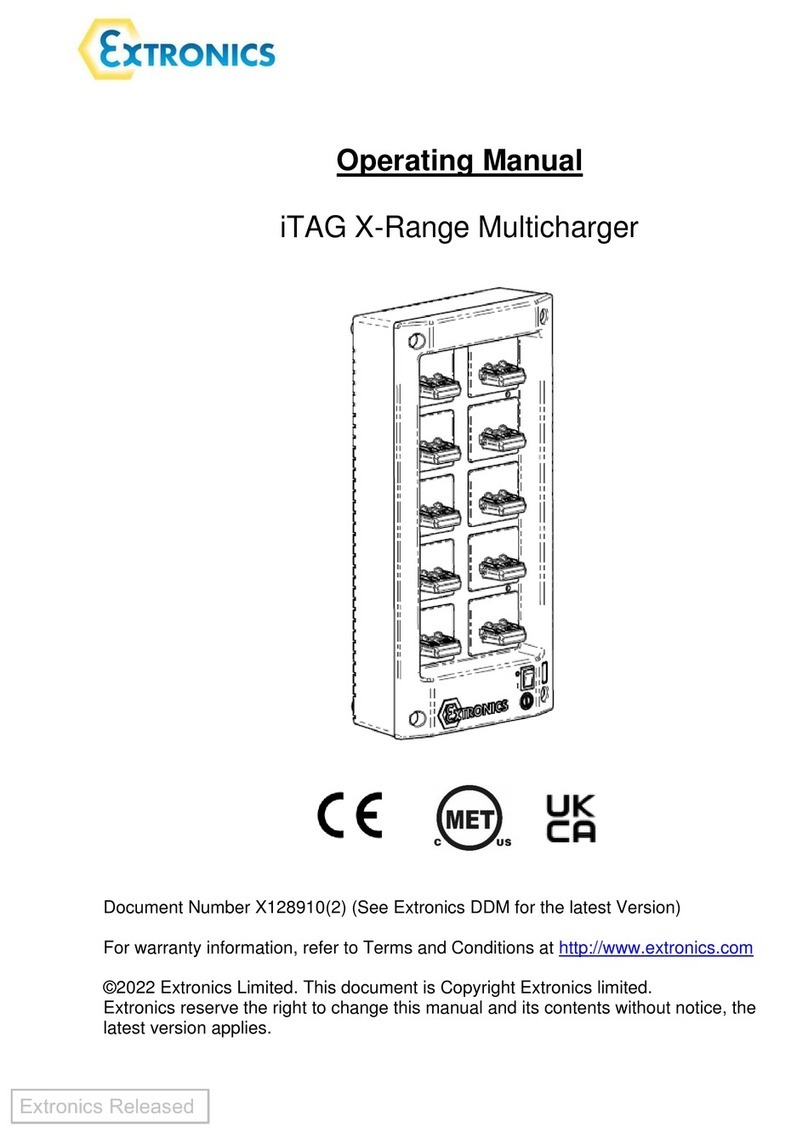

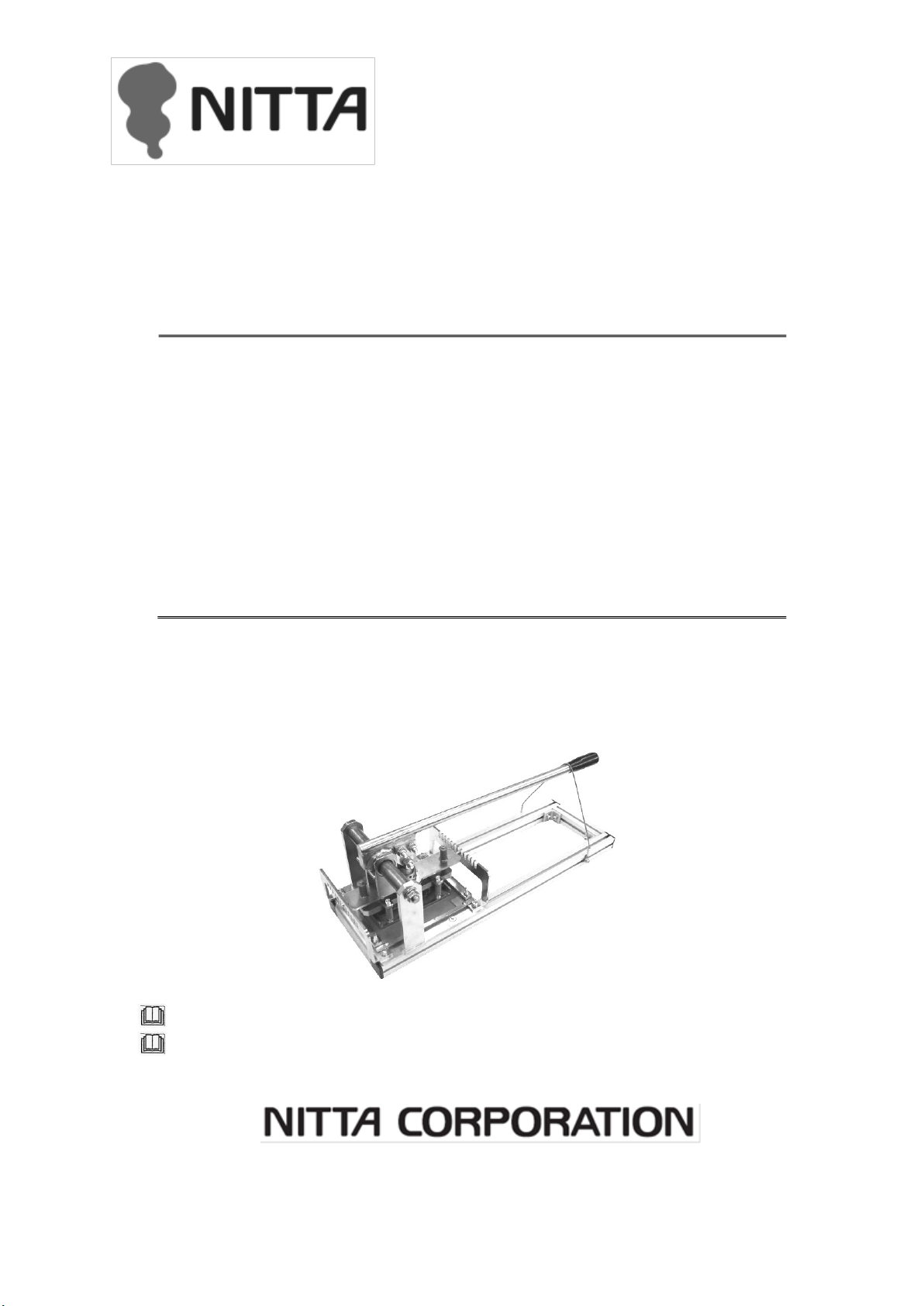

Nitta PolySprint FP70-10-50 User manual

This manual suits for next models

4

Table of contents

Other Nitta Industrial Equipment manuals

Nitta

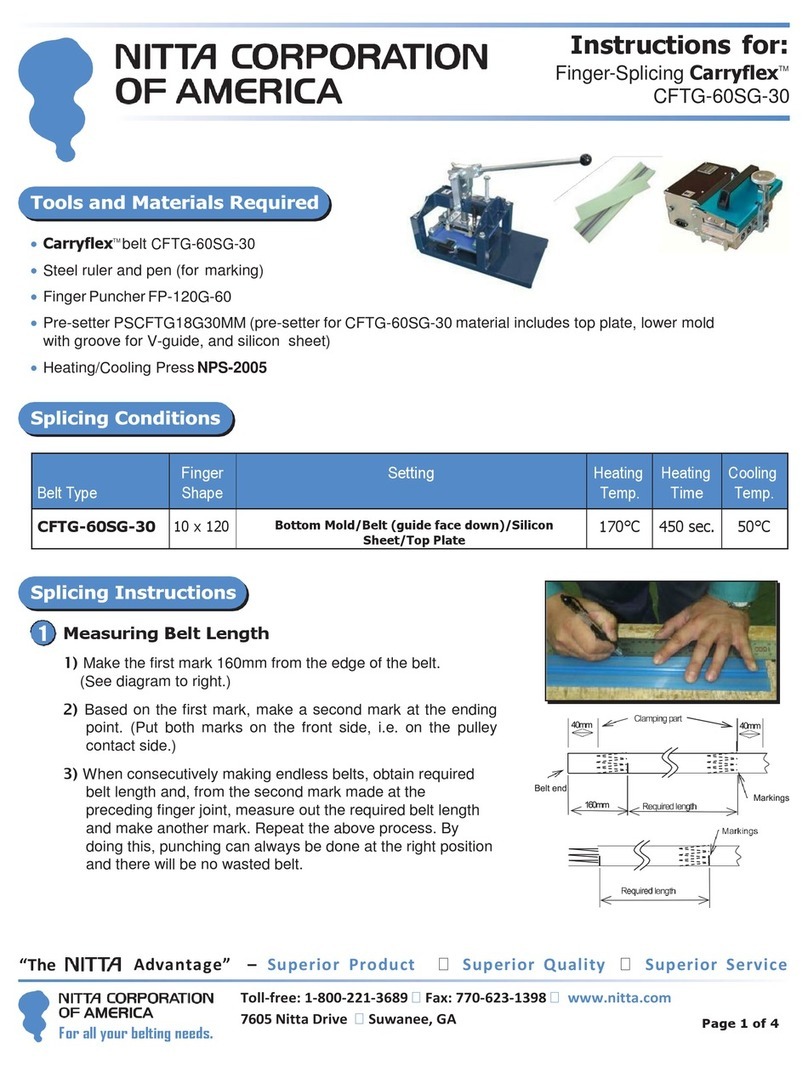

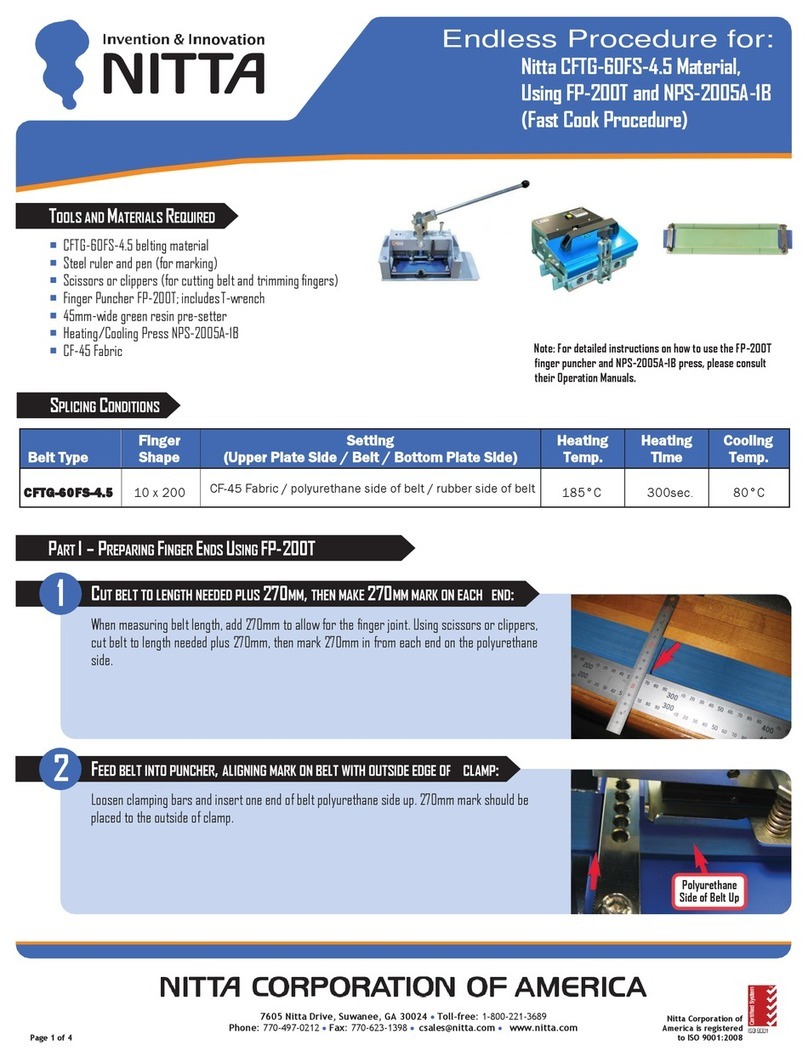

Nitta Carryflex CFTG-60SG-30 User manual

Nitta

Nitta FP-200T User manual

Nitta

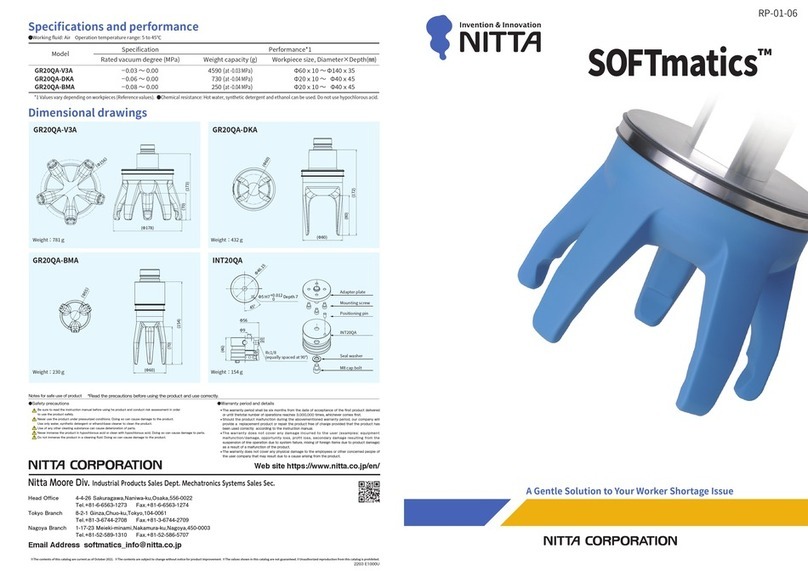

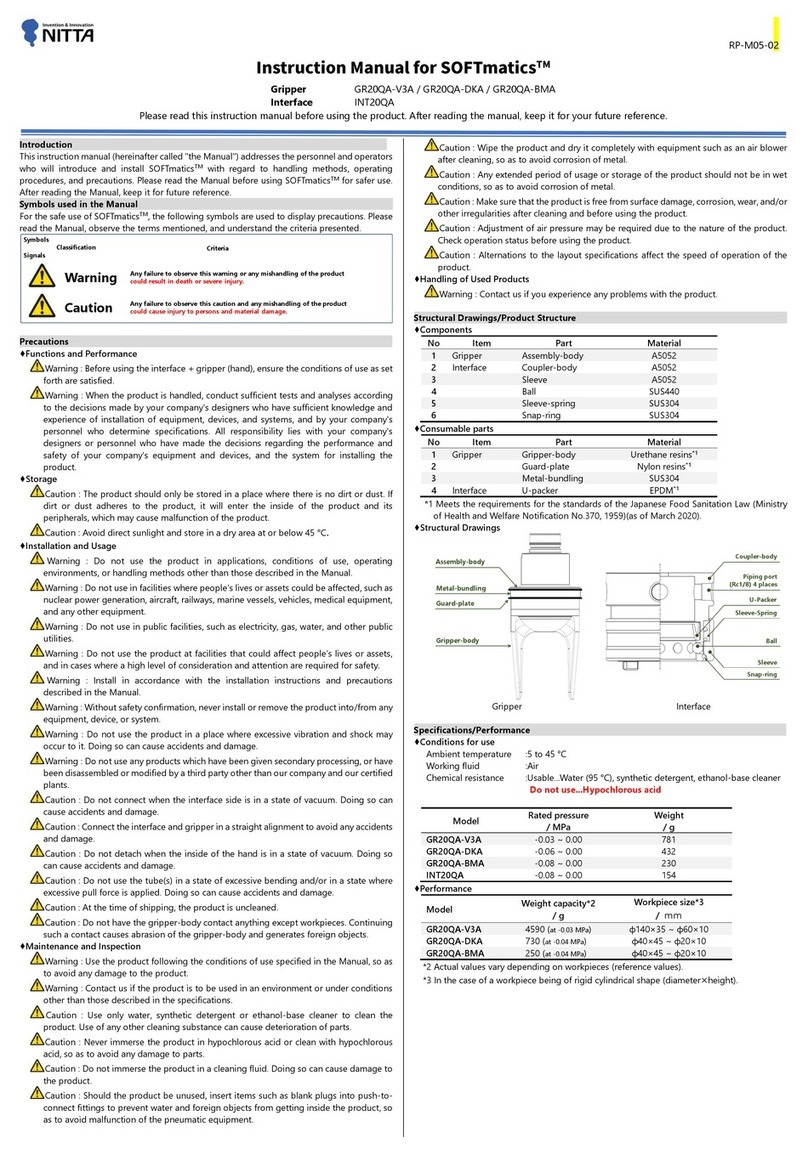

Nitta SOFTmatics User manual

Nitta

Nitta FP-200 User manual

Nitta

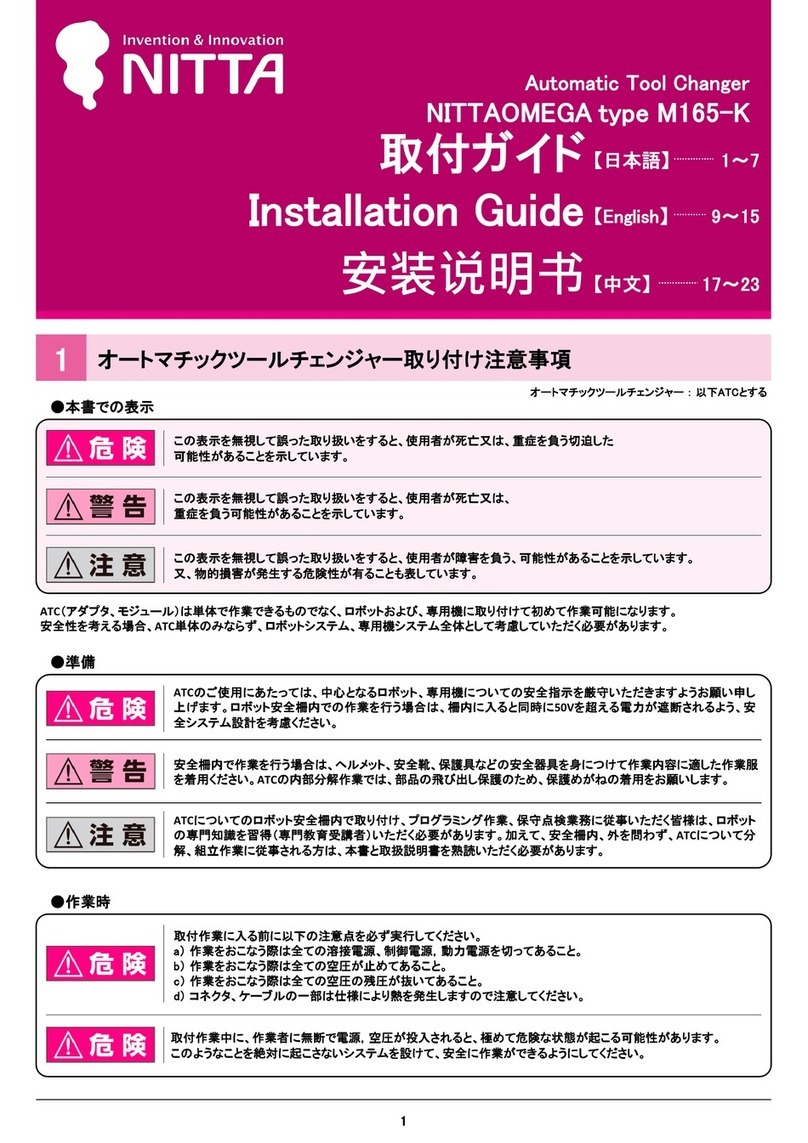

Nitta NITTAOMEGA type M165-K User manual

Nitta

Nitta SOFTmatics GR20QA-V3A User manual

Nitta

Nitta SEB User manual

Nitta

Nitta NPS-1205C User manual

Nitta

Nitta CFTG-60FS-4.5 User manual

Popular Industrial Equipment manuals by other brands

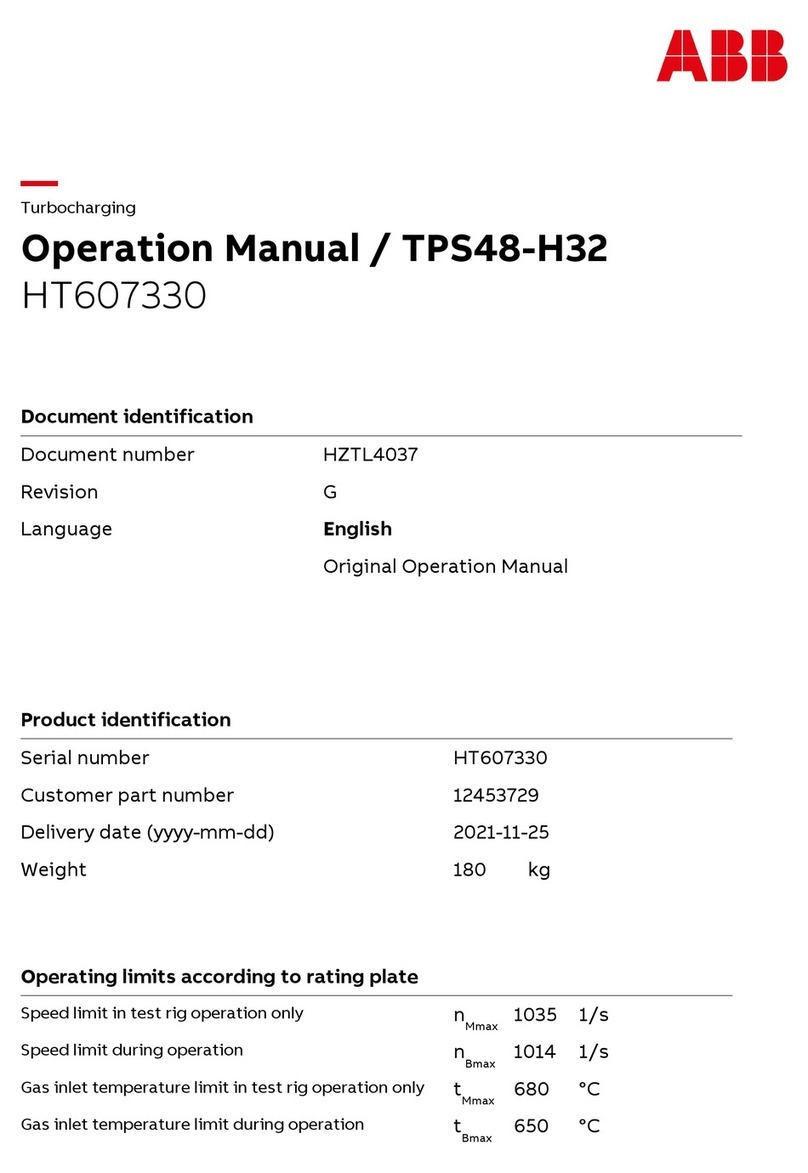

ABB

ABB HT607330 Operation manual

Wacker Neuson

Wacker Neuson RD 7 Series Operator's manual

Nakanishi

Nakanishi HTS1501 Operation manual

DANA

DANA MO213S10 Maintenance and repair instruction manual

ELTEX

ELTEX EXR5C Series operating instructions

Dorner

Dorner 3200 Series Installation, maintenance & parts manual

Total Source

Total Source 164TA9661 operating manual

INOXPA

INOXPA NHS VERTICAL AGITATOR Ex Installation, service and maintenance instructions

AIE

AIE G Series INSTALL & MAINTENANCE MANUAL

Grundfos

Grundfos Oxiperm 164 D Quick reference guide

SIP

SIP Winntec 09807 Y440105 manual

Transforming Technologies

Transforming Technologies IN1202-22 Operation manual