5

SAFE USE

This advice on safe use is intended to enable you to avoid incorrect use and to reduce

the risk of unnecessary accidents, and should be read prior to installation and use

of the drying cabinet.

USES

CAUTION! This equipment is only in-

tended to be used to dry fabrics washed

in water.

The drying cabinet can be used by

children aged 8 or over and persons (in-

cluding children) with physical, sensory

or mental impairments, provided they

have received guidance or information

on how to use the drying cabinet safely

and understand the risks that can occur.

Do not allow children to play in or on the

drying cabinet. Keep an eye on children

when they are in the immediate vicinity

of the cabinet.

Cleaning and maintenance must not be

carried out by children without supervi-

sion.

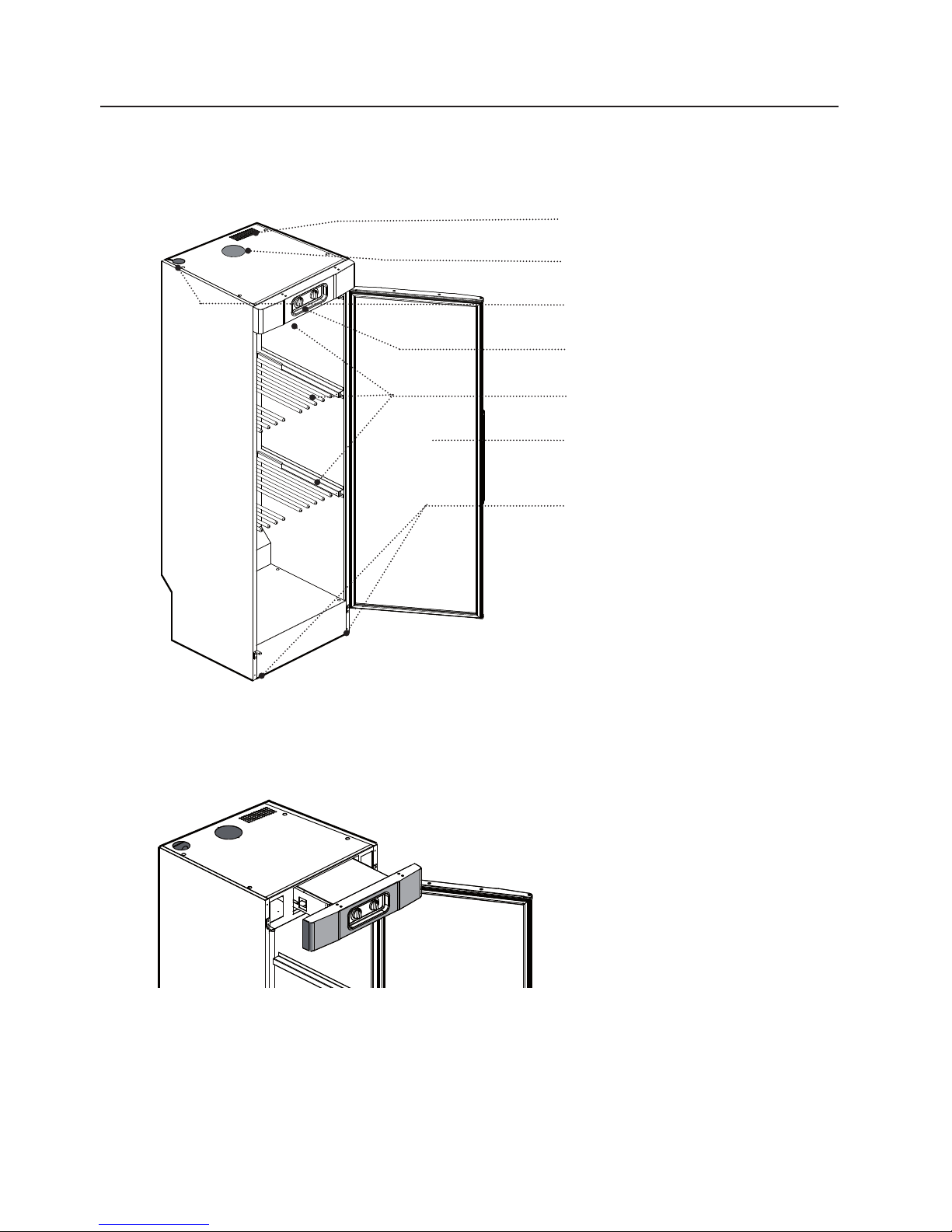

TECHNICAL SAFETY

Check the drying cabinet for visible

damage before installing it. A damaged

drying cabinet must not be used as it may

pose a hazard.

The drying cabinet must only be con-

nected to a grounded socket installed

in accordance with applicable safety

regulations. After installation the wall

socket must be accessible so that the

power supply to the drying cabinet can

be disconnected at any time.

Check that the data on the drying cabi-

net’s data plate (fuse, voltage and fre-

quency) is in agreement with the mains

supply at the place where the cabinet is

installed.

The drying cabinet must not be con-

nected using an extension cable as the

necessary safety cannot be guaranteed

(risk of overheating).

If the mains lead is damaged it must

be immediately replaced, and only by

the manufacturer, the manufacturer’s

service agent or similar qualied persons

to avoid danger.

This drying cabinet meets applicable safety requirements. Incorrect use may, however,

lead to injuries and damage to property.