2

“Regal Rexnord” is not indicative of legal entity.

Morse is a registered trademark of Borg-Warner Corporation, used herein under exclusive license.

Regal Rexnord and Morse are trademarks of Regal Rexnord Corporation or one of its affiliated companies.

© 2008, 2022 Rexnord Corporation, All Rights Reserved. MCIM22031E • Form# 4146-004E

C. After Installation

1. Check clutch for smoothness of operation under overrunning

condition.

D. Lubrication

1. The clutch is prelubricated with grease. If oil lubrication is required,

wash out the clutch with mineral spirits or kerosene before

installation.

2. The following lubricants are recommended:

Oil:

Multi-purpose automatic transmission fluid.

Grease:

+20°F to 125°F (max. ambient temp.). Use premium ball

bearing grease NLGI #1, #2, or ISO 100 or equivalent.

NOTICE: Do not use lubricants of the EP Type (extreme pressure

characteristics) or those containing slippery additives such as

molybdenum disulfide and graphite.

E. Maintenance

1. Periodically inspect clutch for adequacy of lubrication.

NOTICE: Consult Application Engineering at 1-800-626-2093 when

applying this unit as a backstop to prevent reverse rotation of an

induction motor.

F. General Information

1. Application Engineering: 1-800-626-2093.

CAUTION! Do not use the clutch above its torque or speed ratings. Do

not attempt to take this clutch apart.

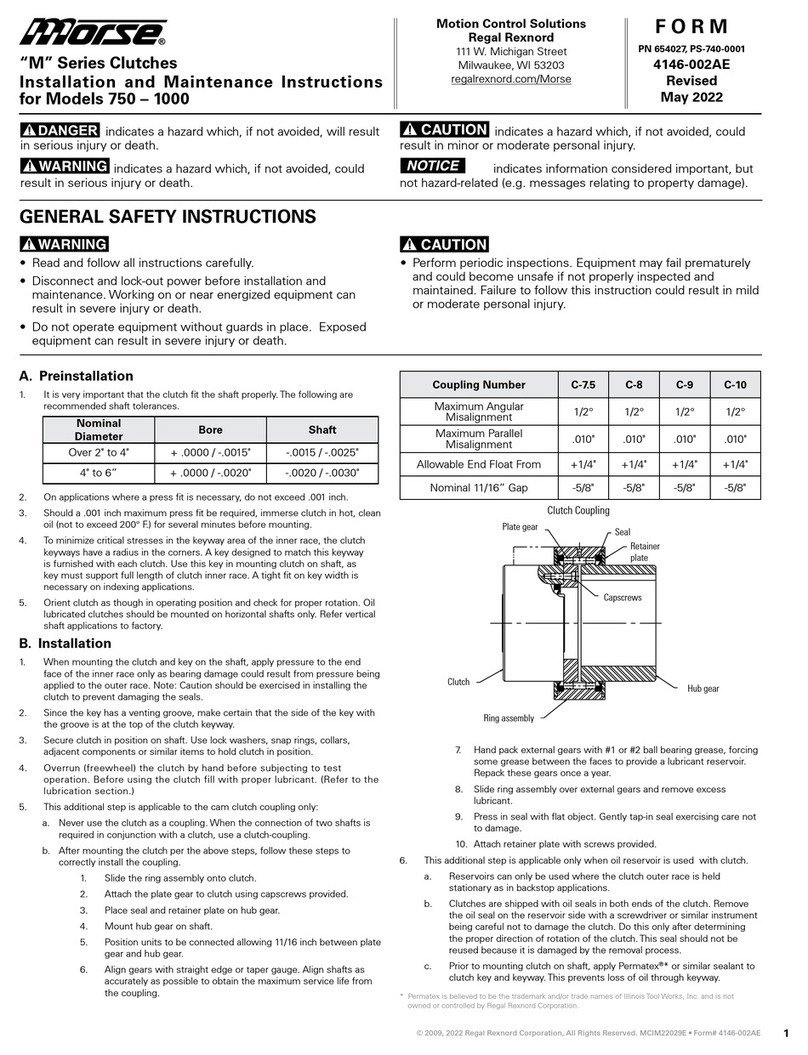

B. Installation

1. The arrow on the inner race indicates the direction of inner race

engagement.

2. Install to the housing of sprocket, gear, etc.

- For press fit types (KK, KK-1K, KK-2GD, KK-2GD1K); Press outer

race

- For keyed outer race type (KK-2K); Use the key provided to secure

the housing and clutch, because the fit is neither press nor loose.

Then, install ball bearing. Never use a setscrew on outer race to fix

the key because it may deform the outer race.

3. Installation to shaft

- For press fit types (KK, KK-2GD); Press housing (clutch is already

installed) to the shaft by applying force to the inner race of clutch.

- For keyed inner race types (KK-1K, KK-2K, KK-2GD1K); Use the key

provided to install to the shaft.

4. Key and keyway

Standard key and keyway are DIN6885.3. However, the depth of

inner keyways for KK25-1K, KK25-2K and KK25-2GD1K are 0.5mm

shallower than standard. So, the depth of shaft keyway should be

0.5mm deeper. Standard inner race key and keyway for KK40-1K,

KK40-2K and KK40-2GD1K are DIN6885.1.

5. When pressing clutch to the shaft and housing, do not press inner

race or outer race separately but press them simultaneously.

6. Refer to the catalog for key dimensions.

7. The clutch is an integral assembly and cannot be taken apart for

installation. As the torque is transmitted only by friction contact and

the N 6 tolerance for housing bore could under some conditions

produce slight clearance, the application of Loctite Bearing Mount is

recommended. If use of adhesive is not possible, the outer race of

the clutch can be locked into position by axial clamping.

CAUTION! Do not hammer on the clutch assembly during installation

as damage to the ball races can occur. Particular care should always be

taken to make sure that even pressure is applied only to the race with

interference fit.