Nitta SOFTmatics GR20QA-V3A User manual

RP-M05-02

Gripper GR20QA-V3A / GR20QA-DKA / GR20QA-BMA

Interface INT20QA

Please read this instruction manual before using the product. After reading the manual, keep it for your future reference.

Introduction

This instruction manual (hereinafter called "the Manual") addresses the personnel and operators

who will introduce and install SOFTmaticsTM with regard to handling methods, operating

procedures, and precautions. Please read the Manual before using SOFTmaticsTM for safer use.

After reading the Manual, keep it for future reference.

Symbols used in the Manual

For the safe use of SOFTmaticsTM, the following symbols are used to display precautions. Please

read the Manual, observe the terms mentioned, and understand the criteria presented.

Precautions

♦Functions and Performance

Warning : Before using the interface + gripper (hand), ensure the conditions of use as set

forth are satisfied.

Warning : When the product is handled, conduct sufficient tests and analyses according

to the decisions made by your company's designers who have sufficient knowledge and

experience of installation of equipment, devices, and systems, and by your company's

personnel who determine specifications. All responsibility lies with your company's

designers or personnel who have made the decisions regarding the performance and

safety of your company's equipment and devices, and the system for installing the

product.

♦Storage

Caution : The product should only be stored in a place where there is no dirt or dust. If

dirt or dust adheres to the product, it will enter the inside of the product and its

peripherals, which may cause malfunction of the product.

Caution : Avoid direct sunlight and store in a dry area at or below 45 °C.

♦Installation and Usage

Warning : Do not use the product in applications, conditions of use, operating

environments, or handling methods other than those described in the Manual.

Warning : Do not use in facilities where people’s lives or assets could be affected, such as

nuclear power generation, aircraft, railways, marine vessels, vehicles, medical equipment,

and any other equipment.

Warning : Do not use in public facilities, such as electricity, gas, water, and other public

utilities.

Warning : Do not use the product at facilities that could affect people’s lives or assets,

and in cases where a high level of consideration and attention are required for safety.

Warning : Install in accordance with the installation instructions and precautions

described in the Manual.

Warning : Without safety confirmation, never install or remove the product into/from any

equipment, device, or system.

Warning : Do not use the product in a place where excessive vibration and shock may

occur to it. Doing so can cause accidents and damage.

Warning : Do not use any products which have been given secondary processing, or have

been disassembled or modified by a third party other than our company and our certified

plants.

Caution : Do not connect when the interface side is in a state of vacuum. Doing so can

cause accidents and damage.

Caution : Connect the interface and gripper in a straight alignment to avoid any accidents

and damage.

Caution : Do not detach when the inside of the hand is in a state of vacuum. Doing so

can cause accidents and damage.

Caution : Do not use the tube(s) in a state of excessive bending and/or in a state where

excessive pull force is applied. Doing so can cause accidents and damage.

Caution : At the time of shipping, the product is uncleaned.

Caution : Do not have the gripper-body contact anything except workpieces. Continuing

such a contact causes abrasion of the gripper-body and generates foreign objects.

♦Maintenance and Inspection

Warning : Use the product following the conditions of use specified in the Manual, so as

to avoid any damage to the product.

Warning : Contact us if the product is to be used in an environment or under conditions

other than those described in the specifications.

C aution : Use only water, synthetic detergent or ethanol-base cleaner to clean the

product. Use of any other cleaning substance can cause deterioration of parts.

Caution : Never immerse the product in hypochlorous acid or clean with hypochlorous

acid, so as to avoid any damage to parts.

Caution : Do not immerse the product in a cleaning fluid. Doing so can cause damage to

the product.

Caution : Should the product be unused, insert items such as blank plugs into push-to-

connect fittings to prevent water and foreign objects from getting inside the product, so

as to avoid malfunction of the pneumatic equipment.

Caution : Wipe the product and dry it completely with equipment such as an air blower

after cleaning, so as to avoid corrosion of metal.

Caution : Any extended period of usage or storage of the product should not be in wet

conditions, so as to avoid corrosion of metal.

Caution : Make sure that the product is free from surface damage, corrosion, wear, and/or

other irregularities after cleaning and before using the product.

Caution : Adjustment of air pressure may be required due to the nature of the product.

Check operation status before using the product.

Caution : Alternations to the layout specifications affect the speed of operation of the

product.

♦Handling of Used Products

Warning : Contact us if you experience any problems with the product.

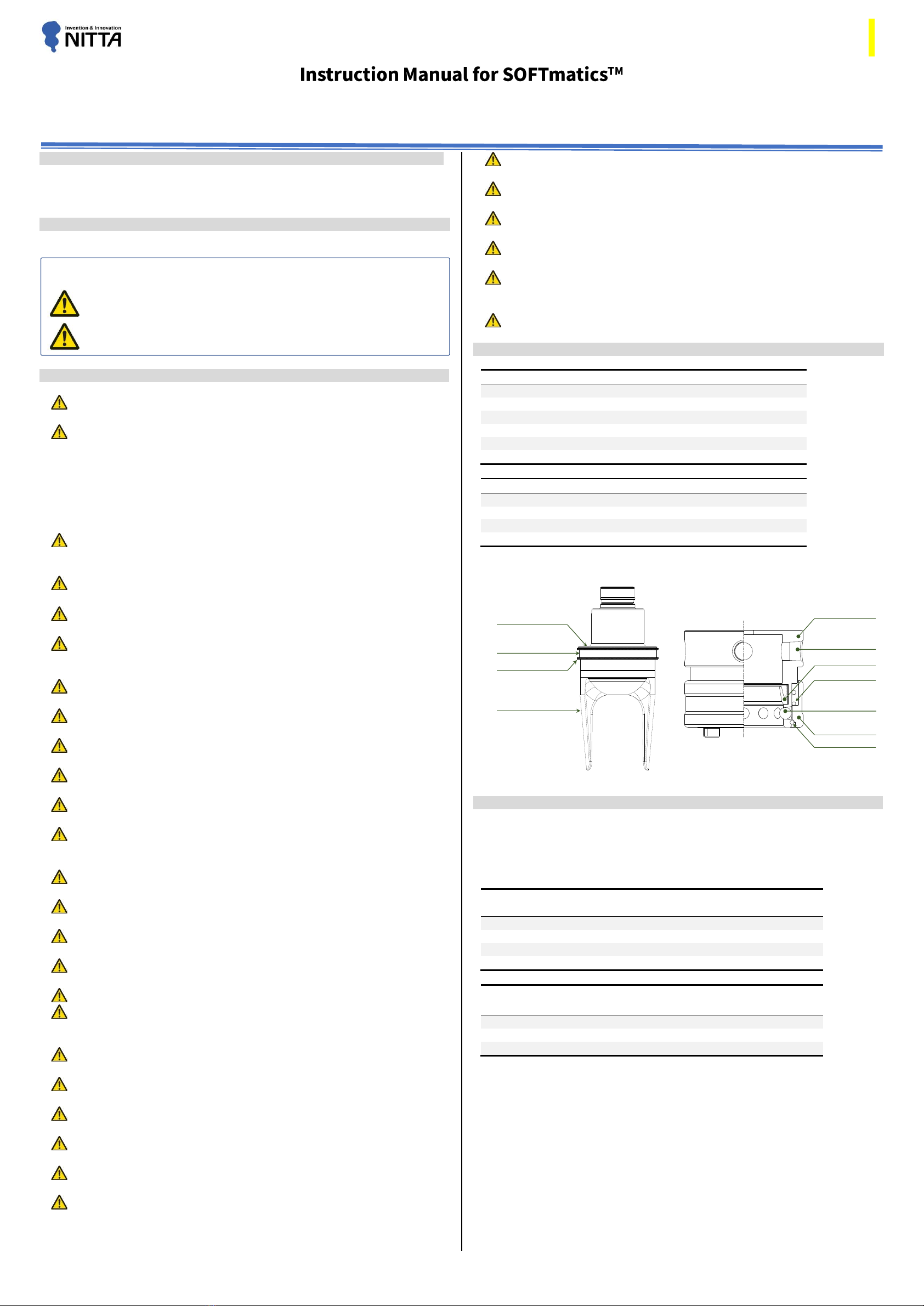

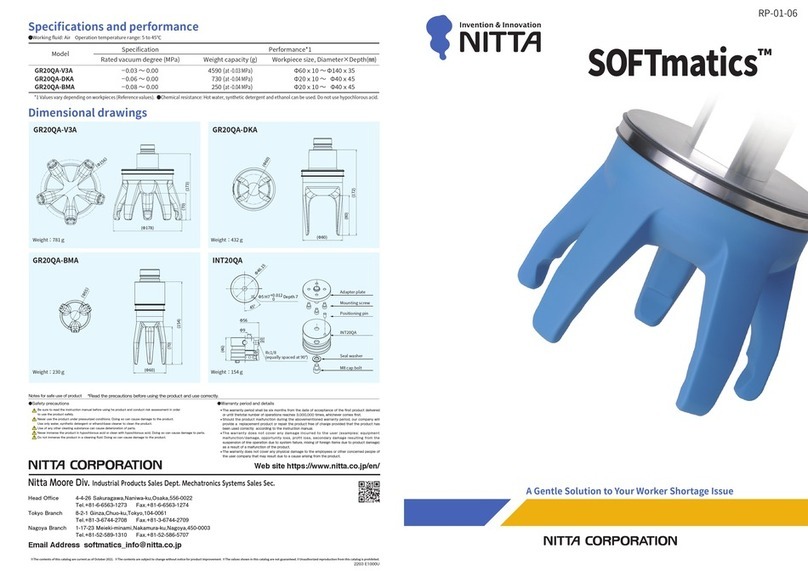

Structural Drawings/Product Structure

♦Components

No

Item

Part

Material

1

Gripper

Assembly-body

A5052

2

Interface

Coupler-body

A5052

3

Sleeve

A5052

4

Ball

SUS440

5

Sleeve-spring

SUS304

6

Snap-ring

SUS304

♦Consumable parts

No

Item

Part

Material

1

Gripper

Gripper-body

Urethane resins*1

2

Guard-plate

Nylon resins*1

3

Metal-bundling

SUS304

4

Interface

U-packer

EPDM*1

*1 Meets the requirements for the standards of the Japanese Food Sanitation Law (Ministry

of Health and Welfare Notification No.370, 1959)(as of March 2020).

♦Structural Drawings

Gripper

Interface

Specifications/Performance

♦Conditions for use

Ambient temperature

:5 to 45 °C

Working fluid

:Air

Chemical resistance

:Usable...Water (95 °C), synthetic detergent, ethanol-base cleaner

Do not use...Hypochlorous acid

Model

Rated pressure

/ MPa

Weight

/ g

GR20QA-V3A

-0.03 ~ 0.00

781

GR20QA-DKA

-0.06 ~ 0.00

432

GR20QA-BMA

-0.08 ~ 0.00

230

INT20QA

-0.08 ~ 0.00

154

♦Performance

Model

Weight capacity*2

/ g

Workpiece size*3

/ mm

GR20QA-V3A

4590 (at -0.03 MPa)

ф140×35 ~ ф60×10

GR20QA-DKA

730 (at -0.04 MPa)

ф40×45 ~ ф20×10

GR20QA-BMA

250 (at -0.04 MPa)

ф40×45 ~ ф20×10

*2 Actual values vary depending on workpieces (reference values).

*3 In the case of a workpiece being of rigid cylindrical shape (diameter×height).

Warning

Symbols

Classification

Signals

Criteria

Any failure to observe this warning or any mishandling of the product

could result in death or severe injury.

Caution Any failure to observe this caution and any mishandling of the product

could cause injury to persons and material damage.

Guard-plate

Assembly-body

Gripper-body

Metal-bundling

U-Packer

Snap-ring

Coupler-body

Sleeve

Sleeve-Spring

Ball

Piping port

(Rc1/8) 4 places

RP-M05-02

Operating Mechanisms

Before operating the product, ensure the conditions of use specified in the Manual are satisfied.

-By decompressing the inside of the hand, the gripper-body will change to a closed shape for

gripping.

-By recompressing the inside of the hand (atmospheric relief), the gripper-body will change to

an open shape for releasing a workpiece.

-The state of the gripper can be controlled by adjusting the air pressure inside the hand within

the terms of the conditions of use.

Instructions for Mounting and Demounting the Product from a Robot.

Follow the instructions below for mounting the product on a robot and demounting the product.

Caution : Mount and demount the product on/from a robot which is in a stable and

suitable position after stopping the robot safely.

<Items to prepare>

The following items are needed on every robot.

-Interface 1

-Seal washer 1 ... For mounting Adapter plate and Interface

-M8 cap bolt 1 ... For mounting Adapter plate and Interface

-Positioning pin 1 ... For positioning Adapter plate and Interface

-Adapter-plate Optional ... Prepare if necessary for installation

Following the figure below, mount an interface onto the adapter-plate which has already been

mounted on the robot. The layout below is an example (the configuration of the adapter-plate

in the figure is an example for reference).

Caution : Prepare M8 screws (female) for the adapter-plate for securing the interface.

Caution : Use a seal washer (e.g. Model: SGSWF8) to secure the vacuum degree inside

the hand.

Attachment and Detachment of Interface and Gripper

♦Upon the connection of the interface and gripper

(1)Recompress the air pressure on the interface side (on the robot or equipment) to the

atmospheric air pressure level.

(2)Remove any foreign objects in the connection.

(3)Insert the gripper while pulling the sleeve of the interface.

(4)Align for positioning, press down to the position where the sleeve returns to and manages

complete connection.

Caution : Do not connect a gripper when the interface side is in a state of vacuum.

Caution : Connect the interface and gripper in a straight alignment.

♦Detachment of interface and gripper

(1)Return the air pressure inside the hand to the atmospheric air pressure level.

(2)Pull the gripper in the parting direction while pulling the sleeve.

Caution : Lubricate the U-Packer inside the interface when attachment and detachment

are difficult. Recommended lubricating grease : MOLYKOTE® HP-500 Grease (DuPont

Toray Specialty Materials K.K.)

Caution : Do not make a detachment when the inside of the hand is in a state of vacuum.

Doing so can lead to accidents and damage.

Caution : To avoid any injury, be careful of the protrusion when attaching and detaching.

Example of layout

Caution : Connect a pneumatics fitting to the port (Rc1/8 thread) of the interface, and

cover the ports that are not used with items such as blank plugs.

Replacement of Consumable Parts

Long-time usage may cause the deterioration of consumable parts in the gripper and interface.

Our company offers the replacement of consumable parts (fee required). Please use the contact

information below to make such a request.

Warranty

♦Warranty Period

-The warranty period is limited to six months from the date of acceptance of the first product

delivered or until the total number of operations reaches 3,000,000 times (in accordance with

standard conditions established by our company), whichever comes first.

♦Warranty Coverage

-Should the product malfunction and/or fail during the abovementioned warranty period, our

company will provide a replacement product or repair the product free of charge, provided

that the product has been used correctly in accordance with the conditions and statements of

precaution, which include conditions for use and handling procedures, set forth in the Manual.

-The warranty does not cover any damage incurred by the user (examples: equipment

malfunction/damage, opportunity loss, profit loss, secondary damage resulting from the

suspension of line operation due to system failure, mixing of foreign items due to product

damage) as a result of a malfunction of the product.

-The warranty does not cover any physical damage to the employees of the user company or

other concerned people that may result due to a cause arising from the product.

(1) Malfunction arising from any reasons unpredictable due to our level of science and

technology before shipment.

(2) Malfunction arising from fire, earthquake, flood, other disasters, voltage error, or other

reasons for which our company bears no responsibility.

♦Acceptable Usage

-The product is not intended to be used outdoors or under conditions or environments not

specified in the equivalent instruction manual, etc., and is therefore not acceptable. However,

exemption is possible, at the sole risk of the user company, when the user company has

consulted with our company in advance, has acknowledged ratings and performance after

ensuring the specifications of the product, and has adopted necessary safety measures. Further,

even in such cases, the coverage of the warranty is the same as above.

♦Changes to Specifications

-The name, specifications, appearance, accessories, and others described in the Manual are

subject to change without notice for improvement and for other reasons.

For inquiries

♦About SOFTmaticsTM

For more details, please use the contact form on our website, or contact us at the addresses

below.

♦About the catalogue

The catalogue can be downloaded from the homepage of our company.

Nitta Moore Div. Industrial Products Sales Dept. Mechatronics Systems Sales Sec.

Head Office

4-4-26 Sakuragawa, Naniwa-ku, Osaka, Osaka 556-0022

TEL: +81 6-6563-1273 FAX: +81 6-6563-1274

Tokyo Branch

8-2-1 Ginza, Chuo-ku, Tokyo 104-0061

TEL: +81 3-6744-2708 FAX: +81 3-6744-2709

Nagoya Branch

1-17-23 Meieki-minami Nakamura-ku, Nagoya, Aichi 450-0003

TEL: +81 52-589-1310 FAX: +81 52-586-5707

No reproduction of figures, pictures, and text used in the Manual is permitted.

Copyright© 2022 NITTA CORPORATION.

All rights reserved.

Grippng forceGrippng force

Decompression

Decompression

Recompression

OPEN CLOSED

M8 cap bolt

Seal washer

Interface

Positioning pin

Adapter-plate

Sleeve

Interface

NGOK

Sleeve

Gripper

1

2

U-Packer

Protrusion

Examples of models for vacuum ejectors

VSC

-H15-10A10S (CKD Corporation)

VHH15

-1002 (Nihon Pisco Co., Ltd)

CV

-15LS (COMVUM Ltd.)

Vacuum ejector

2-port solenoid valves

Air supply

Fitting

Vacuum gauge

SOFTmaticsTM

Regulator

This manual suits for next models

3

Other Nitta Industrial Equipment manuals

Nitta

Nitta SEB User manual

Nitta

Nitta NITTAOMEGA type M165-K User manual

Nitta

Nitta FP-200 User manual

Nitta

Nitta NPS-1205C User manual

Nitta

Nitta SOFTmatics User manual

Nitta

Nitta PolySprint FP70-10-50 User manual

Nitta

Nitta CFTG-60FS-4.5 User manual

Nitta

Nitta Carryflex CFTG-60SG-30 User manual

Nitta

Nitta FP-200T User manual

Popular Industrial Equipment manuals by other brands

Viessmann

Viessmann vitotronic 200-h operating instructions

WPG

WPG MRT4 Series operating instructions

3M

3M Attest 390 Operator's manual

Nidec

Nidec LEROY-SOMER LSA 43.3 IC7 L7 Installation and Maintenance

Ricoh

Ricoh Bridge Unit BU5010 Field service manual

Mitsubishi Electric

Mitsubishi Electric NF250-SEV instruction manual