19

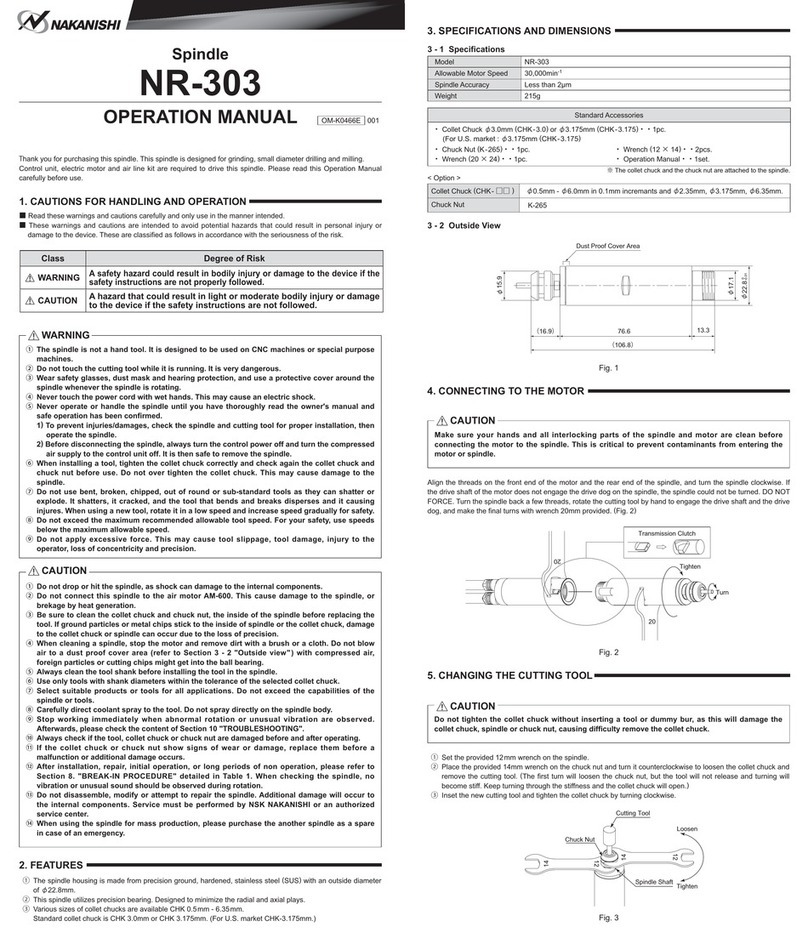

①Do not drop or hit this spindle, as shock can damage to the internal

components.

②When replacing the collet holder, make sure the inner face of the spindle

and taper surfaces of the collet holder are clean. (Clean them if debris is

found.) Ground particles or metal chips stuck to the surface will cause

run-out or damage to the collet chuck and spindle. Loss of concentricity

will cause spindle damage due to the lack of precision.

③When cleaning a spindle, stop the motor and remove debris with a soft

brush or a cloth. Do not blow air into the spindle with compressed air as

foreign particles or cutting debris may get into the ball bearing.

④When replacing the tool, make sure the tool shank, collet chuck, chuck

nut and inner face of the collet holder are clean. If ground particles or

metal chips stick to the inside of the collet chuck, damage to the collet

holder or spindle can occur due to the loss of precision.

⑤When sizing the correct collet chuck size to the tool shank diameter,

a tolerance of +0 ~

-

0.01mm is strongly recommended. A tool shank

within the +0 ~

-

0.1mm range is mountable, however, this may cause

poor concentricity and or insufficient tool shank gripping force.

⑥Select suitable products or tools for all applications. Do not exceed the

capabilities of the spindle or tools.

⑦Carefully direct coolant spray to the tool. Do not spray directly on the

collet holder and spindle body.

⑧Stop working immediately when abnormal rotation or unusual vibration

are observed. Afterwards, please check the content of section " 10.

TROUBLESHOOTING ".

⑨Always check if the tool, collet chuck are damaged before and after

operating.

⑩If the collet chuck, chuck nut or the collet holder show signs of wear

or damage, replace them before a malfunction or additional damage

occurs.

⑩Do not use bent, broken, chipped, out of round or sub-standard tools,

as this may cause them to shatter or explode. Tools with fractures or

a bent shank will cause injury to the operator. When using a new tool,

rotate it in a low speed and increase speed gradually for safety.

⑪Do not exceed the maximum recommended allowable tool speed. For

your safety, use speeds below the maximum allowable speed.

⑫Do not apply excessive force. This may cause tool slippage, tool

damage, injury to the operator or loss of concentricity and precision.

CAUTION

WARNING