ix

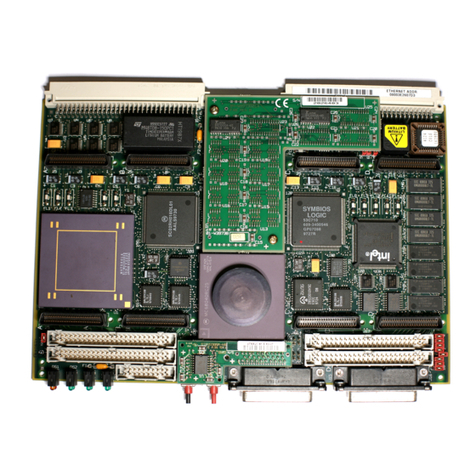

ASICs..................................................................................................................4-3

Block Diagram...........................................................................................................4-4

Functional Description...............................................................................................4-4

Data Bus Structure..............................................................................................4-4

Microprocessor ...................................................................................................4-6

MC68xx040 Cache......................................................................................4-6

No-VMEbus-Interface Option............................................................................4-7

Memory Options.................................................................................................4-7

DRAM .........................................................................................................4-7

SRAM..........................................................................................................4-8

About the Battery.........................................................................................4-9

EPROM and Flash Memory......................................................................4-10

Battery-Backed-Up RAM and Clock................................................................4-11

VMEbus Interface and VMEchip2...................................................................4-12

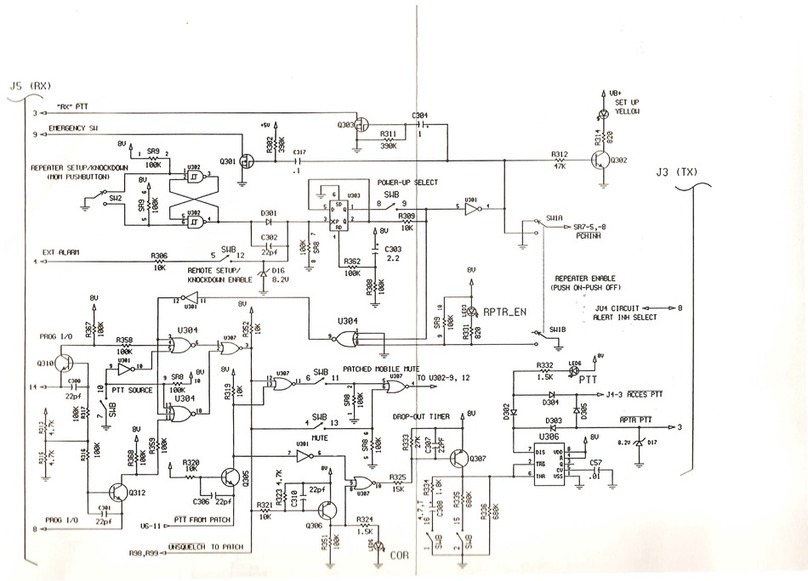

I/O Interfaces ....................................................................................................4-12

Serial Communications Interface ..............................................................4-12

IndustryPack (IP) Interfaces......................................................................4-16

Ethernet Interface ......................................................................................4-16

SCSI Interface............................................................................................4-17

SCSI Termination......................................................................................4-17

Local Resources................................................................................................4-18

Programmable Tick Timers.......................................................................4-18

Watchdog Timer........................................................................................4-18

Software-Programmable Hardware Interrupts...........................................4-19

Local Bus Timeout ....................................................................................4-19

Local Bus Arbiter..............................................................................................4-20

Connectors........................................................................................................4-20

Remote Status and Control........................................................................4-20

CHAPTER 5 Pin Assignments

Connector Pin Assignments.......................................................................................5-1

IndustryPack A, B, C, D Connectors.........................................................................5-1

Remote Reset Connector - J6.....................................................................................5-3

Serial Port Module Connector - J15...........................................................................5-3

Serial Port 2 Connector - J18.....................................................................................5-4

Serial Port 1/Console Connector - J25.......................................................................5-5

VMEbus Connectors - P1, P2....................................................................................5-6