SFH-50 Quick Start Guide

iii

SFH-50 Quick Start GuideSFH-50Quick Start Guide

Contents

Chapter 1 Quick Start..................................................................... 1

Safety........................................................................................1

Overview .................................................................................1

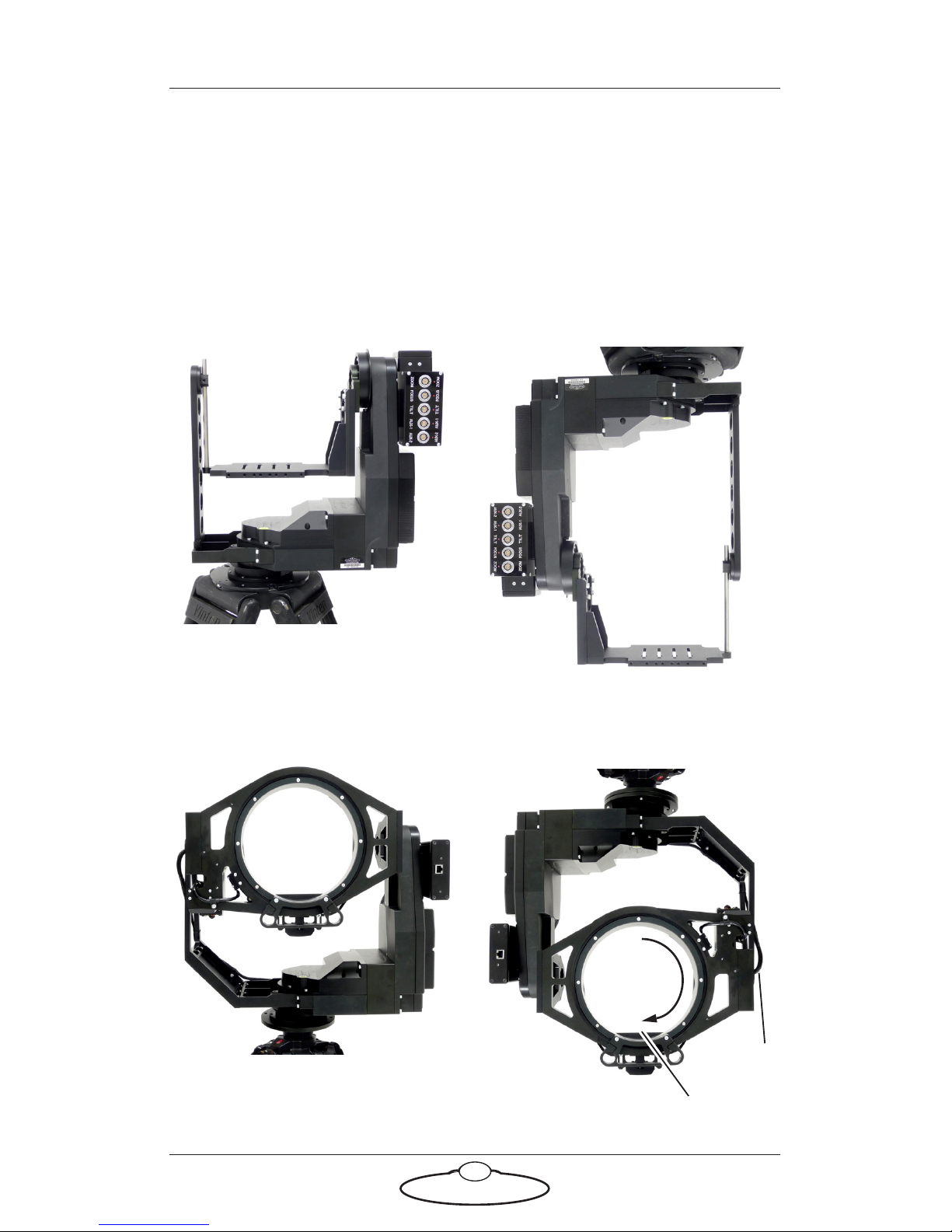

Setting up the hardware ........................................................2

Connecting the cables ...........................................................9

Quad-box example, for an SFH-50 head with

stepper motors...............................................................9

Ulti-box example, for an SFH-50 head with

servo motors................................................................11

Your first session ..................................................................12

Subsequent sessions.............................................................15

Appendix 1 Troubleshooting........................................................... 16

Typical symptoms, causes, and actions .............................16

Working with Local Area Networks ..................................17

Introduction to LAN addresses ................................17

Managing LAN addresses with Flair........................19

Appendix 2 SFH-50 Panel ............................................................... 23

Introduction to SFH-50 connections ................................23

Interface boxes ............................................................23

Notes on head-controller communication

methods........................................................................23

Quad-box and Octo-box connector summary ................24

Quad-box and Octo-box connector pin-out

information...........................................................................26

Stepper motor connector...........................................26

Power 18-36 Volts connector ....................................26

Serial RS232 connector ..............................................26

Trigger connector .......................................................27

Data In connector.......................................................27

Data Out connector....................................................27

Ulti-box connector summary.............................................28

Ulti-box connector pin-out information ..........................30

Servo motor connector ..............................................30

Program serial connector ..........................................30

Power connector .........................................................31

Camera Accessory connector....................................31

Data In connector.......................................................32