NIMO ECO Dryer 2.0 HP User manual

Other NIMO Dryer manuals

NIMO

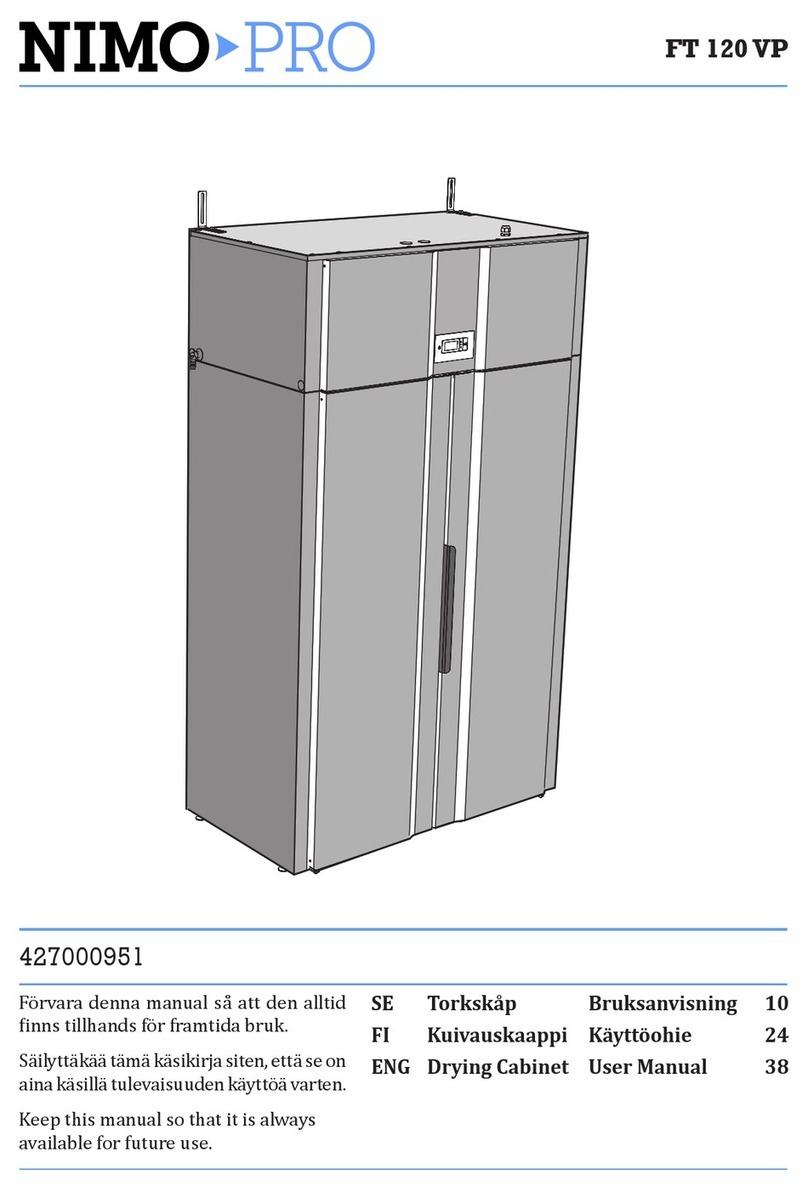

NIMO PRO FT 120 VP User manual

NIMO

NIMO ETS 1700E User manual

NIMO

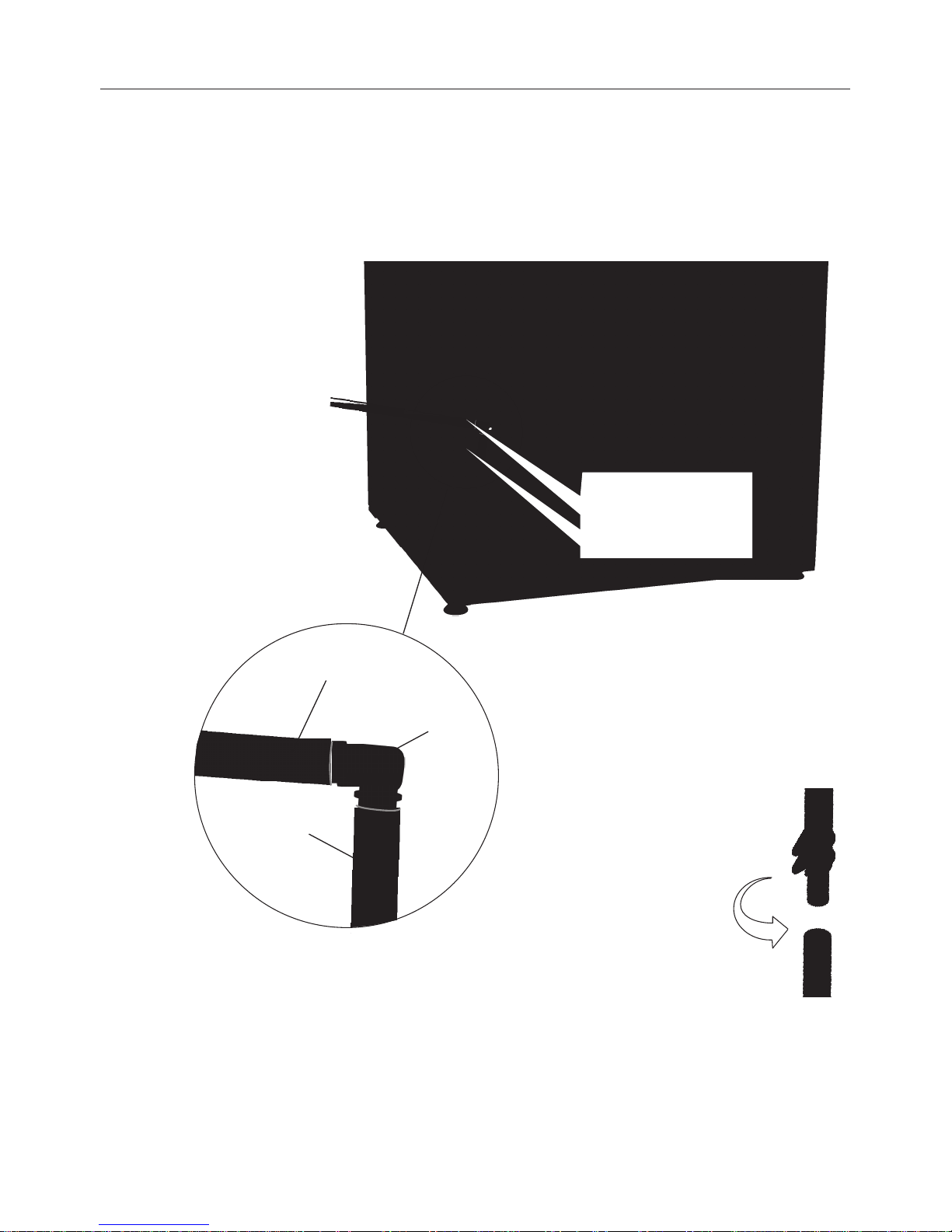

NIMO ECO Dryer 2.0 HP User manual

NIMO

NIMO ETS 1500 User manual

NIMO

NIMO PRO FT 120 FL User manual

NIMO

NIMO Easy Dryer 1900 User manual

NIMO

NIMO KM 80 User manual

NIMO

NIMO FT 120 VP User manual

NIMO

NIMO ETS 1500 E User manual

NIMO

NIMO KM 80 User manual

Popular Dryer manuals by other brands

Alliance Laundry Systems

Alliance Laundry Systems TMB795C Installation

Asko

Asko T793C operating instructions

Kenmore

Kenmore 8041 - 5.8 cu. Ft. Capacity Electric Dryer installation instructions

Frigidaire

Frigidaire CAQE7077KW0 use & care

Bosch

Bosch WTX8HKM9SN User manual and installation instructions

Sharp

Sharp KD-NHH9S7GW2-PL user manual