18

⑥Never operate or handle the Spindle and brushless motor until you have thoroughly

read the Operation Manuals and safe operation has been con¿rmed.

1) To prevent injuries / damages, check the Spindle, brushless motor and cutting tool

for proper installation, before operating the Spindle and brushless motor.

2) Before disconnecting the Spindle and brushless motor, always turn the control

power off and turn the compressed air supply to the CONTROLLER off. Then it is

safe to remove the Spindle and brushless motor.

⑥When installing a Spindle to a ¿xed base, make sure the ¿xed base is grounded in

order to avoid the risk of an electric shock

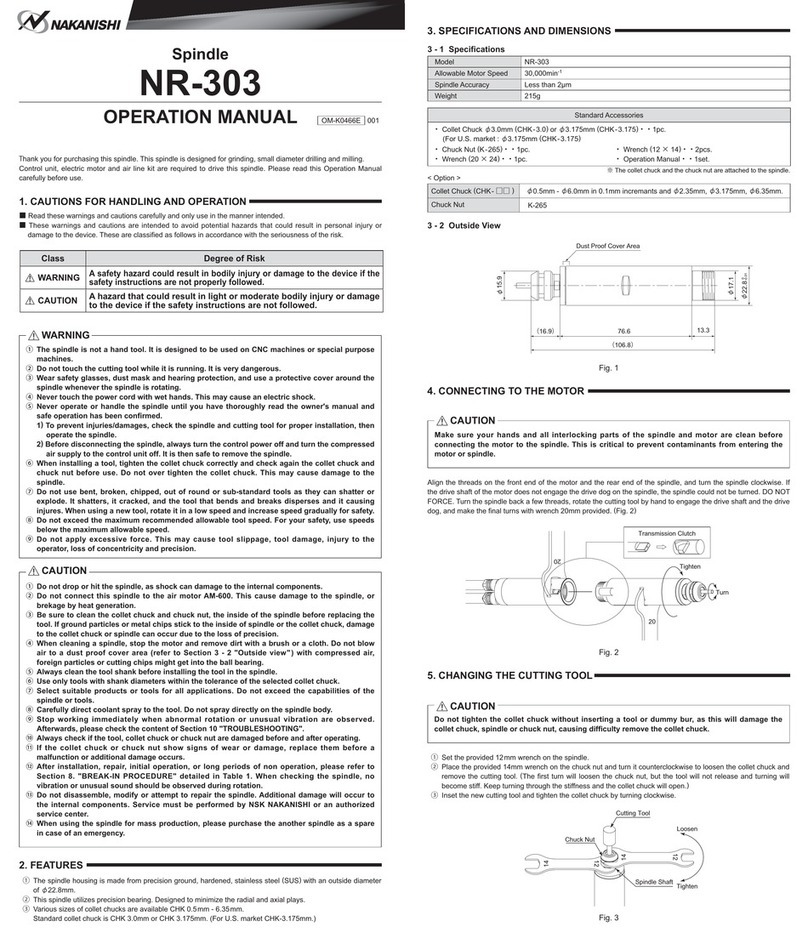

⑦Stop the brushless motor prior to operating the lever. If lever operation is performed

during spindle rotation, contact with internal components will damage the spindle.

⑧Make sure that lever position is LOCK before rotating with mounting cutting tool.

⑨Ensure that the mounted the collet holder to the Spindle before rotate the Spindle.

⑩When installing a tool in the collet holder, tighten the collet correctly then re-check the

collet and collet nut before operating. Do not overtighten the collet. This may cause

damage to the collet holder.

⑪Do not use bent, broken, chipped, out of round or sub-standard tools, as this may

cause them to shatter or explode. Tools with fractures or a bent shank will cause injury

to the operator. When using a new tool, rotate it in a low speed and increase speed

gradually for safety.

⑫Do not exceed the maximum recommended allowable tool speed. For your safety, use

speeds below the maximum allowable speed.

⑬Do not apply excessive force. This may cause tool slippage, tool damage, injury to the

operator or loss of concentricity and precision.

WARNING

①Do not drop or hit this Spindle, as shock can damage to the internal components.

②Do not connect this Spindle to the reduction gear. This may cause collet breakage by

overload.

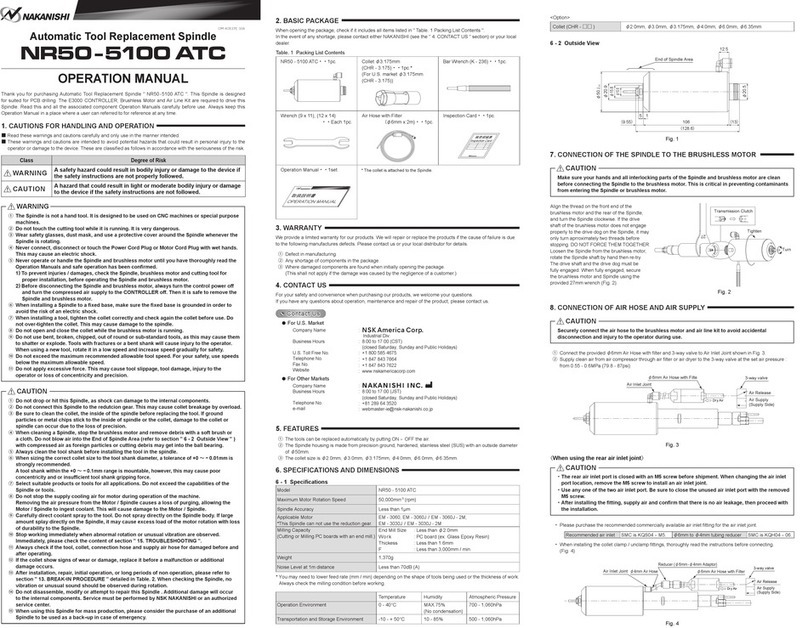

③Make sure the inner face of the spindle and taper surfaces of the collet holder are clean

(Clean them if debris is found.) mounting or before replacing the collet holder.

Ground particles or metal chips stuck to the surface will cause run-out or damage to

the collet and spindle. Loss of concentricity will cause spindle damage due to the lack

of precision.

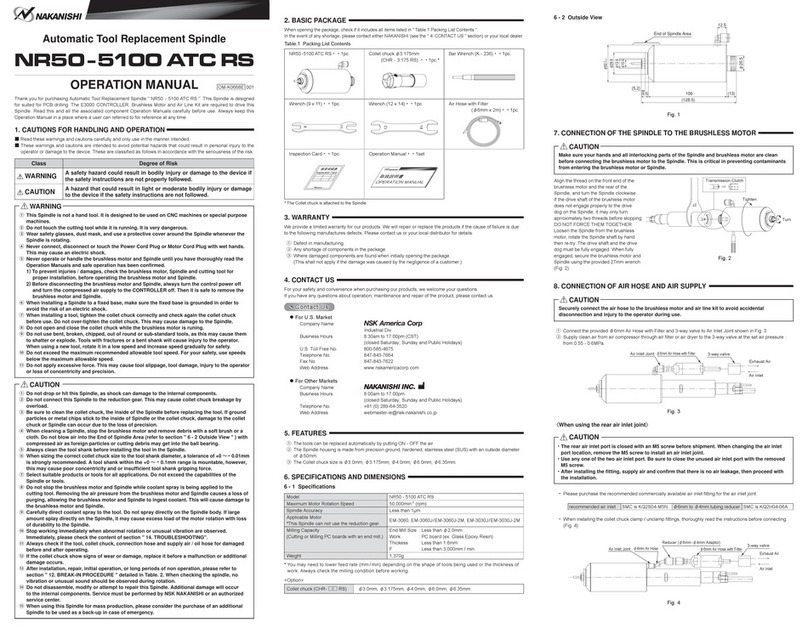

④When cleaning a Spindle, stop the brushless motor and remove debris with a soft

brush or a cloth. Do not blow air into the dust proof cover area (refer to section " 6 - 2

Outside View " ) with compressed air as foreign particles or cutting debris may get into

the ball bearing.

⑤When replacing the tool, make sure the tool shank, collet, collet nut, and inner face of

the collet holder are clean. If ground particles or metal chips stick to the inside of the

collet, damage to the collet holder or spindle can occur due to the loss of precision.

⑥

When sizing the correct collet size to the tool shank diameter, a tolerance of +0 〜

-

0.01mm

is strongly recommended.

A tool shank within the +0 〜

-

0.1mm range is mountable, however, this may cause poor

concentricity and or insuf¿cient tool shank gripping force.

CAUTION