© Motor City Wash Works, Inc. 48285 Frank, Wixom Michigan 48393 U.S.A. Phone: 248.313.0272 ▪ Fax: 248. 313.0271

8MANULWPBRINS01 11-18-20 REV 1.0 www.motorcitywashworks.com 1

PIVOTING WHEEL BLASTER INSTALLATION MANUAL

Part #:7AXISAIRPNL0002, 3, 4 & 7WHELBLSTRDRV01, 02 & 7WHELBLSTRPAS01, 02

TABLE OF CONTENTS

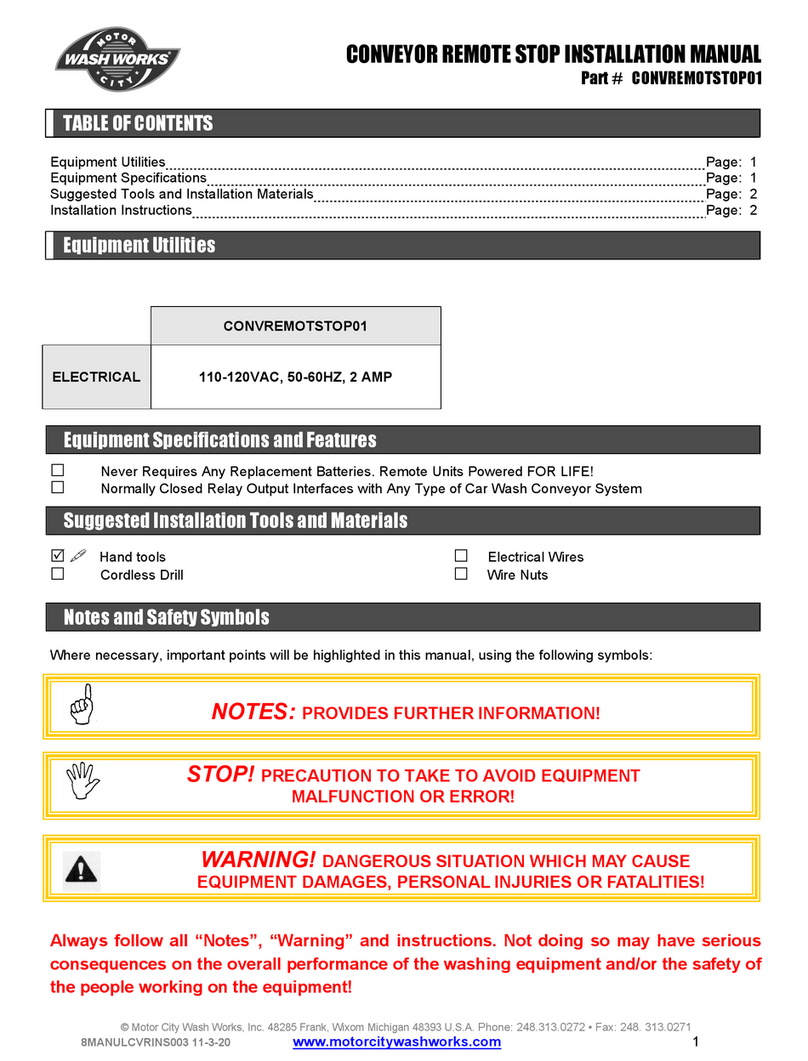

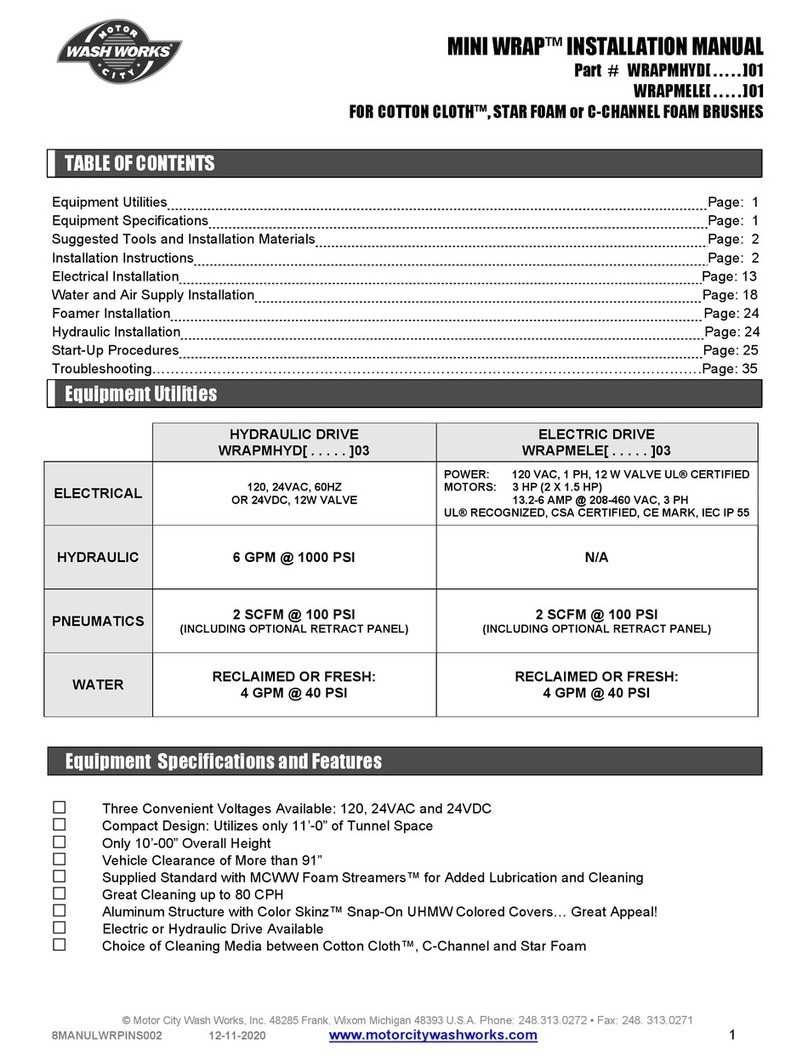

Equipment Utilities Page: 1

Equipment Specifications Page: 1

Suggested Tools and Installation Materials Page: 1

Installation Instructions Page: 2

Maintenance Page: 6

Troubleshooting……………………………………………………………………………………………………..…Page :14

Warranty………………………………………………………………………………………………………………..Page: 17

Equipment Utilities

Equipment Specifications and Features

Leg Weldment:

Height: 18-1/4”

Slot: From the Floor, the Height is 4-3/16” (H), Slot Length is 10” (L), Traveling Distance is 5-1/2”

Integrated Aluminum H2O Filter

Integrated Pneumatic Air Cylinder, Mechanically Pivots the Manifold

Three Positions to Set Desired Pivoting Angle:

Furthest: Approx. ± 15°

Middle: Approx. ± 20°

Inside: Approx. ± 25°

Suggested Installation Tools and Materials

Safety Goggles Hammer

Measuring Tape Wedge Anchor Bolts 1/2”

Torpedo Level Amp Meter/Volt Meter

Hammer Drill with Required bits Wire Stripper

Standard Allen Wrenches Teflon Tape

Set of Standard Combo Wrenches 1/4” OD Polyflow Tubing

Three & Six Nozzle Pivoting Wheel Blaster, 120 VAC / 24 VAC / 24 VDC Air Panels

ELECTRICAL POWER: 120 VAC / 24 VAC / 24 VDC

PNEUMATICS

25-50 PSI OPERATING PRESSURE

WATER

RECLAIMED OR FRESH:

THREE NOZZLE: 9 GPM

SIX NOZZLE: 18 GPM