7

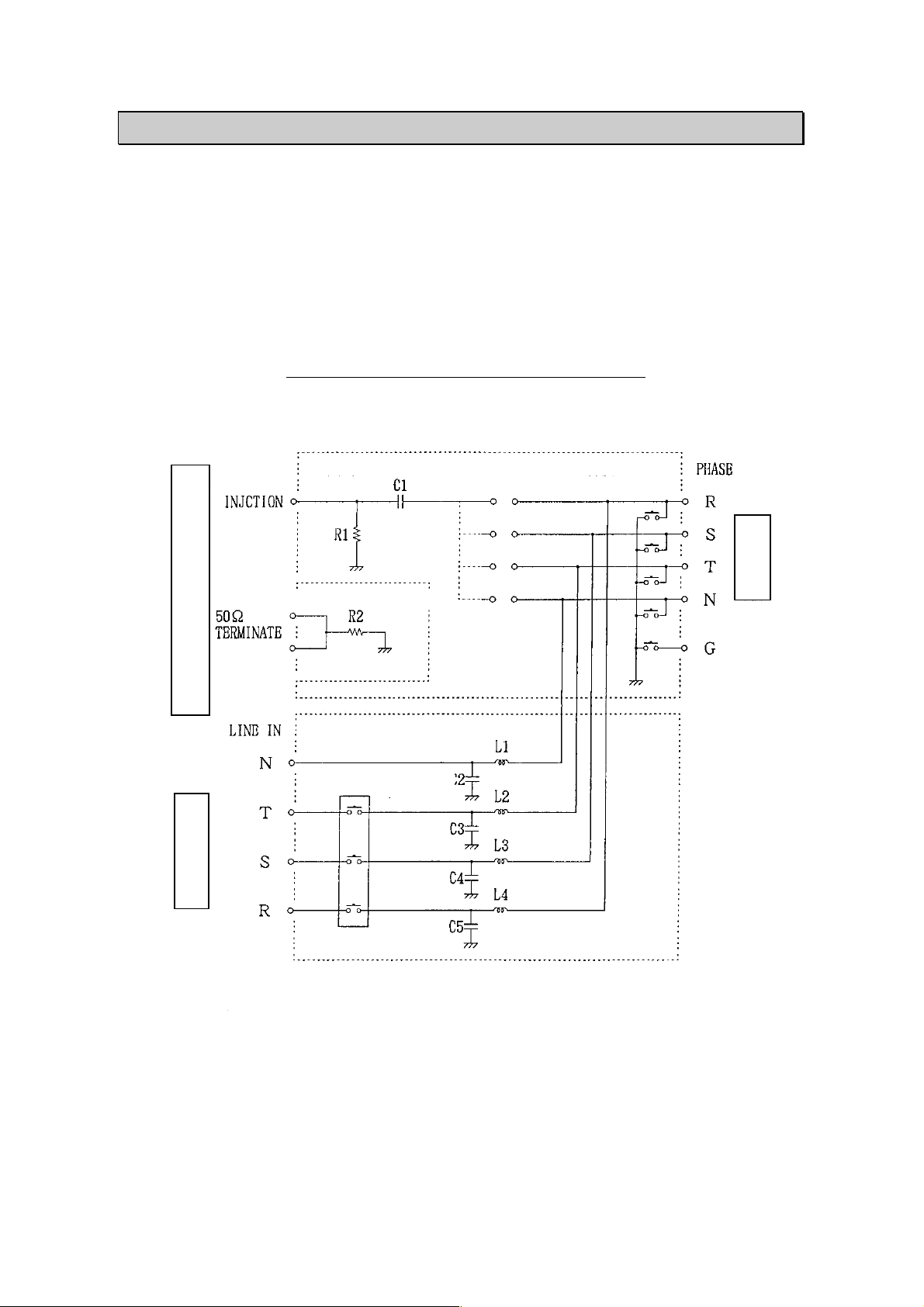

9. The AC INPUT (AC inlet) terminal on the rear panel has a conductor for safety

grounding connection. This unit shall be connected to a properly grounded service

outlet through the AC INPUT. hen this unit is not grounded through the AC INPUT,

PE terminal positioned next to it shall be used. [Precautions for connection]

10. High voltages exist inside the unit. Never open the covers. [Precautions for human

body]

11. NOISE LABORATORY and its sales agents shall have no liability against any accident

resulting in injury or death, any damage to equipment or any resultant damage thereof,

which is caused by abuse or careless handling of this unit. [Precautions for human

body, operation, environments and connection]

12. The G terminal provided on the front panel of this unit functions as the signal

reference ground for testing. The PE terminal (EUT) is for the protective earth

conductor for the EUT. The protective earth terminals for this unit itself are the AC

inlet earth pin (AC INPUT) and PE positioned in close proximity. These SG, EUT PE,

simulator PE are independent each other. hen conducting tests, make connections

according to Section 8 OPERATION. [Precautions for operation and connection]

13. The test rig used in conjunction with this unit should be insulated against a minimum

voltage of 8kV (when the built-in 50Ω

ΩΩ

Ω terminator disconnected from the test circuit).

[Precautions for environments]

14. During test, high level of electromagnetic radiation may be generated depending on

the type or nature of the EUT and thus causing interference with nearby electronic

equipment and radio communication equipment. In such case, the user may have to

take measures such as a faraday cage, shielded room, shielded cable and so on.

[Precaution for environments]

15. Be sure to connect the ground plane to the safety ground. [Precautions for operation

and safety]

16. To ensure safety in operation, use the accessories (use power cord and LINE input

cable with relevant safety agency approval) and optional equipment supplied by our

company. Use of others may degrade the safety and performance of this unit.

[Precaution for handling and safety]

17. Do not use nor keep the unit in a hot or cold environment (Operating temperature:

15°C~35°C/Operating humidity range: 25~75%) otherwise, the unit may be damaged or

only exhibit limited performance. [Precaution for environments]

18. If condensation is found, fully dry the unit before operating it, otherwise, the unit may

be damaged or only exhibit limited performance. [Precautions for environments]

19. Do not drop the unit or do not give strong shock to the unit. [Precaution for handling]

20. hen installing the unit, do not block the vent. [Precaution for environments]

21. Do not supply voltage exceeding the rated voltage range. [Precautions for installation

and connection]