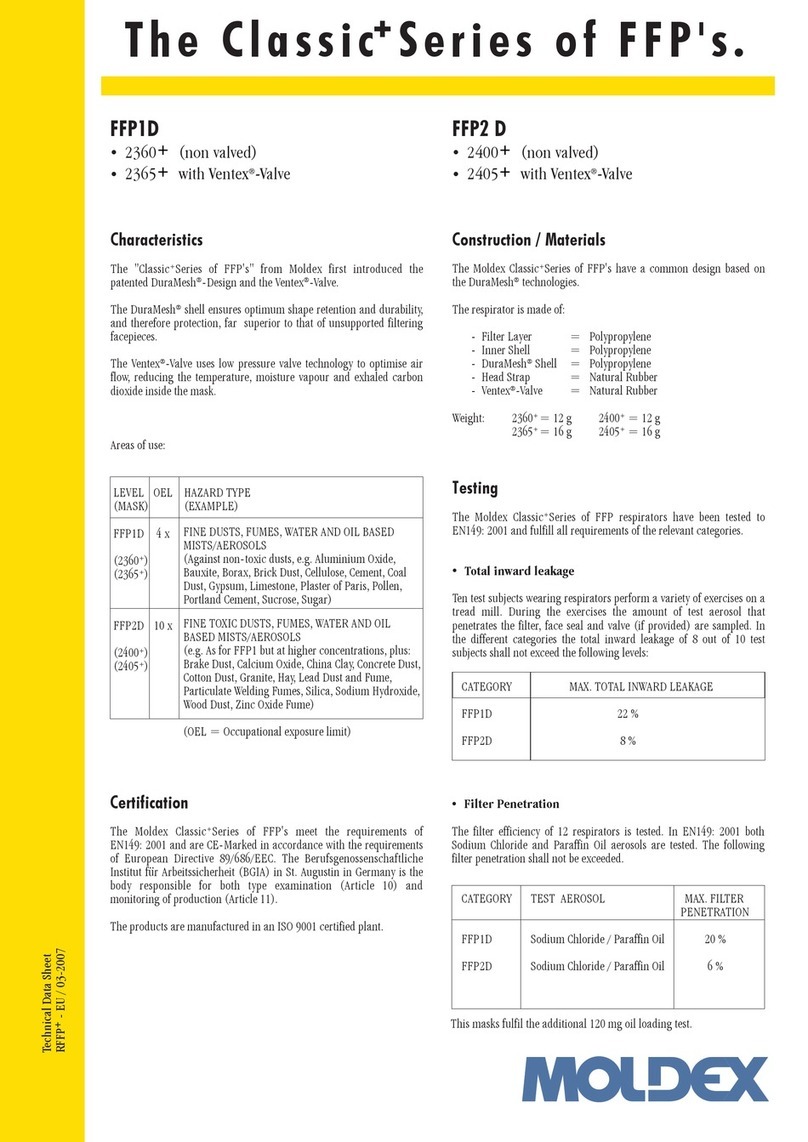

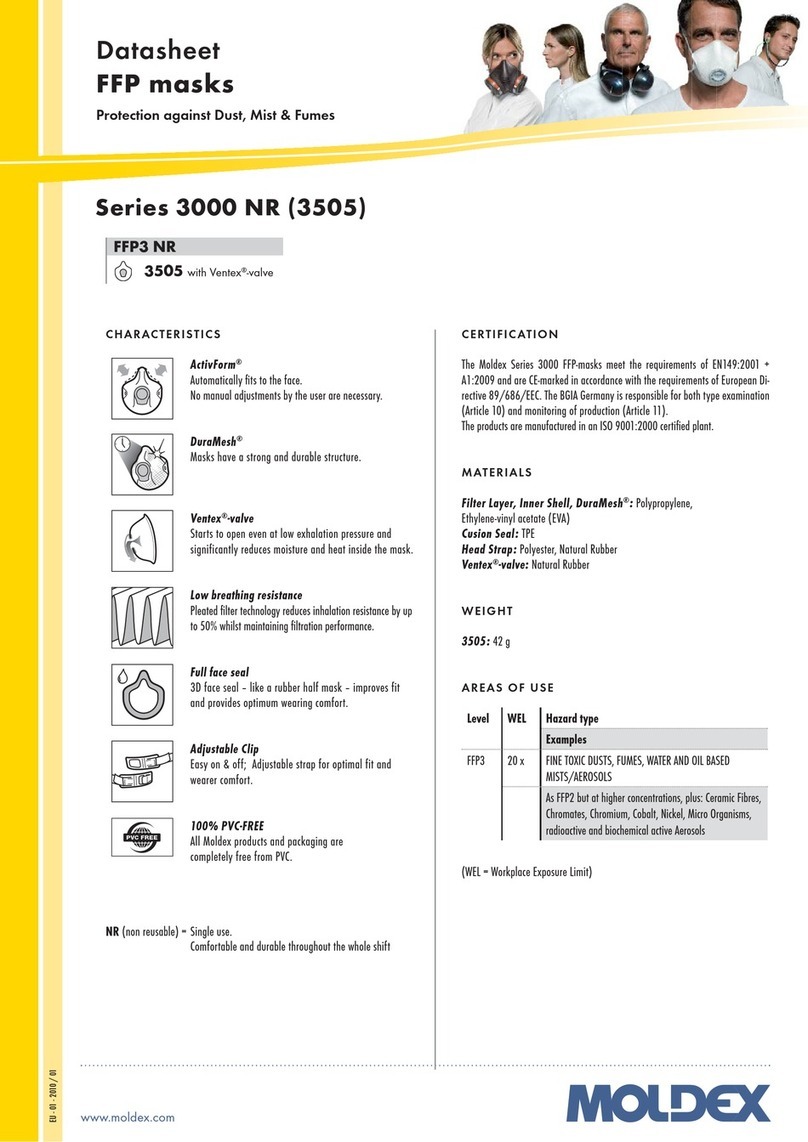

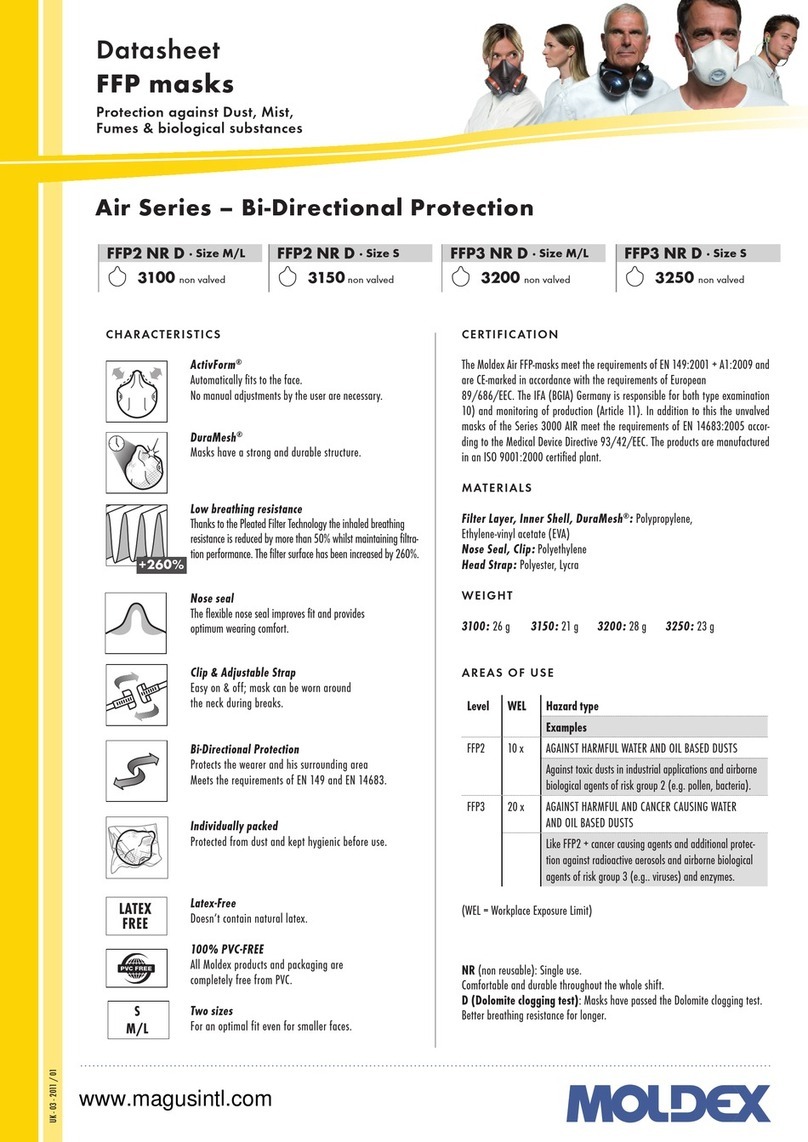

CHANGEOUT SCHEDULES

OSHA 1910.134(d) requires that the employer implement a

change schedule for cartridges based on objective informa-

tion or data that will ensure cartridges are changed before the

end of their service life (see OSHA1910.134 for complete

text). A cartridge’s useful service life is how long it provides

adequate protection from harmful chemicals in the air. The

service life of a cartridge depends on many factors, including

environmental conditions, breathing rate, cartridge filtering

capacity and the amount of contaminants in the air.

If you know what the chemical is and how much of it you are

exposed to, then you are ready to estimate how long your

respirator cartridges will work and apply the safety factor.

You must use some type of objective data to develop a

changeout schedule. Options for determining a cartridge’s

service life include:

1. Conducting experimental tests.

2. Using a mathematical model like the “Advisor Genius” or

“Breakthrough Software.”

3. Using the manufacturer’s recommendation. (Refer to the

Estimated Cartridge Breakthrough Time in the Moldex

Chemical Selection Guide. This data is only provided as a

guide.)

For more detailed information on these methods, refer to

OSHA’s website at:

w

ww

ww

w.

.o

os

sh

ha

a.

.g

go

ov

v/

/S

SL

LT

TC

C/

/e

et

to

oo

ol

ls

s/

/r

re

es

sp

pi

ir

ra

at

to

or

ry

y/

/a

ad

dv

vi

is

so

or

r_

_g

ge

en

ni

iu

us

s_

_

w

wo

oo

od

d/

/a

ad

dv

vi

is

so

or

r_

_g

ge

en

ni

iu

us

s.

.h

ht

tm

ml

l

w

ww

ww

w.

.o

os

sh

ha

a.

.g

go

ov

v/

/S

SL

LT

TC

C/

/e

et

to

oo

ol

ls

s/

/r

re

es

sp

pi

ir

ra

at

to

or

ry

y/

/a

ad

dv

vi

is

so

or

r_

_g

ge

en

ni

iu

us

s_

_

w

wo

oo

od

d/

/b

br

re

ea

ak

kt

th

hr

ro

ou

ug

gh

h.

.h

ht

tm

ml

l

13

Moldex has developed laboratory data for some of the

chemicals where we recommend the use of our 8000 Series

Respirator. You may use this information as a guide to

develop these schedules. Read the warnings and suggestions

on the next page before using this data to develop your

changeout schedule.

Remember this data is only valid for the Moldex 8100 and

8600 cartridges. Use the correct chart for the respective

cartridge. Use any data provided with caution as each

workplace has its own unique variables.

Be sure to read all footnotes provided at the end of each chart.

CARTRIDGE BREAKTHROUGH TIMES

R

RE

EA

AD

DT

TH

HI

IS

SW

WA

AR

RN

NI

IN

NG

G

The following pages contain laboratory generated break-

through times for some of the chemicals that Moldex suggests

its 8100 and 8600 cartridges to be used against. These

breakthrough times were developed by Miller-Nelson Research

under specific laboratory conditions. Tests were run at 72

degrees F (22 degrees C), 50% relative humidity, and 25 liters

per minute for a pair of cartridges. Miller-Nelson Research

used a challenge concentration of 1000 ppm for certain repre-

sentative chemical families and was then able to calculate

estimated breakthrough times at other concentrations for vari-

ous chemicals. These are laboratory generated breakthrough

times and should only be used as a tool in developing your

own changeout schedules. No claims can be made as to their

relationship to actual use conditions. There are other factors

that must be considered in developing changeout schedules

specific to your workplace. These factors include but are not

limited to actual employee work rate, ambient temperature,

ambient relative humidity, whether or not the challenge

chemicals have good warning properties, whether other con-

taminants are also present, use patterns, and maintenance.

Use this data only as a tool to develop your own changeout

schedules. It is the employer’s responsibility to ensure that

the appropriate type of respiratory protection is chosen for

use against a particular contaminant, and that respirators are

used in accordance with a comprehensive respiratory protec-

tion program in compliance with 29 CFR 1910.134 or any

other regulation with which you may be required to comply.

Finally, OSHA has on its website other means of calculating

breakthrough times for various chemicals. You may also wish

to consider use of this website in developing your changeout

schedules. Be advised that actual service life can vary con-

siderably from those calculated using these models. These

models only provide rough estimates. Some of the data you

will need specific to the Moldex cartridges in order to use the

models on the OSHA website are:

• 8100 has an average of 36.7 grams Organic Vapor Carbon,

its height is 2.13 cm, inside diameter is 7.85 cm.

• 8600 has an adsorbing equivalent of 28 grams Organic

Vapor Carbon as calculated by Miller-Nelson Research,

it’s height is 2.34 cm, inside diameter is 7.85 cm.

These weights were estimated by Miller-Nelson using meth-

ods based on his tests. It is suggested that you use default

values provided by OSHA for the other cartridge specific

parameters. Lastly, in order for the OSHA models to be used

you may have to provide other pertinent data on the chal-

lenge agent which may be found on the MSDS or from the

chemical manufacturer. These models can be found at

www.osha.gov/SLTC/etools/respiratory/advisor_genius_w

oods/advisor_genius.html. They are called “Advisor Genius”

and “Breakthrough Applications.” As with the following table,

14