Nitta FP-200T User manual

GM-NIT-17001E

Follow this manual when using the Finger Puncher.

Please pass this manual to the Finger Puncher users for a safe and trouble-free

operation.

F

Fi

in

ng

ge

er

r

P

Pu

un

nc

ch

he

er

r

F

FP

P-

-2

20

00

0T

T

OPERATOR'S MANUAL

- 1 -

Table of Contents

1. Precautions for the Safety ............... 2

2. Confirmation of Product .................. 4

3. Specification ..................................... 4

4. Operation Environment .................... 5

5. Storage Environment ....................... 5

6. Name of each parts .......................... 6

7. How to Make a Finger Joint ............ 7

8. Troubleshooting ............................... 9

9. Spare parts ........................................ 9

10. Maintenance ...................................... 9

11. Inspection ........................................ 12

12. Parts List ......................................... 13

13. Warranty and after-sales service ....... 15

- 2 -

1. Precautions for the Safety

Please go over these safety precautions carefully to secure a correct and safe

operation of the Finger Puncher FP-200T

Disregarding instructions marked with this symbol may lead

to death or serious injury.

Disregarding instructions marked with this symbol may lead

to injury or property damage.

WARNING

Do not use the Finger Puncher for any application other than the

intended purpose of making belts endless.

Use for any unintended purpose may cause an unexpected accident.

A person with experience and skills should always operate,

maintain and inspect the Finger Puncher.

Handling by an inexperienced person may cause injury.

Do not dismantle or remodel the Finger Puncher under any

circumstance. Please note the Finger Puncher uses a sharp

blade. Dismantling or remodeling the Finger Puncher may cause

physical injury.

For repair or inspection, please contact Nitta, your local distributor or

agent in your area.

Use a dry cloth for cleaning the Finger Puncher. To prevent fire,

do not use alcohol, benzine, thinner or any other inflammable

solvent.

CAUTION

WARNING

WARNING

WARNING

WARNING

WARNING

- 3 -

This machine is not intended for the physical, sensory or mental

handicapped persons use. They must have the supervision of a

person responsible for their safety, if they use this machine.

Failure to do this may cause injury.

Do not allow the child to handle this machine. Keep this machine

in the place where child's hand does not reach.

Failure to do this may cause injury.

CAUTION

Do not use the Finger Puncher under the following conditions:

・ Under a corrosive gas environment

・ Under an ambient temperature of 5℃ or below

・ Under an ambient temperature of 40℃ or above

・ Under a high humidity environment (humidity surpassing 85%)

・ In places exposing the puncher to steam or water drops

To prevent physical injury, use the Finger Puncher on a stable

working bench or table that will not collapse.

Before using the Finger Puncher, be sure to inspect the puncher

in accordance with the procedure described on page 12 to help

prevent injury.

CAUTION

CAUTION

CAUTION

WARNING

WARNING

- 4 -

2. Confirmation of Product

Thank you for choosing our Finger PuncherFP-200T

Check that the product is exactly what you have ordered. Use

of the wrong product may cause injury.

2-1)Confirmation of Product

Confirm the following items upon accepting delivery of your order. Contact Nitta,

your local distributor or agent in your area if you find any deficiency or defect in

your item.

① Are descriptions on the face plate the same as those of your order item?

Please confirm the model type.

② Has the product been damaged during transportation?

③ Has a nut or screw slackened?

2-2)How to Read Face Plate

2-3)Inquiries

When making inquiries, please inform our sales representative of the model type

and the production serial number.

3. Specifications

3-1)Outline of Finger Puncher

①The Finger Puncher is exclusively designed for manually punching finger

splice able NITTA’s Carryflex belts with a cutting blade assembly.

②The Finger Puncher is compatible with the following endless specifications:

Finger geometry 200mm length×10mm pitch

Belt wide Max.45mm

Belt thickness 4~6mm

3-2)Major Specifications of Finger Puncher

Type FP-200T

Outer Dimension 480 mm W x232 mm Lx350 mm H

Weight 22.0kg

②Production serial number

FP-200T

1 7 0 0 1

CAUTION

①Model type

- 5 -

4. Operation Environment

Ambient Temperature 5-40℃ (no condensation)

Ambient Humidity 15-85%RH

Place of Use Indoors (free from dust, water)

Environment No inflammable, combustible or corrosive gas; no steam

Use the Finger Puncher under the above conditions.

5. Storage Environment

Ambient Temperature 5-40 ℃ (no condensation)

Ambient Humidity 15-85%RH

Place of Use Indoors (free from dust, water)

Environment No inflammable, combustible or corrosive gas; no steam

When the Finger Puncher is not in use, it should be stored under

the above conditions.

CAUTION

CAUTION

- 6 -

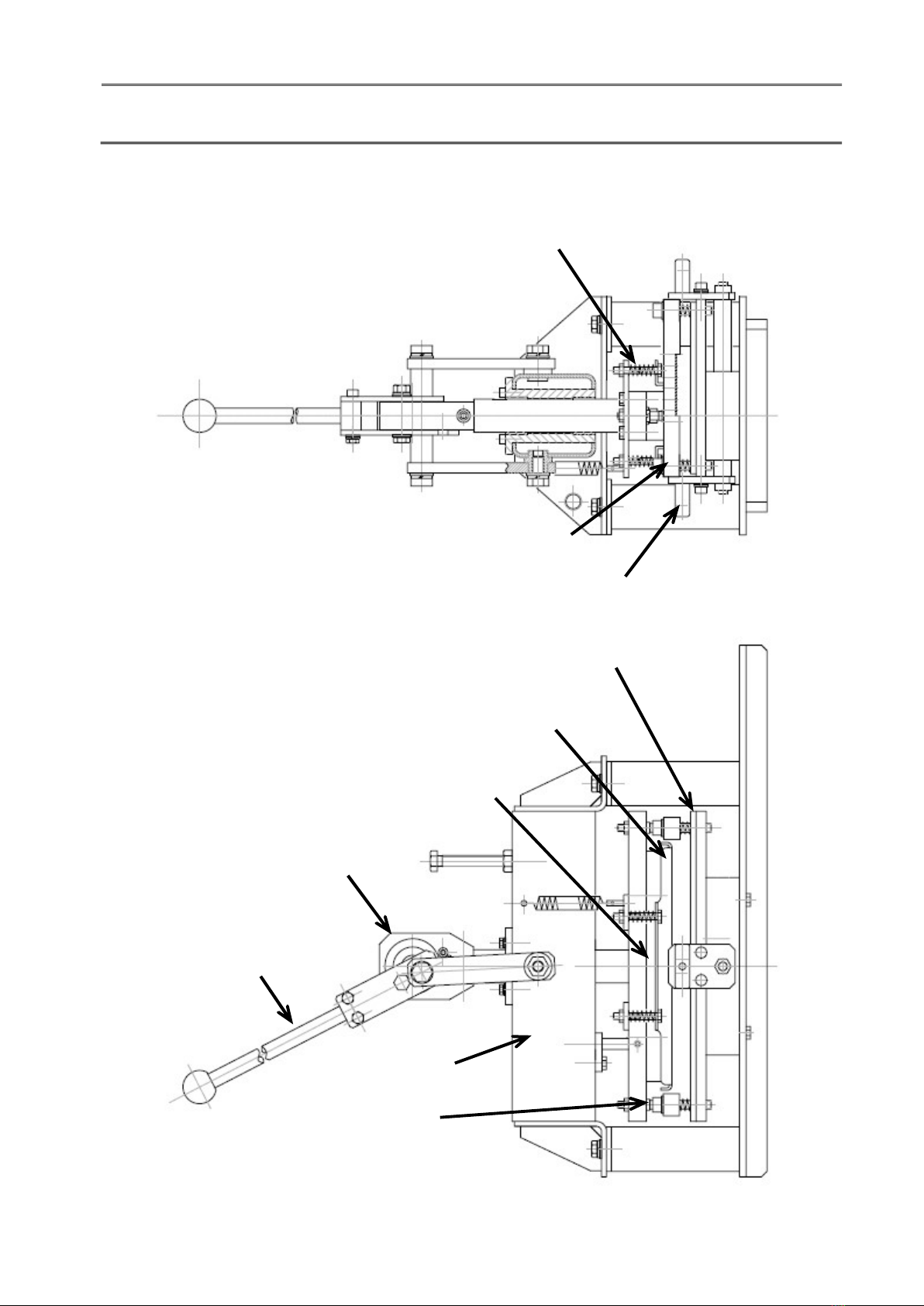

6. Name of Each Parts

EJECT PLATE

HANDLE BAR

BOLT

CUTTING BLADE

BELT CLAMP BAR

T type HANDLE

TOP FRAME

CAM HOLDER

CUTTING SHEET

SPRING

- 7 -

7. How to Make a Finger Joint

7-1) Required Tool (tool prepared in advance)

a. Finger Puncher

b. Tape Measure or Ruler

(for measurement of belt length)

c. Ballpoint Pen or Felt Pen (for marking)

d. Hexagon Wrench

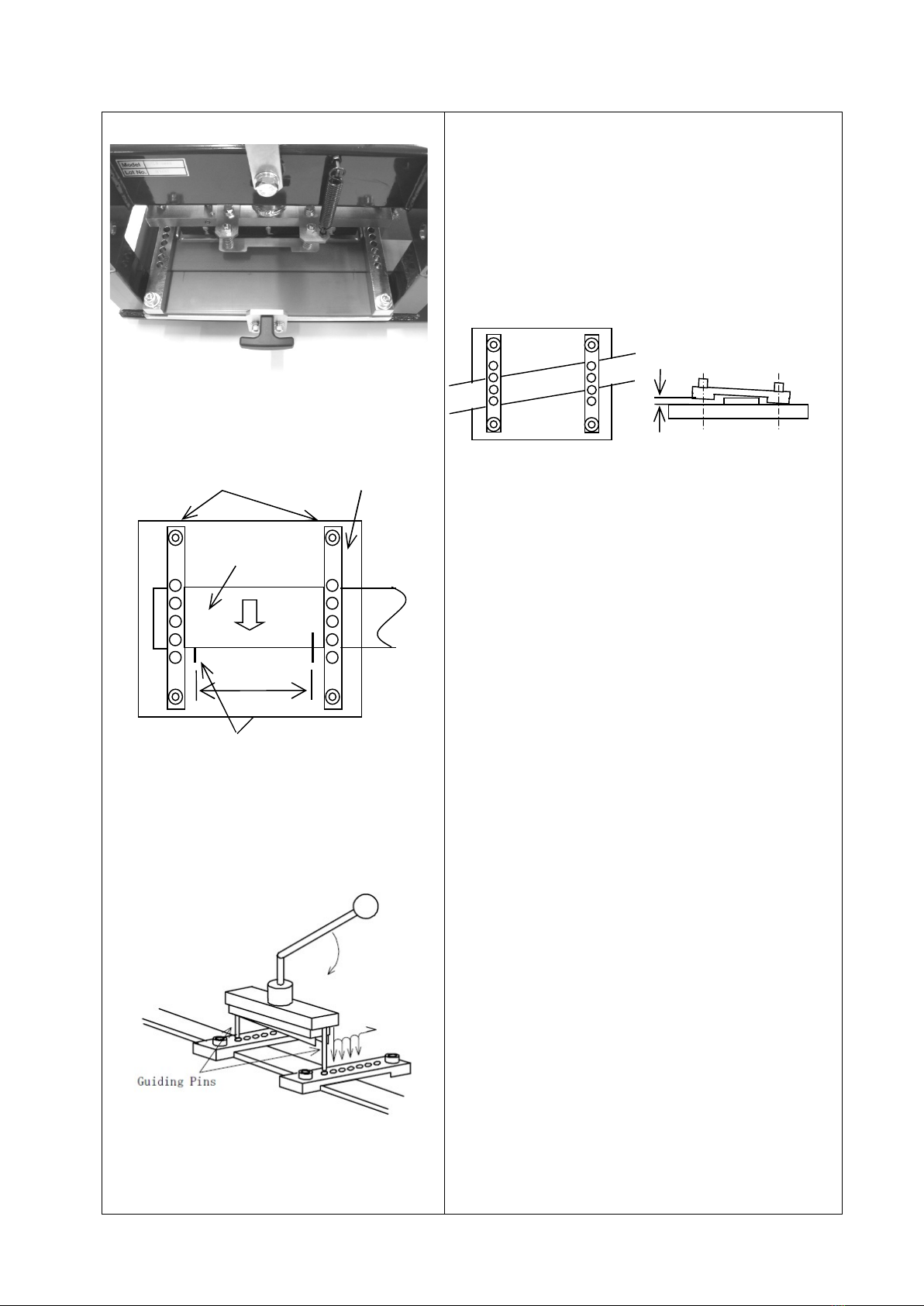

7-2) How to Measure Belt Length

Measure belt length and mark on the belt.

1) Measure Length from cut end.

2) Measure length from finger end

(For continuous measuring)

① The first mark 240mm from the edge of

the belt. (See diagram to left.)

② Based on the first mark, make a

second mark at the ending point of the

required belt length -5mm. (Put both

marks on the front side, i.e. on the

operator side.)

③ When consecutively making endless

belts, obtain required belt length and

from the second mark made at the

preceding finger joint, measure out the

required belt length and make another

mark. Repeat the above process. By

doing this, punching can always be

made at the right position and there

will be no wasted belt.

a

b.

C

Markings

Required length -5mm

Belt end

Markings

40mm

240mm

Clamping part 40mm

Required length -5mm

d

- 8 -

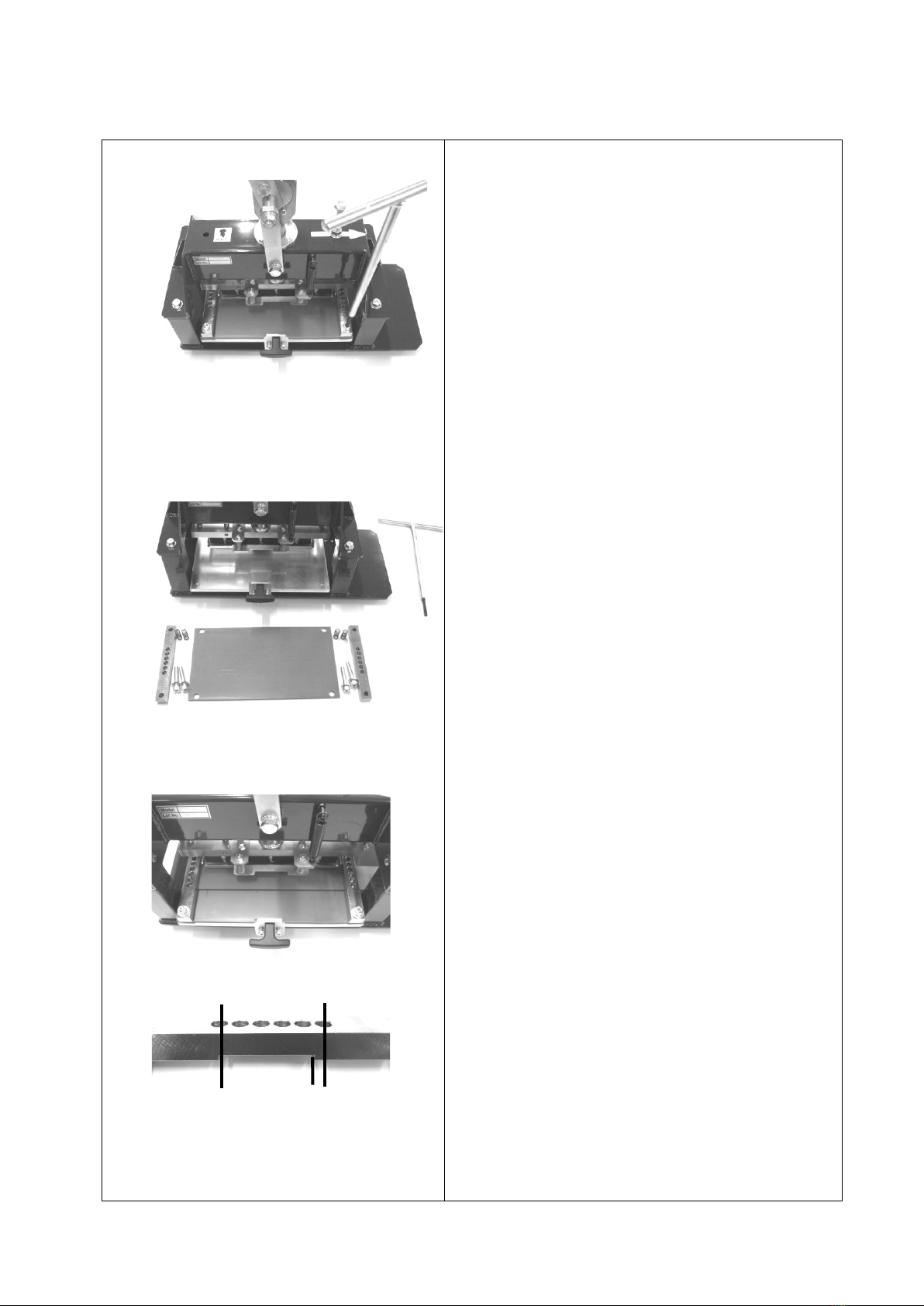

7-3) How to Make a Finger Joint

① Loosen bolt on clamping bar and insert a

belt end in one side of finger puncher.

② Place the belt to coincide marks on the

belt and the table.

③ Fasten the bolts on both clamps with a

wrench to secure the belt position.

※Do not tighten bolts tight. (2 N · m or less)

④ Continuous punching

After punching one end of a belt, pull out the

Belt through clamping bar until next

punching position.

⑤ Both ends cut belt

Each ends must be insert from opposite

side clamping bar and place the same side

edge of groove of the clamping bar.

⑥ Align the support table so that guide pins

on the cutter line up with a set of

alignment holes on either end of the

clamps.

⑦ Push downward on the handle carefully to

check the alignment of the pins.

⑧ Return the handle and move the support

table over so the next set will accept the

guide pins.

⑨ Repeat step ⑥-⑧.

NO

200 ㎜

Clamp bars Cutting Sheet

Belt

Mark 200 ㎜ joint length on the table.

Set both belt ends to same side of the

clamp

- 9 -

8. Troubleshooting

If there are any finger joints which are not cut out properly when a belt is punched,

follow the directions described in the “Maintenance” section on pages 9-11.

If the problem is not solved after following these directions, please contact Nitta,

your local distributor or agent in your area for advice.

9. Spare parts

1. Cutting sheet

2. Cutting blade

10. Maintenance

10-1) How to Perform Maintenance

If the handle bar does not move smoothly, Grease is injected from the grease

nipple.

You can change the position of the cutting sheet and both sides of the cutting

sheet can be used. Adjusting the position may solve any problems where a

portion of the finger joint is not cut out.

The cutting sheet and the cutting blade are consumable. Specify the cutting sheet

and the cutting blade for Finger Puncher when you order a new one.

10-2-1)How to Grease cam holder

①Grease is injected from the grease nipple.

- 10 -

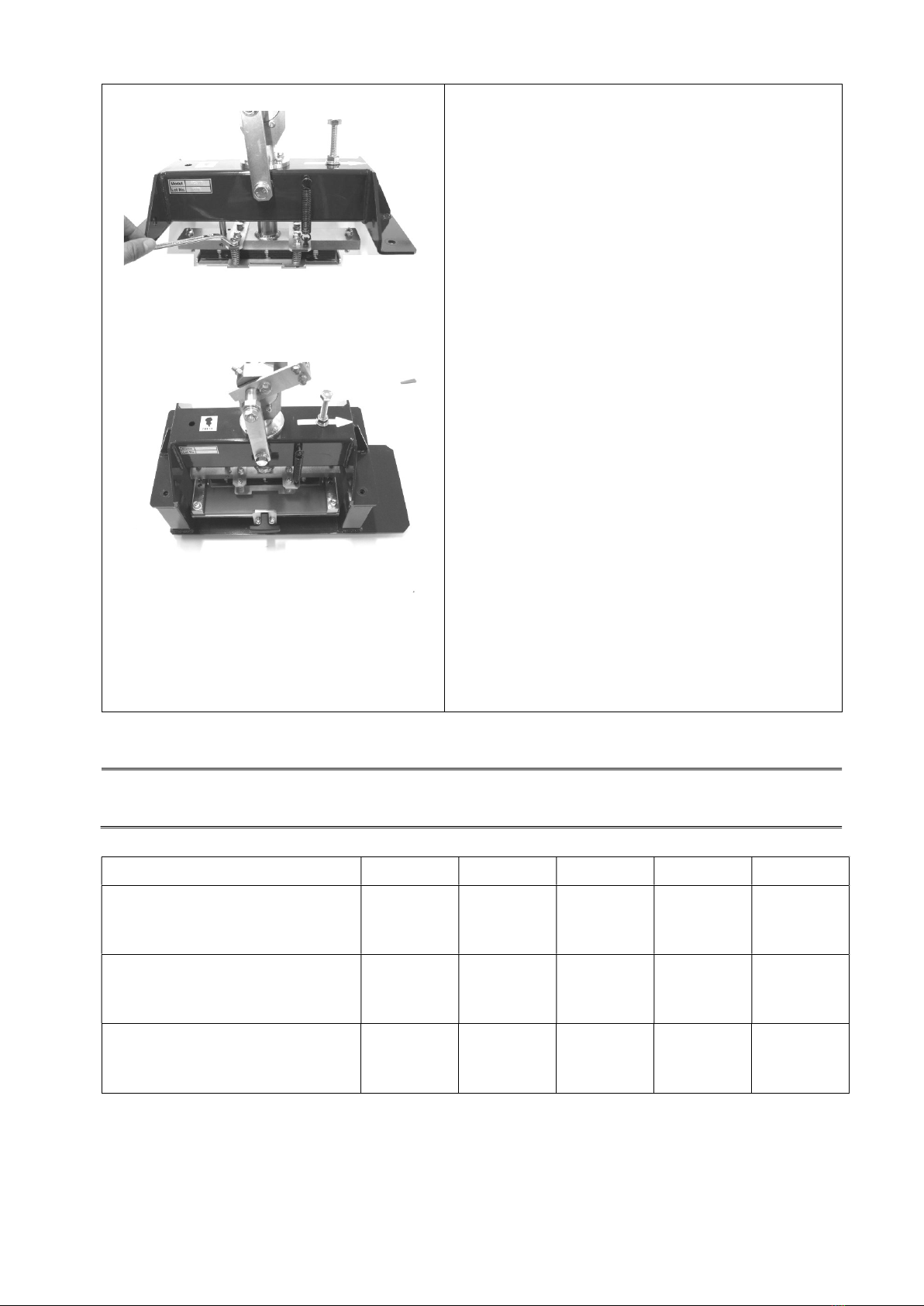

10-2-2)How to the cutting sheet board can use both sides.

① Loosen the bolt, and the bolt, the clamping

bar, and springs are detached.

※ Be careful not to lose them taken out of

the finger puncher.

② Reverse the cutting sheet to turn the

unused side up and insert it back to the

finger puncher.

③ Installed the springs, the clamp bars and

the bolt.

※The clamp bar is assembled to former

position.

5㎜

- 11 -

10-2-3) How to Exchange of cutting blade.

① Loosen the bolt, and the Top Frame is

detached.

※ Be careful not to lose them taken out of

the finger puncher.

② The nut of the eject plate fixation bolt is

loosened.

③ Loosen the bolt, and the eject plate are

detached.

④ Loosen the bolt, and the cutting blade are

detached.

Please never feel after the eject plate. It

is likely to injure it by the cutting blade.

WARNING

- 12 -

⑤ Tighten the bolt, and the eject plate is

assemble.

※The cutting blade is prevented from

protruding beyond the eject plate.

⑥ Tighten the bolt, and the upper frame is

assembled.

※Push downward on the handle carefully to

check the alignment of the pins.

11. Inspection

Inspection items date/staff

date/staff

date/staff

date/staff

date/staff

The puncher body is free of

damage or destruction.

All screws of the puncher

body are tightened.

The belt can be completely

punched out.

Make a copy of this page and use it for inspection prior to each use.

- 13 -

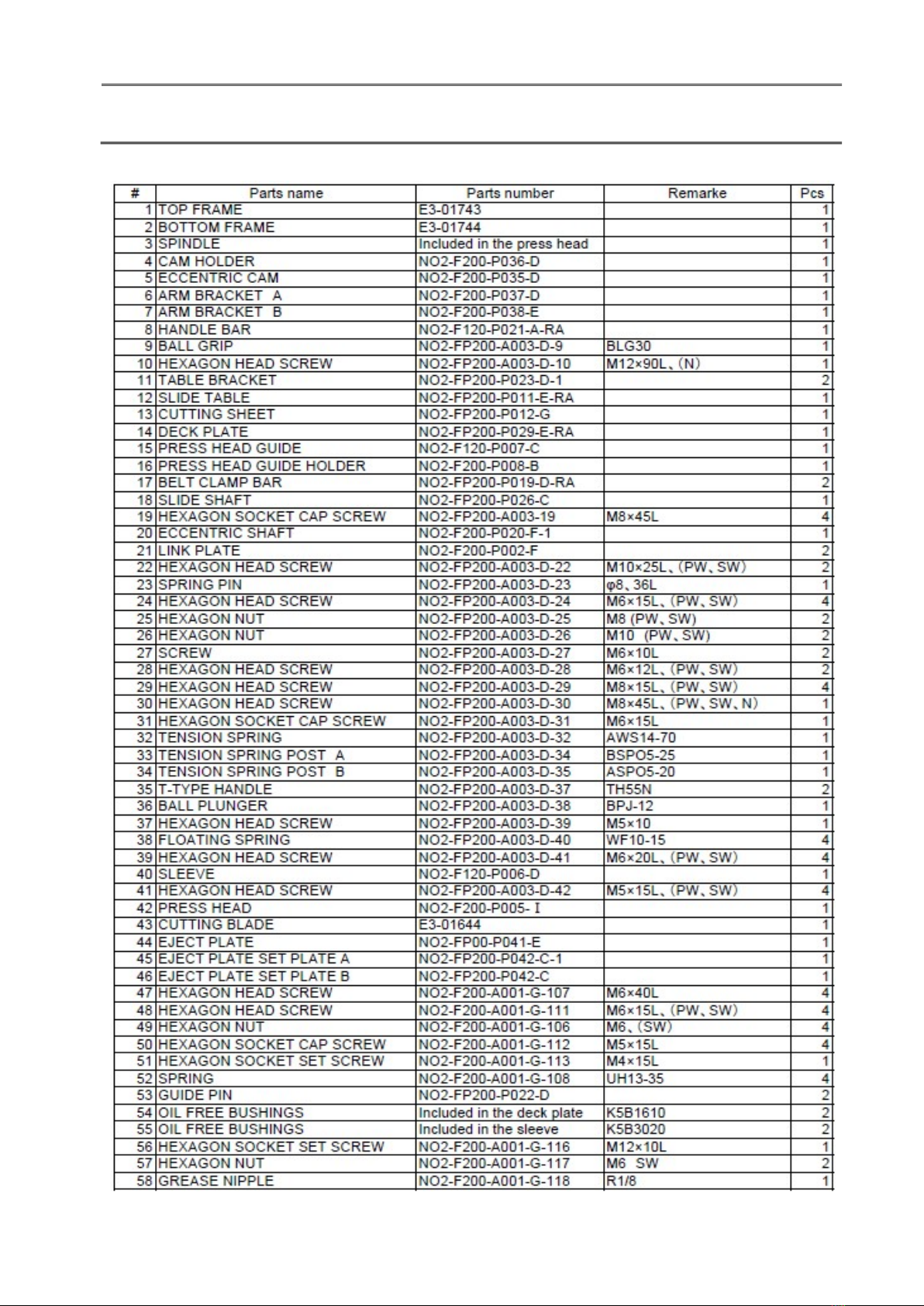

12. Parts List

- 14 -

- 15 -

13. Warranty and after-sales service

1. Warranty period

The warranty period is for one full year after the delivery of the order at your

appointed place.

2. Warranty coverage

1) Should the product malfunction due to causes for which our company is

responsible during the abovementioned warranty period, our company will

provide a replacement product or repair the product free of charge. However,

even within the warranty period the following cases shall not be covered by the

warranty. Please note that even if our company provides a replacement product

or repairs the product, the warranty period will be calculated from the initial date

on which the product was delivered.

① Malfunction arising from any inappropriate conditions, environment, handling

and usage which are not described in the Operation Manual and the Endless

Splicing Procedure.

② Malfunction due to a cause arising from something other than the product,

such as your own device.

③ Malfunction arising from any remodeling or repairing by other than our own

company.

④ Malfunction arising from any reasons unpredictable due to our level of

chemistry and technology before shipment.

⑤ Malfunction arising from fire, earthquake, flood, other disasters, voltage error,

or other external factors for which our company bears no responsibility.

⑥ Malfunction where it can be confirmed that, if perishables stipulated by the

Operation Manual and the Endless Splicing Procedure had been maintained

and/or replaced correctly, prevention of the malfunction would have been

possible.

2) The warranty does not apply to perishables. When perishables which have a

limited lifetime are repaired, and should those perishables be determined by our

company to have reached the end of their lifetime, the perishables will be

replaced for a fee.

① Parts which fall under the category of perishables: “cutting sheet”.

② Parts which fall under the category of perishables having a limited lifetime:

“Thomson blade”.

3) The warranty coverage is limited to what is stated in 1) above, and the warranty

does not cover secondary damages (equipment damage, opportunity loss, profit

loss) and any other damage incurred by the user as a result of a malfunction of

the product.

4) After the warranty period, if after examination the product is repairable, our

company will repair it upon request.

- 16 -

Memo

- 17 -

Oct, 2020 Rev6 FP-200T-E

Table of contents

Other Nitta Industrial Equipment manuals

Nitta

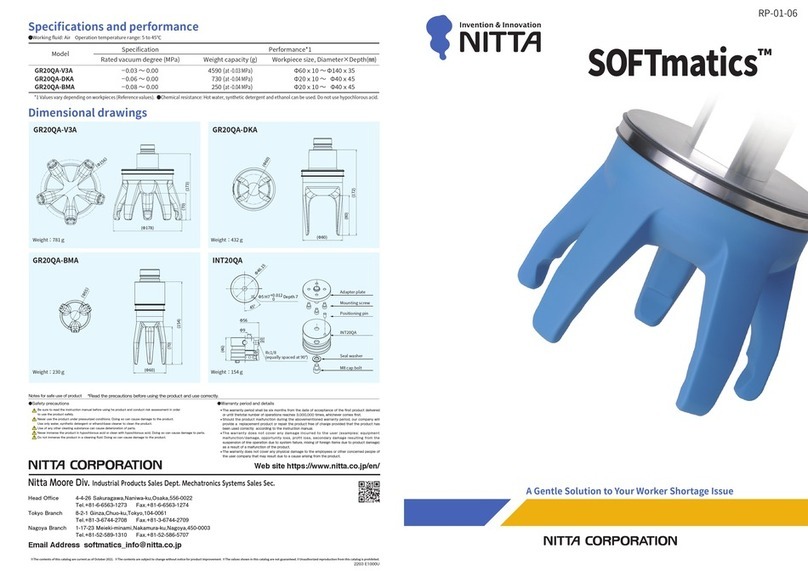

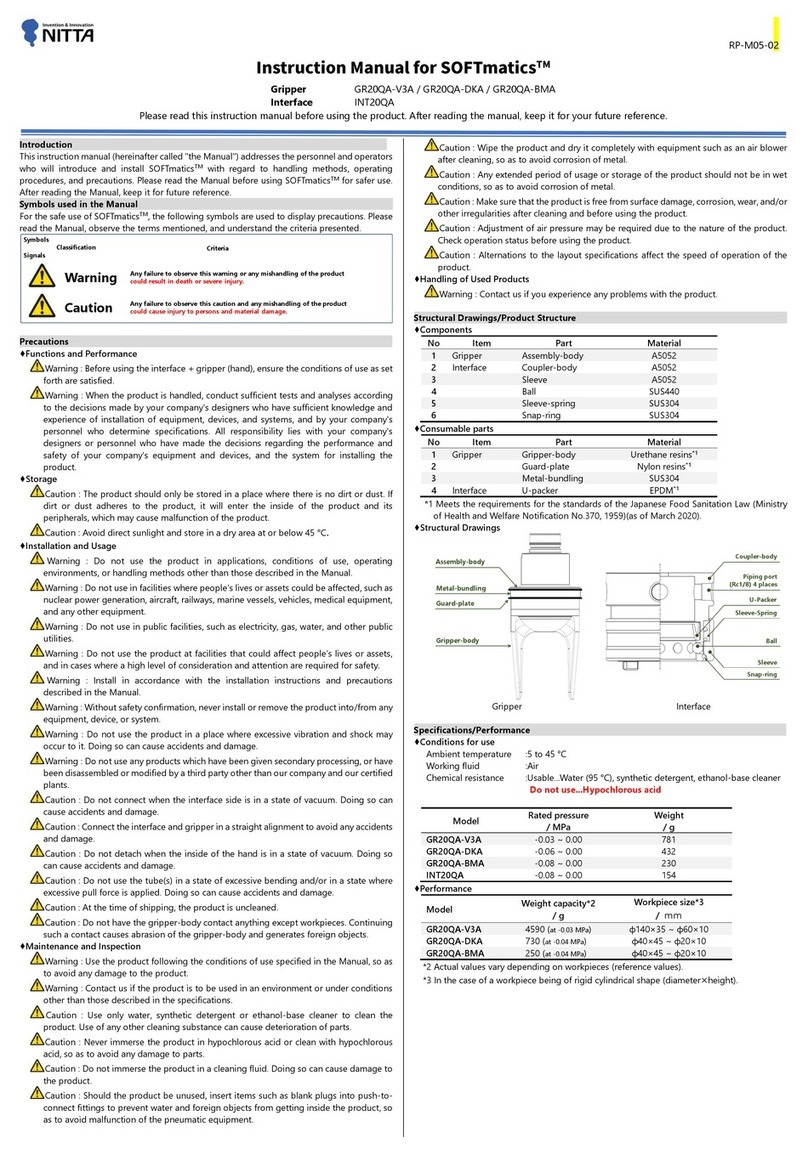

Nitta SOFTmatics User manual

Nitta

Nitta FP-200 User manual

Nitta

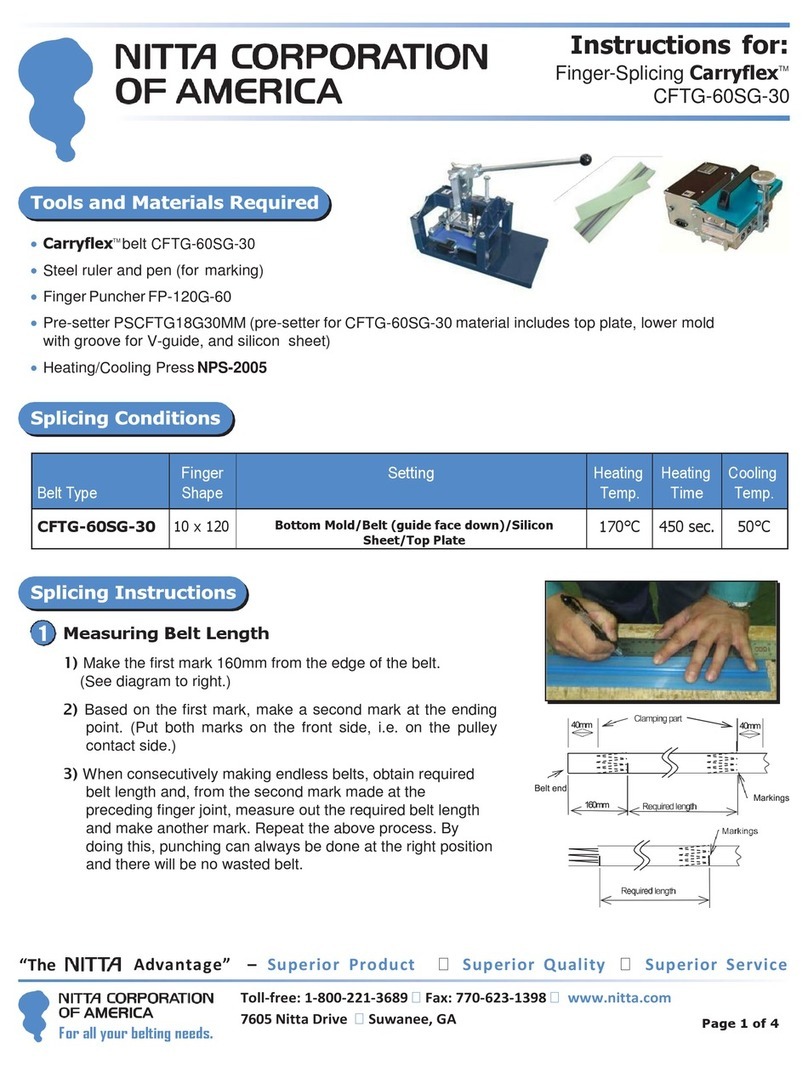

Nitta Carryflex CFTG-60SG-30 User manual

Nitta

Nitta SOFTmatics GR20QA-V3A User manual

Nitta

Nitta PolySprint FP70-10-50 User manual

Nitta

Nitta SEB User manual

Nitta

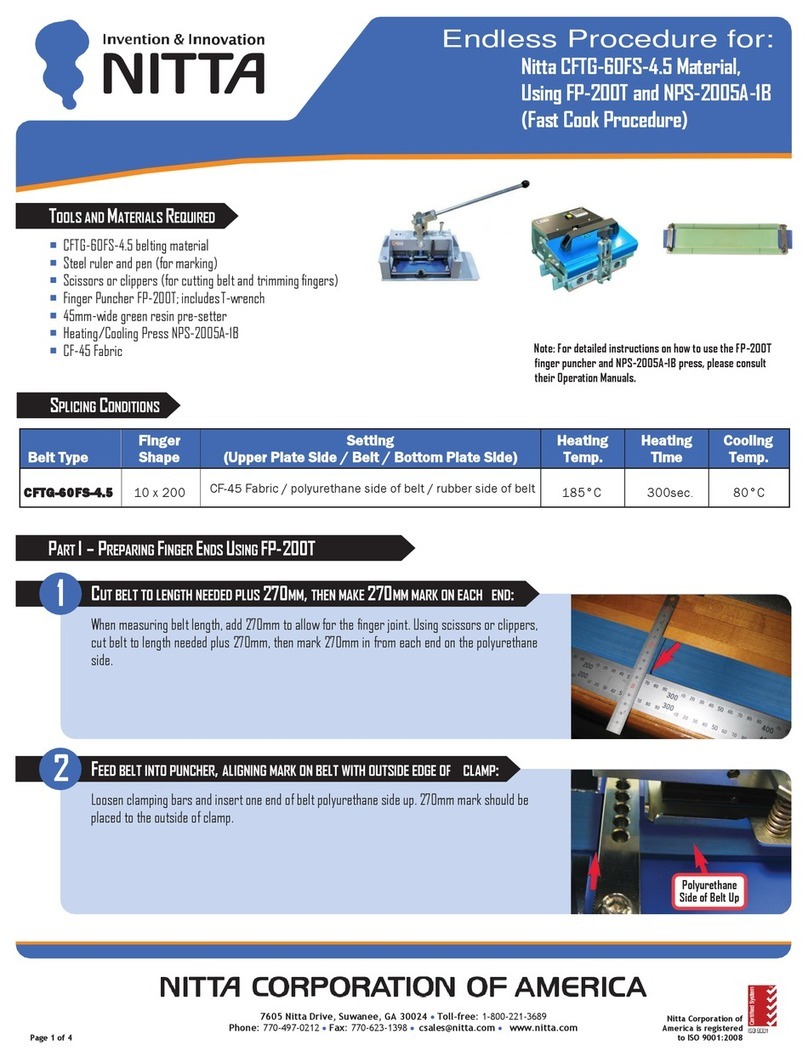

Nitta CFTG-60FS-4.5 User manual

Nitta

Nitta NPS-1205C User manual

Nitta

Nitta NITTAOMEGA type M165-K User manual