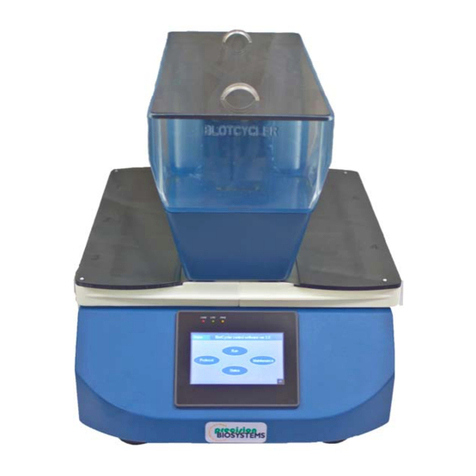

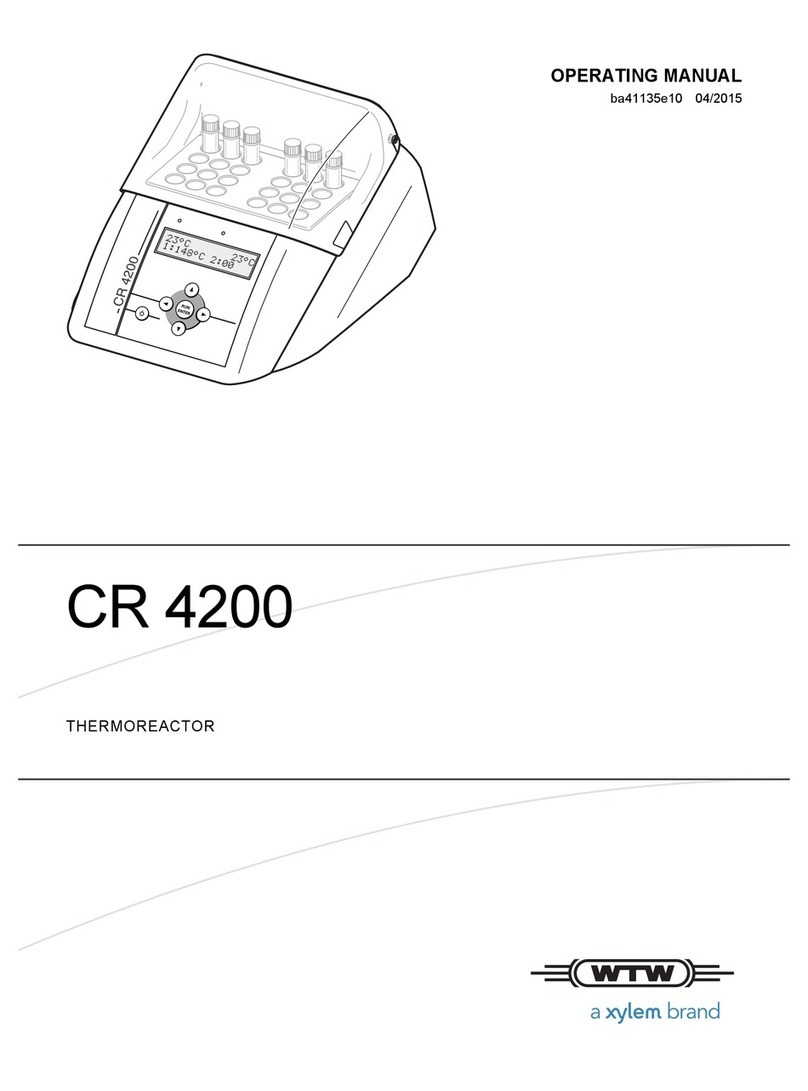

fig.9

LMC-56 Service Manual - V.1AD Version - 1, May 2022 Page 4

10. To replace the Imbalance sensor:

– release the Imbalance sensor wire from wire straps;

– unscrew the two screws (fig.8/2) remove the Imbalance sensor;

– replace the Imbalance sensor;

– re-assemble the unit.

11. To replace the Voltage Converter Board:

– unscrew the fixing screws of all wires

and disconnect them (fig.8/1);

– unscrew the four screws on the Voltage Converter board

(fig.8/3) and release it;

– replace the Voltage Converter board;

– re-assemble the unit.

12. To replace the Power Board:

– disconnect all wire terminals from the Power board;

– unscrew the fixing screws of power wires

and disconnect them (fig.8/4);

– unscrew the three screws on the Power board (fig.8/5);

– replace the Power board;

– re-assemble the unit.

13. To replace AC-DC Power Supply:

– unscrew the screws (fig.8/7) and release the wires;

– unscrew the five screws (fig.8/6) and lift base plate;

– unscrew the four screws on base plate underside and release Power Supply;

– replace the AC-DC Power Supply;

– re-assemble the unit.

14. To replace the Button Board:

– disconnect the terminal from the Button Board;

– unscrew the four screws (fig.10/2) on the Button board ;

– replace the Button board;

– re-assemble the unit.

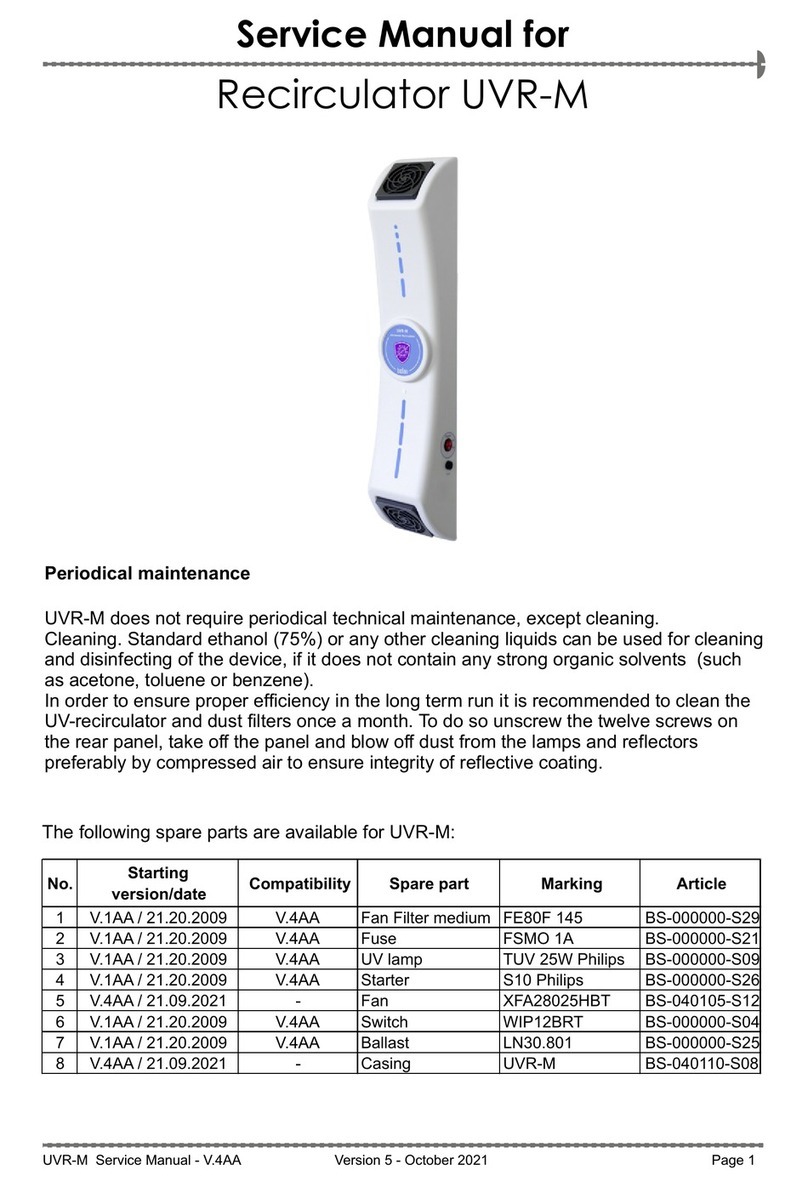

15. To replace the Optocouple board/Lid lock sensor:

– disconnect Optocouple board wire from the power board (fig.7/4);

– unscrew the two screws and remove the Optocouple (fig.9/1);

– replace the Optocouple and re-assemble the unit;

Note: Using screws (fig.9/1) adjust optocouple board position so when lock is

closed, the sensor is crossed (fig.9, scheme).

16. To replace the Solenoid:

– disconnect Solenoid wire from the power board (fig.7/5);

– unscrew the nut (fig.9/2);

– unscrew the four screws (fig.10/3) and remove the Solenoid;

– replace the Solenoid and re-assemble the unit.

Note: Using screws (fig.10/3) adjust optocouple board position so when

lock is closed, the sensor is crossed (fig.9, scheme).

17. To replace the Microswitch:

– disconnect Microswitch terminal from Power Board (fig.7/6);

– unscrew the two screws on the Microswitch (fig.9/3);

– replace the Microswitch;

– re-assemble the unit.

Note: Adjust new lever shape same as in replacable microswitch.

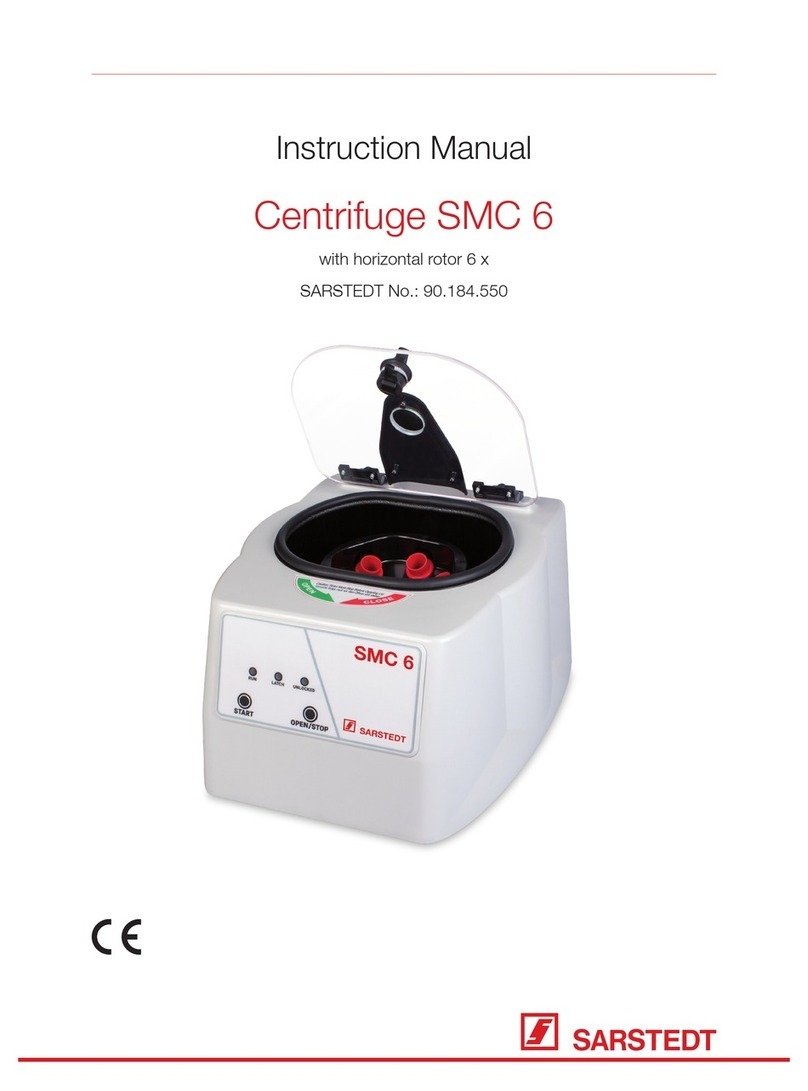

Power board

fig.8

Close up of power board

1

2

fig.10

Transformer

13

AC

AC

-

+

scheme.2

35

4

G

G

+Up

+12

1

4

2

Vfig.8

Casing removed

1

imbalanc

voltage convertr

power board

power supply

Vfig.9

Lid lock and front panel

Vfig.10

Lid lock and front panel

7. To replace the Microprocessor:

– with the help of special tool or using a small, flat tip screwdriver carefully

remove the Microprocessor (fig.7/5);

Do not mix up correct side installing the new one!

The Microprocessor’s and connector’s shape

has the same notch (1. scheme).

Use special tool for microprocessor installation, do not touch

microprocessor pins with bare hands, while replacing

microprocessor use ESD-protection – wrist strap.

Microprocessor is delivered already programmed.

– replace the Microprocessor;

– re-assemble the unit.

8. To replace the Button Board:

– disconnect the terminal from the Button Board;

– unscrew the two screws on the Button board (fig.7/3);

– replace the Button board;

– re-assemble the unit.

3. To replace the Microswitch (fig.8/5):

– disconnect Microswitch terminal from Power Board (fig.8/3);

– unscrew the two screws on the Microswitch (fig.8/4);

– replace the Microswitch;

– re-assemble the unit.

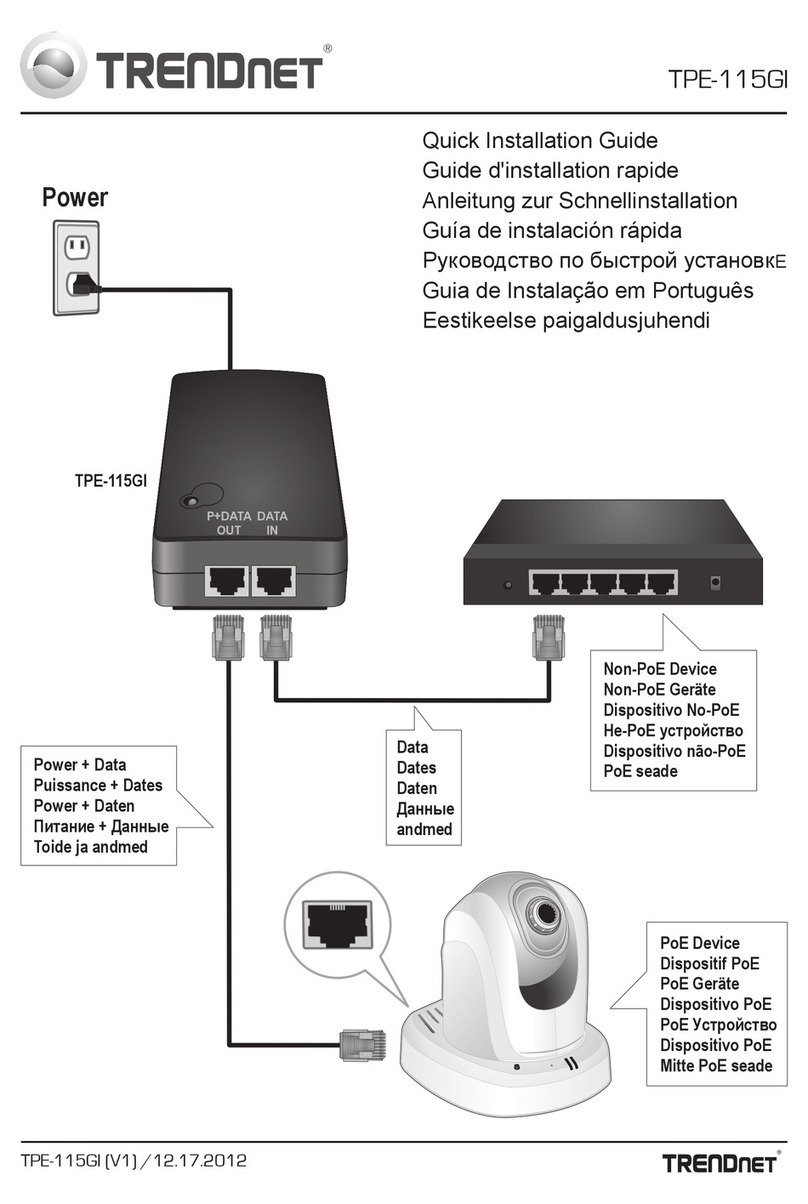

9. To replace the Power Board:

– disconnect all the terminals from the Power board;

– unscrew the fixing screws of power wires

and disconnect them (fig.9/1);

– unscrew the two screws on the Power board (fig.7/2);

– replace the Power board;

– check voltage between connectors (fig.9)

[G] - [+ U ] correct voltage range 26-34V

p

and [G] - [+ 12] correct voltage range 10-14V;

– re-assemble the unit.

10. To replace the Bridge:

– disconnect the four terminals of the Bridge;

– unscrew the one fixing screw of the Bridge (fig.10/4);

– replace the Bridge;

– re-assemble the unit.

Checking of the Diode Bridge:

– connect multimeter probes to side leads (scheme.2);

– turn the multimeter on diode checking mode;

– take measurement, it should be some value;

– change the probes with each other;

– take measurement, it must be a 0 V;

– repeat this process on each side leads (together 8 measurements);

Note: There must be in total four measurements when multimeter

show 0 and four measurements when show a value. If not then

the bridge is damaged.

1

2

3

45

6

7

2

1

Closed Open

2. To replace the Solenoid:

– disconnect the spring (fig.5/1);

– unscrew the four screws (fig.4/1) and remove the Solenoid;

– replace the Solenoid (fig.4/5) and re-assemble the unit.

Disassembling for Control, Button boards, Microprocessor

and Microswitch:

1. Disconnect the Microswitch power wire from the control board (fig.4/2).

2. Unscrew the six screws on the solenoid holder plate (fig.4/3) and remove it.

3. To replace the Microswitch (fig. 5/2):

– unscrew the two screws on the Microswitch (fig.5/2);

– remove the Microswitch;

– install the new Microswitch (fig.5/3) in the place;

– adjust the lever of microswitch as shown at (fig.5/4);

– connect the terminals;

– re-assemble the unit.

4. To replace the Optocouple board:

– disconnect Optocouple board wire from the power board (fig.8/1);

– unscrew the two screws and remove the Optocouple (fig.5/5);

– replace the Optocouple and re-assemble the unit;

Note: Using screws (fig.5/5) adjust optocouple board position so when lock is

closed, the sensor is crossed (fig.6/1, scheme).

5. To replace Control Board:

– disconnect the terminals from the Control Board;

– unscrew the four screws on the Control Board assembly (fig.7/2);

– remove Control Board;

– replace the Control Board;

– re-assemble the unit.

Note: LCD Board connected with Control Board via socket.

During installation avoid mechanical strain of LCD Board.

If washers was applied between Control and LCD Board before

disassembling, then mount them back while re-assembling.

6. To replace LCD Board:

– disconnect the terminals from the Control Board;

– unscrew the four screws on the Control Board assembly (fig.7/2);

– remove the LCD Board located under the control board;

– replace the LCD Board;

– re-assemble the unit.

Note: During installation avoid mechanical strain of LCD Board.

If washers was applied between Control and LCD Board before

disassembling, then mount them back while re-assembling.

LCD contrast tuning

– after replacing the Control Board or the LCD Board, LCD display need

contrast tuning;

– to tune contrast of the display, it is necessary to connect to the

circuit and switch the unit without re-assembling;

– take necessary precautions against electric shock hazard;

– connect the cables and power wires;

– plug in the power cord to the circuit and switch on the unit;

– the display lites up;

– turn the potentiometer screw (fig.7/4) and tune the display contrast;

– re-assemble the unit.

14. To replace the Imbalance sensor:

– pull out three cotter pins (fig.12/2) and lift up the motor assembly;

– on device underside pull out failed shock absorber cotter pin;

– install the new shock absorber and secure it with the pins;

– re-assemble the unit.

2

3

3 4

4