TABLE OF CONTENTS

1INTRODUCTION..................................................................................................................................1

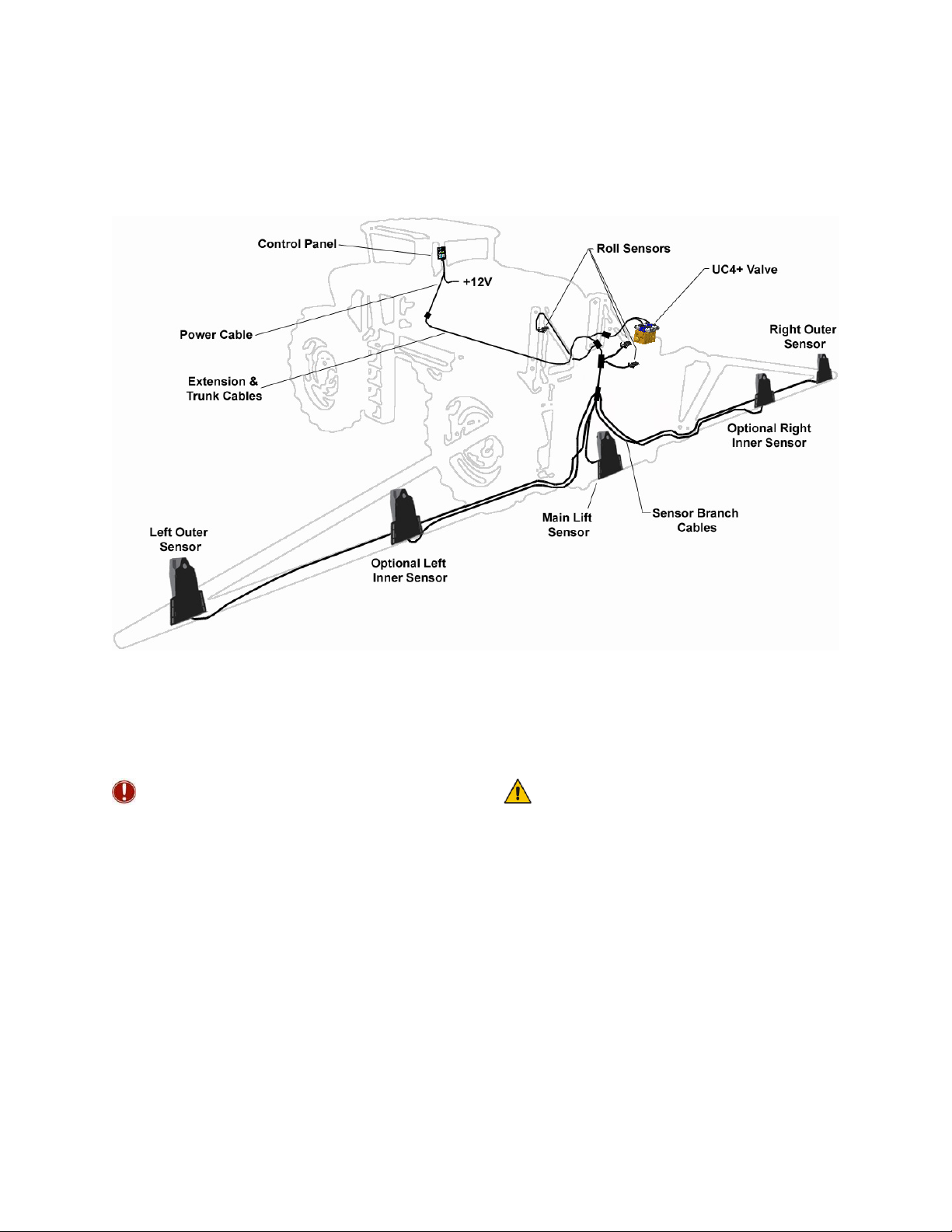

2GENERAL SYSTEM DESCRIPTION ..................................................................................................2

3PARTS LISTS ......................................................................................................................................3

4INSTALLATION PROCEDURE...........................................................................................................7

4.1EXISTING SYSTEM CHECK ...............................................................................................................7

4.2BOOM SPEED TEST........................................................................................................................7

4.3WING SENSOR INSTALLATION.........................................................................................................9

4.4MAIN LIFT SENSOR INSTALLATION..................................................................................................13

4.5ROLL SENSOR INSTALLATION.......................................................................................................14

4.5.1Boom Frame Roll Sensor Mounting......................................................................................15

4.5.2Intermediate Frame Roll Sensor Mounting ...........................................................................16

4.5.3Reference Frame Roll Sensor Mounting...............................................................................17

4.6HYDRAULIC INSTALLATION ...........................................................................................................18

4.6.1Valve Assembly.....................................................................................................................18

4.6.2Valve Mounting......................................................................................................................19

4.6.3Hydraulic Plumbing ...............................................................................................................20

4.7ELECTRICAL INSTALLATION..........................................................................................................21

4.8COMPLETING THE INSTALLATION ..................................................................................................24

5ELECTRICAL REFERENCE – CABLE DRAWINGS........................................................................25

5.1ITEM C01: 44662B-40 –SENSOR TRUNK CABLE .........................................................................25

5.2ITEM C02: 44668 –CABLE UC4 SENSOR BRANCH.......................................................................25

5.3ITEM C02B: 44664 –CABLE UC4 CAN NODE DUAL 5FT...............................................................26

5.4ITEM C05: 44674 –CABLE UC4 SENSOR ROLL BIAS ...................................................................26

5.5ITEM C10: 44650-12 –CABLE POWER BOOM CONTROL CASE IH 4260........................................27

5.6ITEM C11: 44658-07 –WIRING HARNESS UC3 BOOM CONTROL PIGTAIL TO SHROUD...................27

5.7ITEM C12: 44659D –CABLE VALVE PATRIOT/CASE IH 4260........................................................28