Thank you for purchasing the DIAL Bore Gauge.

Please read this manual thoroughly before use for proper operation.

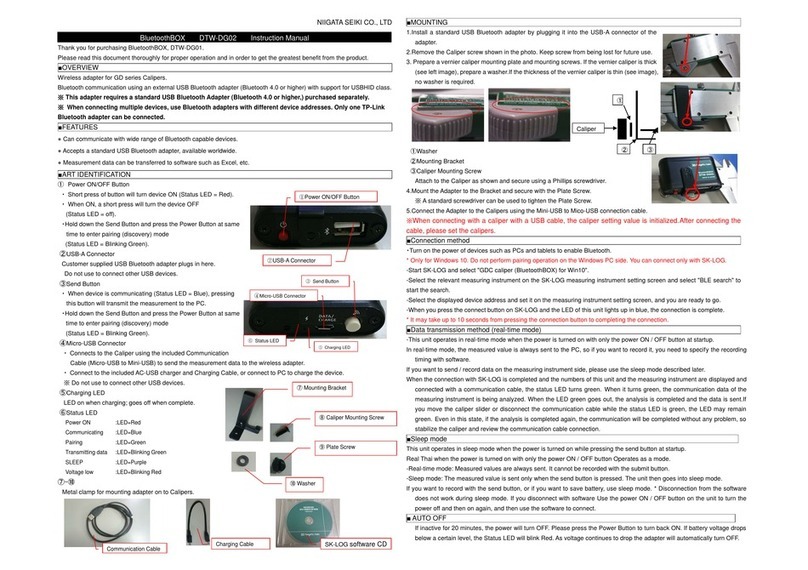

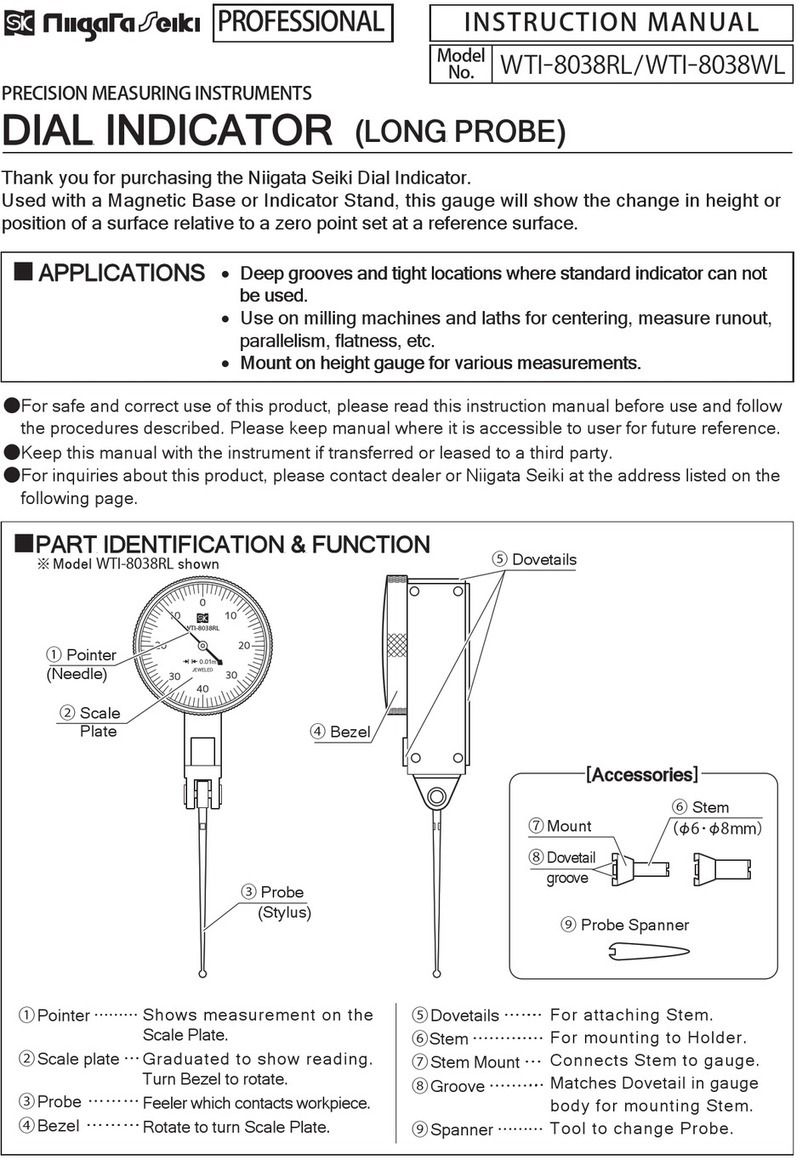

Model No. : CDI-50 / CDI-100 / CDI-160 <combined>

DIAL BORE GAUGE

Revolution Counter

Model No. CDI-50

35〜50

15

5

1.2

0.5, 1, 2, 3 mm (One each)

1.05

CDI-100 CDI-160

50〜100

0.01

18

6

3

1.6

1.1

50〜160

18

6

1.6

1.15

Measuring Range

Graduation

Wide Range Accuracy

Adjacent Error

Repeat Accuracy

Extension Washer

Weight

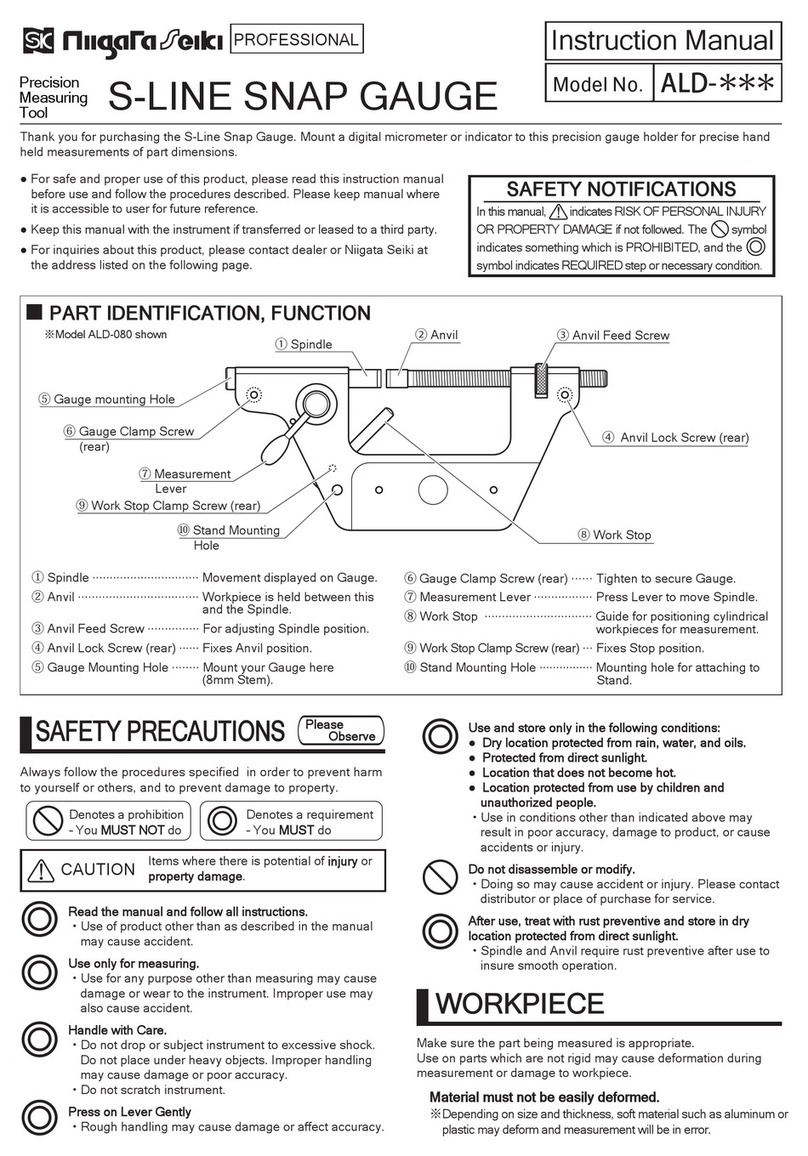

Bezel

Extension Washer

Protective Cover

Extension Rod

55mm Sub Rod

(CDI-160 only)

Extension Rods:

CDI-50・・・・・35, 40, 45, 50mm (4 pieces)

CDI-100・・・50, 55, 60, 65, 70, 75, 80, 85, 90, 95, 100mm (11 pieces)

CDI-160・・・

50, 55, 60, 65, 70, 75, 80, 85, 90, 95, 100, 105mm

(12 pieces)

+Sub Rod 55mm (1 piece)

Grip

Dial Indicator

Pointer

(0.01mm)

(1mm)

Spacer

Indicator

Face

Extension Rod

Rod Mounting

Nut

Rod Mounting Nut

Shaft

Probe Tip

Length below grip - 150mm

Guide

Measurement Head

Clamp Screw

Clamp

Screw

*

:Including supplied Dial Indicator.

*

*

*

This is a precision instrument, use care not to drop or mishandle.

Please do not disassemble or modify.

Keep instrument away from water and oil.

Use only with provided Extension Rod, Washers, and Sub Rod.

Keep instrument away from direct sunlight or high temperatures

such as in a car, or near a stove or heat source.

After use, remove dust and cutting chips, and apply rust

preventative oil to Extension Rod and Washers. When not in use

store in original storage case.

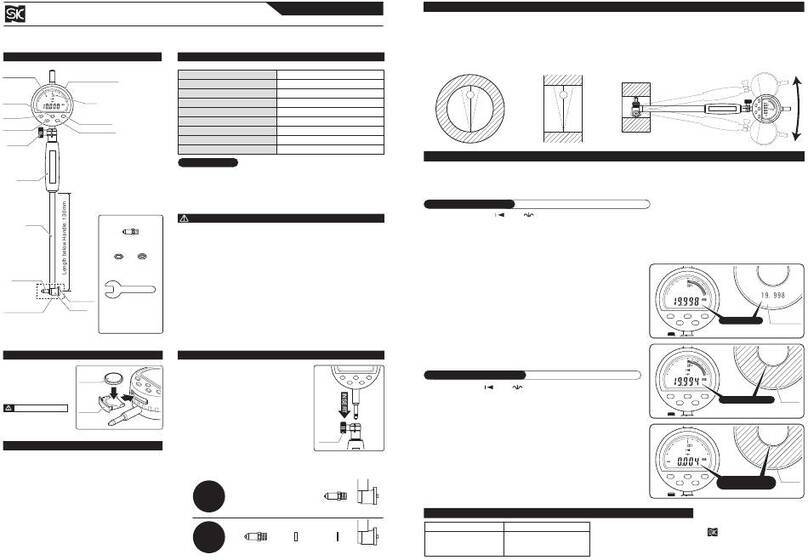

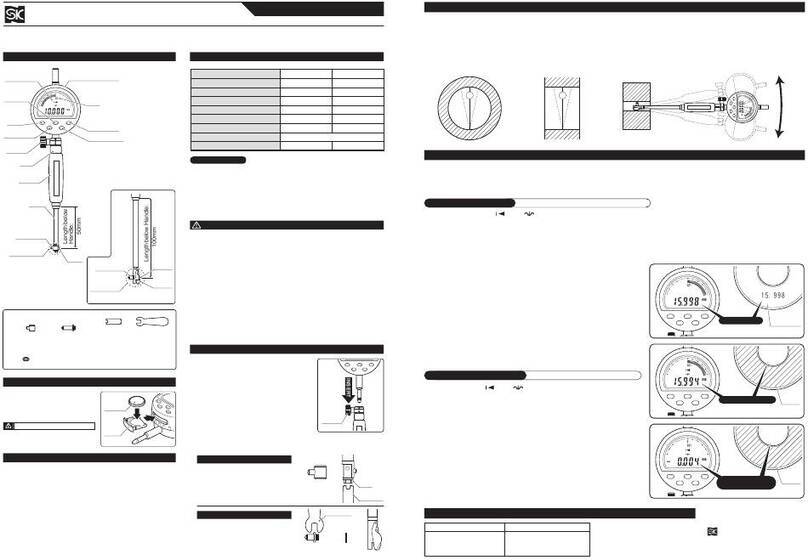

This product is for measuring inside diameter. Use only as

directed. Improper use may cause accident or injury.

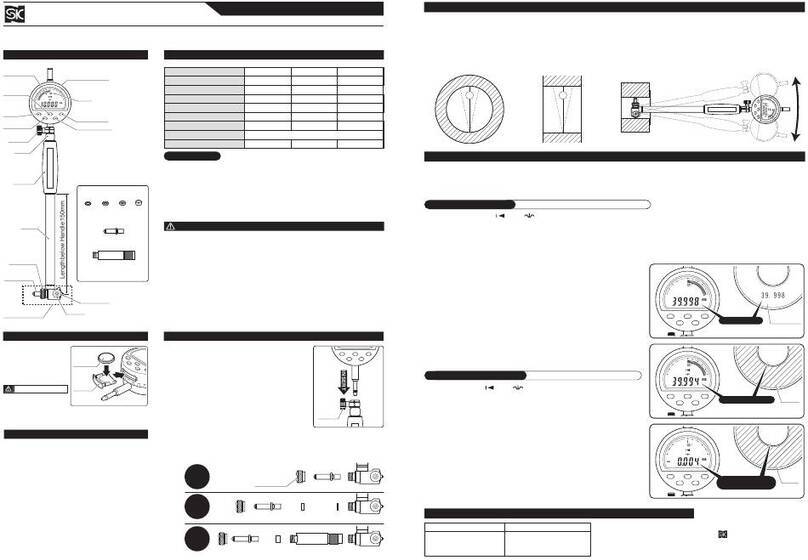

②Loosen the Clamp Screw and insert the Dial

Indicator until the Pointer rotates 1/10 turn or more.

Secure by tightening the Clamp Screw.

①Remove the protective cover by unscrewing the two

screws that hold the cover in place.

※To reattach the protective cover, please refer to the section:

“Attaching the Protective Cover”

③Chose combination of Rod, Washer, and Sub Rod (CDI-160D only)

applicable for desired measurement range.

Remove the Rod Mounting Nut and install the selected Rod,

Washers and Sub Rod, then replace Mounting Nut to secure to body.

※When selecting washers, use combination with fewest washers.

●

●

●

●

●

●

●

0.5mm 1mm 2mm 3mm

1/10 rotation

or more Extension Rod

60mm

Extension

Rod

60mm

Extension

Rod

60mm

Extension

Washer

2mm

Extension

Washer

0.5mm

+ +

Extension

Washer

3mm

Sub Rod

55mm

+ +

Example: For 60mm Measurement

Example: For 62.5mm Measurement

Example: For 118mm Measurement

■PART IDENTIFICATION

■ASSEMBLY

■SPECIFICATIONS

■NOTICE

Insert

INSTRUCTION MANUAL

(mm)

(mm)

(μm)

(μm)

(μm)

(mm)

(kg)

Single Probe Measuring Range