P.O. Box 1306, Newport Beach, California 92663 • Phone: 714-751-0488 • Fax: 714-957-1621 • E-Mail: techservice@newmarpower.com

www.newmarpower.com

9

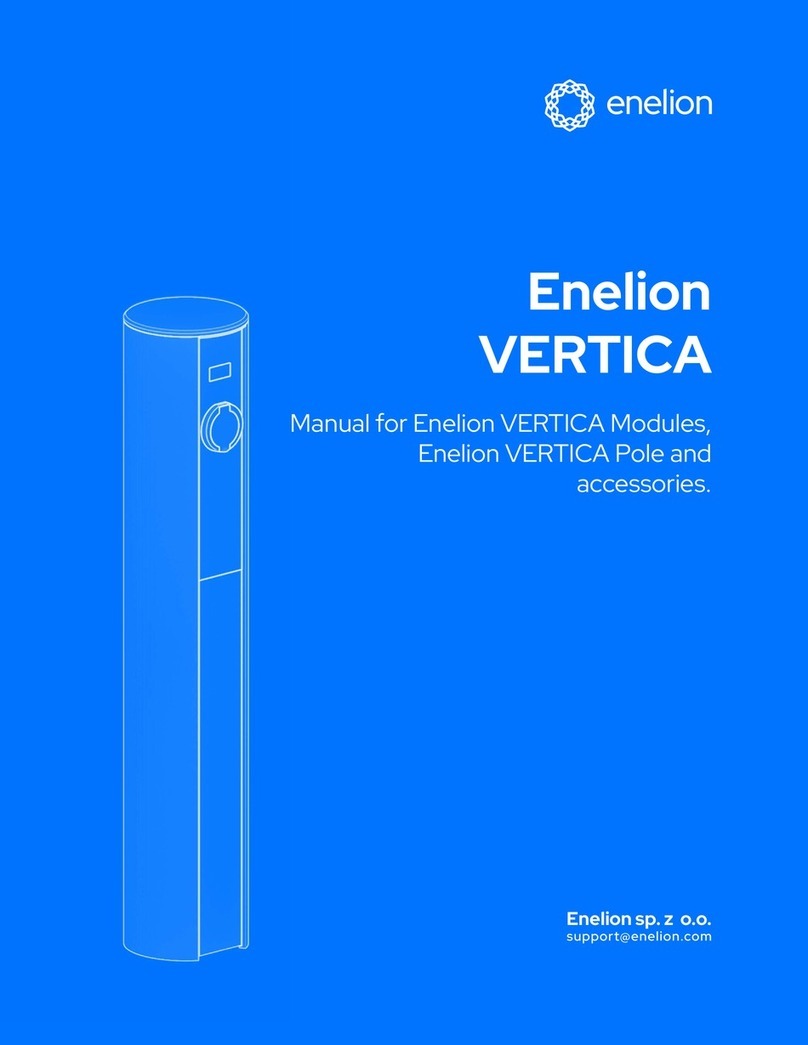

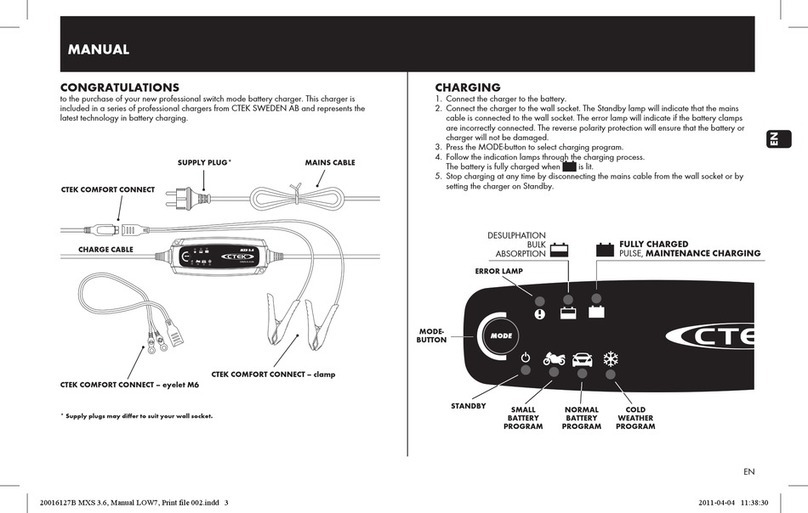

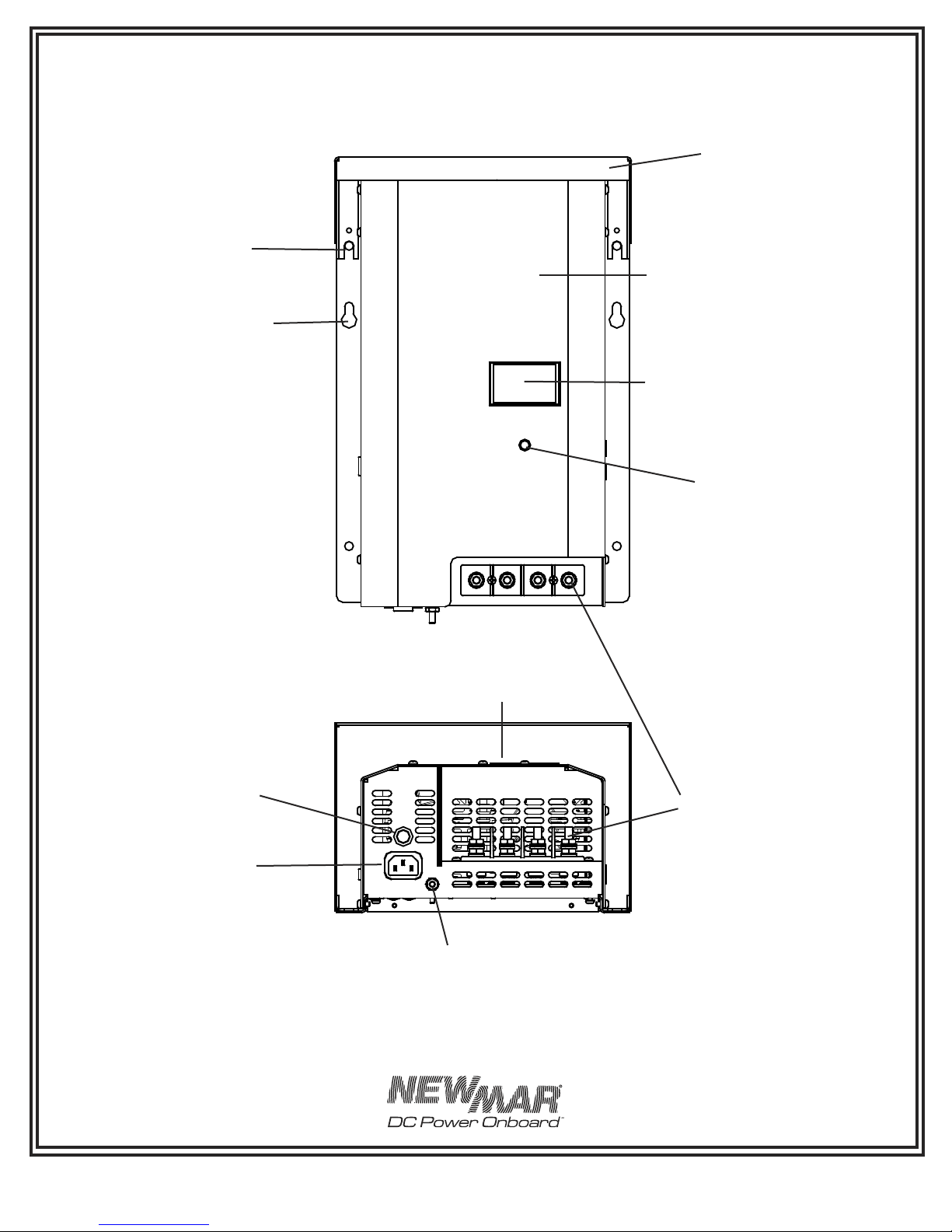

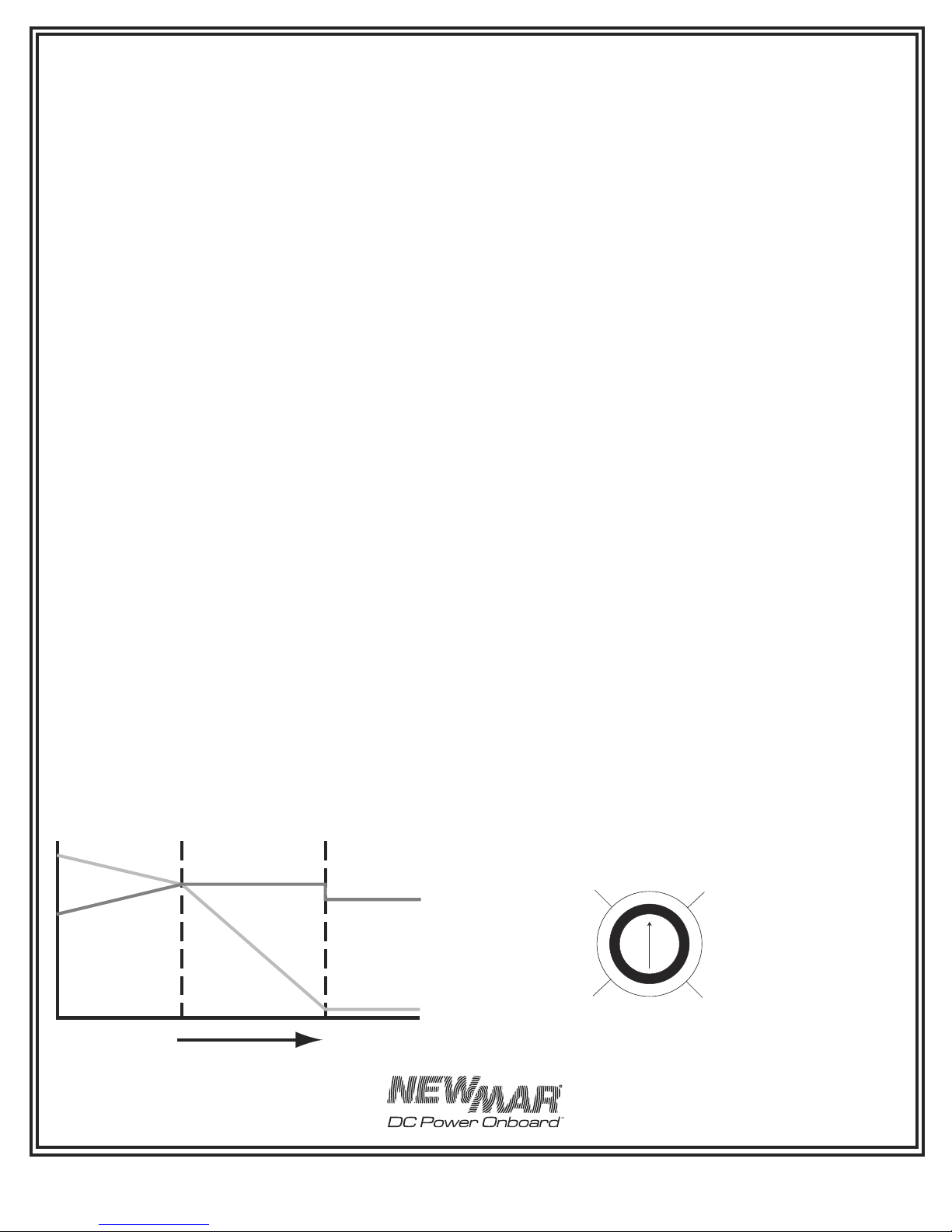

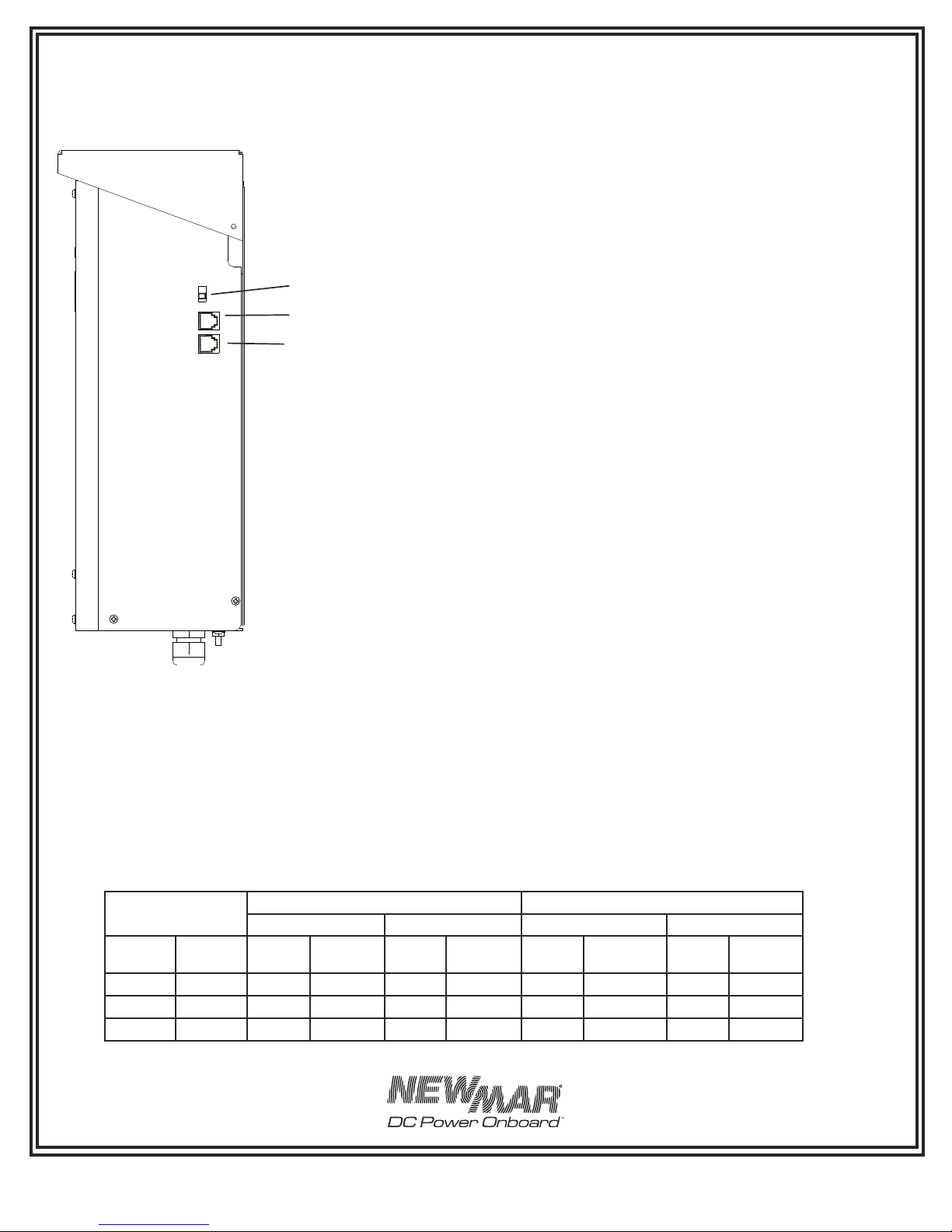

C) Gel-Cell/Lead Acid Selector Switch

According to most battery manufacturers, the ideal charging

regimen for gel-cell and wet or flooded lead acid batteries differs

somewhat.

The gelled electrolyte in a sealed battery may be lost or damaged

by high voltage and, once lost, cannot be replaced as it can

with a wet lead acid battery. Manufacturers of gel-cells usually

recommend an ideal charge voltage which is slightly lower for a

gel-cell than a lead acid battery.

However, when the charger is in the float voltage mode over

lengthier periods of time, gelled electrolyte in a sealed battery

is not susceptible to evaporation, as is the non-immobilized

electrolyte of a wet lead acid battery. This evaporation can be

accelerated by the applied voltage. Consequently, the ideal float

voltage is slightly higher for a gel-cell than a lead acid battery.

The ideal charge/float regimen has been programmed into the

Phase Three Charger for either sealed gel-cell or flooded lead acid

batteries. Simply make the proper selection for your battery type

via the slide switch on the right side of the charger. The switch

positions are indicated on the front panel (up for Gel-Cell batteries,

and down for Lead-Acid/AGM type batteries). Use a ball point

pen or similar object to slide it into the correct position. The charger

is shipped from the factory set for Lead-Acid/AGM batteries.

Note: A wide variety of batteries are available which do not

conform to conventional descriptions as “gel-cell” or “lead-acid”.

You are advised to consult the manufacturer of your particular

battery as to proper charging regimen, and use the battery

type selection switch setting which most closely conforms to the

recommended voltages.

See the SPECIFICATIONS section for the actual preset charge and

float voltages for each battery type/charger model.

D) Remote Monitor Panel Option

A Remote Monitor Panel is available from NEWMAR (model RP)

which will enable you to monitor the charger’s status at-a-glance

from a remote location. Red and green L.E.D.’s indicate whether

the charger is in the bulk, absorption or float phase of the charge

cycle. In addition, the panel features a re-initialize button, which,

when pressed, will cause the charger to restart the three phase

cycle. This resets the time-out circuit (see section B, Time-Out

Circuit, above). Note: The charger may not stay in the bulk or

absorption mode after pressing the re-initialize button. If batteries

are at or near full charge, the charger will quickly revert to the

float mode.

The panel comes pre-wired with 30’ of cable and 4 mounting

screws. Simply install the panel at the desired location and insert

the plug on the end of the cable into the remote panel jack

which is located on the right side of the charger. (See FIGURE

5) The remote panel jack is identified on the front panel. Note:

Inadvertently putting the remote panel plug into the temp

compensation jack (or vice versa) will not harm the charger.

If additional cable length is required, additional cable is

commonly available from most electronics supply retailers such as

Radio Shack/Tandy. Request a 6 conductor modular-to-modular

line cord (part number 279-422, 25 feet long) and a 6 pin modular

in-line non-reversing coupler (part number 279-423).

E) Temperature Compensation Option

Because low battery temperature increases resistance to charging

and high battery temperature reduces impedance, requiring

a lower charge voltage, the ideal charging voltage will vary

depending on the temperature of the battery’s environment when

it is being charged.

If a charger has a fixed output voltage which is ideal at, say 72_

F that same output may cause a battery charged in consistently

high temperature environment to be overcharged, resulting

in excessive loss of electrolyte. Conversely, if the batteries are

in a consistently cool environment, they may be chronically

undercharged, resulting in sulfation of the battery plates. Either of

these two conditions will shorten battery life.

Therefore, the Phase Three Charger is designed to utilize an

optional remote sensor (available from NEWMAR, model TCS-

12/40) which provides automatic temperature compensation. The

remote sensor will signal the charger to fine tune its output voltage

so that it is properly matched to the temperature of the battery/

battery environment. The adjustment rate is approximately -3mV

per cell per _C. (Note: The temperature compensation option is

strongly recommended for sealed, valve-regulated or gel-cell

batteries.)

The remote sensor is provided with 30’ of cable (model TCS-12/24-

40 is provided with 40’ of cable). One end of the cable is plugged

into the temperature compensation jack which is located on the

right side of the charger. (See FIGURE 5.) The temp sensor jack is

identified on the front panel. If additional cable length is required,

additional cable is commonly available from most electronics

supply retailers as Radio Shack/Tandy. Request a 6 conductor

modular-to-modular line cord (part number 279-422, 25 feet long)

and 6 pin modular in-line non-reversing coupler (279-423).

The sensor itself should be mounted on the inside of the battery

box, or more ideally, mounted onto one of the batteries using a

clamp or a small amount of silicon-type adhesive. The sensor has

a hole in the center which will accommodate a #6 screw. If you

have access to the exterior of a wall of the battery box, you may

drill a hole in the wall of the box and run the screw through to

mount the sensor onto the interior wall. Use caution when drilling

so that you do not accidently puncture the case of any battery

inside the box.

Important note: When wiring multiple units in parallel (see section

III-E) and using the temperature compensation option, you must

use a separate sensor for each charger, and the sensors must be

mounted close together in the same battery box or on the same

battery for proper operation.

FIGURE 5: Gell-Cell/Lead Acid Selector