© Motor City Wash Works, Inc. 48285 Frank, Wixom Michigan 48393 U.S.A. Phone: 248.313.0272 ▪ Fax: 248. 313.0271

8MANULCVRINS003 11-3-20 www.motorcitywashworks.com 2

Installation Instructions

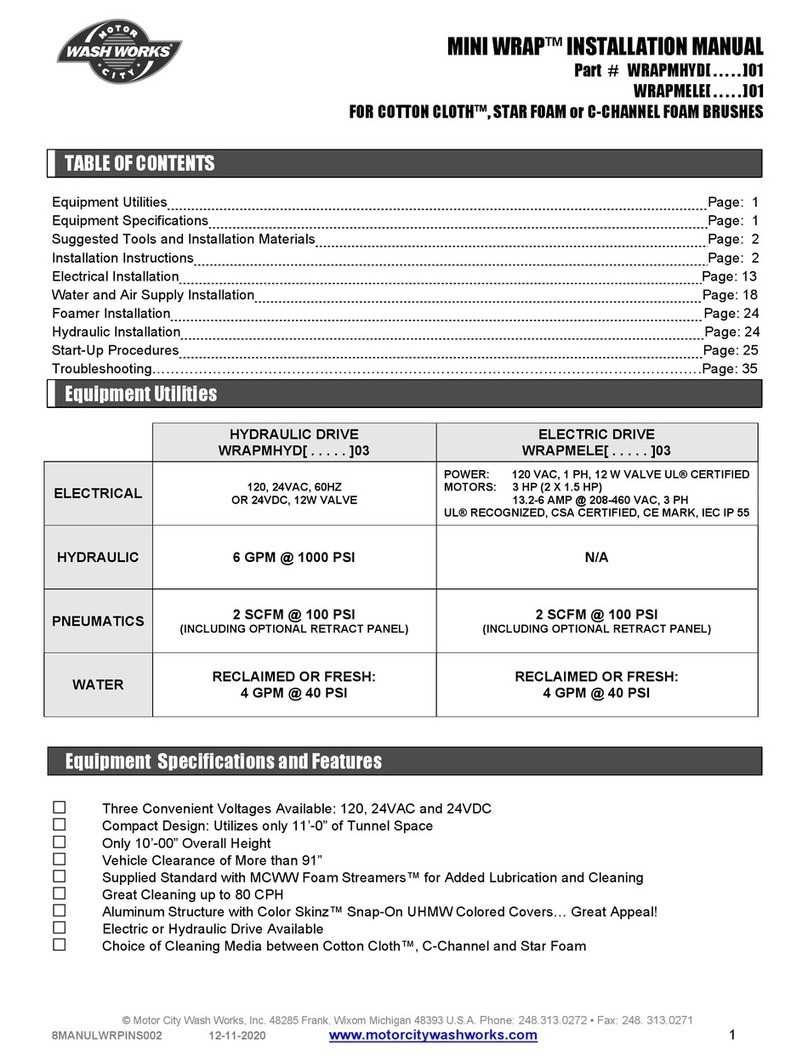

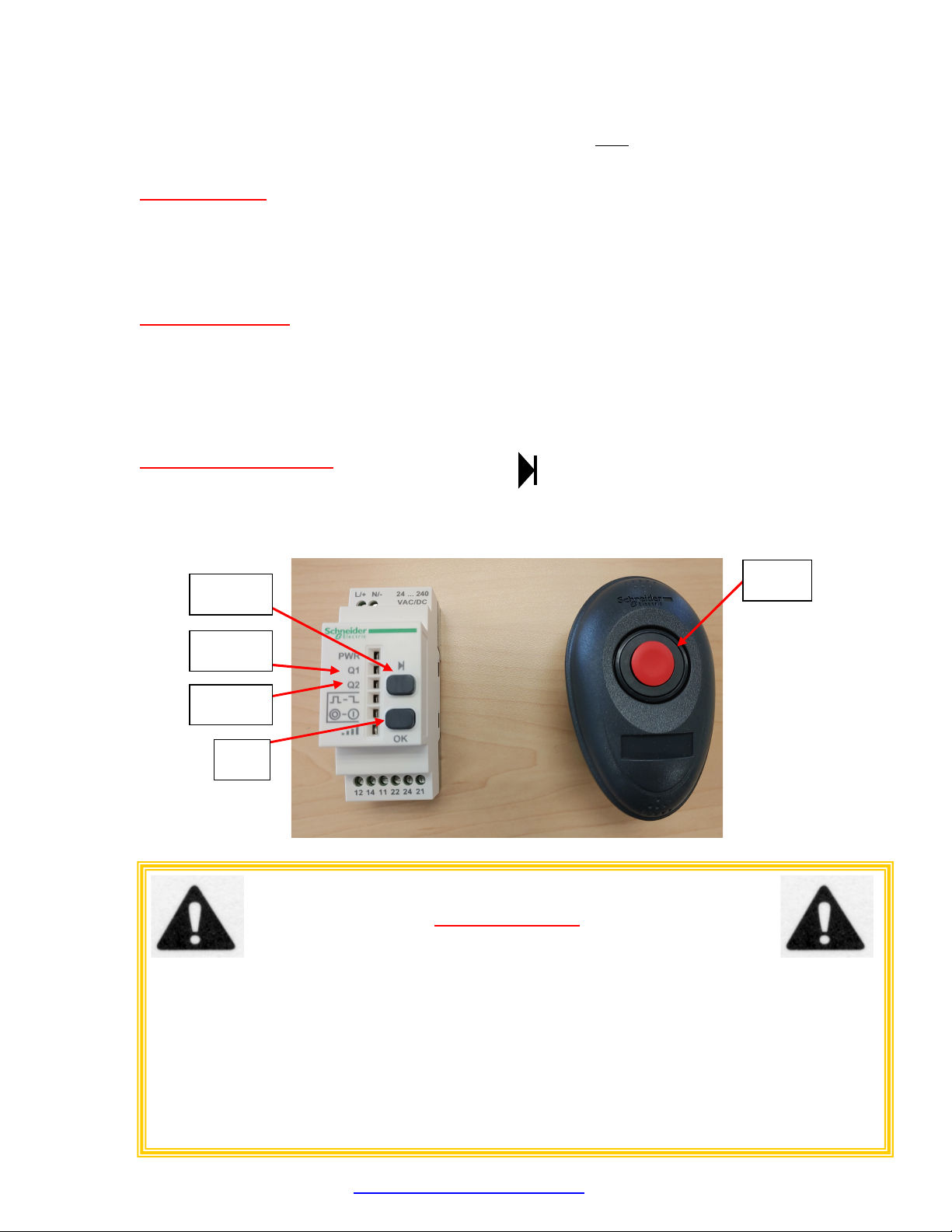

Open all boxes and crates and verify that you have all the required components as well as all your

installation material. Your anti-collision system comes with a control box (see Picture #1), 15FT of 3/4”

liquid tight flexible conduit, one end cap and a 18mm vehicle sensor with 30FT cord (Picture #2).

REMOTESTOP0001

SYSTEM OK

8DCALREMSTP0001

POWER

WASH WORKS

R

M

C

I

T

Y

T

0

MOTOR CITY WASH WORKS

UNIVERSAL HAND HELD

REMOTE STOP SYSTEM

STOPPED

PUSH

TO

RESTART

* USE REMO TE STOP TO TURN OFF

CONVE YOR OR WASH EQU IPMENT

WHE N NEEDED.

* THE MCWW UNIVERSA L REMOTE STOP

CANNOT REPL ACE EMERGENCY

STOP BUTTONS. INSTALL

READILY AVA ILABLE EMERGENCY STOP

BUTTONS ON EAC H SIDE OF THE

WASH BAY.

* WHENEVER AN EMERGENCY STOP

BUTTON IS PUSHED, IT IS TO BE

RESET ONLY BY THE PERSON WHO

INITIALLY STOPPED THE E QUIPMENT

AFTER THE EMERGEN CY.

FA ILU RE T O F OLLOW THESE RULES

M AY LEA DS TO EQUIPMENT DAMAGES,

PERSONAL INJU RI ES OR DEATH!

DANGER!

7ELECHASTRS0001

7CONVELCPNL0001

Picture #1: Control Box w/Remote Transmitters

Mount the electrical control box (7CONVELCPNL0001) in a dry area in the mechanical room and in close

proximity to the center of the wash bay (you will need to install the antenna assembly in the middle of the

wash bay, on the mechanical room wall and connect it to the control box).

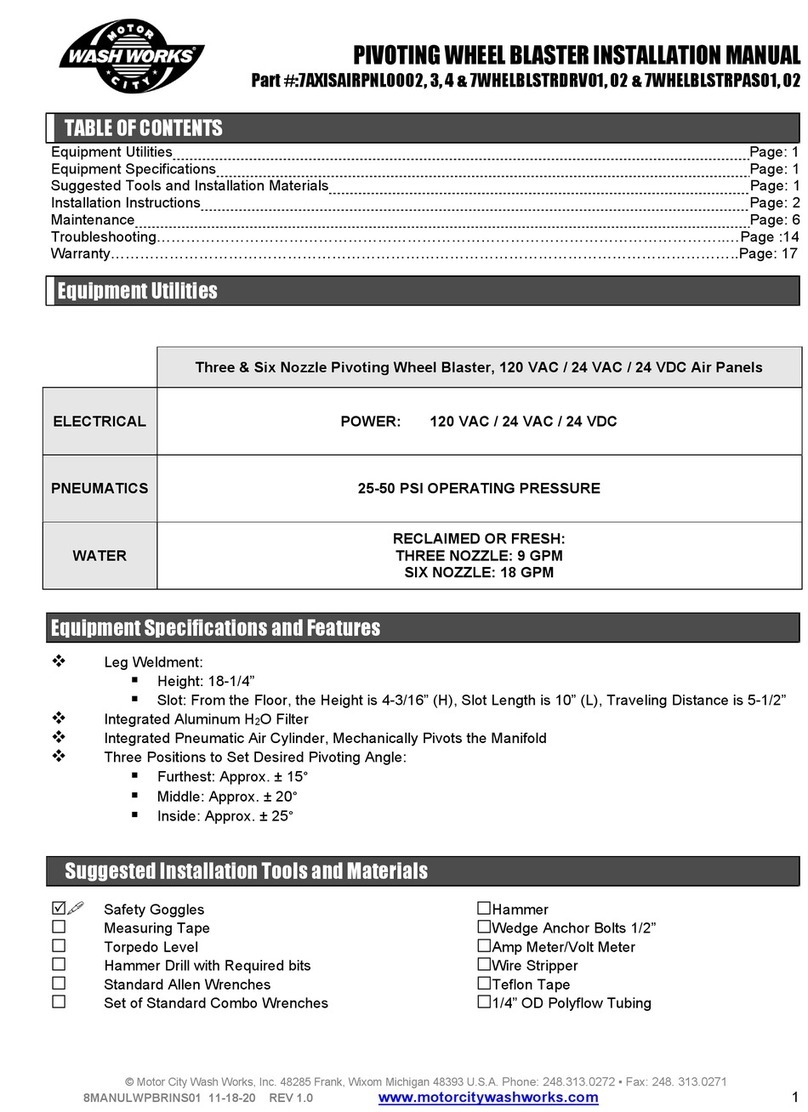

Mount the antenna assembly in the middle of the wash bay, on the mechanical room wall and about 10ft

off of the floor and connect it to the control box located in the mechanical room.

Picture #2: Antenna Assembly

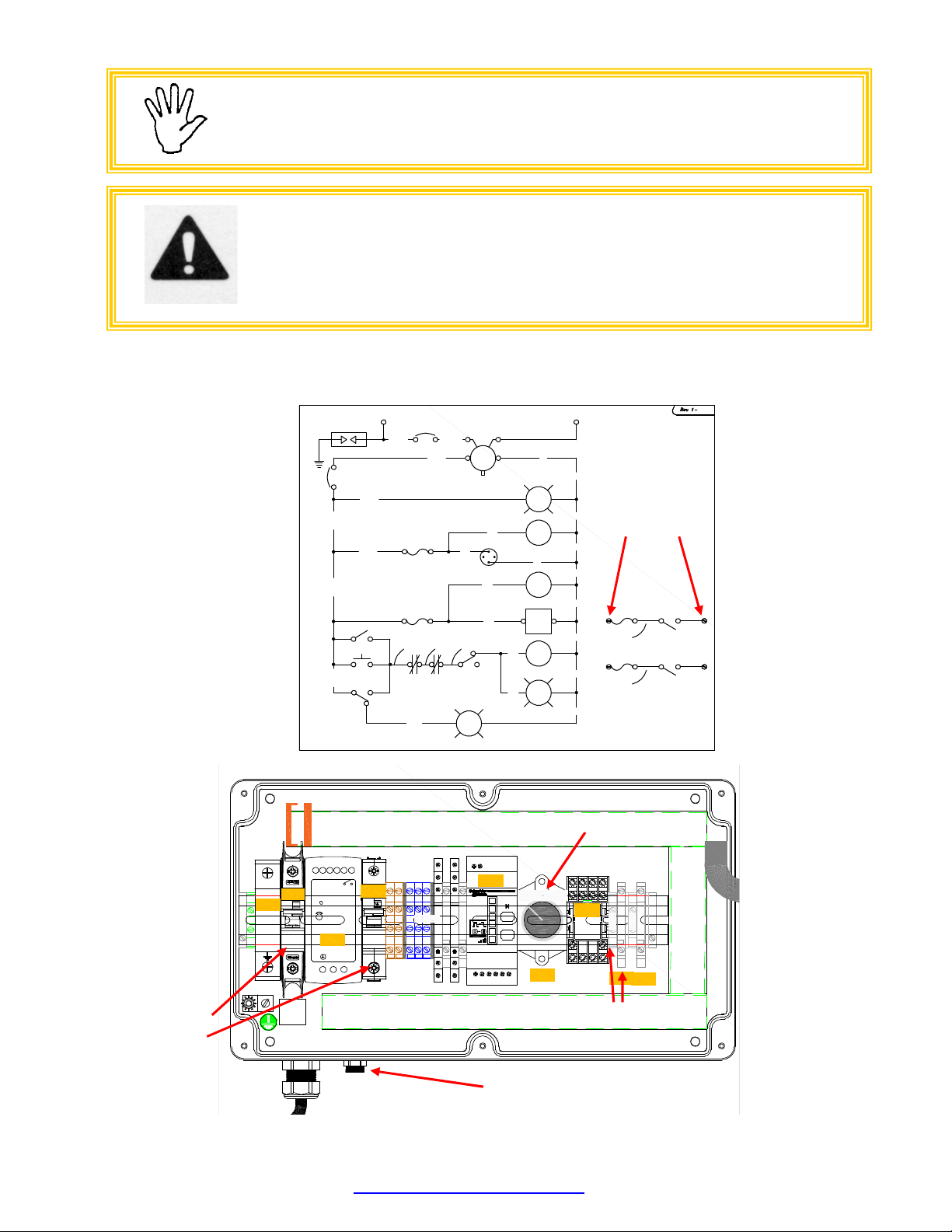

Connect the control box to a 120VAC, 1PH separate breaker circuit from the building 120VAC sub-panel

(lighting panel).

CABLE CONNECTOR

7ELECHARTRS0001