English

Operating

Procedure

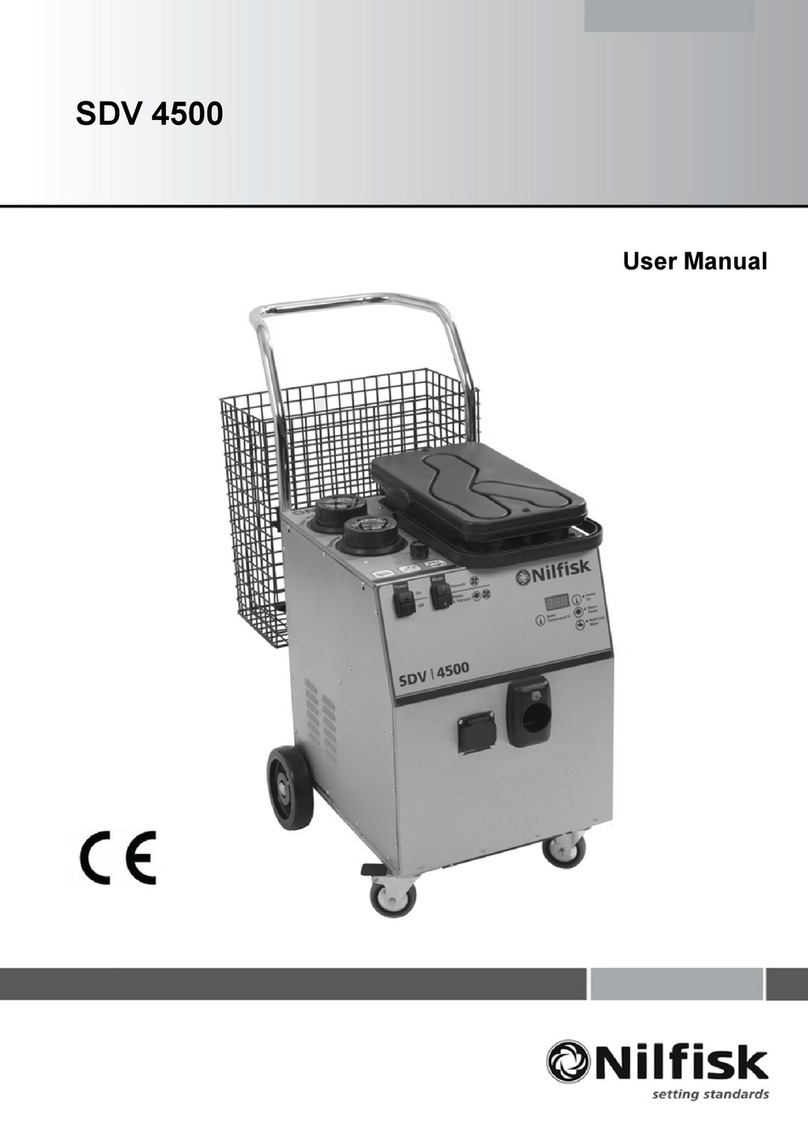

- Switch mode switch (Number

12 Diagram B) to position 11.

This will switch on the boiler

elements and will enable you to

use the handle controls on the

hose once connected.

- Fill the cold water tank (Number

2 Diagram A) with clean cold

water only.

Anything other than clean cold

water used in the water tank

will void the manufacturer’s

warranty.

-Connect the Detergent Bottle

(Diagram D) to the detergent

connection point (Number 1

Diagram A) on the machine.

- Fill the detergent bottle

(Diagram D) with Nilfisk

approved detergent.

Unapproved detergent may be

harmful or dangerous to the

machine or the operator using

the machine. This may cause

irrepairable damage to seals

and will void the

manufacturer’s warranty.

- Connect the Vacuum Hose to

the front of the machine (Number

6 Diagram A) ensuring it locks

into position. To release the

vacuum hose from the socket

slide the red button upwards at

the same time as pulling the hose

out.

If the Hose becomes damaged

the complete hose must be

replaced. Do not attempt this

task yourself, contact a Nilfisk

approved supplier for

replacement.

- Connect the Steam Hose to the

front of the machine (Number 7

Diagram A) ensuring it is pushed

in all the way and the pin on the

flap locks into the hole on the

hose.

Grease “O” rings on steam pin

before connecting.

To release the steam hose, lift

the flap and pull.

- Plug the power cable into a 240

Volt supply.

Inspect the electric cable

before every use. If the cable

becomes damaged at anytime

the complete cable must be

replaced by a Nilfisk approved

distributor.

Never touch the power cable or

plug with wet hands

Always unplug the machine

when:

- The machine is not in use.

- Cleaning the machine.

- Any maintenance work is

being carried out.

- Switch the On/Off switch

(Number 11 Diagram B) to the

ON position. The Heater On light

LED (Number 13 Diagram B) will

illuminate.

- Allow approximately 10 minutes

for the boiler to heat the water.

- When the Steam Ready LED

(Number 14 Diagram B)

illuminates the machine is ready

to be used.

- The handle controls are now

active.

- The red trigger on the hose

handle will release steam when

pressed.

- The red button on the side of the

handle will lock the steam trigger

in the off position.

- Pressing the left hand switch on

top of the handle will activate the

vacuum.

- Pressing the right hand

momentary switch located on the

top of the handle will activate the

detergent pump. Hold the

switch as long as you need to

dispense the detergent.

Releasing the switch will stop the

detergent supply.

- The steam output can be

adjusted by the steam control

knob (Number 3 Diagram A)

- Choose and fit the required

accessory (Diagram C) to the

hose handle. Lock the accessory

in place by turning the accessory

locking clip.

When changing accessories

during use please note these

will be hot.

During Use

Cold Water Tank Empty

(Number 2 Diagram A)

-Refill the cold water tank when

the refill cold water LED (Number

15 Diagram B) is illuminated. A

buzzer will sound and the steam

will no longer come out of the

nozzle when the steam switch on

the handle is pressed.

- Always empty the collection

tank each time the cold-water

tank is refilled.

- The pumps will not work when

the cold-water tank is empty.

- Once the cold water refill LED is

illuminated the boiler heater will

remain on for 30 minutes. If the

cold-water tank is not refilled

within 30 minutes and the

machine is left powered on the

boiler heater will switch off.

Detergent Bottle Empty

(Diagram D)

- If the detergent does not come

out of the nozzle when the

detergent switch on the handle is

pressed, refill the detergent bottle

(Diagram D)

Collection Tank Full (Number 4

Diagram A)

- Always empty the collection

tank each time the cold-water

tank is refilled.

- The pitch of the motor noise

changes and there is no suction

at the nozzle.

- Switch off the machine,empty

the collection tank and rinse

clean.