Nilfisk-Advance STEAMTEC 312 User manual

STEAMTEC 312

Operating Instructions

Betriebsanleitung

Notice d’utilisation

Gebruiksaanwijzing

Istruzioni sull’uso

Driftsinstruks

Bruksanvisning

Driftsvejledning

Käyttöohje

Navodila za uporabo

Uputstvo za rad

Prevádzkový návod

Provozní návod

Instrukcja obsługi

Kezelési utasítás

Ðóêîâîäñòâî ïî ýêñïëóàòàöèè

Instrucciones de manejo

Instruções de operação

Οδηγίες λειτουργίας

Ýþletme kýlavuzu

303000433 d (11.2013)

english ...............................................1-3, 61-66

deutsch ...............................................4-6, 61-66

français ...............................................7-9, 61-66

nederlands .......................................10-12, 61-66

italiano ...........................................13-15, 61-66

norsk ...........................................16-18, 61-66

svensk ...........................................19-21, 61-66

dansk ...........................................22-24, 61-66

suomi ...........................................25-27, 61-66

slovensći ...........................................28-30, 61-66

hrvatski ...........................................31-33, 61-66

slovenský...........................................34-36, 61-66

český ...........................................37-39, 61-66

polski ...........................................40-42, 61-66

magyar ...........................................43-45, 61-66

ðóññêèé ...........................................46-48, 61-66

español ...........................................49-51, 61-66

português.........................................52-54, 61-66

ελληνικά ...........................................55-57, 61-66

türkçe ...........................................58-60, 61-66

STEAMTEC 312

STEAMTEC 312

1

For your own safety open the safety catch.

– Refilling the boiler

– Emptying the boiler

The use of the steam cleaner is

subject to valid national regula-

tions. Besides the operating

instructions and the binding

accident prevention regula-

tions valid in the country of use,

observe recognized regulations

for safety and proper use.

Do not use any unsafe work

techniques.

Before start-up

Before starting up the cleaner,

check that it is in proper condi-

tion.

Do not switch the cleaner on if

there is no water in the boiler.

Do not start the cleaner near

explosive and/or easily flamma-

ble substances.

Use only tap water or distilled

water to fill the boiler. Distilled

water extends the service life of

the cleaner. Cleaning agents,

scents, solvents and other

chemical substances may dam-

age the cleaner and may be a

risk to health.

Regularly check whether the

steam hose and power cord

are damaged or show signs of

age. Only use the cleaner if the

steam hose and power cord are

intact.

Check the rated voltage of

the steam cleaner before con-

necting it to the mains supply

system. Ensure that the voltage

shown on the rating plate cor-

responds to the voltage of the

local mains power supply.

Never touch the plug and elec-

trical cables with wet hands.

It is recommended that the

steam cleaner should be con-

nected via a residual current

circuit breaker. This stops the

supply of electricity if the leak-

age current to earth exceeds 30

mA for 30 ms or it has an earth

tester circuit.

During use

Never leave the cleaner unsu-

pervised when it is connected.

Never turn the cleaner over or

tilt it while it is in operation.

Never use the cleaner when

other people are nearby.

Place the cleaner as far away

as possible from the object to

be cleaned.

Filling aperture must not be

opened during use.

Do not leave the cleaner near to

sources of heat (fire, radiators,

heating fans or other equipment

that radiates heat) and never

cover the cleaner.

The steam jet can be danger-

ous if it is misused. Never direct

the jet on to persons, animals,

electrically powered equipment

or the cleaner itself.

Remove condensed water from

the nozzle before starting up

the cleaner and after every

work break. To clean the nozzle,

direct the steam jet into a tank

or sink and actuate the steam

lever on the steam gun. After

cleaning the nozzle you can

begin work again as normal.

CAUTION:

Materials containing asbestos

and other hazardous substanc-

es should not be cleaned.

Do not use the steam jet to

clean switches, sockets, con-

trollers, etc. and other electrical

parts on electrical cleaners.

Make sure that the child-proof

lock is actuated on the handle

during work breaks.

Before using

the steam

cleaner, al-

ways read the

operating in-

structions and keep

them readily available.

The cleaner should only be

used by persons acquainted

with its use.

The appliance is not to be used

by children or persons with

reduced physical, sensory or

mental capabilities, or lack of

experience and knowledge, un-

less they have been adequately

supervised by a responsible

person to ensure that they can

use the appliance safely (IEC/

EN 60335-1) (deviations for

Australia and New Zealand).

Young children should be su-

pervised to ensure that they

do not play with the appliance

(IEC/EN 60335-1) (deviations

for Australia and New Zealand).

CAUTION:

Danger of scalding! The steam

produced by the appliance can

reach very high temperatures.

Metal parts, water and hot

steam can cause severe burns.

Avoid contact with hot cleaner

surfaces, emerging water and

steam.

The pressure tank is under

pressure during operation. For

this reason, never open the

safety catch during operation.

Be careful particularly during

the following work as there may

still be hot steam in the cleaner:

– Opening the safety catch.

The safety catch has a pres-

sure relief hole. Open the

safety catch by one or two

turns. Wait until no steam

emerges. Then completely

STEAMTEC 312

2

To prevent the cleaner from

being used inadvertently dur-

ing work breaks, switch off the

cleaner and pull out the mains

plug.

Allow the cleaner to cool down

completely before storing it or

opening the safety catch.

Store the cleaner in a dry place.

CAUTION!

Unsuitable extension cords can

represent a source of danger.

Always unwind cord from the

reels completely to prevent the

power cord overheating.

Extension cords are not recom-

mended, however if necessaray

refer to the following recom-

mendations:

Cord length m Cross section

up to 20 m ø1.5mm² ø2.5mm²

20 to 50 m ø2.5mm² ø4.0mm²

Do not damage the power cord

(e.g. by driving over it, pulling or

crushing it).

Disconnect the power cord by

grasping the plug only (do not

pull or tug the power cord).

Keep the power cord away from

hot surfaces.

CAUTION:

Never immerse the cleaner or

its parts in or under water or

other liquids. Risk of electric

shock.

The cleaner may only be con-

nected to a correctly installed

plug socket.

Switching on the cleaner may

cause voltage fluctuations.

Voltage fluctuations should

not occur if the impedance at

the transfer point is less than

0.15If in doubt ask your local

electricity supplier.

Observe the latest edition of the

IEC regulations.

Maintenance and repair

CAUTION!

Always remove the plug from

the power supply before clean-

ing or carrying out maintenance

work on the cleaner.

Carry out only the maintenance

operations described in the

operating instructions. Use only

original Nilfisk spare parts.

The power cord must not differ

from the version specified by

the manufacturer and may only

be replaced by a repair service

centre authorised by the manu-

facturer.

Do not make technical modifi-

cations to the cleaner.

Please contact your local

authorized Nilfisk equipment

distributor for all other mainte-

nance or repair needs!

Accessories and spare parts

Use only the accessories sup-

plied with the cleaner or speci-

fied in the operating manual.

Use original Nilfisk-spare parts

only. The use of other parts can

adversely affect safety.

Recycling the steam cleaner

Make the old

cleaner unusable

immediately.

1. Unplug the cleaner and cut

the power cord.

Do not discard of electrical ap-

pliances with household waste.

As specified in European Direc-

tive 2002/96/EC on old electri-

cal and electronic appliances,

used electrical goods must

be collected separately and

recycled ecologically.

Contact your local authorities or

your nearest dealer for further

information.

Guarantee

Our general conditions of busi-

ness are applicable with regard

to the guarantee.

Subject to change as a result of

technical advances.

Tests and approvals

The cleaner has been approved

in accordance with IEC/EN

60335-2-54.

Purpose

This cleaner is for domestic use

only.

Only use the cleaner for the

cleaning jobs described in the

operating manual.

This cleaner is suitable for

cleaning heat and moisture re-

sistant surfaces.

Read the operating manuals for

the machines and equipment

that you clean as there may be

limitations stated by the manu-

facturer. Do not use the cleaner

for ovens, microwaves, deep

freezers, refrigerators and other

electrical equipment.

CAUTION:

In the case of heat and mois-

ture sensitive materials, make a

test on a concealed place first.

Begin with a low steam setting

and keep a minimum distance

of 6 cm. The high steam tem-

perature/quantity may dam-

age the object to be cleaned

(e.g. varnished parquet, wood,

wood ceilings, plaster, window

frames, surface-treated wood,

decorative beams, etc.).

Below we have listed some ex-

amples of applications:

STEAMTEC 312

3

Floors

Walls

Tiles, stone floors, plastic

floors, linoleum

Marble: Never clean marble directly with the floor nozzle without a cloth.

It may be necessary to clean marble floors several times to completely

remove old cleaning agents and grease stains. Select a low steam setting

for this cleaning job. You can increase it as required.

Tiles and ceramic floors: Black marks form in the crevices as a result of

water and cleaning agents. Dust and other remains collect there. For daily

cleaning stretch a fresh, clean cloth over the floor nozzle and secure it

with the fastening clamps. Slide the floor nozzle gently over the floor. To

use all of the cloth as far as possible, you can move it on the floor nozzle

or reverse it. If the dirt is stubborn, you may clean the floor directly with

the fold out brush without a cloth. The bristles loosen the dirt from the

crevices and remove it. Subsequently, cover the floor nozzle with a cloth

again and wipe over the floor again.

Wände Tiles, washable wallpaper

Window

cleaning

Windows, shop windows,

mirrors

Window panes: Use the window nozzle. Apply steam from top to bottom.

Scrape the rubber strip over the glass without steam in order to remove

the condensed water. Make sideways movements from top to bottom in

order to avoid marks.

CAUTION In winter the front sides of the windows must be preheated.

Hold the nozzle 5-10 cm in front of the pane and allow the heat to act. Se-

lect a low steam setting for inside cleaning of the windows. A high steam

setting can be used for outside cleaning.

Upholstery Furniture, cars, boats Fit the floor nozzle directly on to the steam gun and use it with a clean

white cotton cloth. Work using quick steam spurts so that the fabric does

not become soaked. Treat stubborn stains with patience. Carefully steam

one particular spot for not longer than one minute. Then wait five minutes

and repeat the cleaning. Make circular movements, sideways and back

and forth movements so that steam penetrates into all upper layers of the

fabric. Finish the cleaning by brushing the fabric in one direction to give

the fabric an even appearance.

Textiles Curtains, shower curtains,

freshening of outer cloth-

ing, stain removal

The cleaner is excellently suited to smooth folds in clothes. It is sufficient

to steam the fabric from a certain distance. The steam smoothes the folds

without soaking the fabric as other steam devices for fabrics do.

Sanitary

installations

Fittings, baths, shower cu-

bicles and partitions, WCs,

sauna, kitchens

1)

To clean a bath or shower, use the round brush to clean the rails of show-

er cubicles and other parts that are difficult to access or very dirty. The

window wiper is very efficient to clean areas covered with tiles.

To clean sanitary installations, use the jet nozzle with or without the round

brush. Use a sponge or kitchen paper to remove excessive moisture and

remaining dirt.

Kitchen fit-

tings

Grills

1)

, extractors

1)

,

kitchen cabinets, oven ac-

cessories

Furniture Window frames, furniture,

decorative beams, lamps

1)

,

chimney bricks, blinds,

glass cabinets

Blinds: Use the small round nylon brush. Move the brush so long over the

surface until steam penetrates it.

Blinds made of PVC must be treated quickly with steam. In the case of

blinds made of fabric, test the material beforehand for colour fastness.

Cars Dashboards, upholstery,

door hinges, wheel rims

Aluminium/steel

To clean the inside of your car, use the floor brush with a cloth for uphol-

stery and other parts and follow the instructions for domestic cleaning. Do

not use the brush without a cloth when you clean leather parts. For hub

caps it is best to use the jet nozzle with the round brush attachment.

Bicycles,

motorbikes

Frames, wheel rims,

spokes, saddles

1)

Do not use the steam jet to clean switches, sockets, controllers, etc. and other electrical parts on electrical cleaners.

Technical data

Voltage 220/240 V ; 50/60 Hz Tank volume 1.2 l

Fuse 10 A

Max. temperature

130 °C

Power consumption 1450 W

Working pressure

3.8 bar

Type of protection (splash

water protected)

IP X4

61

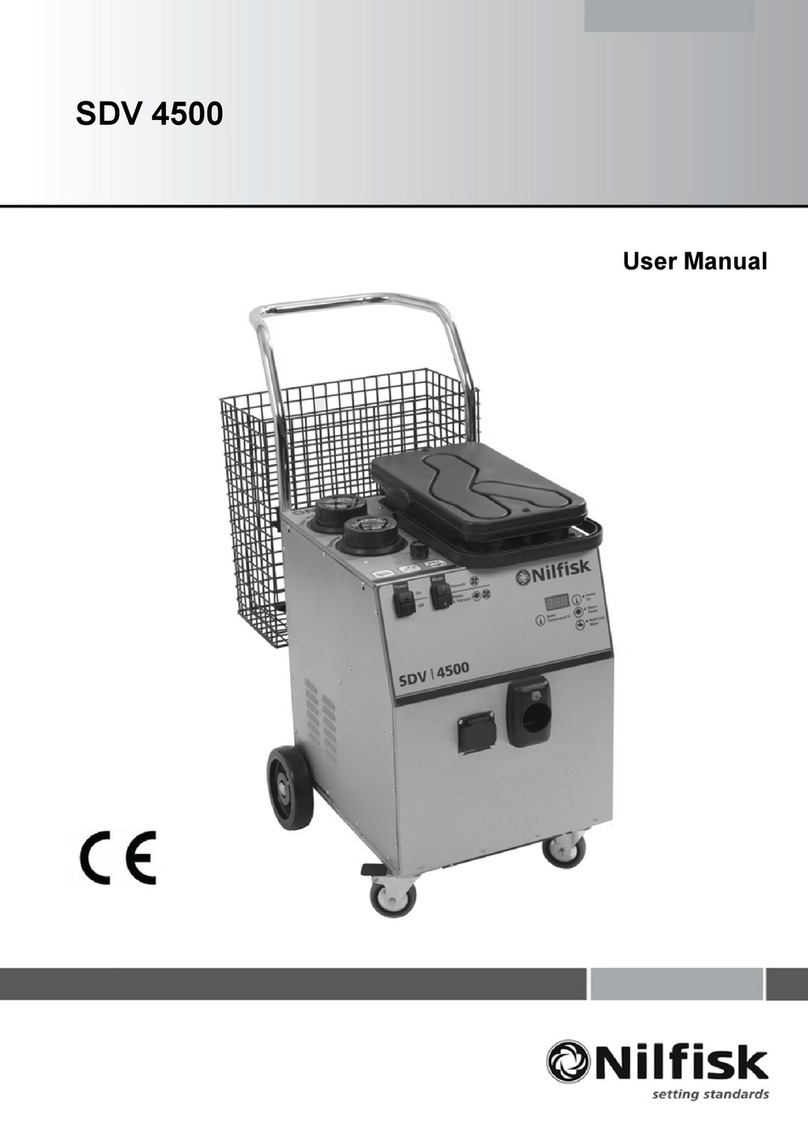

STEAMTEC 312

303000422

303000424

303000419

303000426

303000428

303000423

303000420

303000429

Operating elements /

Accessories

Bedienelemente /

Zubehör

Eléments de

commande /

Accessoires

Bedieningselementen

/ Toebehoren

Organi di comando /

Accessori

Betjeningselementer /

Tilbehør

Manöverelement /

Tillbehör

Betjeningselementer /

Tilbehør

Hallintalaitteet /

Tarvikkeet

Elementi upravljanja /

Pribor

Elementi posluživanja /

Pribor

Ovládacie prvky /

Príslušenstvo

Ovládací prvky /

Příslušenství

Elementy sterujące /

Wyposażenie

Kezelőelemek /

Tartozék

Органы управления /

принадлежности

Elementos de manejo

/ Accesorios

Elementos

de operação/

Accessórios

Στοιχεία χρήσης /

Συμπληρωματικός

εξοπλισμός

Kumanda elemanlarý /

Aksesuarlar

62

STEAMTEC 312

1 2

3

4 5

6 7

8

Assembling the

cleaner

Gerät zusammen-

bauen

Assembler l‘appareil

Toestel samenbou-

wen

Montaggio

dell‘apparecchio

Montere maskinen

Hopmontering av

apparaten

Samling af apparatet

Laitteen kokoaminen

Sestavitev naprave

Sagraditi uređaj

Zmontovaťspotrebič

Montáž spotřebiče

Montaż urządzenia

A készülék

összeállítása

Сборка

пароочистителя

Ensamblar el aparato

Montar o aparelho

Συναρμολόγηση

συσκευής

Cihazýn montajý

63

STEAMTEC 312

H2O

1

2

3

4

max. 1,2 l

Adding water

Wasser einfüllen

Remplir d‘eau

Water ingieten

Riempimento con

acqua

Fylle på vann

Påfyllning av vatten

Påfyldning af vand

Veden täyttö säiliöön

Polnjenje vode

Napuniti vode

Naplniťvodu

Plnění vodou

Napełnianie wodą

A víz betöltése

Наполнение воды

Llenar agua

Encher de água

Πλήρωση με νερό

Suyun doldurulmasý

64

STEAMTEC 312

1

2

3

4

Switching on the cleaner

and controlling the quantity

of steam

Gerät einschalten /

Dampfmenge regeln

Mettre l‘appareil en service /

régler la quantité de vapeur

Toestel inschakelen / dam-

phoeveelheid regelen

Accensione

dell‘apparecchio/regolazio-

ne della quantità di vapore

Slå på maskinen / regulere

dampmengden

Inkoppling av apparat /

reglering av ångmängd

Opstart af apparatet /

regulering af dampmængde

Laitteen käynnistäminen /

höyrymäärän säätely

Vklop naprave / reguliranje

količine pare

Uključiti uređaj / regulirati

količinu pare

Spotrebičzapnúť/ nastaviť

množstvo pary

Zapnutí přístroje / regulace

množství páry

Włączanie urządzenie /

regulacja ilości pary

A készülék bekapcsolása / a

gőzmennyiség szabályozása

Включение

пароочистителя /

регулировка количества

пара

Conectar el aparato /

Ajustar el caudal de vapor

Ligar o aparelho / Regular a

quantidade de vapor

Ενεργοποίηση συσκευής /

ρύθμιση όγκου ατμού

Cihazýn çalýþtýrýlmasý / buhar

miktarýnýn ayarlanmasý

65

STEAMTEC 312

1

2

3

4

1-2 x

5

H2O

max. 1,2 l

Refilling the boiler

Wiederbefüllen des

Kessels

Remplir de nouveau

la chaudière

Opnieuw vullen van

de ketel

Rabbocco della

caldaia

Fylle opp kjelen

Påfyllning av

vattenbehållare

Genopfyldning af

kedelen

Säiliön täyttö

uudelleen

Ponovno polnjenje

kotla

Ponovno punjenje

kotla

Nové naplnenia

zásobníka

Opětné naplnění kotle

Ponowne napełnianie

kotła

A víztartály újratöltése

Повторное

наполнение емкости

Relleno de la caldera

Voltar a encher a

caldeira

Επαναπλήρωση

λέβητα

Kazanýn tekrar

doldurulmasý

Other manuals for STEAMTEC 312

2

This manual suits for next models

2

Table of contents

Other Nilfisk-Advance Steam Cleaner manuals

Nilfisk-Advance

Nilfisk-Advance SDV 4500 User manual

Nilfisk-Advance

Nilfisk-Advance SO 4500 User manual

Nilfisk-Advance

Nilfisk-Advance SO 4500 User manual

Nilfisk-Advance

Nilfisk-Advance SDV 4500 User manual

Nilfisk-Advance

Nilfisk-Advance Multi Brush Manual

Nilfisk-Advance

Nilfisk-Advance SDV 8000 User manual

Nilfisk-Advance

Nilfisk-Advance SDV 8000 User manual