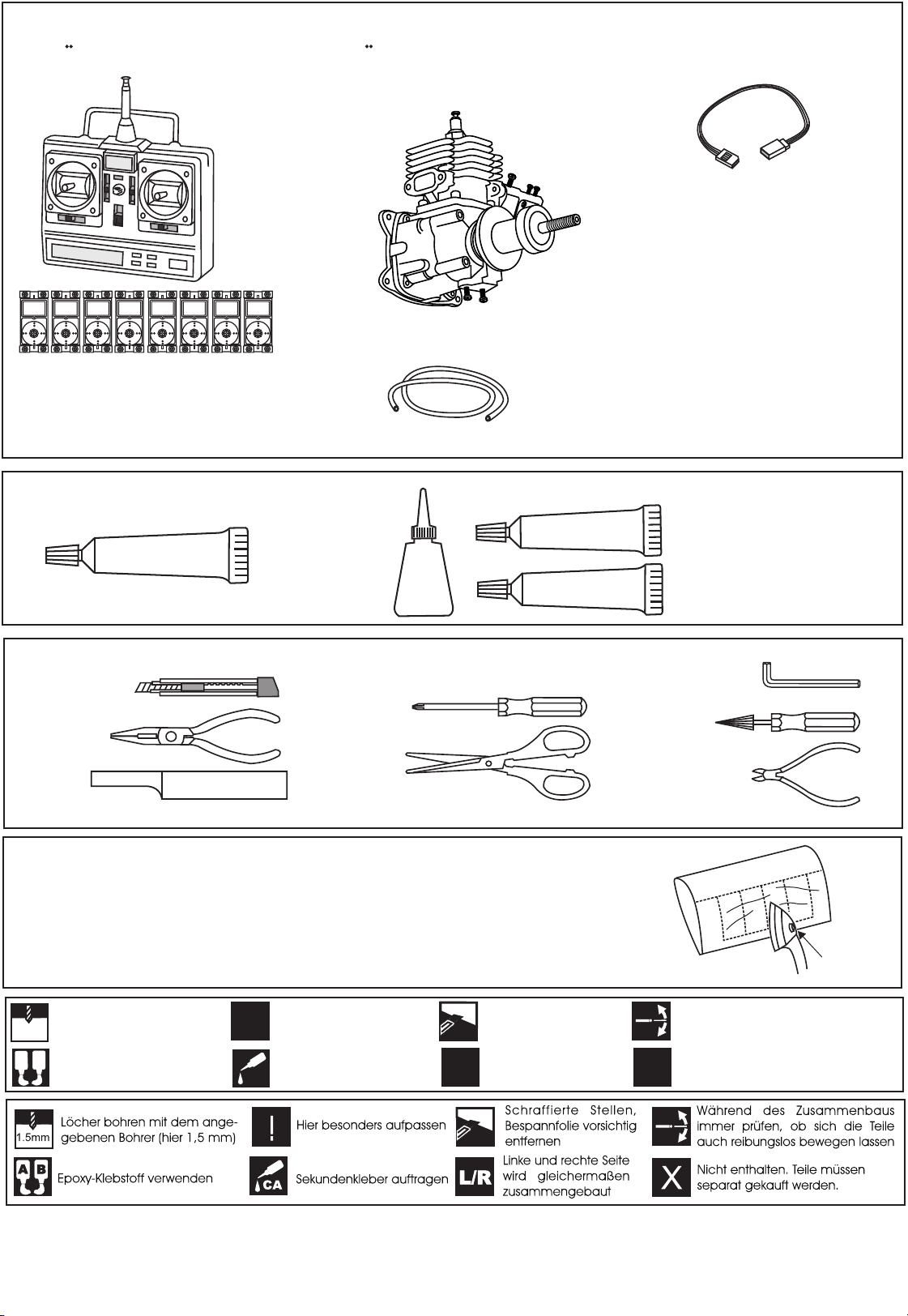

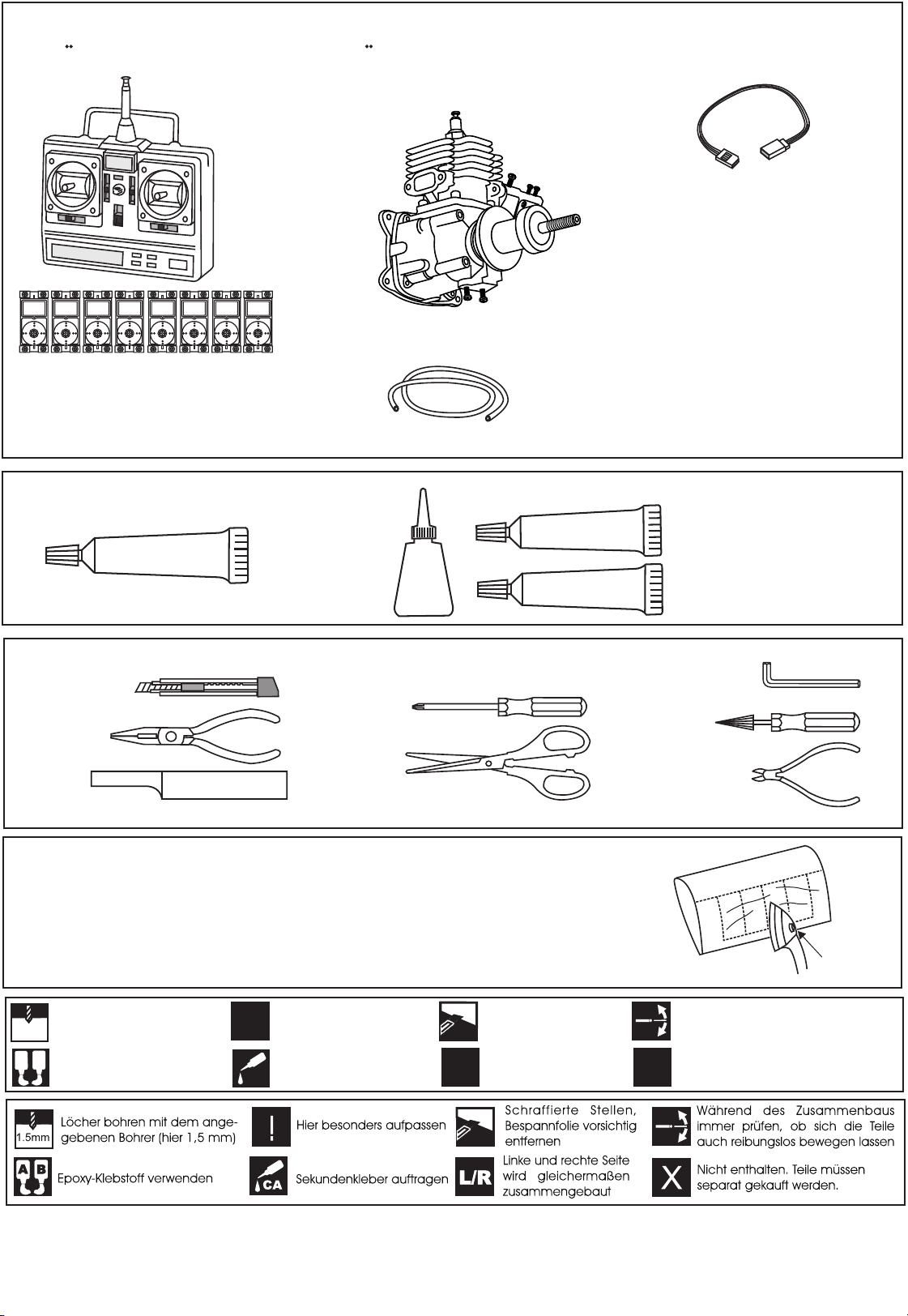

1.5mm

AB

!

CA

L/R

Assemble left and right

sides the same way.

X

Drill holes using the stated

size of drill

(in this case 1.5 mm Ø)

Use epoxy glue

Take particular care here

Hatched-in areas:

remove covering

film carefully

Not included.

These parts must be

purchased separately

Check during assembly that these

parts move freely, without binding

Apply cyano glue

Low setting

SILICON

EPOXY A

EPOXY B

CA

GLUE

Epoxy Glue (5 minute type)

Silicon sealer

Cyanoacrylate

Glue

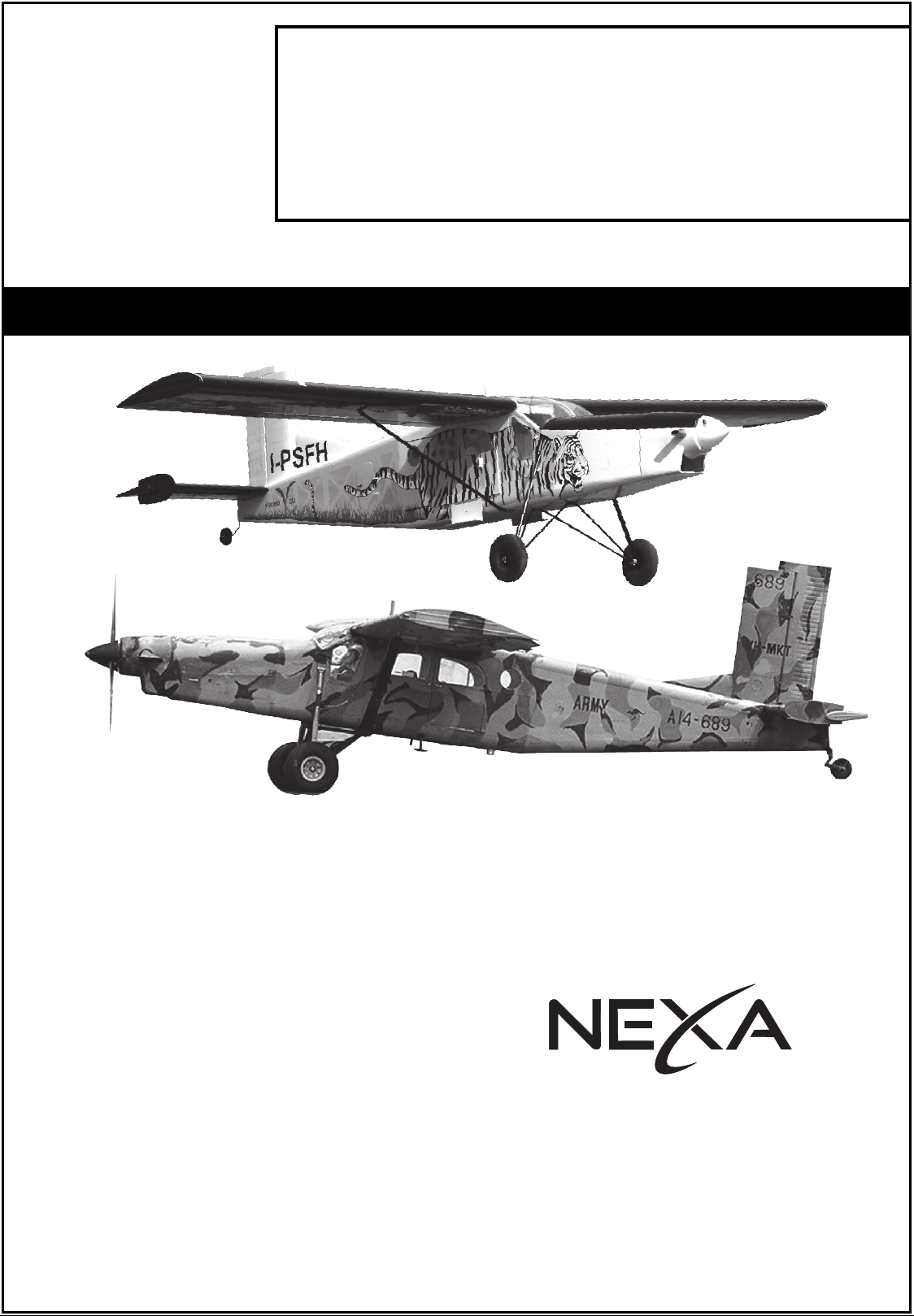

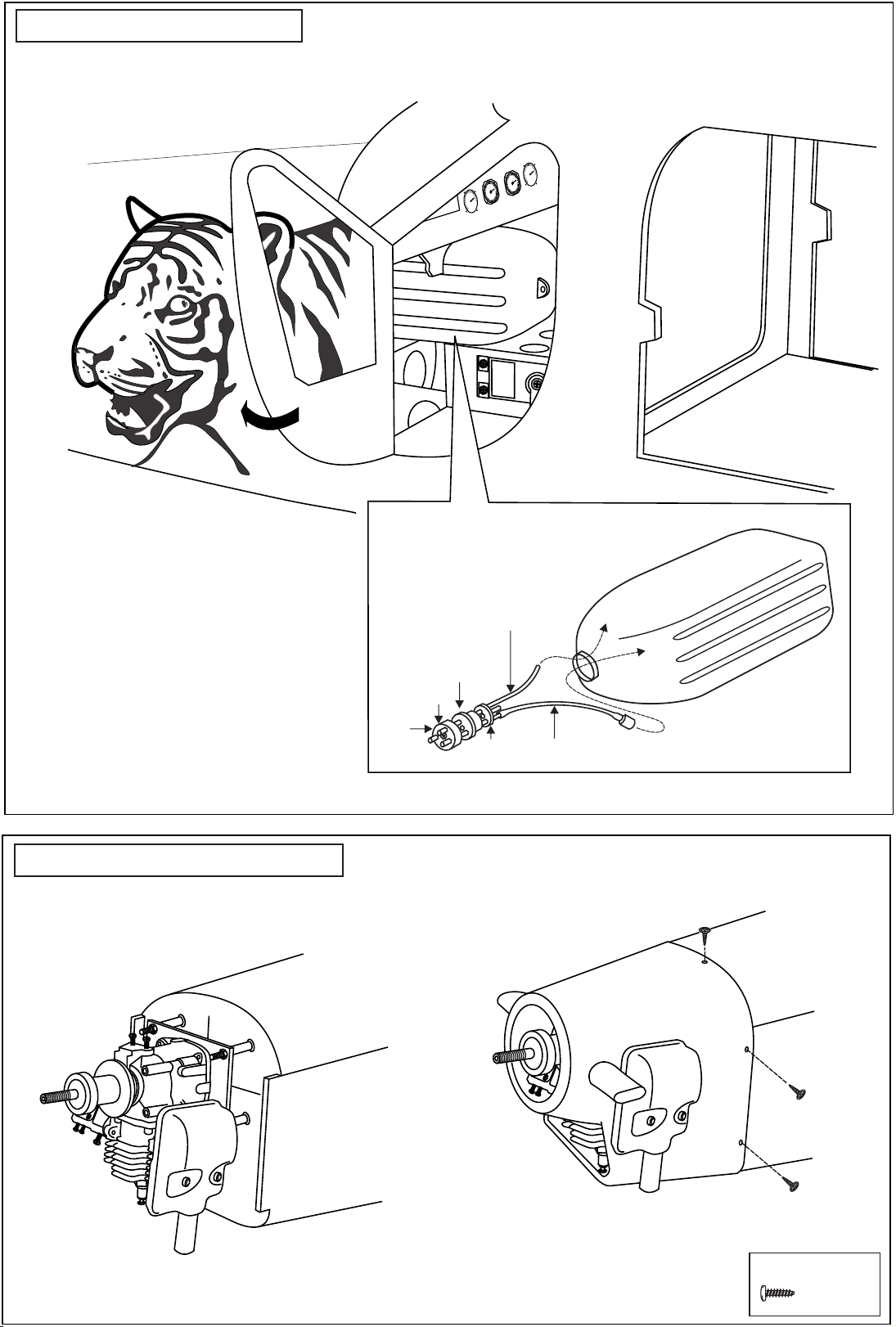

Minimum 6 channel radio

for airplane with 8 servos

Fuel tube

Extension for aileron

servo, Flap servo.

REQUIRED FOR OPERATION (Purchase separately)

Epoxy Glue (30 minute type)

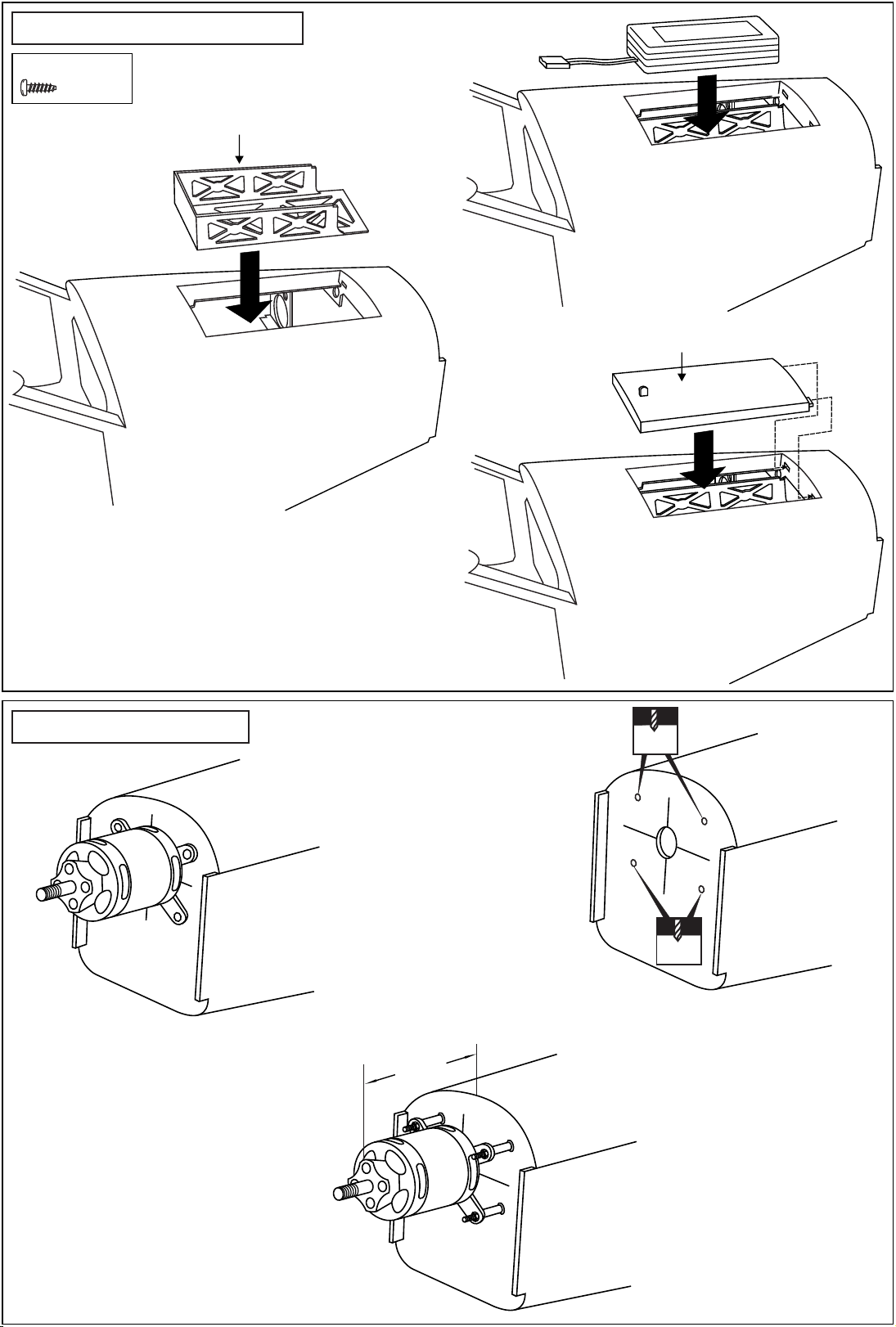

TOLLS REQUIRED

Hobby knife

Needle nose Pliers

Phillip screw driver

Awl

Scissors Wire Cutters

(Purchase separately)

Hex Wrench

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

Sander

Masking tape - Straight Edged Ruler - Pen or pencil - Drill and Assorted Drill Bits

Read through the manual before you begin, so you will have an overall idea of what to do.

(Purchase separately)

.Motor control x1 .Aileron x2

.Elevator x2 .Rudder x1

.Flap x 2

CONVERSION TABLE

1.0mm = 3/64”

1.5mm = 1/16”

2.0mm = 5/64”

2.5mm = 3/32”

3.0mm = 1/8”

4.0mm = 5/32”

5.0mm = 13/64”

6.0mm = 15/64”

10mm = 13/32”

12mm = 15/32”

15mm = 19/32”

20mm = 51/64”

25mm = 1”

30mm = 1-3/16”

45mm = 1-51/64”

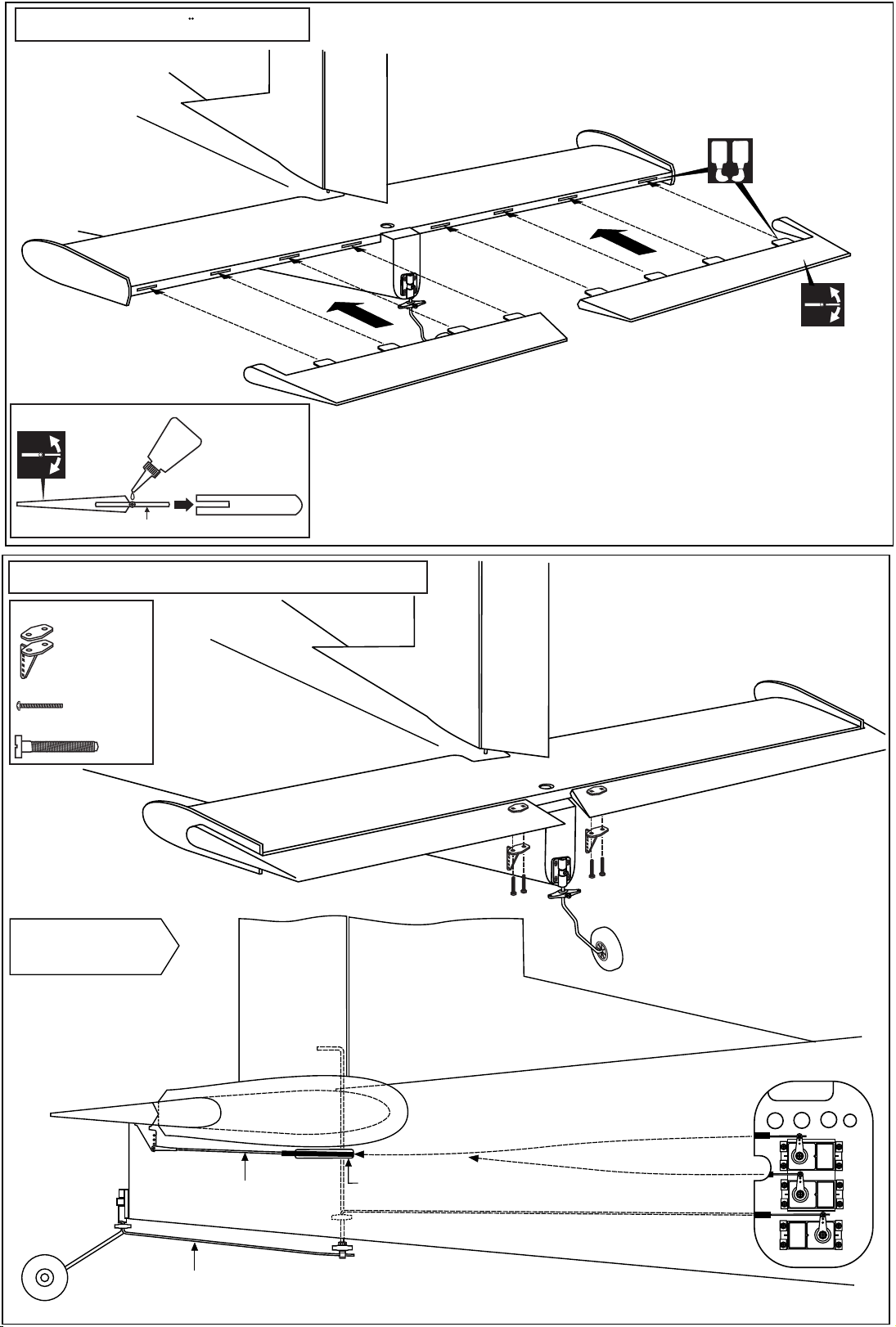

If exposed to direct sunlight and/or heat, wrinkels can appear. Storing the

model in a cool place will let the wrinkles disappear. Otherwise, remove

wrinkles in covering film with a hair dryer, starting with

low temperature. You can fix the corners by using a hot iron.

Bei Sonneneinstrahlung und/oder Wärme kann die Folie erschlaffen bzw. Falten

entstehen. Verwenden Sie ein Warumluftgebläse (Haartrockner) um evtl. Falten aus der Folie

zu bekommen. Die Kanten können Sie mit einem Bügeleisen behandeln. Nicht zuviel Hitze anwenden !

BENOTIGTE KOMPONENTEN FUR DEN ABFLUG (Nicht enthalten)

Klebstoff

Epoxy-Klebstoff (30min-Typ)

Epoxy-Klebstoff (5min-Typ)

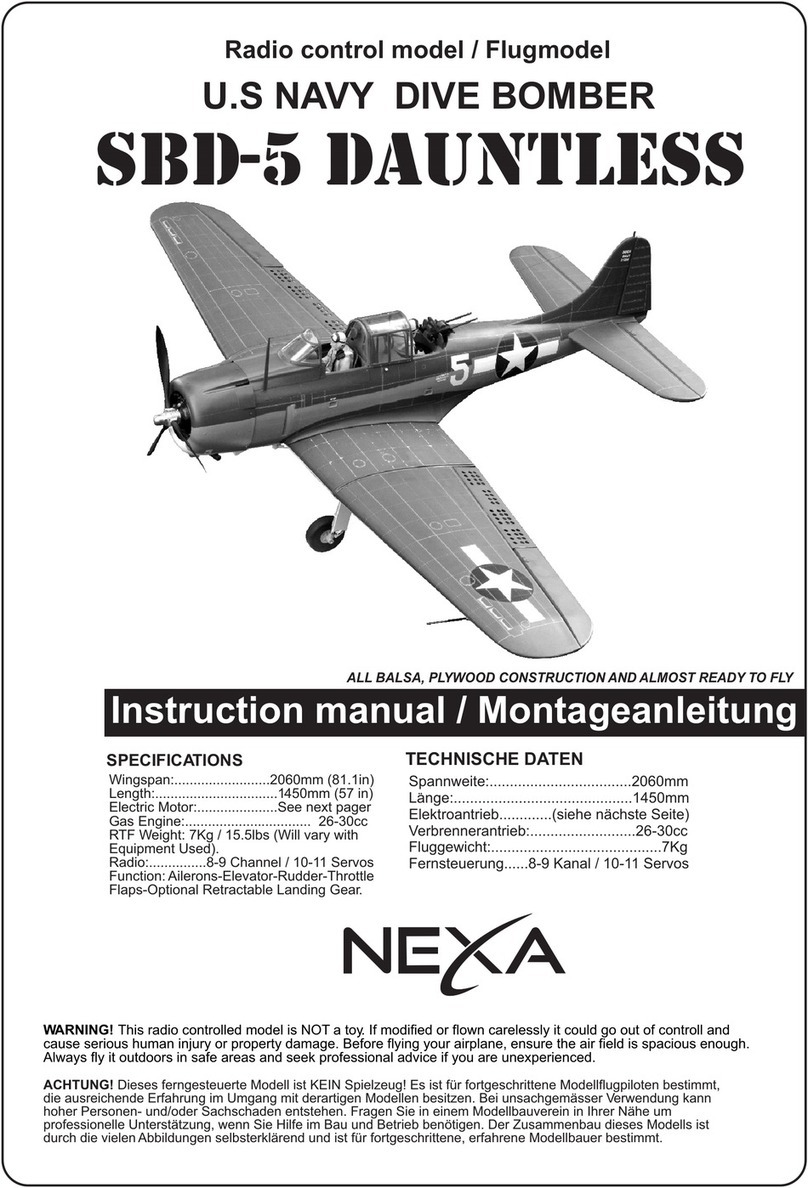

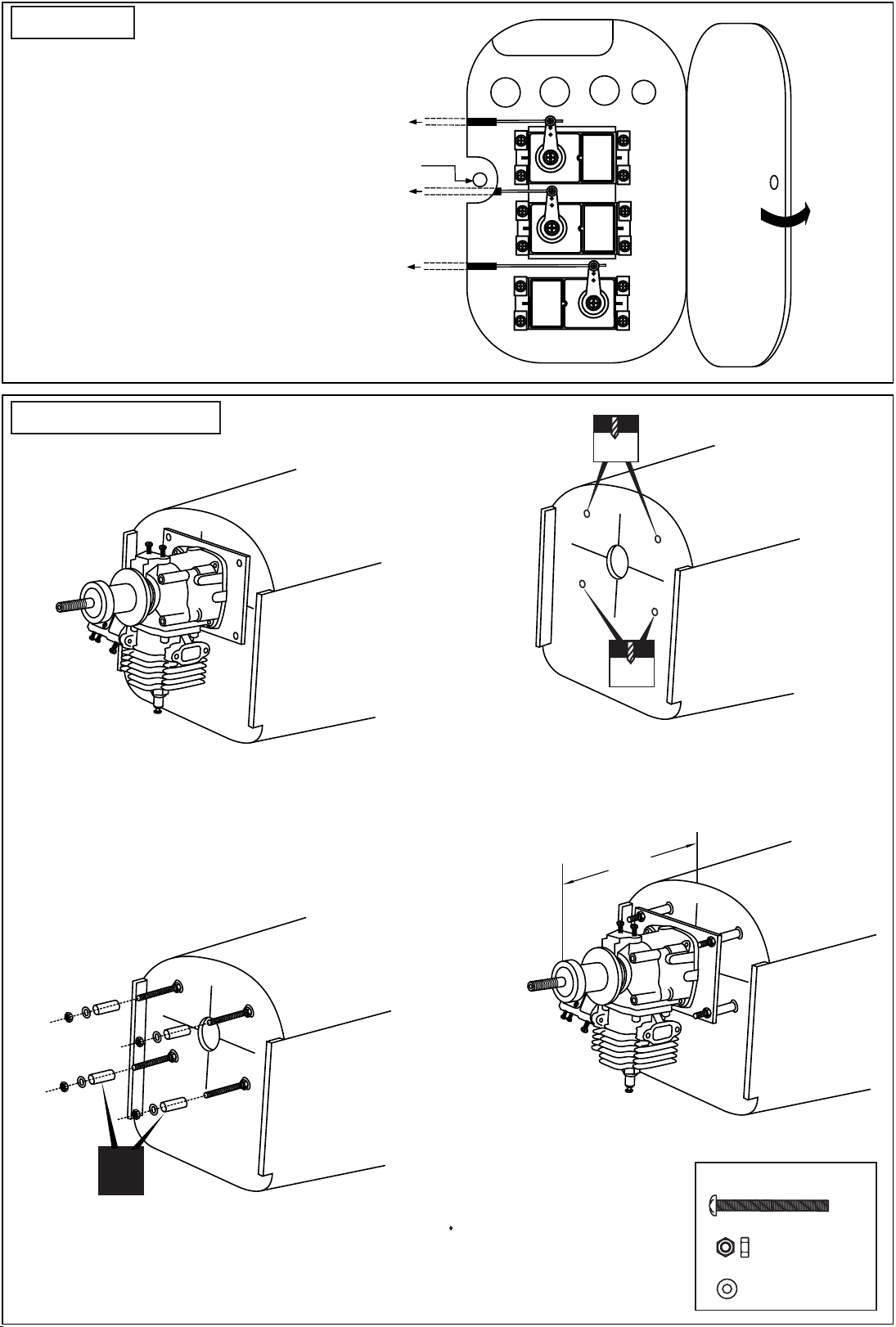

Gas Engine: 26 ~ 30cc