IPH

6 The Interface Solution Experts

Installation

The installation of the IPH is carried out in three

phases. The first phase is the physical mounting of the

unit. Next is the electrical connections phase, and

finally, pneumatic connections can be made. It is

strongly recommended that IPH’s be installed in this

order. It is also strongly suggested that each unit be

calibrated according to the instructions in this manual

before being placed into service.

The IPH may be installed at any angle: either surface-

mounted or attached to pipe or round conduit. When

deciding on the placement of the IPH unit, make sure

to consider the possibility of needing to: access the

front panel, check the fittings, read the -FR1 Option

gauge, or drain the filter.

Closed Loop/Open Loop. The IPH should be

installed in a closed loop. A closed loop is the best

way to measure a control variable. It also helps

determine if a deviation from a desired value exists and

provides feedback for actuator loading pressure.

An open loop has limitations that are not consistent

with precise control. Long term drift of the loop dynam-

ics, load fluctuations that require constant adjustments

of the actuator loading pressure, and performance

quality variations due to inconsistencies between

operating personnel are all problems commonly

associated with open loops. A controlled variable

cannot be directly measured in an open loop; this

prevents compensating adjustments to the system

input.

Phase One: Mounting

Figure 2 gives the IPH’s outline dimensions. The

illustration also gives the dimensions of the available

-FR1 Option hardware, which is recommended for

most installations.

After placing the IPH in the desired location and

orientation, secure the housing with the optional pipe

mounting hardware or other appropriate fasteners.

If you have further questions on how to mount the IPH,

contact your Moore Industries Sales Representative for

assistance.

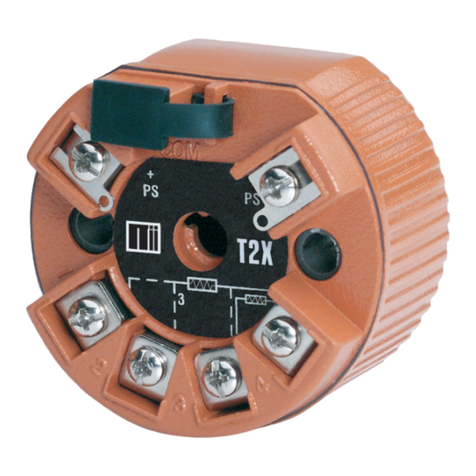

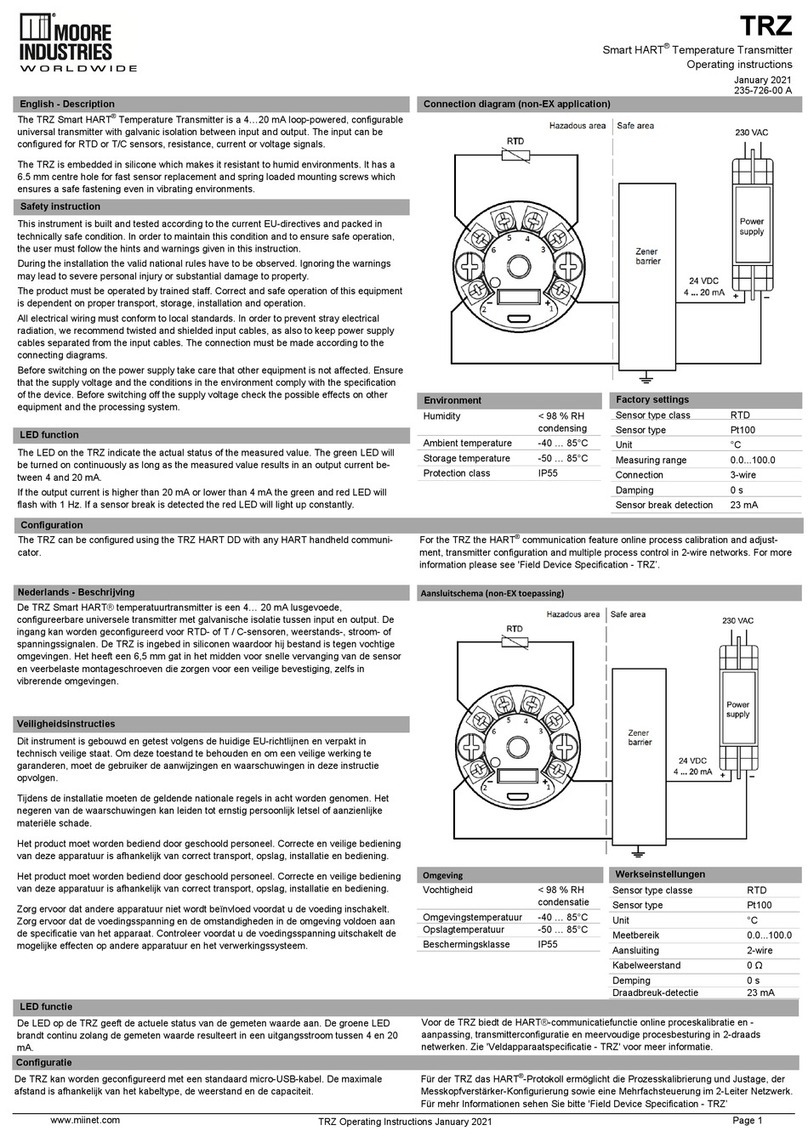

Phase Two: Electrical Connections

To complete the electrical connections, route the wiring

through the conduit port to the terminal block, then use

a slotted-tip screwdriver with a maximum head width of

3 mm (0.125 inch) to loosen the terminal screws.

The terminals are comprised of compression-screw

sockets that accommodate 22-14 AWG wiring.

Connect positive lead (+) to terminal labeled “+I”, and

negative lead (–) to terminal labeled “–I”. Tighten the

terminal screws until snug.

Use shielded, twisted-pair wiring for low-level input.

Ground the shielding wire as close as possible to the

installed IPH.

Phase Three: Pneumatic Connections

To complete the final phase of installation, the pneu-

matic connections, connect the supply line to the

1/4-inch NPT female port labeled “IN”. Connect the

output line to the 1/4-inch NPT female port labeled

“OUT”.

Seal all fittings with Teflon®tape, or equivalent. Always

“blow down” (purge) all tubing and the controlled

device before connecting the IPH.

Filters. The IPH requires filtered, dry, regulated,

instrument-quality air to prevent clogging and to ensure

extended periods of maintenance-free operation.

Moore Industries suggests the following levels of

filteringprotection:

• Pre-filter – A general purpose “rough” filter, used

to reduce particulate matter to 5 microns in size.

Also removes bulk liquids. Although not required,

this filter is especially recommended to protect the

0.01 micron final filter when used.

• Final Filter – A second, final filter is recom-

mended, to remove particulate matter in sizes

down to 0.01 micron. This filter removes virtually

all condensable liquids from the air stream as well.

• Filter/Regulator Module Option – A combined

filter/regulator assembly, the -FR1 Option, offered

as an accessory for the IPH, removes particles

down to 0.01 micron, supplying regulated, instru-

ment-quality air to the unit. This space-saving

module is affixed to the IPH supply port, and

comes with a pressure gauge scaled in both psi

(0-60) and bars (0-4).

NOTE:

For NEMA4X and IP55 Installations, the unit must be

mounted vertically or within 45 degrees of vertical.