© Motor City Wash Works, Inc. 48285 Frank, Wixom Michigan 48393 U.S.A. Phone: 248.313.0272 ▪ Fax: 248. 313.0271

8MANULDNSINS003 03-21-18 www.motorcitywashworks.com 1

SINGLE AND THREE BRUSHES DRY-N-SHINE Rev 3

INSTALLATION MANUAL

TABLE OF CONTENTS

Equipment Specifications Page: 1

Equipment Features Page: 1

Suggested Tools and Installation Materials Page: 2

Installation Instructions Page: 3

Electrical Installations Page: 17

Pneumatic Installations Page: 28

Plumbing Installations Page: 29

Operations and Startup Page: 30

Maintenance Page: 45

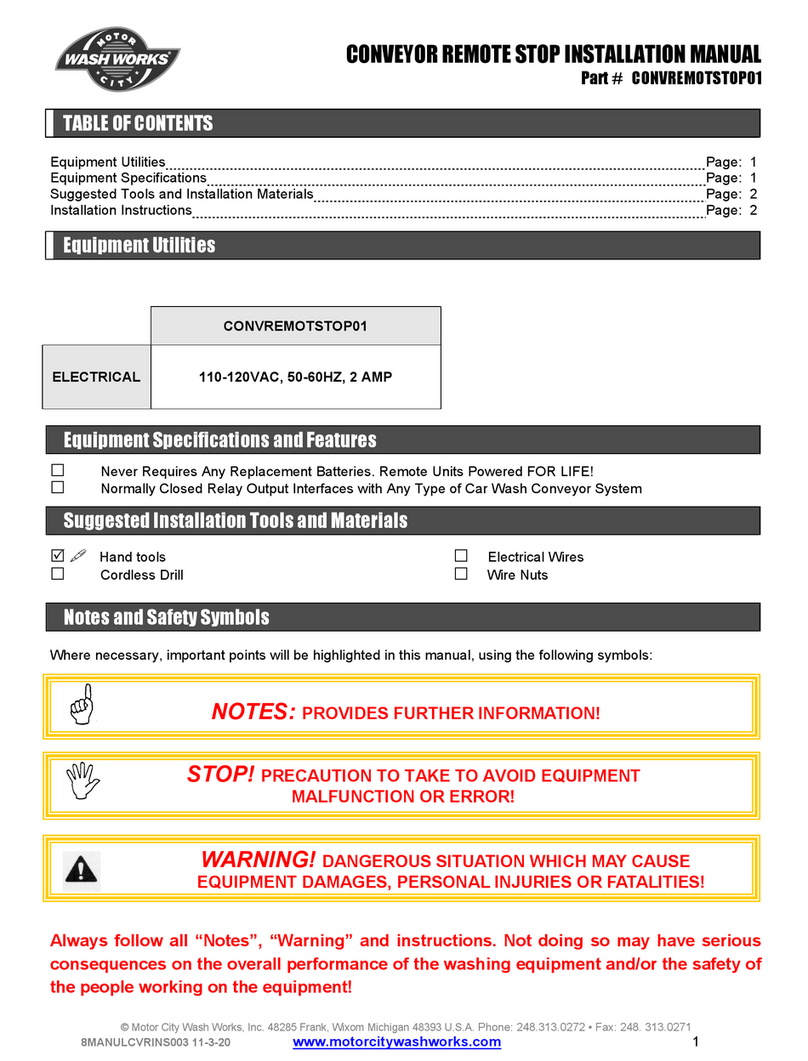

Equipment Requirements

Notes and safety Symbols

Where necessary, important points will be highlighted in this manual, using the following symbols:

NOTE: PROVIDES FURTHER INFORMATION!

WARNING! DANGEROUS SITUATION WHICH MAY CAUSE

EQUIPMENT DAMAGE, PERSONAL INJURIES OR FATALITIES!

Always follow all notes, warnings, and instructions. Failure to do so may have serious consequences on

the overall performance of the equipment and/or the safety of the people working on the equipment!

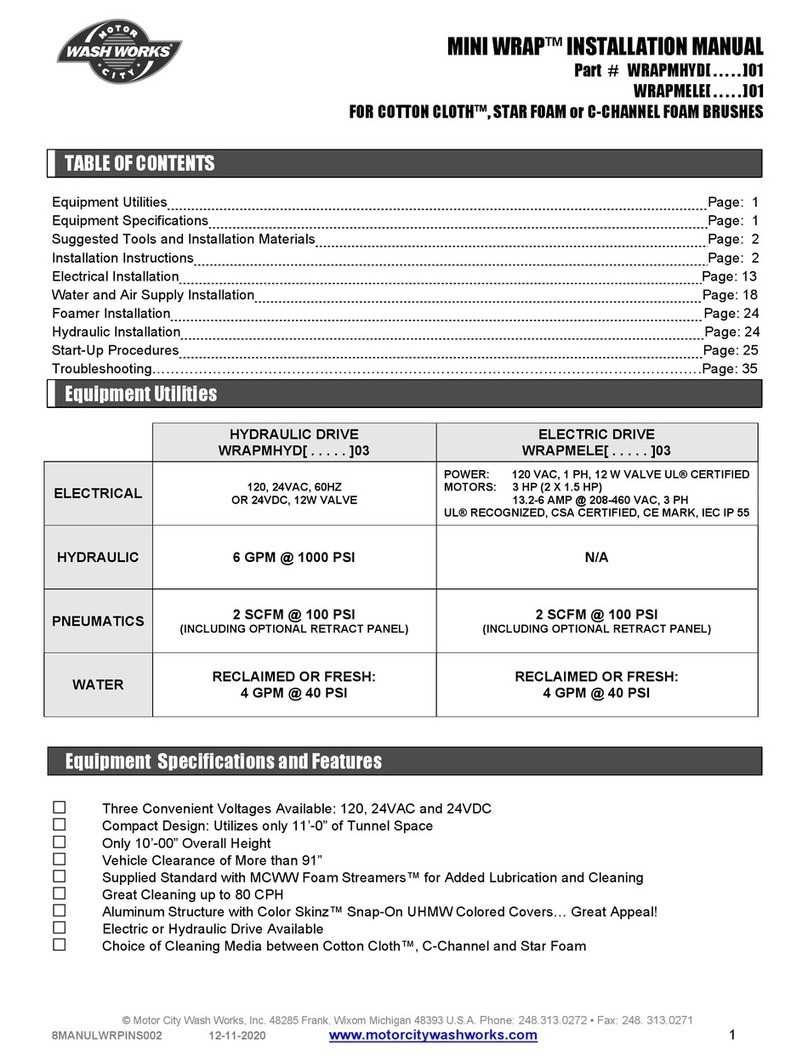

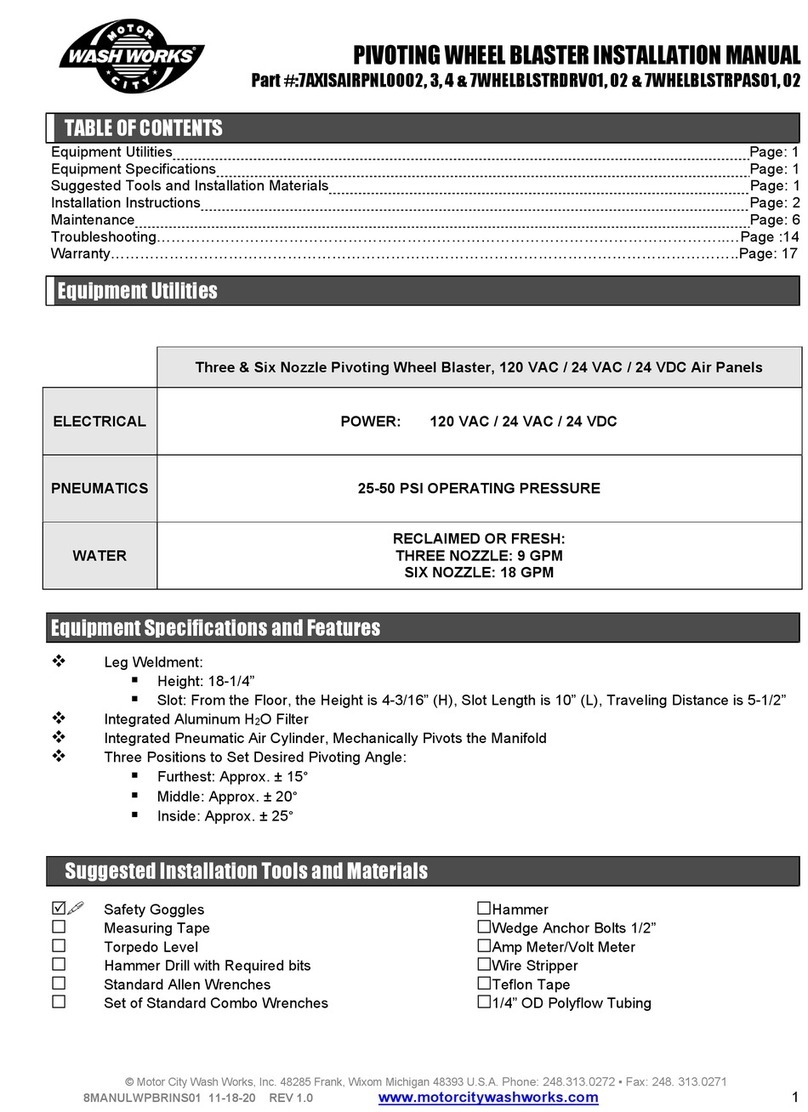

TOP WHEEL ONLY TOP WHEEL AND SIDE WHEELS

ELECTRICAL

POWER:

208V SYSTEM: ONE 40 AMPS 3PH CIRCUIT

480V SYSTEM: ONE 20 AMPS 3PH CIRCUIT

CONTROL:

1 TOP WHL READY SIGNAL CW CONTROLLER

1 E-STOP OK SIGNAL CW CONTROLLER

POWER:

208V SYSTEM: ONE 40 AMPS 3PH CIRCUIT

480V SYSTEM: ONE 20 AMPS 3PH CIRCUIT

CONTROL:

1 TOP WHL READY SIGNAL CW CONTROLLER

1 SIDE WHLS READY SIGNAL CW CONTROLLER

STOP OK SIGNAL CW CONTROLLER

PNEUMATICS 3 SCFM 3 SCFM

WATER 10 GPM @ 40 PSI 10 GPM @ 40 PSI

STOP! PRECAUTION TO TAKE TO AVOID EQUIPMENT

MALFUNCTION OR ERROR!