NoiseKen ESS-801 User manual

INSTRUCTION MANUAL

IEC 61000-4-2

ESD TEST ENVIRONMENT

MODEL ESS-801

NOISE LABORATORY CO LTD.

5.01Edition

AEC00004-00E-4B

Description MODEL

Test table 03-00039A

Insulation sheet 03-00004A

Vertical coupling plane 03-00005A

Horizontal coupling plane 03-00020A

Ground plane 03-00007A

Cable with discharge resistors 05-00054B

NOTICE

•

The contents of this instruction manual are subject to change without prior notice.

•

No part of this instruction manual may be reproduced or distributed, in any form or by

any means, without the authorization of Noise Laboratory Co., Ltd.

•

The contents of this instruction manual have been thoroughly examined. However, if

you find any problems, misprints, or missing information, please feel free to contact our

sales agent who you purchased our product from.

•

Noise Laboratory Co., Ltd. assumes no responsibility for any loss or damage resulting

from improper usage, failure to follow this instruction manual, or any repair or

modifications of this product undertaken by a third party other than Noise Laboratory

Co., Ltd. or its authorized person.

•

Noise Laboratory Co., Ltd. assumes no responsibility for any loss or damage resulting

from remodeling or conversion solely undertaken by the user.

•

Please note that Noise Laboratory Co., Ltd. cannot be held responsible for any

consequences arising from the use of this product.

1

The following instructions form an integral part of this product and must be available to the operating

personnel at all times. All the safety instructions and advice notes are to be observed. This instruction

manual should be kept the place the operator can always consult it.

1. IMPORTANT SAFETY PRECAUTIONS

This product is originally intended to be used as a ready ESD

test test-up for table-top equipment to the EN/IEC 61000-4-2

standard. Do not use this product for any purposes other than

the EMC testing porposes.

As for the handling of test equipment, its peripheral equipment

and EUT (Equipment Under Test), refer to the instruction manual

of each equipment.

A number of safety recommendations are listed in "Basic safety

precautions" mentioned later. Be sure to read them before setting a

test environment, connection and starting a test.

2

Memorandum

3

2. APPLICATION FORM FOR INSTRUCTION MANUAL

To:Noise Laboratory Co., Ltd.

We place an order for an instruction manual.

Product:ESD Test Environment

Model:

ESS-801

Applicant:

Company name:

Address:

Department:

Person in charge:

Tel No.:

Fax No.:

Cut off this page "APPLICATION FORM FOR INSTRUCTION MANUAL"

from this volume and keep it for future use with care.

When an INSTRUCTION MANUAL is required, fill in the above Application Form

and mail or fax it to the following sales department of our company.

To: NOISE LABORATORY CO., LTD.

1-4-4 CHIYODA, CHUO-KU, SAGAMIHARA CITY,

KANAGAWA PREF., 252-0237 JAPAN

Tel: +81-42-712-2051 Fax: +81-42-712-2050

Cut line

Cut line

4

Memorandum

5

1. IMPORTANT SAFETY PRECAUTIONS...................................................................................1

2. APPLICATION FORM FOR INSTRUCTION MANUAL............................................................3

3. CONTENTS...............................................................................................................................5

4. PREFACE..................................................................................................................................7

5. BASIC SAFETY PRECAUTIONS .............................................................................................8

5-1.

Hazard symbols ....................................................................................................................8

5-2.

Fundamental Safety Precautions..........................................................................................8

6. SPECIFICATIONS...................................................................................................................10

7. PRODUCT CONTENTS ..........................................................................................................12

8. ASSEMBLING INSTRUCTIONS.............................................................................................14

8-1.

Assembling the ground plane .............................................................................................14

8-2.

Assembling the test table....................................................................................................15

9. OPERATING PRECAUTIONS ................................................................................................18

10. TEST CONFIGURATION (INFORAMATIVE) .......................................................................20

11. WARRANTY..........................................................................................................................22

12. MAINTENANCE ....................................................................................................................24

13. NOISE LABORATORY SUPPORT NETWORK ...................................................................25

3. CONTENTS

6

Memorandum

7

We thank you very much for your purchase of this product (ESD Test Environment as per EN/IEC

61000-4-2 standard). This product is a ready-made test environment conforming to the IEC standard

for table-top equipment. In addition, this product is also applicable to other ESD tests and other types of

EMC test.

To ensure the safe and correct procedure of electrostatic discharge tests, thoroughly read this

Instruction Manual together with the instruction manual for the discharge gun being used. It is

recommended that the contents of the Manual be thoroughly understood and used as a ready

reference for operation.

This instruction manual was prepared so that any person who can

observe the prescribed test method and operating precautions

may safely handle and fully utilize this ESD Test Environment

(Model ESS-801).

This instruction manual describes the basic construction,

specification, and assembling way of this product as well as the

configuration of the related equipment for ESD immunity test.

Keep this manual by your side or other proper location so that it

may be readily available when using the ESS-801.

For floor-standing equipment, the other ready-made test

environment MODEL:ESS-801GL is readily available as the

optional product for the NoiseKen ESD simulators.

Features

1. In combination with the NoiseKen ESD simulator, this product offers a ready-made test environment

for ESD tests as per the EN/IEC 61000-4-2 standard.

2. Made by wood, the test table minimizes the loss of energy produced by the simulator, leading to

reproducible tests.

4. PREFACE

8

5-1. Hazard symbols

It expresses a WARNING.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in

death or serious

injury.

【WARNING labels may be present on the associated equipment you use. Please be sure to refer to the safety

precautions provided in the relevant product manual.】

It expresses a CAUTION.

CAUTION indicates a potentially hazardous situation

which, if not avoided,

may result in minor or

moderate injury.

5-2. Fundamental Safety Precautions

1. Test table shall be assembled before use. For assembling, follow the assembling instructions

shown in a later part of this manual. Assembling can be performed only in a safe place and

by two or more persons. Follow the general safety instructions of the users’ work place.

Working in an inappropriate environment may lead to an injury.

【Precautions for human body, environment and safety】

2. As the ground plane is a thin plate, wear gloves when handling them. As it is weighty part

(over 7kg), be careful not to drop it on your feet.

【Precautions for installation and safety】

3. The top board of the test table must be fixed to the legs with the blocks. However, when

relocating the product, check that the top board has been firmly fixed. If the top board has not

been not firmly fixed, it may come off from the legs, resulting in a danger.

Before carrying the table, unload all items from it first. Carriage shall be done by two or more

persons.

【Precautions for handling and safety】

4. Install the test table on a flat floor surface. After installation, check to see that the 4 legs are in

touch with the floor.

【Precautions for installation and environment】

5. Test Table is capable of withstanding up to 100kg. Never exceed this load limit. Avoid

concentrating loads to the edges of the table. Never apply strong shock or power in the

horizontal direction.

【Precautions for handling】

5. BASIC SAFETY PRECAUTIONS

5.BASIC SAFTY PRECAUTIONS

9

6. Never step on or sit on the table. Never use the product as unintended.

【Precautions for handling】

7. The test table is made of wood. Avoid using or storing this product in a high or low

temperature, or high humidity environment. (Operating temperature range: 15~35°C/

Operating humidity range: 25~75%). Never put any device which generates fire, high heat or

vapor on or in proximity to the table. Never expose it to liquid, such as chemicals, or gas.

【Precautions for handling, installation, and environment】

8. As the vertical coupling plane is a thin plate, carefully handle it. Otherwise you may suffer an

injury. Pay special attention to handling of this plane.

【Precautions for handling】

9. To ensure the safe and correct procedure of EMC tests, the contents of this manual should be

thoroughly understood and used as a ready reference for operation. It is also recommended

to read this Instruction Manual together with the instruction manuals of test equipments being

used as well as related standards.

【Precautions for human body, operation, environment and connection】

10. Do not wipe this product with thinner, alcohol or other solvent. When the body is dirty, soak a

cloth into neutral detergent, squeeze out the detergent from the cloth and wipe the body with

the cloth.

【Precautions for handling】

11. When repair, maintenance work or internal adjustment is required, our company's service

engineer or our designated service engineer takes charge of such work.

【Precautions for handling and environment】

12. NOISE LABORATORY and its selling agents shall not be liable for any accident resulting in

injury or any physical damage due to abuse or mishandling of this unit, and also shall not

assume the responsibility for any resultant damages.

【Precautions for human body, operation, environments and connection】

10

※Uniformly distributed static load

ESD Test Environment [all assembled]

6. SPECIFICATIONS

Description Model Dimensions:mm Thickness:mm

Quantity

Material,Note

Test table 03-00039A 1600

×

800

×

800

(Weight

:22kg)── 1

Top board:lauan plywood

legs,beam:poplar

Load limit

:100kg

※

Insulation sheet

03-00004A 1450×650 0.5 1sh Polyvinyl chloride

Vertical coupling

plane 03-00005A 500×500 1.5 1sh Plane:aluminum

Stand:bakelite

Center adapter:delrin

Ground plane 03-00007A 1800×1000

(Weight

:7.2kg)

1.5 1

set

= 3

sh

Aluminum

Horizontal

coupling plane 03-00020A 1600

×

800

(Weight

:5.2kg)

1.5 1

sh

Aluminum

Cable with

discharge

resistors 05-00054B length:2000 ── 2

pcs

470 kΩx 2

Insulation sheet

Vertical coupling plane

Horizontal

coupling plane

Cable with discharge resistors

Test table

Ground plane

11

Memorandum

12

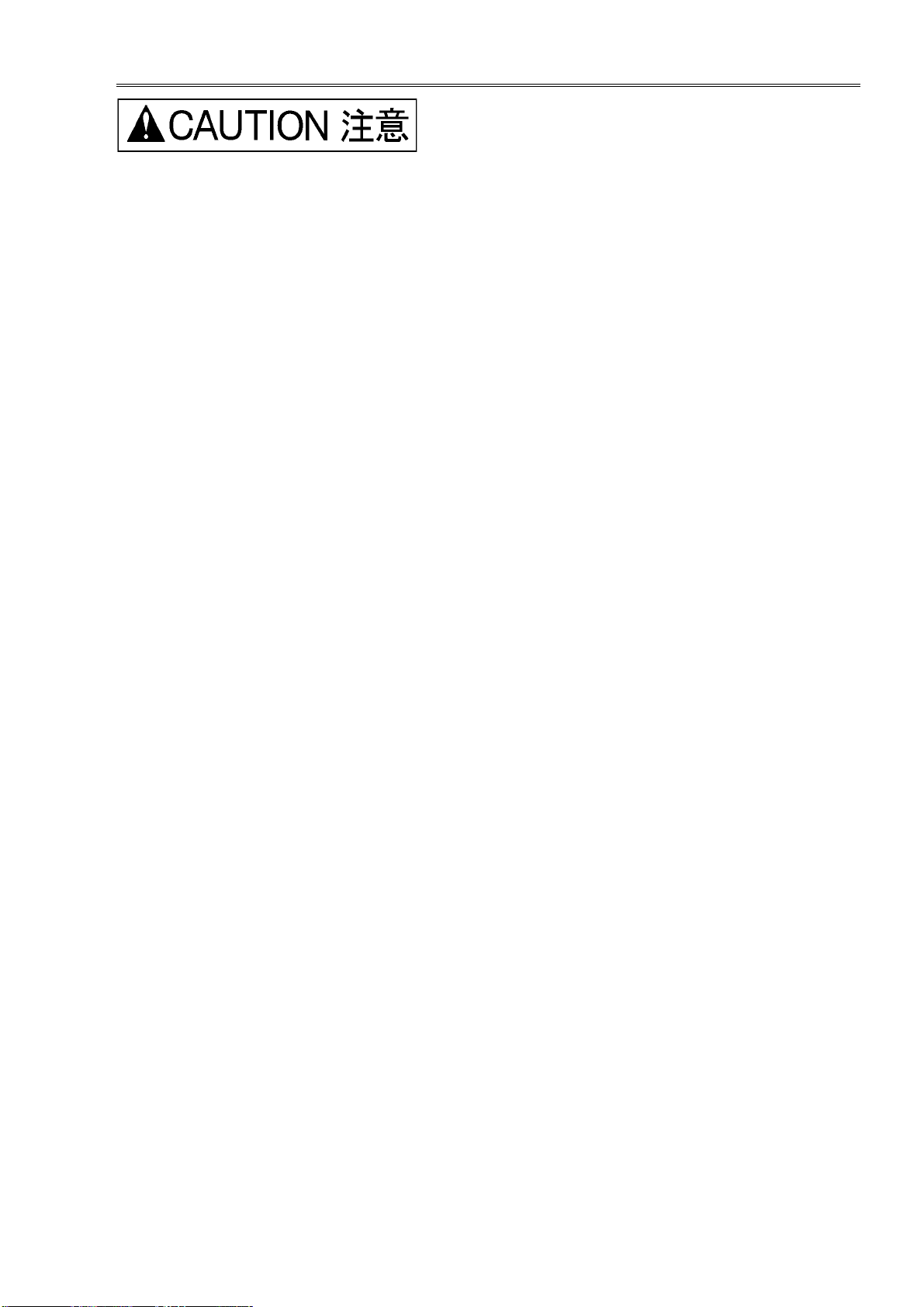

Test table

(MODEL 03-00039A)

Top board with a horizontal coupling plane······························································1

Legs················································································································2

Beam···············································································································2

Wedge··············································································································4 pcs.

Retaining block···································································································4 pcs.

Insulation sheet

(MODEL 03-00004A) ··································································

1 sh

Horizontal coupling plane attached to the table top

(MODEL 03-00020A)··········

1 sh

Ground plane

(MODEL 03-00007A) ······································································

3 sh

Screw M3 with washer··························································· 14 (including 2 spares)pcs

7. PRODUCT CONTENTS

Top board

Legs

Beam

Wedge

Retaining block

Insulation sheet

(Color: White)

Ground plane

Screw M3

13

Cable with discharge resistors

(MODEL 05-00054B)

··································2 pcs.

Screw M4 with a washer··················································································· 4 pcs.

Vertical coupling plane

(MODEL 03-00005A)

Vertical coupling plane····················································································· 1 sh

Stand············································································································ 2 pcs

Center adapter ······························································································· 1 pcs

Instruction manual

(this booklet)

····························································1

Center adapter

Screw M4

Vertical coupling plane

Stand

Instruction Manual

Cable with discharge

resistors

14

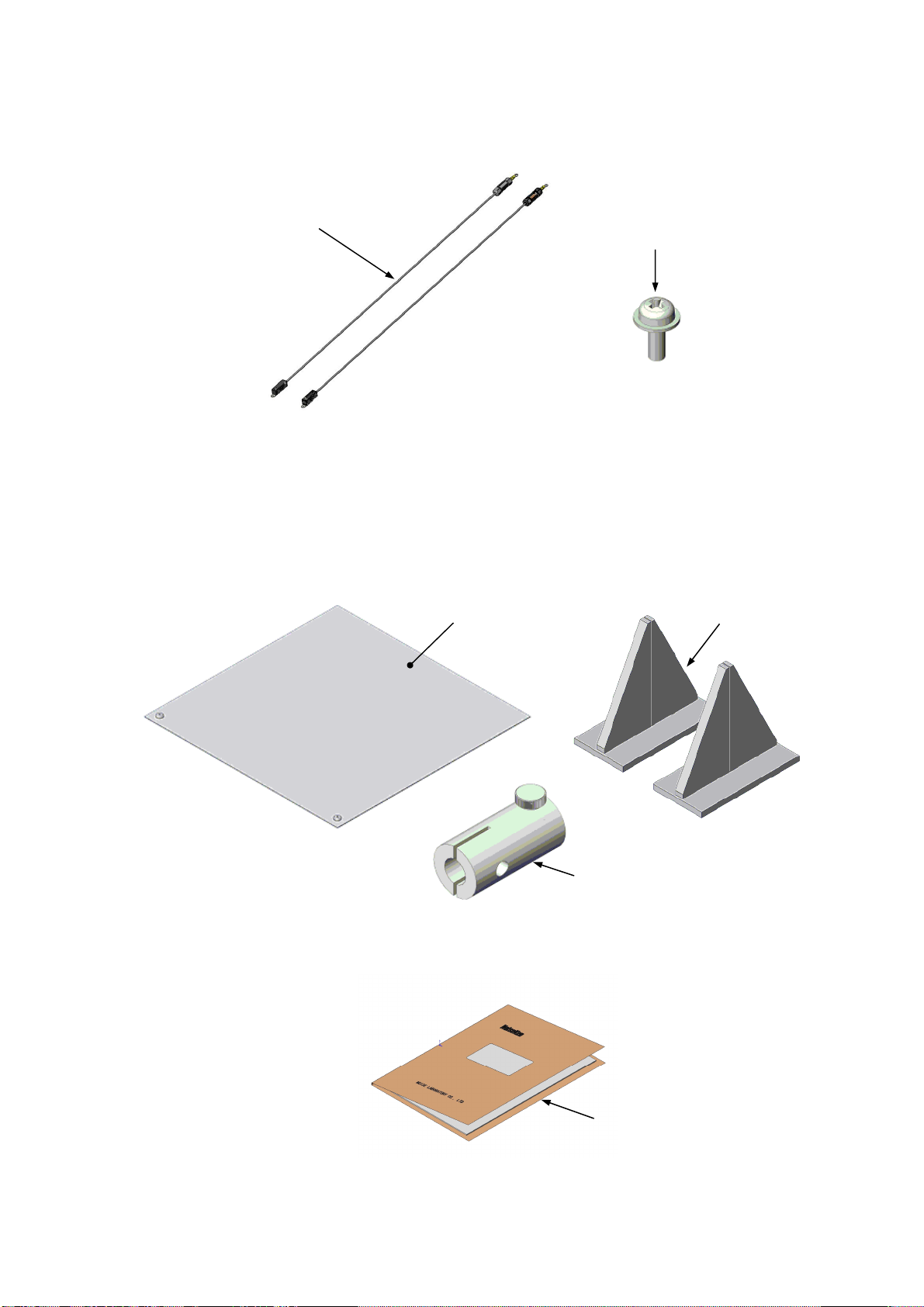

8-1. Assembling the ground plane

As the figure shows, align the screw holes of a plane (after ripping off its protective film)to those of the

others and fix them by the supplied M3 screws.

8. ASSEMBLING INSTRUCTIONS

Ground plane

Screw M3

φ4 hole

M3 Screw hole

【Assembled】

15

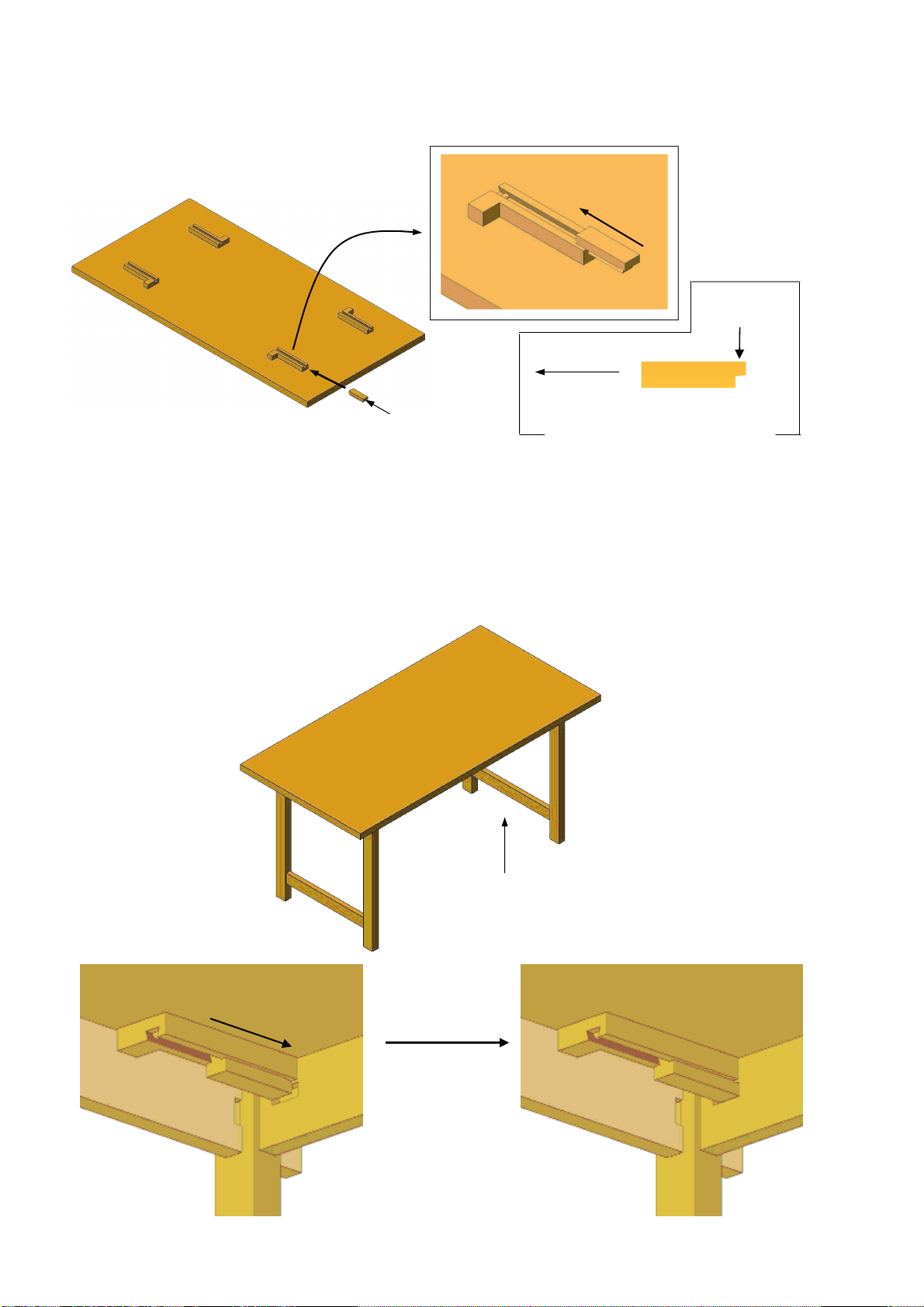

8-2. Assembling the test table

①Insert the beams to the grooves of the legs (Beams have no direction).

Legs

Beam

16

② Insert the retaining blocks to the rails at each corner of the backside of the top board.

Each block shall be firmly inserted to the half-depth with the projection outwards.

③Put the top board on the legs assembled in step ①(The rails are to be positioned within the

legs).

④Following the step ③, manually insert the retaining blocks to the angle holes of the legs, to

their dept.

Important:

::

:Be sure to proceed with all four corners. Work in the correct manner,

otherwise, the top board will slip, leading to danger with the personnel.

Retaining block

Gaze up

Insert blocks to

angle holes

firmly with

ensuring fitting is

right.

From beneath the table

Insert this way

Projection

The Retaining block from the side

17

⑤Manually insert the wedges to the angle holes of the beams. Proceed for all four corners.

⑥Hit the wedges with a plastic hammer.

Important:

::

:Hard hitting may cause damages to the product.

⑦Now the product has been fully assembled. Check to see that there is no jounce.

【Fully assembled】

flat surface

Insert this way

The wedge from the top

flat surface

(

illus

t

ration not to scale

)

18

9. Operating Precautions

To ensure safety, the following advices shall be observed.

1. Install the test table on a flat floor surface. After installation, check to see that the 4

legs are in touch with the floor. If the floor is tilted or bumpy, the table may jounce,

which may lead to a drop of the object put on the table.

2. The top board of the test table must be fixed to the legs with the blocks. However,

when relocating the product, check that the top board has been firmly fixed. If the top

board has not been firmly fixed, it may come off from the legs, resulting in a danger.

3. The test table is capable of withstanding up to 100 kg. Never exceed this load limit.

Avoid concentrating loads to the edges of the table.

Never apply strong shock or power in the horizontal direction. If you step or sit on the

test table, you may suffer an injury.

4. For the test table, periodic checks are recommended for the wedges and retaining

blocks that there is no irregularity.

5. To ensure the safe and correct procedure of EMC tests, the contents of this manual

should be thoroughly understood and used as a ready reference for operation. It is

also recommended to read this instruction manual together with the instruction

manuals for the associated products.

Table of contents

Other NoiseKen Test Equipment manuals

NoiseKen

NoiseKen FNS-AX4-A20-N2447 User manual

NoiseKen

NoiseKen LSS-F02 Series User manual

NoiseKen

NoiseKen LSS-F03 Series User manual

NoiseKen

NoiseKen EPS-02Ev3 User manual

NoiseKen

NoiseKen LSS-720B2 User manual

NoiseKen

NoiseKen ESS-S3011 User manual

NoiseKen

NoiseKen LSS-6000 Series User manual

NoiseKen

NoiseKen INS-AX2 Series User manual

NoiseKen

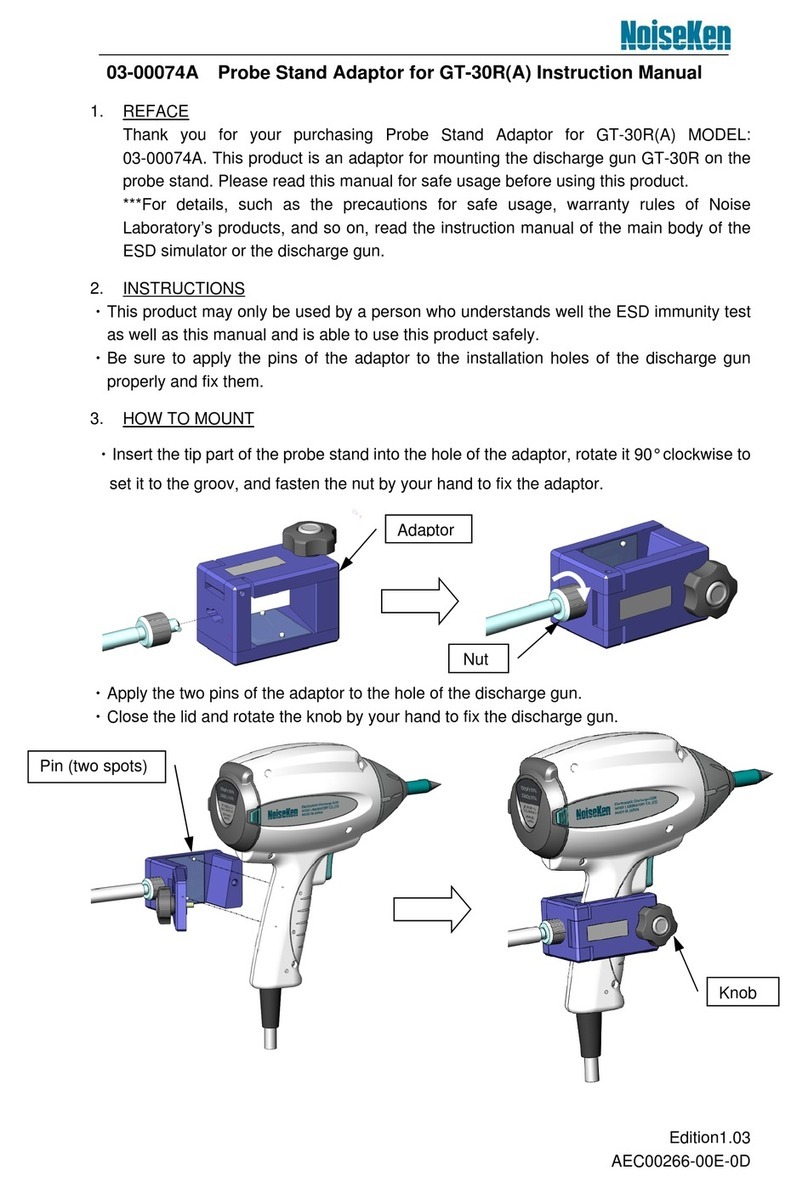

NoiseKen 03-00074A User manual

NoiseKen

NoiseKen 01-00006A User manual