The Specialist In Drum Handling Equipment

Model 85i-SS

Stainless Steel Drum Karrier

Operator’s Manual for Morse Model 85i-SS Stainless Steel Drum Karrier

Serial number 0218 to ____ (MMYY)

morsedrum.com

Copyright 2019 - Morse Mfg. Co., Inc. Form PL85i-SS (0218-____) (Updated 18 Nov, 2019) 3

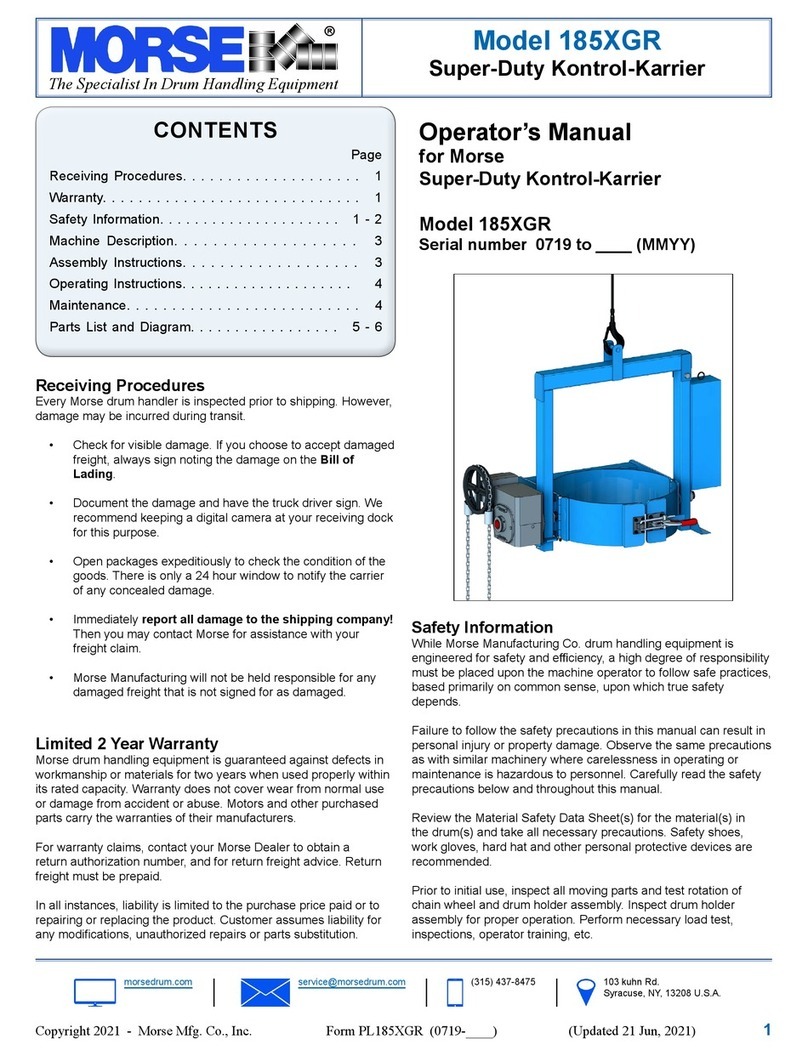

Machine Description

Model 85i-SS Stainless Steel Drum Karrier is designed to lift, transport

and dispense a standard 55-gallon (210 liter) steel drum 22.5” (57 cm) in

diameter. The maximum capacity is 800 Lb. (363 kg). The capacity is derated

to 500 Lb. (227 kg) for a half-full drum. The half-full rating is based on the tilt

mechanism’s capacity for handling an unbalanced bottom-heavy drum.

Options

To Handle a Smaller Drum:

A smaller diameter drum can be handled with the correct size 55/30SS•

SeriesDiameterAdaptor(seegure2.1)installed(seeDiameter Adaptor

literature).

To Handle a 55-Gallon (210 liter) Plastic or Fiber Drum:

Tohandlea55-gallon(210liter)plasticorberdrumwithtoprim,youmust

install either the Bracket Assembly or the Top Rim Clamp.

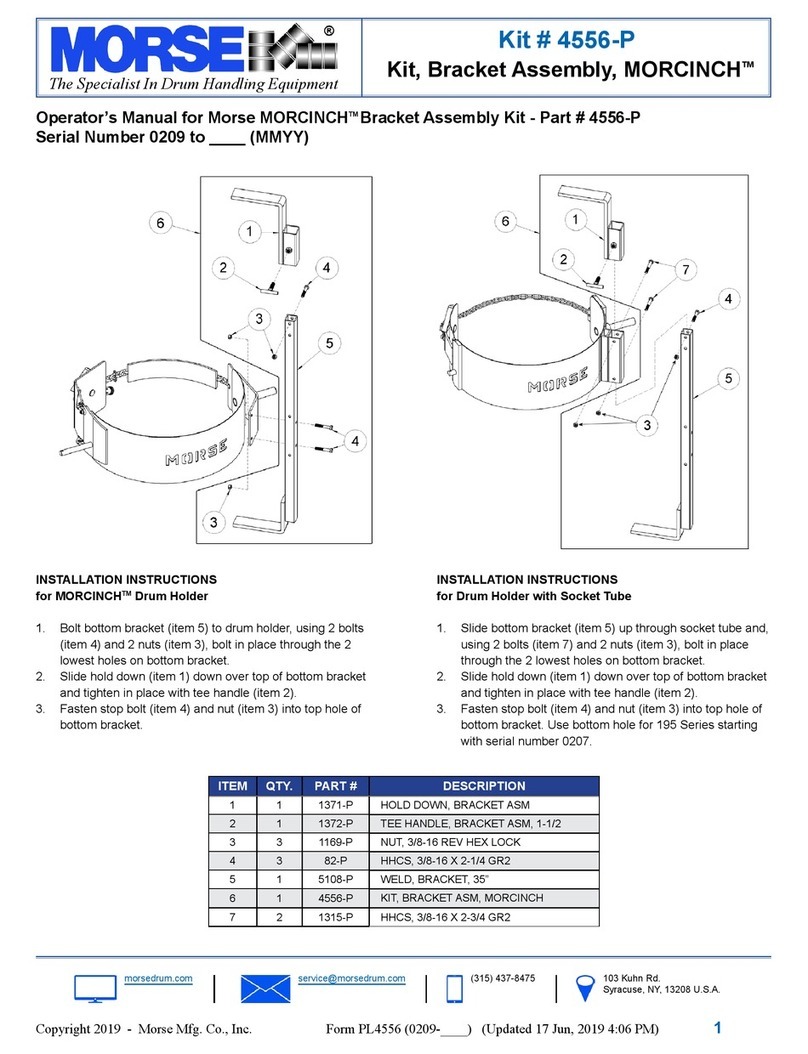

The• Bracket Assembly (Kit # 4556SS-P) is required to handle a

RIMLESSplasticorberdrum-adrumwithoutatoprim(seegure

2.2). You can use the Bracket Assembly with a 55-gallon (210 liter)

plastic,steelorberdrum.Thebraceattopandbottomofthedrum

prevent it from slipping lengthways through the drum holder. It adjusts

for a drum 31” to 39” (79 to 99 cm) tall.

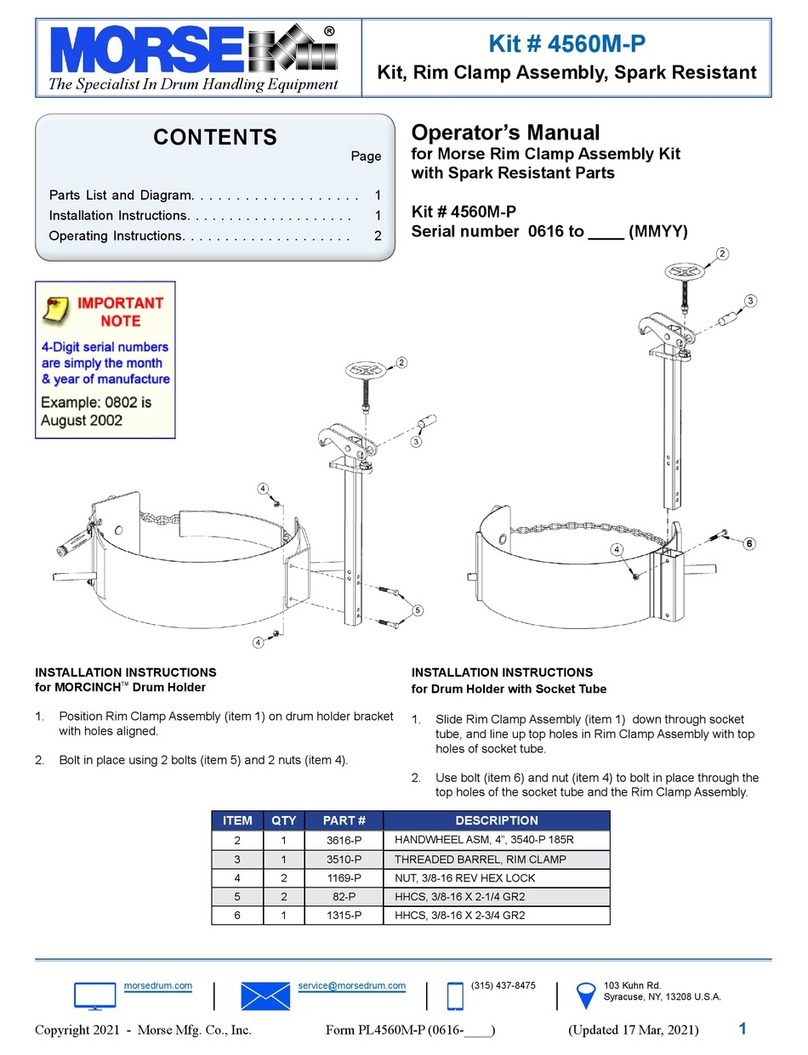

The• Top Rim Clamp (Kit # 4560SS-P) grips the upper rim of your drum

topreventitfromslippingthroughthedrumholder(seegure2.3).You

can use the Top Rim Clamp with a 55-gallon (210 liter) plastic, steel or

berdrumwithsuitabletoprim.

Important

Review the Material Safety Data Sheet(s) for the material(s) in the1.

drum(s) and take all necessary precautions. Safety shoes, work gloves,

hard hat and other personal protective devices are recommended.

Please read all instructions thoroughly before attempting to operate your2.

new Morse drum handler.

The 85 Series Drum Karriers have a maximum capacity rating of 800 Lb.3.

(363 kg) for a FULL drum and 500 Lb. (227 kg) for a HALF-FULL drum,

and are designed to lift and move a drum of the size and type noted

above. DO NOT exceed this rating. Exceeding this rating or handling

drums other than those mentioned above is unsafe and could result in

equipment damage, excessive wear, awkward or dangerous handling.

When loading, unloading, operating, or maintaining your MORSE drum4.

handler, always use care and good judgment. Maintain secure footing

andarmhold.Keephandsandlooseclothingawayfromallmoving

parts. Never allow anyone to be below any part of a raised drum handler

or drum. Read operating instructions and review the pictures in the sales

brochure before operation.

The 85 Series are a “Group 1 structural and mechanical” below-the-5.

hook lifting device which are covered by the American National Standard

ASME B30.20. The user should comply with all aspects of this standard.

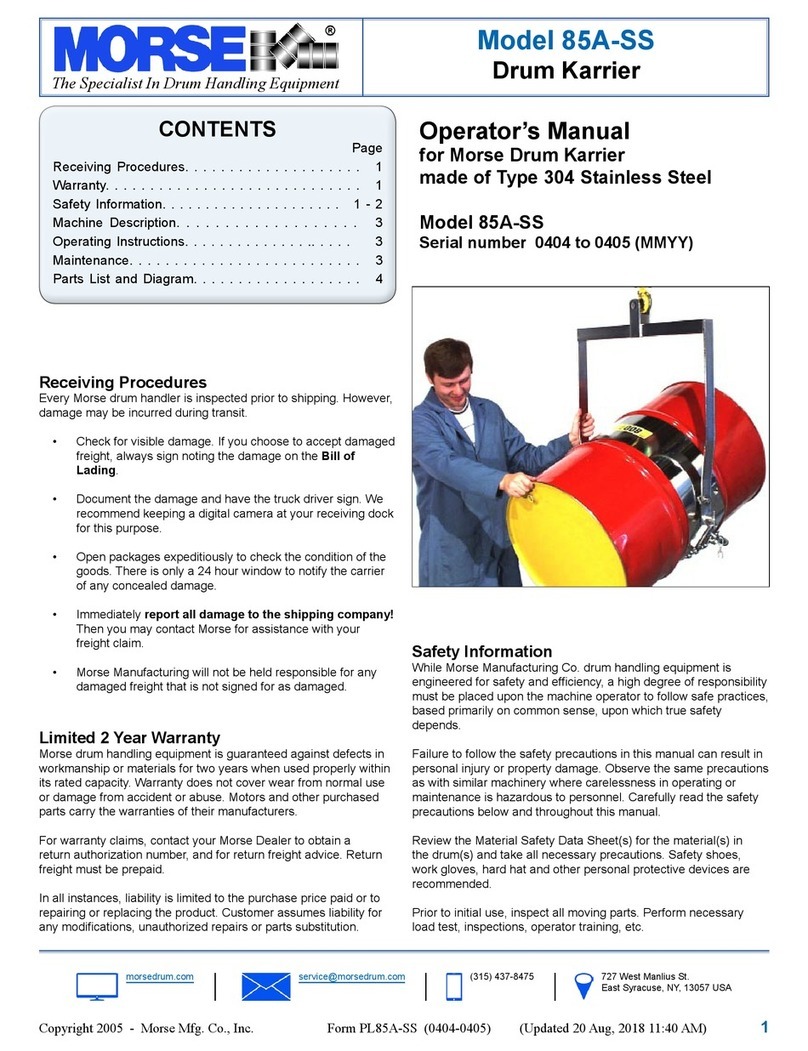

Figure 2.1

Diameter Adaptors

Diameter Adaptor # 55/30SS-16 shown is for 15.5” to

16” (39.4 to 40.6 cm) diameter drum. It has integrated

brackets that adjust for a drum up to 38” (96.5 cm) tall.

Figure 2.3

Plastic drum being lifted

with part number 4560SS-P

Top Rim Clamp Assembly

installed.

Figure 2.2

Plastic drum being lifted

with part number 4556SS-P

Bracket Assembly installed.