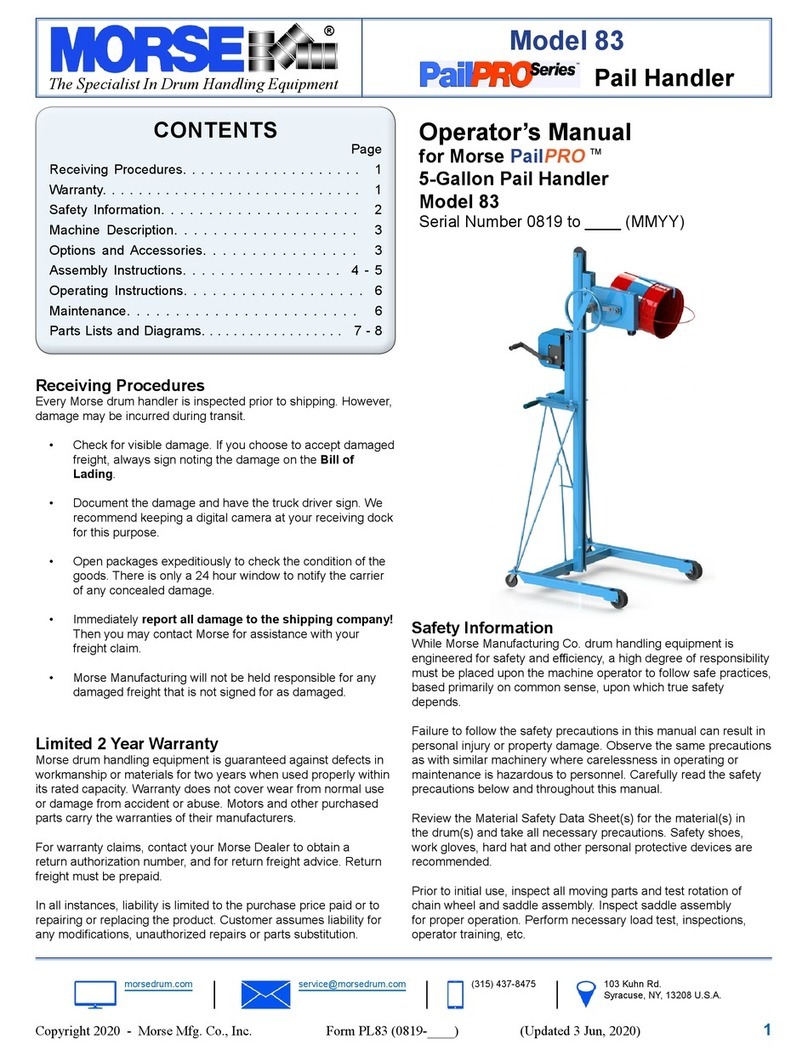

The Specialist In Drum Handling Equipment

Model 185AM

Kontrol-Karrier with Spark Resistant Parts

Operator’s Manual for Morse Model 185AM Kontrol-Karrier with Spark Resistant Parts

Serial number 0507 to 0309 (MMYY)

www.morsedrum.com

Copyright 2009 - Morse Mfg. Co., Inc. Form PL185AM (0507-0309) (Updated March 15, 2018 2:16 PM) 4

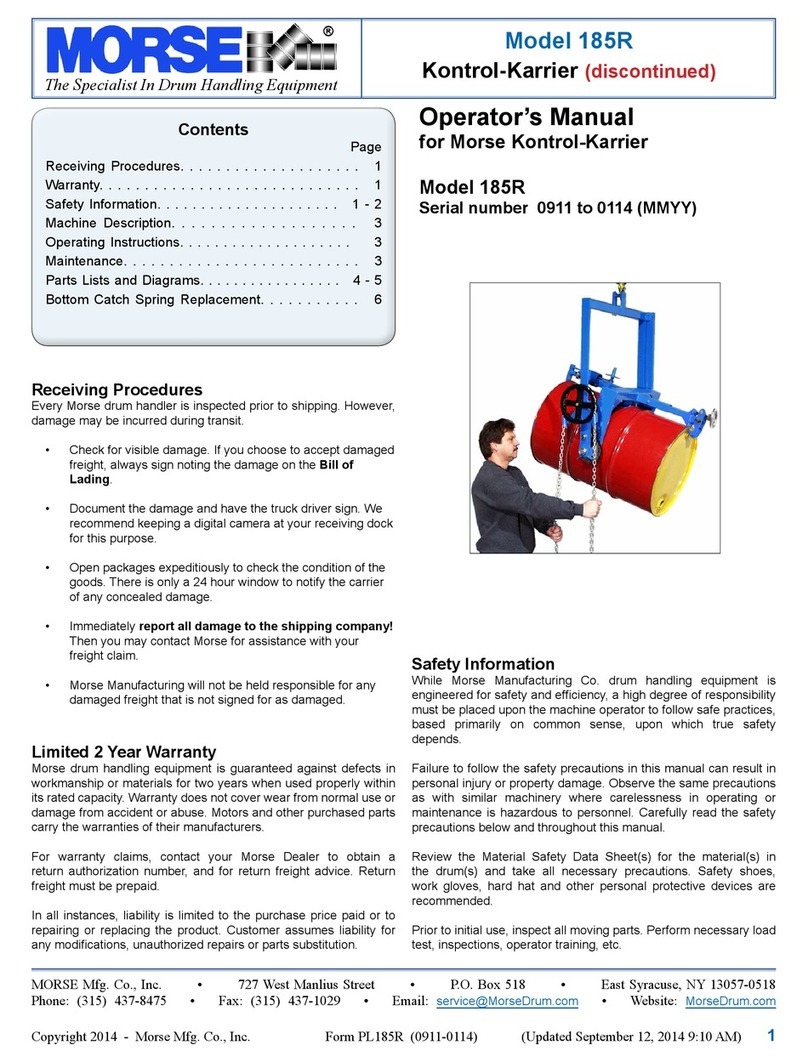

ITEM # QTY. PART # DESCRIPTION

1 * 1 1-P CHAINWHEEL#1-1/2W/GUIDESR

2 1 3-P TRIANGLE&SHAFTW/BOLTS

3 12 2B-P CHAIN,1/0BRASS,PERFT

4 * 1 2435-P CHAIN,PULL,BRASS,1/0,12’

5 * 2 735-P KEY,WOODRUFF,SIZE9,ASA606

6 * 1 19-P BEARING,3/4”IDX2-1/2”

7 2 55-P WASHER,3/4SAEFL1-1/2OD

8 * 1 11-P SPROCKET,#3512T,3/4”BORE

9 1 15-P COLLAR,3/4”ID

10 * 1 7-P BEARING,3/4”IDX1-1/2”

11 1 16-P COLLAR,1”ID

12 * 1 18-P BEARING,1”IDX2-1/2”

13 * 1 12-P CHAIN,ROLLER,#35W/MLINK

14 * 1 795-P LINK,MASTER,#35CHAIN

15 * 1 13-P SPROCKET#3536T,3/4”BORE

16 * 1 14-P GEAR,PINION,7TOOTH

17 1 29-P SPACER,SPURGEAR.15”

18 2 22-P SHCS,3/8-24X5/8

19 * 1 23-P GEAR,SPUR,72T,1”HOLE

ITEM # QTY. PART # DESCRIPTION

20 1 47M-P OVERHEADYOKE,185MSERIES,SR

21 1 725AM-P** SADDLEASM,285AM,SR

23 1 4079-P HHCS,M8X60MMCL8.8,8MM

24 1 4081-P NUT,M8ESNA,8MM

25 * 1 4408-P CHAIN,CINCH,9/32SS,38LINK

27 1 64-P ROLLPIN,3/16X1-1/4

29 1 1296-P HHCS,1/4-20X7-1/2GR5

30 1 1297-P NUT,1/4-20REVHEXLOCK

31 1 4409-P GRIP,HANDLE7/8”X4-3/4”RED

32 * 1 169-P SPRING,PAWL

33 1 168-P PAWL,WITHDRILLEDHOLE

34 1 170-P SCREW,3/8DIAX5/8SHOULDER

35 1 710-P RETAINER,RATCHETPUSHNUT3/4

36 1 165SS-P RATCHET,STEEL-IT

37 1 165KITM-P KIT,RATCHETTIGHTENER,SR

38 1 PLATE,RATCHETHINGE,1/4”,SR(NOTSOLDSEPARATELY)

39 * 1 726M-P *** HINGEPLATECPT,1/4”SR

* Recommended spare parts

**Item21“SADDLEASM”(drumholderassembly)includesappropriateattachedmovingparts

(items 23, 24, 25, 29, 30 and 39).

***Item39“HINGEPLATECOMPLETE”includesallcomponentsofitem37installedontoitem38.