9

5

47

6

3

230 mm 1

2

1450 mm

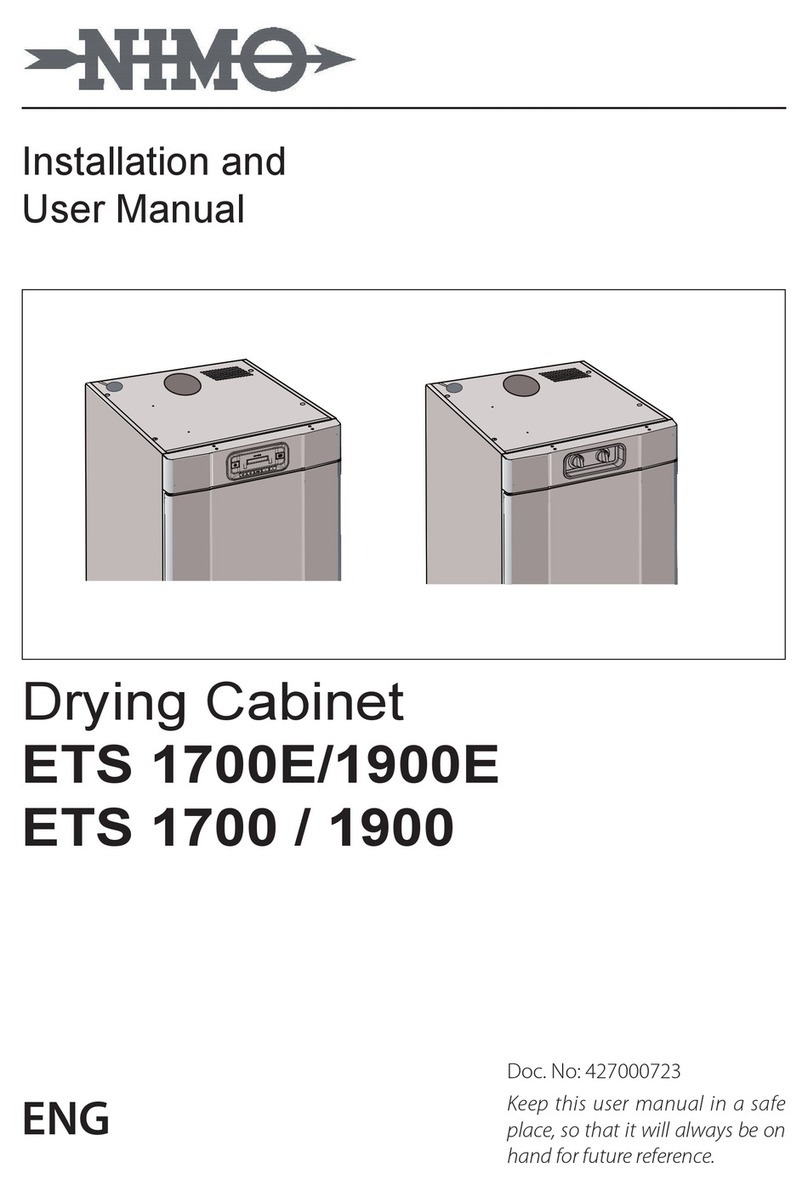

1. Supporting bracket

2. Pre-drilled holes

3. Attachment screw with washer

4. Plastic plug

5. Wall behind the drying cabinet

6. Spacer

7. Drying cabinet back wall

The illustration

shows model

ETS 1500

_____________________________________________

The drying cabinet must be installed and kept indoors.

_____________________________________________

____________________________________________

The drying cabinet must not be installed where high-

pressure water jets are used for cleaning.

____________________________________________

The drying cabinet can conveniently be installed

above a front-loading washing machine.

____________________________________________

However, it must hang on the wall and not placed directly

on top of the washing machine. This is to avoid vibration

when the washing machine is running. A supporting

bracket is supplied with the drying cabinet.

____________________________________________

1

Mark up for the supporting bracket and secure it to the wall

with screws. Screws are supplied in the installation kit.

2 Hang up the cabinet.

The cabinet must be secured to the wall to prevent it tipping

forward.

3

Open the door and drill 8 mm holes in the wall through the

four pre-drilled holes in the rear of the drying cabinet.

4

Insert plastic plugs in to the holes in the wall. Place a spacer

on the screw and install with a washer as shown in the il-

lustration. Screws are supplied in the installation kit.

____________________________________________

WARNING! The drying cabinet must not be used unless

it is xed to the wall, due of the risk of tip-

ping forward.

____________________________________________

POSITIONING

INSTALLATION