Norac Gregson Maverick 120 Series User manual

Table of contents

Other Norac Controllers manuals

Norac

Norac UC4 Total Control User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4 Plus Rogator 1286C User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4+ User manual

Norac

Norac UC4+ User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4+ Raptor Pro 1200 User manual

Norac

Norac UC4+ Roll Control User manual

Norac

Norac UC4 Plus Rogator 64 Series User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4+ TA 1200 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4+ User manual

Norac

Norac UC4+ User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4+ User manual

Norac

Norac UC5 Topcon X30 User manual

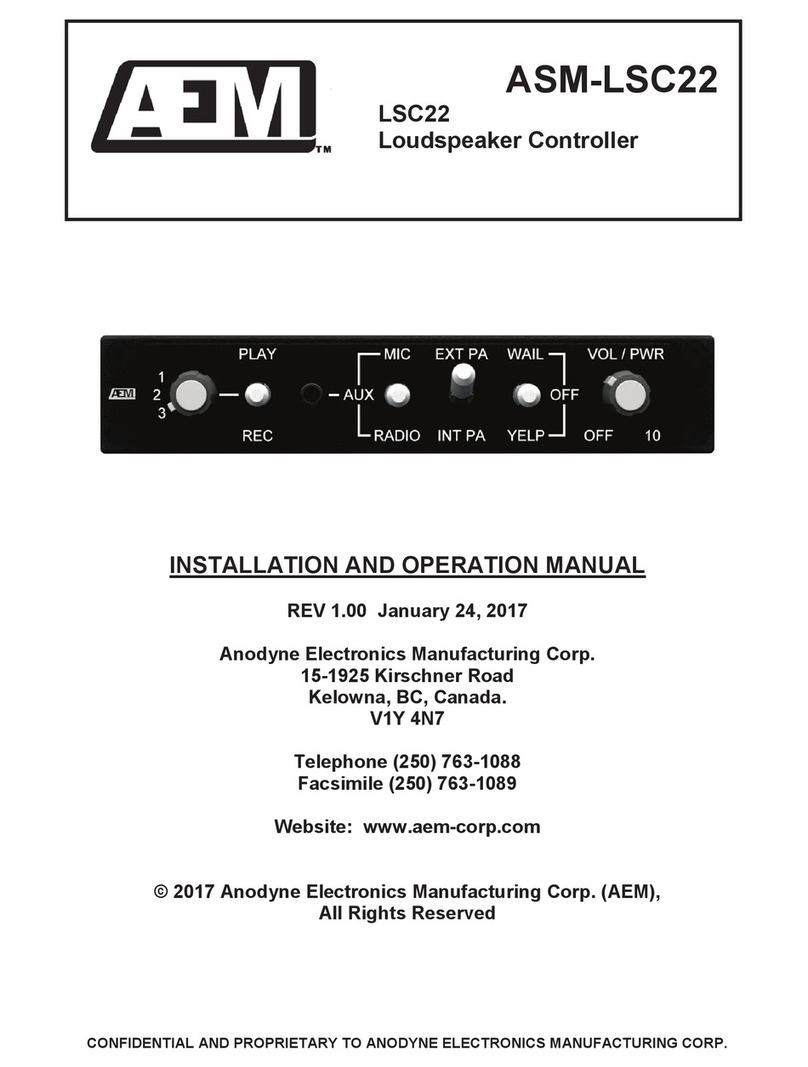

Popular Controllers manuals by other brands

Xylem

Xylem Flygt FGC 400 Installation, operation and maintenance

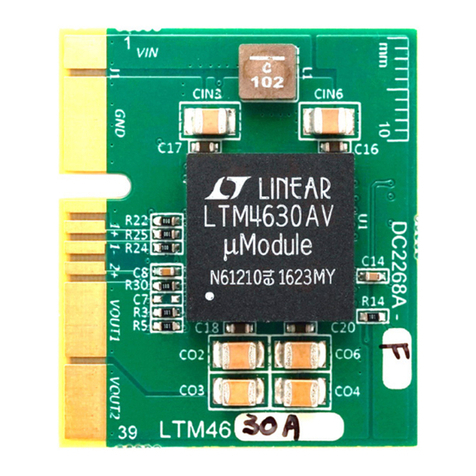

Analog Devices

Analog Devices Linear LTM4630A Demo Manual

Regin

Regin REGIO RC-T instructions

Oracle

Oracle MICROS Kitchen Display Controller 210 Setup guide

Siemens

Siemens MT Series Technical instructions

Intermatic

Intermatic T10000RT Series Installation, operation & service manual