TC-49P

www.multispanindia.com

Page - 4

All safety related codifications, symbols and instructions that appear in this operating manual

or on the equipment must be strictly followed to ensure the safety of the operating personnel as

well as the instrument.

If all the equipment is not handled in a manner specified by the manufacturer, it might impair the

protection provided by the equipment .

Product improvement and upgrade is a constant procedure. So for more updated operating information and support,

Please contact our helpline : +9

1-99

7899

14

7

4/7

6/82 or Email at ser

[email protected] V

er: 0

1-20

1

7

=> Read complete instructions prior to installation and operation of the unit.

WARNING : Risk of electric shock.

3) Cable used for connection to power source, must have a cross section of 1mm or greater. These wires

should have insulations capacity made of at least 1.5kV.

2) To reduce electro magnetic interference, use wire with adequate rating and twists of the same of

equal size shall be made with shortest connection.

4) When extending the thermocouple lead wires, always use thermocouple compensation wires for wiring

for the RTD type, use a wiring material with a small lead resistance (5Ω max per line)and no resistance

differentials among three wires should be present.

1) To prevent the risk of electric shock power supply to the equipment must be kept OFF while doing the

wiring arrangement. Do not touch the terminals while power is being supplied.

5) A better anti-noise effect can be expected by using standard power supply cable for

the instrument.

1) This equipment, being built-in-type, normally becomes a part of main control panel and such in case the

terminals do not remain accessible to the end user after installation and internal wiring.

2) Do not allow pieces of metal, wire clippings, or fine metallic fillings from installation to enter the product

or else it may lead to a safety hazard that may in turn endanger life or cause electrical shock to the operator.

3) Circuit breaker or mains switch must be installed between power source and supply terminal to

facilitate power ‘ON’ or ‘OFF’ function. However this mains switch or circuit breaker must be

installed at convenient place normally accessible to the operator.

4) Use and store the instrument within the specified ambient temperature and humidity ranges as

mentioned in this manual.

Warning Guidelines

Installation Guidelines

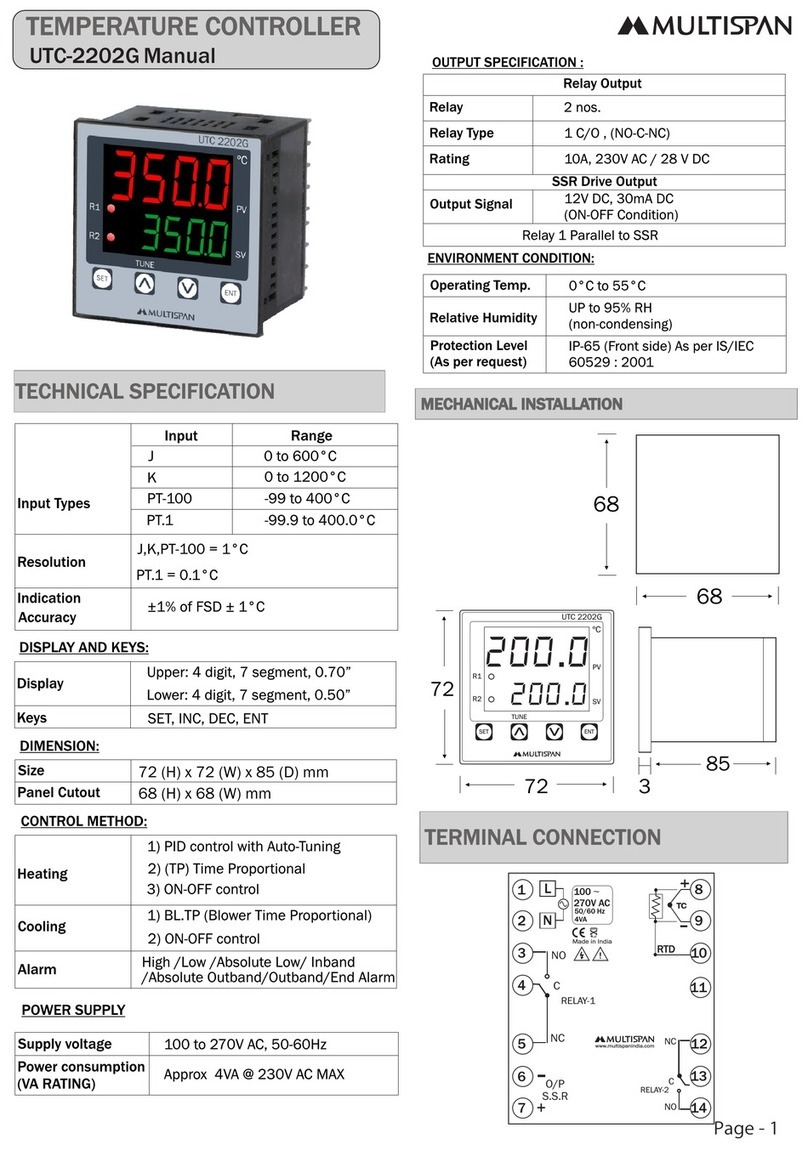

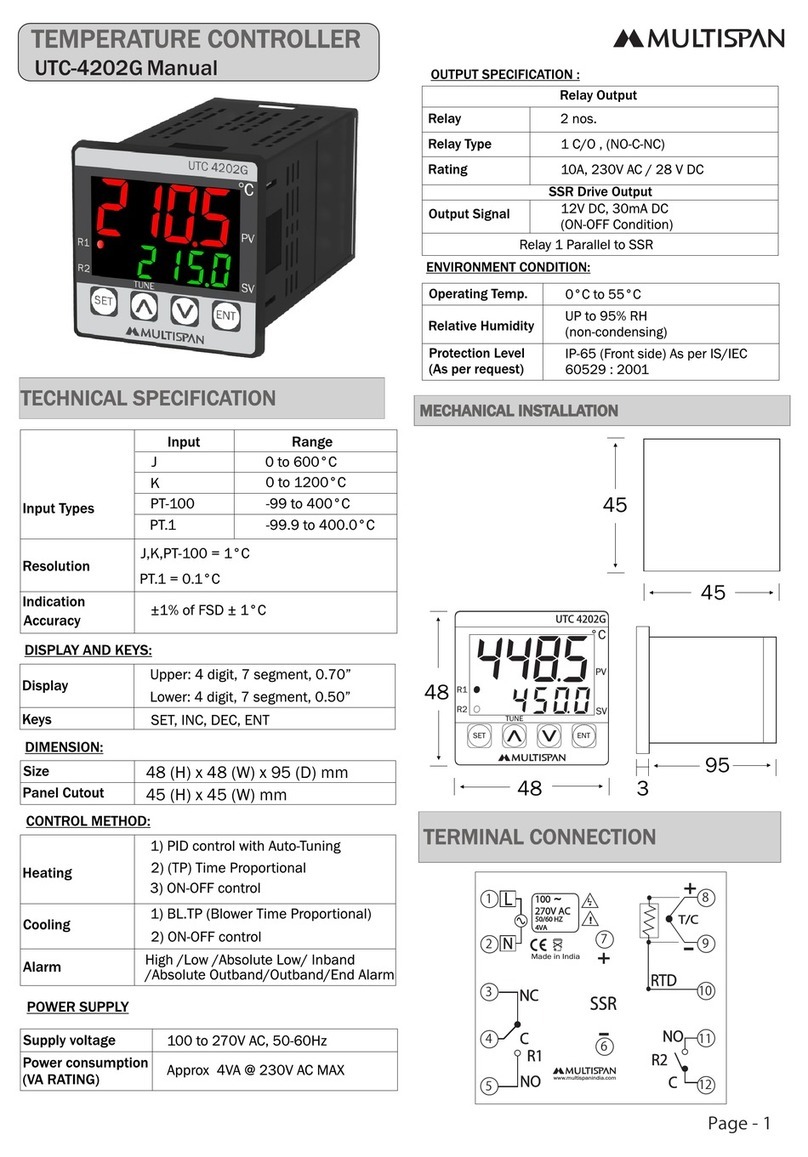

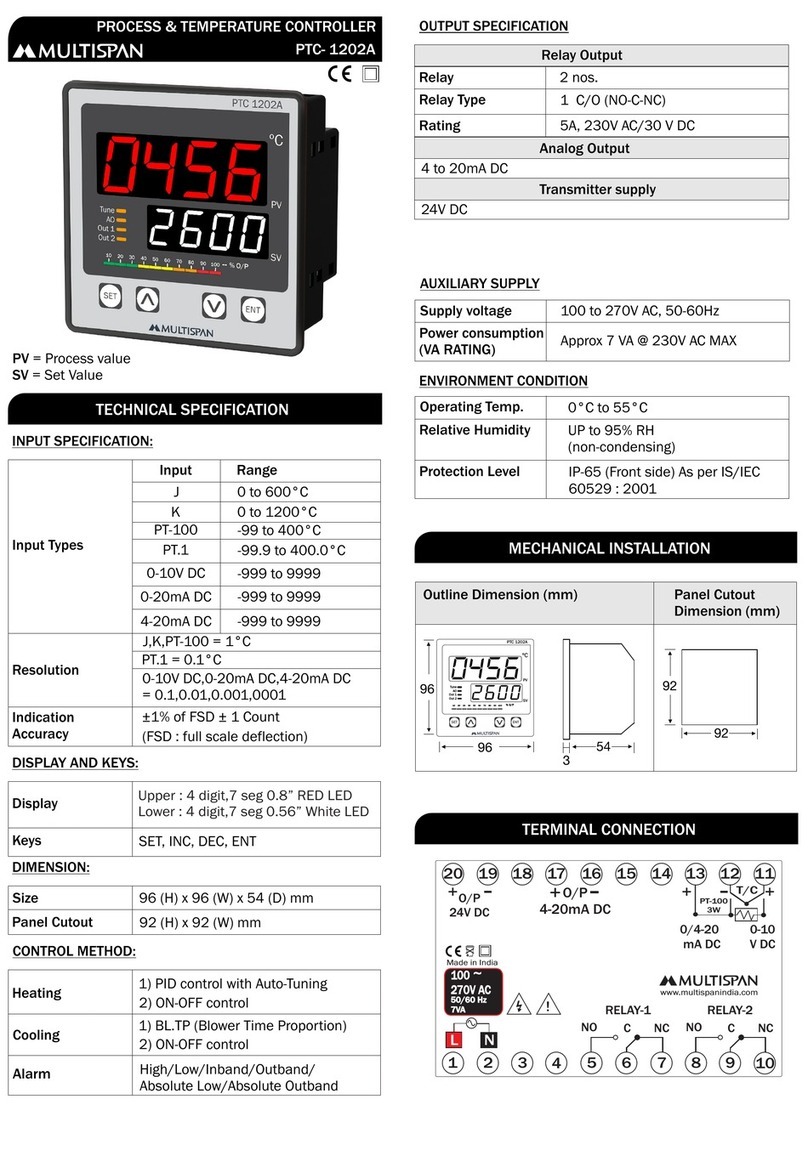

Mechanical Installation

Maintenance

Safety Precautions

1) Prepare the panel cutout with proper dimensions as show above.

2) Fit the unit into the panel with the help of clamp given.

3) The equipment in its installed state must not come in close proximity to any heating source,

caustic vapors, oils steam, or other unwanted process by products.

4) Use the specified size of crimp terminal (M3.5 screws) to wire the terminal block. Tightening the

screws on the terminal block using the tightening torque of the range of 1.2 N.m.

5) Do not connect anything to unused terminals.

1) The equipment should be cleaned regularly to avoid blockage of ventilating parts.

2) Clean the equipment with a clean soft cloth. Do not use isopropyl alcohol or any

other cleaning agent.

3) Fusible resistor must not be replaced by operator.

2

A

B

C

D

EF

MODEL A

48mm 48mm 44mm 44mm 3mm 70mm

BC

D E

F

DIMENSIONS

68mm - 2.68 inches

60mm - 2.36 inches

TC 49P

TUNE

°C