Endless Procedure for:

Nitta CFTG-60FS-4.5 Material,

Using FP-200T and NPS-2005A-1B

(Fast Cook Procedure)

CFTG-60FS-4.5 belting material

Steel ruler and pen (for marking)

Scissors or clippers (for cutting belt and trimming fingers)

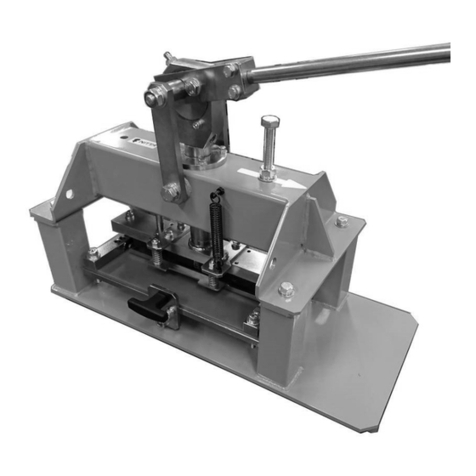

Finger Puncher FP-200T; includesT-wrench

45mm-wide green resin pre-setter

Heating/Cooling Press NPS-2005A-1B

CF-45 Fabric

Note: For detailed instructions on how to use the FP-200T

finger puncher and NPS-2005A-1B press, please consult

their Operation Manuals.

Setting

(Upper Plate Side / Belt / Bottom Plate Side)

CF-45 Fabric / polyurethane side of belt / rubber side of belt

Page 1 of 4

7605 Nitta Drive, Suwanee, GA 30024 •Toll-free: 1-800-221-3689

Nitta Corporation of

America is registered

to ISO 9001:2008

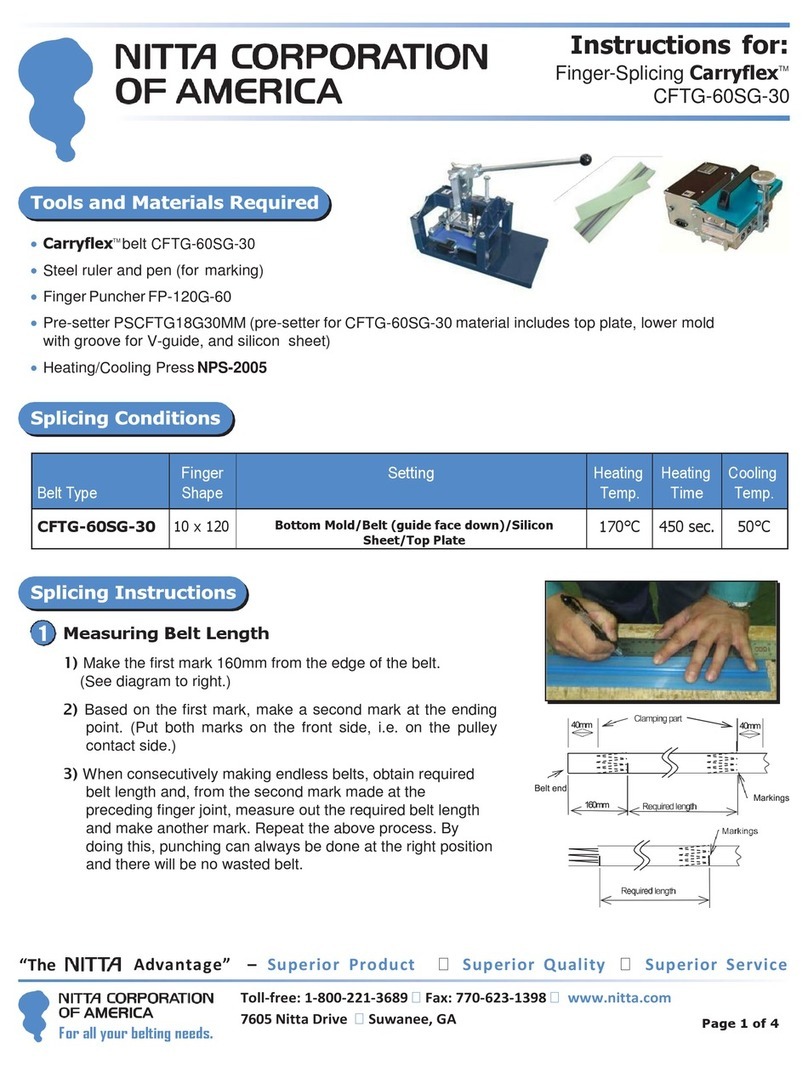

TOOLS AND MATERIALS REQUIRED

PART I –PREPARING FINGER ENDS USING FP-200T

CUT BELT TO LENGTH NEEDED PLUS 270MM, THEN MAKE 270MM MARK ON EACH END:

When measuring belt length, add 270mm to allow for the finger joint. Using scissors or clippers,

cut belt to length needed plus 270mm, then mark 270mm in from each end on the polyurethane

side.

FEED BELT INTO PUNCHER, ALIGNING MARK ON BELT WITH OUTSIDE EDGE OF CLAMP:

Loosen clamping bars and insert one end of belt polyurethane side up. 270mm mark should be

placed to the outside of clamp.

Polyurethane

Side of Belt Up