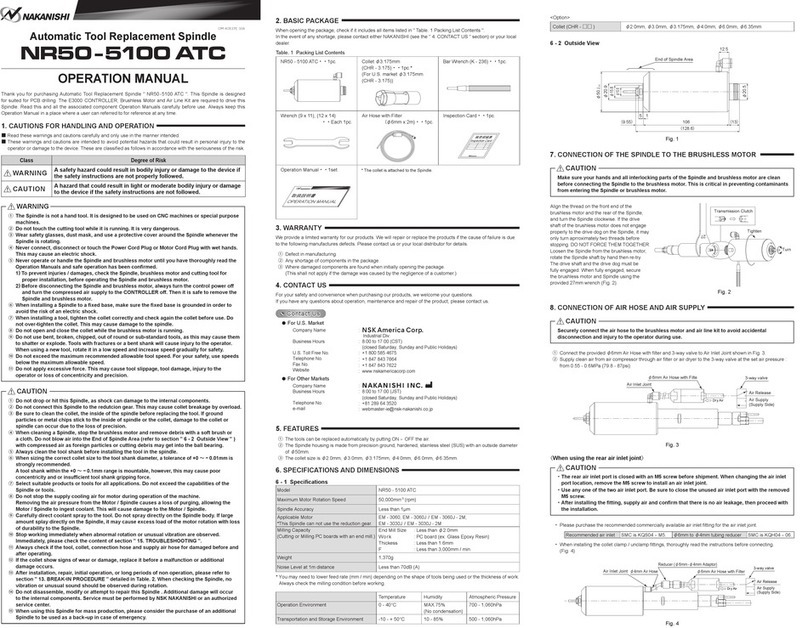

7Installation of spindle

8How to supply air for debris protection

9Guidance for belt installation

10 Break-in procedures

11 Pulley removal procedures

12 Cautions when using grindstone

13 Trouble shooting

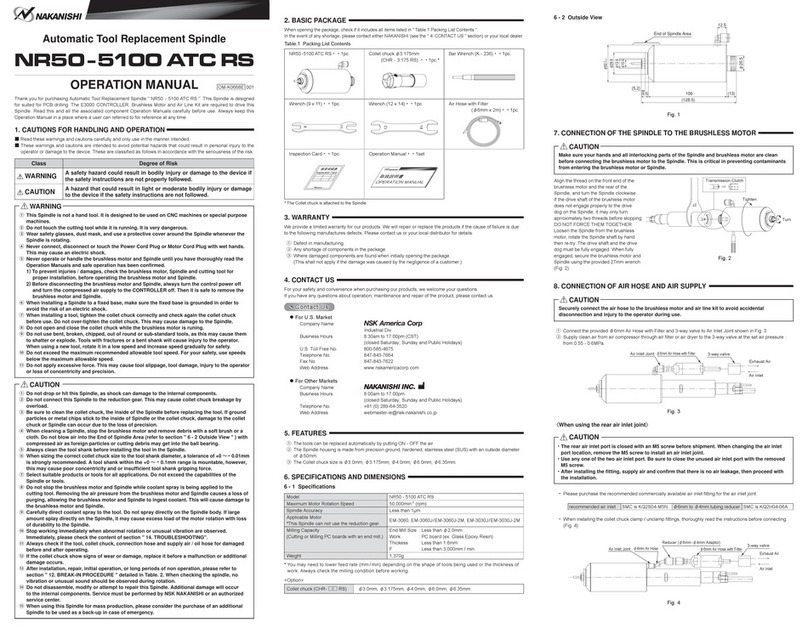

When installing spindle on a holder, it is not recommendable to fix the spindle with a fastening bolt directly

as shown in Fig. 6 because the sheath is deformed and creates rotating malfunction, heat generation, etc.

Therefore, the installation as shown in Fig. 7 is recommended. In case it is impossible, install it as shown

in Fig. 8.

Fig. 6 Fig. 7 Fig. 8

Fastening Bolt Fastening Bolt Fastening Bolt Slit of Bush

Slit

Bush with Slit

Use a standard screw driver to remove the screw and screw in

a M5 0.8 thread quick disconnect fitting.

For spindles with 2 sealing screws you can use either location.

Supply clean, dry air between 0.1-0.3 MPa pressure.

(Please use caution as contaminated air will void warranty.)

For high speed operation increase belt tension to prevent slipage. During normal speed operation please

reduce belt tension to increase rear bearing life.

If the motor pulley and spindle pulley are offset high speed rotation will produce excess vibration, causing

heating build up and reduced life expectancy.

Please limit pulley center to center offset to less than 0.2

mm

.

Please follow the belt makers usage guidelines.

CAUTION :

Please cover all rotating parts to prevent injury.

Danger : Do not use beyond the peripheral speed of 2,000m/min. because it is dangerous.

Fig. 9

PS Series spindles are high speed spindles, but the following break-in procedures are necessary.

During shipping and storage grease settling will occur. If the spindle is rotated at high speed quickly.

Uneven grease coverage will cause heat build up and bearing damage.

After initial fixturing please follow the break-in procedures to insure optimal life expectancy.

Please follow the break-in schedule in table 3.

Table-3 Break-in schedule

Step 1 2 3 4

Maximum

allowable speed

Duration

Checkpoint

30%

15 minute

No abnormal noise

60%

10 minute

80%

10 minute

Same as step 2.

100%

15 minute

Spindle outer case

approximately 20˚C.

Spindle case should be

less than 20˚C. If case

temperature exceeds

20˚C, please shut down

for 20 minutes. After 20

minute cool down

period restart from step

1. If overheating

continues please check

spindle fixture.

Remove the pulley set screw, use a pulley removal tool to remove pulley. Please male a plate to insert

between the pulley removal tool jaws and the pulley to aid in removal.

Plate

Fig. 10

1

2

3

Follow the recommended speed by the manufacturers when using drill, end mill, etc. Do not use them

beyond the recommended speed because it becomes the cause of malfunction.

Make sure the tool shank is clean. If foreign materials and any debris are left in the collet chuck, they

will affect T.I.R specifications.

The recommendable peripheral speed of vitrified grindstone is within the range of 600 to 1,800m/min.

Peripheral speed = D= Grindstone Diameter

N= Grindstone rpm.

D N

1,000

4Mount a stemmed grindstone within 13

mm

of over-hanging

mode. When mounting a stemmed grindstone longer than

13

mm

over-hanging mode, use it by slowing down the motor

speed. (Fig. 11, Table-4)

Fig. 11

Table-4

Over-hang(

mm

)

20

25

50

(min–1)

N0.5

N0.3

N0.1

5

6

7

8

9

10

11

Do not use a poor quality and run-out grindstone with cracks and scratches.

Try to use a grindstone after dressing is made.

In case of grinding, the depth of cutting in one cycle is within 0.02

mm

.

The depth of cutting for single phase grinding is 0.01

mm

. After one cycle of grinding, repeat reciprocating

motion few times and start next cycle of grinding.

Follow the recommended speed by the manufacturers when using drill, end mill, etc. Do not use them

beyond the recommended speed because it becomes the cause of malfunction.

Make sure the tool shank is clean. If foreign materials and any debris are left in the collet chuck, they

will affect T.I.R specifications.

Do not give an excessive shock and do not disassemble uselessly.

It is dangerous to run the run-out grindstone with cracks and bent shank in a high speed suddenly because the

grindstone may be broken of explode and shank may be bent or broken. When rotating a new grindstone or

grindstone without dressing is made, run it with a low air pressure and increase the speed gradually after

confirming the safety.

Table-5

Phenomenon Probable Cause Corrective Action

Vibration of bur

Foreign substance sticking in side

chuck or spindle Clean chuck and spindle interior

In correct chuck nut setting Set chuck nut correctly

Bearings worn out Replace bearings at service center

Noise and abnormal

vibration

Foreign substance sticking in

bearings Replace bearings at service center

Bearings worn out

Tools bent Replace with proper tool

In correct installation of belt Adjust or replace

No rotation Bearings broken Replace with new bearings at

service center

’06.11.003 S

13mm