Norac UC4+ User manual

PLA MAP II 3250 F

Installation Manual

Spray Height Controller

Improving the competitiveness o Industry and Agriculture

through Precision Measurement

Printed in Canada

Copyright 2005-08 by NORAC Systems International Inc.

Reorder P/N: UC4+BC+PL1-INST Rev B (PLA MAP II 3250 F)

NOTICE

NORAC Systems International Inc. reserves the right to improve products and their specifications without notice and without the

requirement to update products sold previously. Every effort has been made to ensure the accuracy of the information contained

in this manual. The technical information in this manual was reviewed at the time of approval for publication.

TABLE OF CONTENTS

1

INTRODUCTION..................................................................................................................................1

2

GENERAL SYSTEM DESCRIPTION ..................................................................................................2

3

PARTS LISTS ......................................................................................................................................4

4

INSTALLATION PROCEDURE...........................................................................................................8

4.1

WING SENSOR INSTALLATION.........................................................................................................8

4.2

MAIN LIFT SENSOR INSTALLATION......................................................................................11

4.3

ROLL SENSOR INSTALLATION.......................................................................................................12

4.3.1

Boom Frame Roll Sensor Mounting......................................................................................13

4.3.2

Chassis Roll Sensor Mounting..............................................................................................14

4.4

HYDRAULIC INSTALLATION ...........................................................................................................15

4.4.1

Valve Assembly.....................................................................................................................15

4.4.2

Valve Mounting......................................................................................................................15

4.4.3

Hydraulic Plumbing ...............................................................................................................16

4.5

ELECTRICAL INSTALLATION..........................................................................................................17

4.6

COMPLETING THE INSTALLATION ..................................................................................................21

5

ELECTRICAL REFERENCE – CABLE DRAWINGS........................................................................22

5.1

ITEM C02: 44668 –SENSOR BRANCH CABLE...............................................................................22

5.2

ITEM C02B: 44664 -CABLE UC4 CAN NODE DUAL.....................................................................22

5.3

ITEM C03: 44656 –CABLE VALVE VARIABLE RATE......................................................................23

5.4

ITEM C10: 44650-39 –CABLE POWER GENERIC SELF-PROPELLED..............................................24

5.5

ITEM C11: 44651-03 –CABLE EXTENSION CABLE VALVE GENERIC..............................................25

5.6

ITEM C14: 44658-28 –CABLE INTERFACE UC4 BC C14 POWER PIGTAIL.....................................26

5.7

ITEM C12: 44658-38 –CABLE INTERFACE UC4 BC C12 DIN ALL...............................................27

5.8

ITEM C16: 44658-39 –CABLE INTERFACE UC4 BC C16 DIN.......................................................28

6

APPENDIX A – VALVE CONNECTOR CHANGE.............................................................................29

1

1

INTRODUCTION

Congratulations on your purchase of the NORAC UC4+ Spray Height Controller. This system is

manufactured with top quality components and is engineered using the latest technology to

provide operating features and reliability unmatched for years to come.

When properly used the system can provide protection from sprayer boom damage, improve

sprayer efficiency, and ensure chemicals are applied correctly.

Please take the time to read this manual completely before attempting to install the system. A

thorough understanding of this manual will ensure that you receive the maximum benefit from

the system.

YOUR INPUT CAN HELP MAKE US BETTER! If you find issues or have suggestions

regarding the parts list or the installation procedure, please don’t hesitate to contact us via

the information given below:

Phone: +1-306-664-6711 all other regions

E-mail: [email protected]

Website: www.norac.ca

2

2

GENERAL SYSTEM DESCRIPTION

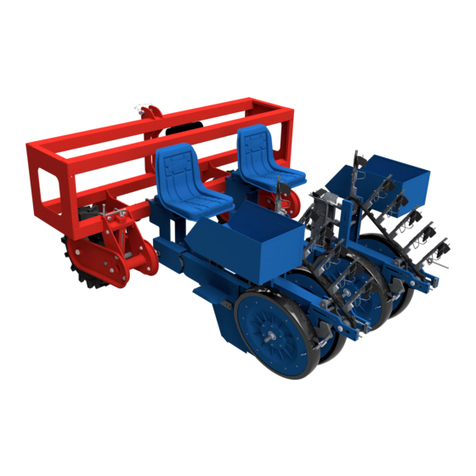

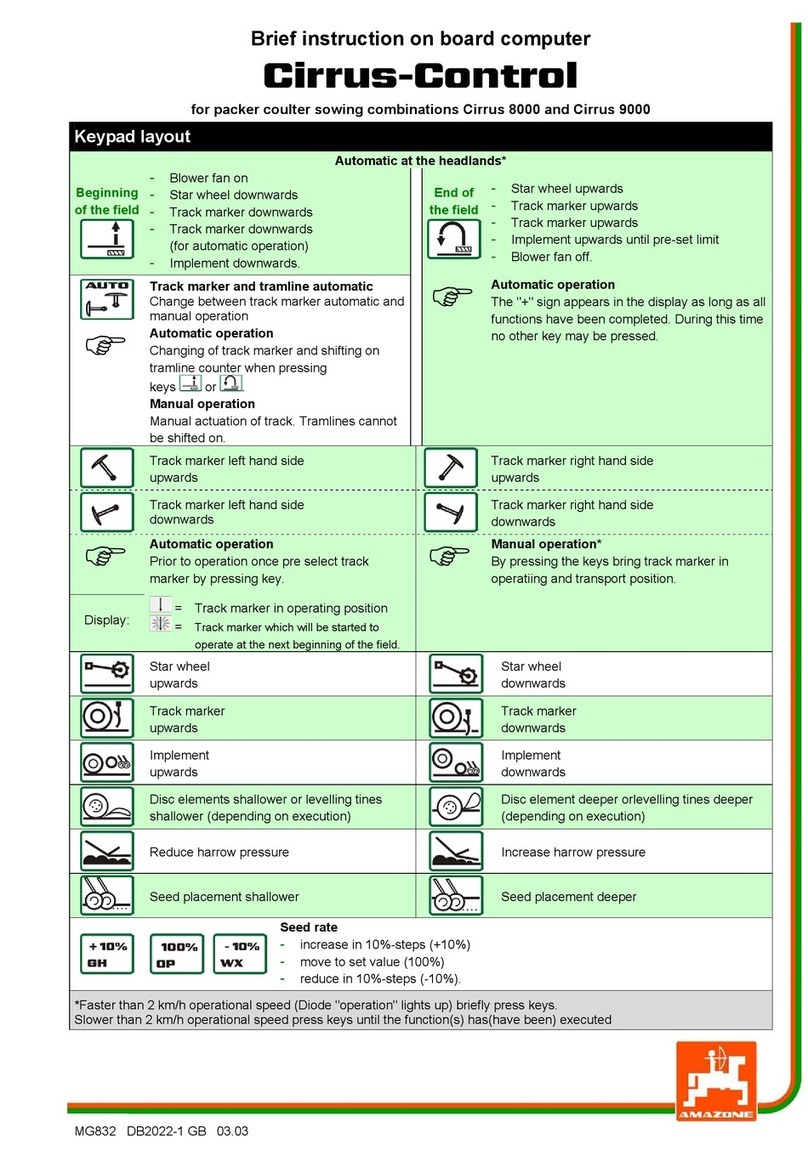

Figure 1 depicts the general system layout of the UC4+ Spray Height Control system.

Figure 1 – System Components and General Location

NOTICE:

Every effort has been made to ensure the

accuracy of the information contained in this

manual. All parts supplied are selected

specially to fit the sprayer to facilitate a

complete installation. However, NORAC

cannot guarantee all parts fit as intended due

to the variations of the sprayer by the

manufacturer. Please read this manual in

its entirety before attempting installation.

ATTENTION:

When installing the UC4+ Spray Height

Control system please be aware that at a

point in the installation your sprayer booms

will be inoperative until the installation is

complete. Any installation procedure

requiring boom movement will need to be

done first. Once the hydraulics have been

disconnected you must complete the

electrical installation before the booms

become operative.

4

3

PARTS LISTS

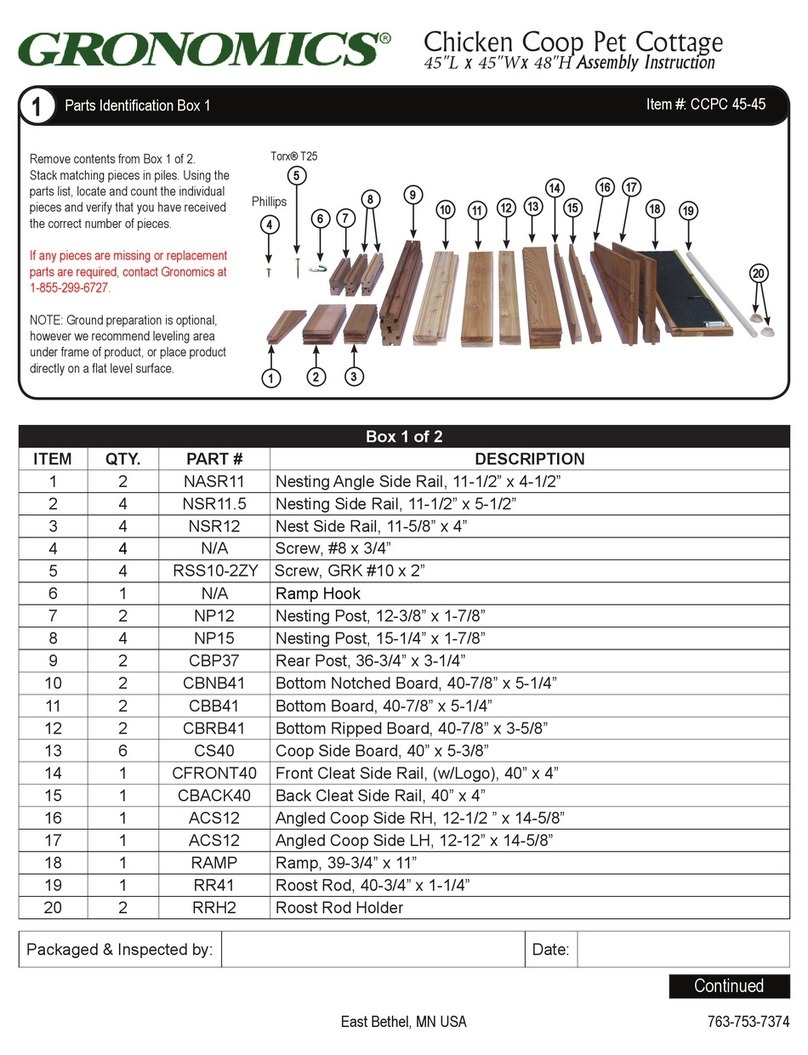

The parts that come with your UC4+ Sprayer Boom System are listed in Table 1. The item number on

the left side of this table references each part.

Please ensure that all parts in your kit are present before proceeding with your installation.

Table 1 – PLA MAP II 3250 F Sprayer Boom Control System Parts (Rev A)

Item Part Number Name Quantity

B05 44706-01 KIT CABLE TIE BLACK 10 PCS 21 IN 150 PCS 7 5 IN 1

B10 44700-06 BRACKET VALVE MOUNTING STD 1

B11 44743 MOUNTING BRACKET MAIN LIFT SENSOR UC4 PLUS 1

B13 44728 MOUNTING BRACKET COMPLETE UC4 BREAKAWAY EXTENDED 2

B14 44724 BRACKET BREAKAWAY SPACER 2IN WITH BOLTS 2

C02 44668 CABLE UC3 SENSOR BRANCH 1 AMP RECEPT 3 AMP PLUG BC 1

C02B 44664 CABLE UC4 CAN NODE DUAL 1

C03 44656D CABLE VALVE VARIABLE RATE DT 1

C10 44650-39 CABLE POWER GENERIC SELF-PROPELLED 1

C11 44651-03 CABLE EXTENSION VALVE GENERIC 1

C12 44658-38 CABLE INTERFACE UC4 BC C12 DIN ALL 1

C14 44658-28 CABLE INTERFACE UC4 BC C14 POWER PIGTAIL 1

C16 44658-39 CABLE INTERFACE UC4 BC C16 DIN 1

E01 4461BC+ UC4 PLUS BOOM CONTROL PANEL 1

E02 44631 UC4 ULTRASOUND SENSOR 3

E03 44641 UC4 PLUS ROLL SENSOR W TEMPERATURE PROBE 1

E04 44642 UC4 PLUS ROLL SENSOR 1

H01 44863-01 HOSE ASSEMBLY 122R2-06 36 IN L 6FJX 6FJX 2

H02 44862-14 HOSE ASSEMBLY 122R2-04 36 IN L 4FJX 4FJX 2

H20 44865-45 HYDRAULICS FITTING KIT - PL1 1

M01 UC4+BC+PL1-INST MANUAL INSTALLATION UC4+ PLA MAP 1

M01A 446BC+MAN6-1 MANUAL UC4+ BOOM CONTROL 2008 OPERATORS SMALL BOOKLET 1

M01B 446BC+MAN6-2 MANUAL UC4+ BOOM CONTROL 2008 QUICK REFERENCE SMALL BOOKLET 1

V01 44933D VALVE BLOCK ASSEM UC5-BC 2-STATION CC/LS VARIABLE RATE DT CONNECTORS 1

5

Table 2 – 44865-45 (Rev A) - Hydraulics Fittings Kit Details

Item Part Number Name Quantity

Picture

F01 103719 MALE ADAPTER - 6MB 4MJ 4

F02 104704 FEMALE JIC CAP - 4FJCN 4

F03 103194 MALE ADAPTER - 6MJ 8MB 2

F04 103993 MALE ADAPTER - 4MJ 4MJ 2

F07 103312 MALE ADAPTER - 6MB 6MJ 2

F08 44928 ORIFICE INSERT 047 IN ONE WAY 4

6 M B - 6 M OR X 90

SIZE IN

1/16

TH'S

GENDER: MALE

OR FEMALE

90

°

ANGLE

SWIVEL

TYPE

GENDER

SIZE

TYPE:

B - ORB

J - JIC

OR - FLAT

FACE

P - PIPE

Fitting Name

Example:

6

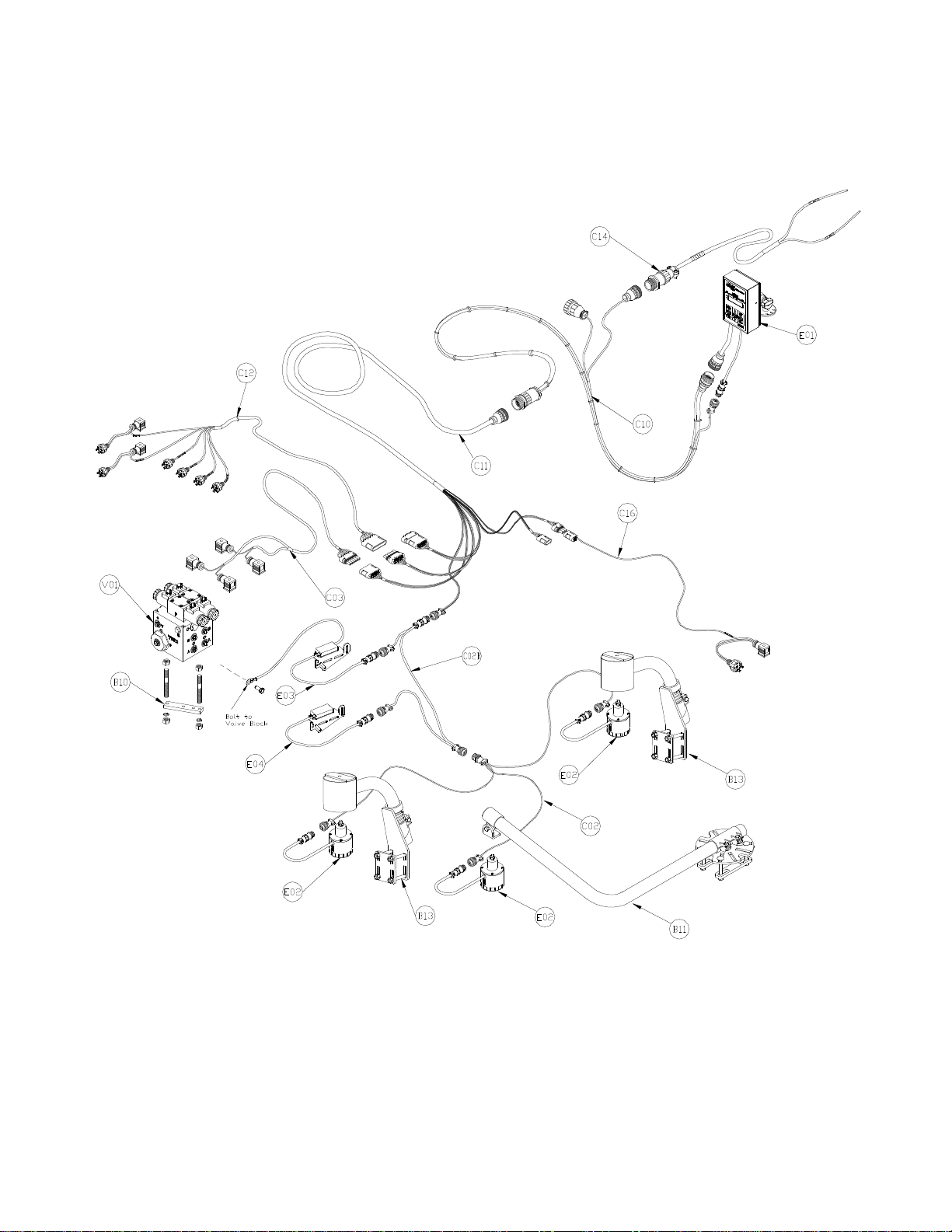

The parts that come with your UC4 System are shown below in their general installation

configuration.

Figure 2 – UC4+ Spray Height Control system Components

*If your valve connectors or cables appear different than shown, refer to Appendix A for more

details.

7

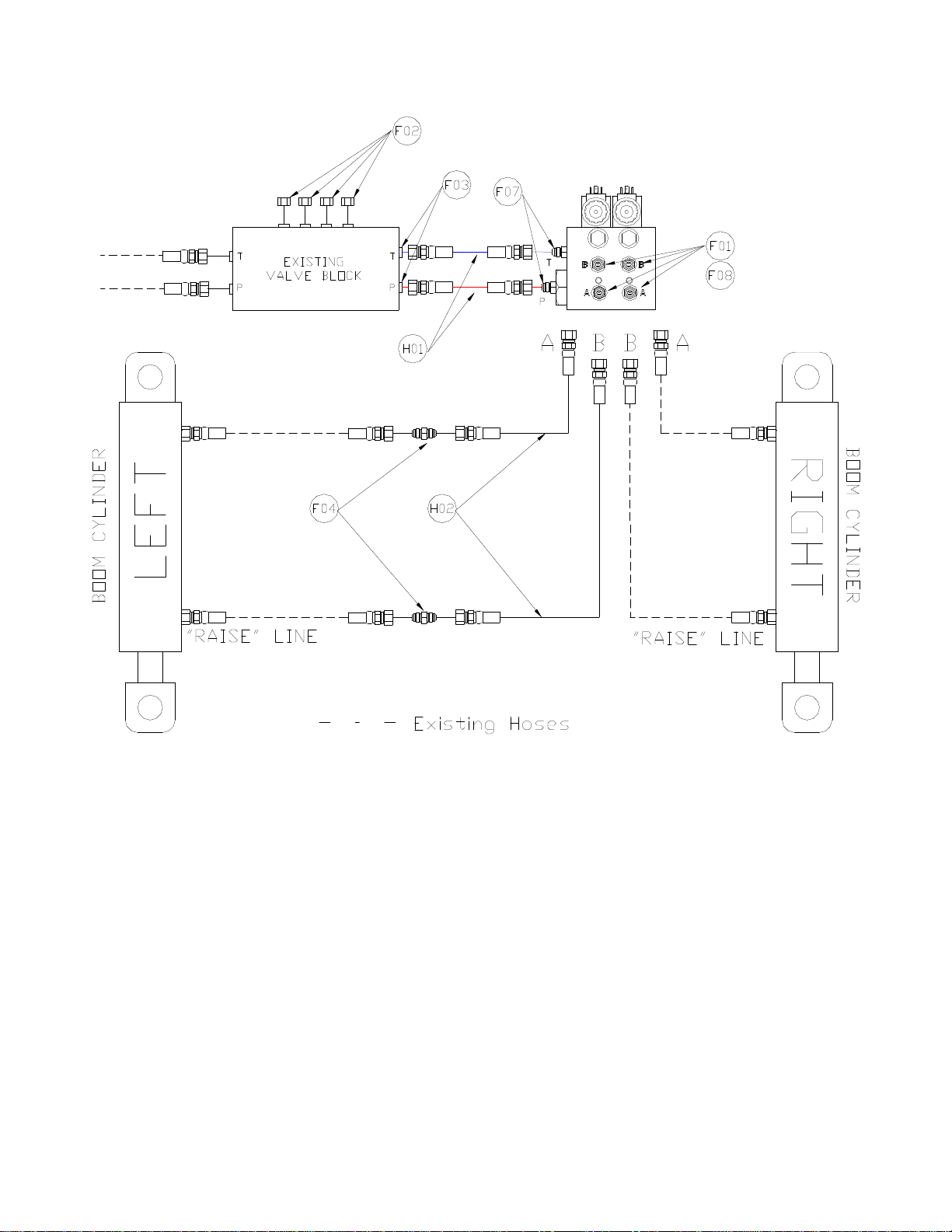

Figure 3 - Hydraulic Plumbing Schematic

8

4

INSTALLATION PROCEDURE

4.1 W

ING

S

ENSOR

I

NSTALLATION

1. Assemble the Breakaway Sensor

Mounting Brackets (B11) as show in

Figure 4 and Figure 5.

Figure 4 – Breakaway Sensor Bracket

Exploded View

Figure 5 – Breakaway Sensor Mounting

Bracket Assembly

To assemble the breakaway sensor

bracket:

a) Assemble the bolt and nut into the

collar.

b) Grease the bottom edge of the collar

and the angled tube of the base.

c) Place the collar onto the angled tube

of the mounting base.

d) Install the spring between the collar

and the upper ring of the base.

e) Insert tube through assembly and

tighten the collar

2. Mount the sensor bracket onto the boom.

If possible, mount the sensor

brackets while the booms are in

their folded position to ensure that

they will not interfere with

anything when the boom is folded

for transport.

3. The mounting brackets can be installed

with the mounting base behind (Figure

9) or in front of the tube (Figure 7).

4. Use the sensor bracket breakaway spacer

(B14) to mount the sensor bracket

(Figure 6).

Figure 6 - Mounting the Sensor

Breakaway Bracket with spacer

Breakway

Bracket

Spacer

9

5. Mount the NORAC UC4+ ultrasonic

sensor (E02) into the sensor brackets.

The sensors should be oriented forward

(ahead) of the boom (see Figure 7 and

Figure 9).

When installing the UC4+ sensors

(E02), start with the smallest serial

number on the left hand side

proceeding to the largest serial

number on the right hand side

(Figure 10).

6. Sensor cables should run through the

mounting bracket tube and then behind

the member the bracket is mounted onto.

Cable-tie the connector in place. The

cable must not be allowed to hang below

the boom (Figure 7).

Figure 7 – Another Acceptable Mounting

Avoid mounting sensors in

locations where they may read

from parts of the boom as shown

in Figure 8.

Figure 8 – Poor Mounting

(Sensor Reading off Boom)

General mounting rules for UC4+

ultrasonic sensors:

a) In its lowest position, the sensor

mouth must be 9 inches or more

from the ground.

b) The bottom of the sensor must be at

least 9 inches in front of the spray

nozzles.

c) The bottom of the sensor must be at

least 9 inches above the spray

nozzles.

d) Ensure that there are no obstructions

within a 12-inch diameter circle

projected directly below the center of

the sensor.

e) The sensor should be approximately

vertical at normal operating heights.

Figure 9 – Sensor Mounting Guidlines

A

B

B

D

C

Ultrasonic

Acoustic Cone

10

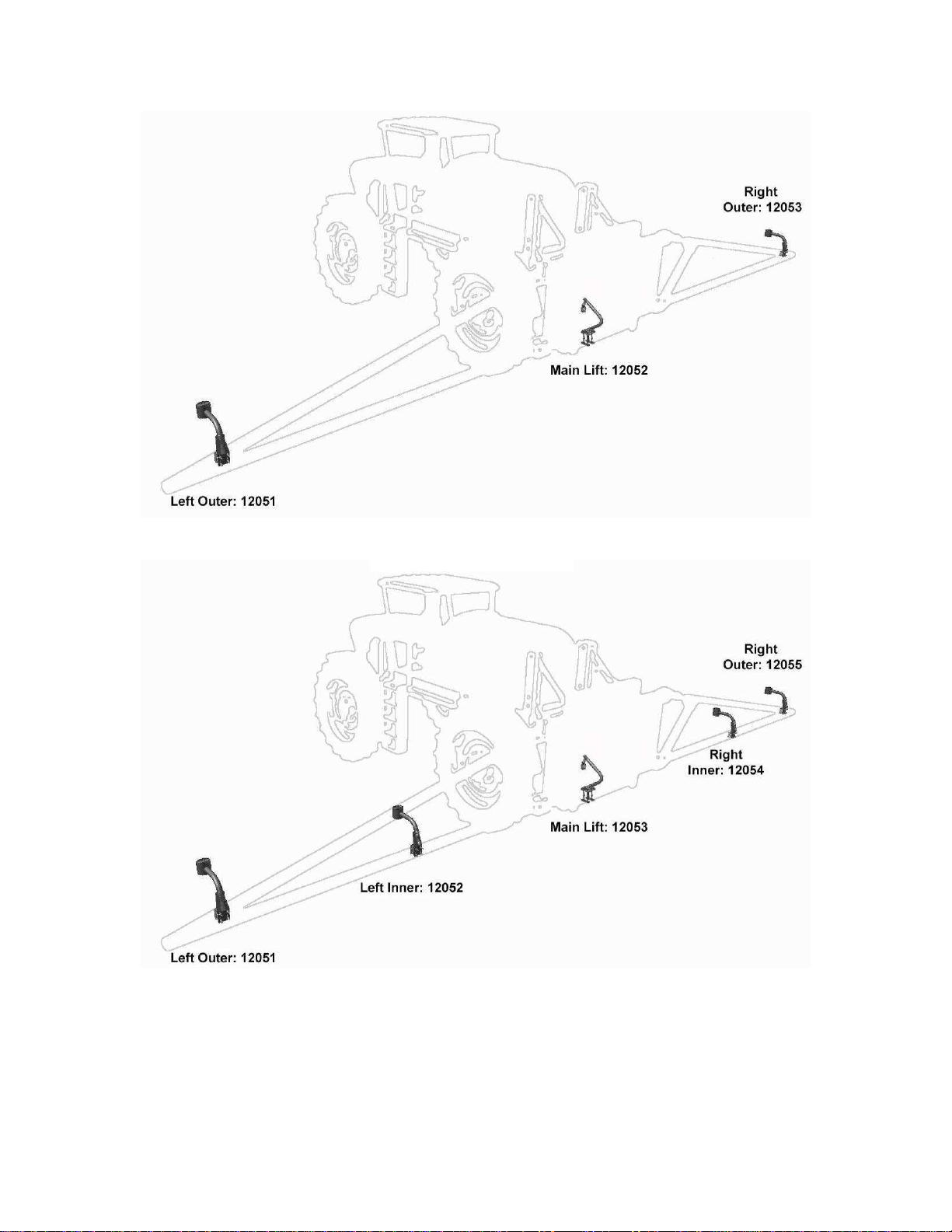

Figure 10 – Sensor Serial Number Installation Location

3 SENSOR SYSTEM

5 SENSOR SYSTEM

11

4.2 MAIN

LIFT

SENSOR

INSTALLATION

1. Assemble the main lift sensor bracket

(B11) as shown in Figure 11.

Figure 11 – Main Lift Sensor Bracket

2. The bracket can then be mounted to the

lowest frame member on the center

section of the sprayer. The bracket

should be mounted so the sensor

mounting collar is in approximately the

center of the sprayer and ahead of the

boom (Figure 12 and Figure 13).

The sensor mounting collar must

not be behind the sprayer’s wheel.

The General Mounting Rules for

UC4+ Ultrasonic Sensors, from the

previous section, must be followed.

Figure 12 – Main Lift Sensor Bracket

Mounting Position

3. Mount the sensor onto the sensor

mounting collar (Figure 12).

Figure 13 – Main Lift Sensor Mounted in

the Correct Location

A common mounting location for the main

lift sensor on a sprayer is shown in Figure

13Error! Reference source not found.. If

desired, the tube part of the bracket can be

cut to a shorter length.

Bracket Tube

Sensor

Mounting Tab

Sensor Mounting

Collar

Bracket Base

12

4.3 R

OLL

S

ENSOR

I

NSTALLATION

When mounting the roll sensors,

be sure they can not contact any

parts of the boom or frame.

Mount the roll sensors to the included

roll sensor brackets using the machine

screws and nylon lock nuts, as illustrated

in Figure 14.

The roll sensors must be mounted

tightly to the brackets.

Figure 14 – Mounting the Roll Sensor to

the Roll Sensor Mounting Bracket

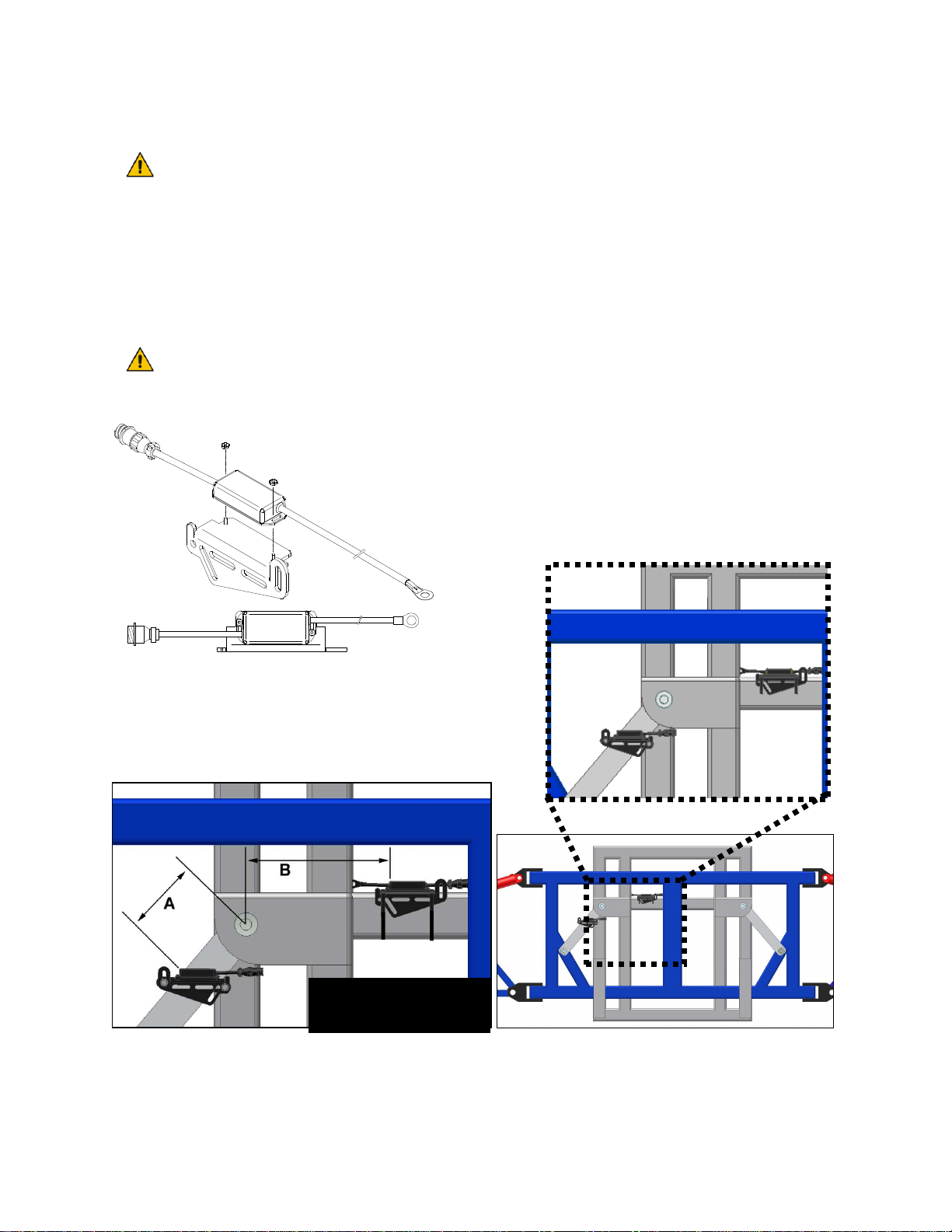

When mounting the roll sensors, use the

following guidelines and refer to Figure 15.

a) The smaller the distance between A

and Bin Figure 15, the better the

performance will be.

b) Ensure the roll sensors are sitting

relatively level when the sprayer

chassis and boom are level.

c) Both roll sensors must be mounted

with the circular AMP connector

facing towards the Right-Hand

Wing (when looking from the rear

of the sprayer).

Figure 15 – General Roll Sensor Mounting Location on a Trapeze Style Boom

Connectors towards

Right-hand Wing

13

4.3.1 Boom Frame Roll Sensor

Mounting

1. Use the supplied hardware to mount the

boom frame roll sensor (E04) as shown

in Figure 16.

When mounting the boom frame roll

sensor follow these guidelines:

a) To prevent bending the bracket,

ensure bolts are placed as close

together as possible (minimize Cin

Figure 16).

b) Be sure to use the roll sensor without

the temperature probe (E04).

c) When the boom is centered (not

rolled over) the roll sensor should be

level with respect to the sprayer

chassis.

d) It is best to mount the roll sensor to

the left hand trapeze link (when

looking from the rear of the sprayer).

e) The roll sensor AMP (circular)

connector MUST exit towards the

right had wing (when looking from

the rear of the sprayer).

Figure 16 – Boom Frame Roll Sensor

Mounted to a Trapeze Link

2. Cable-tie the sensor connector to the

frame with enough slack to allow the

link to rotate.

Make sure the bracket does not

collide with any parts of the

sprayer when the boom rotates.

Also ensure there is enough slack

to allow the roll sensor to rotate.

14

4.3.2 Chassis Roll Sensor Mounting

1. It is often best to cable tie the chassis

roll sensor in place. When mounting the

chassis roll sensor follow the guidelines

and refer to Figure 17.

The chassis roll sensor must be

mounted on a portion of the

sprayer that does not pivot and is

as close to the boom frame roll

sensor as possible (Figure 15).

a) Make sure you are using the roll sensor

with the temperature probe (E03).

b) Ensure the roll sensor is level with

respect to the chassis.

c) The AMP (circular) connector MUST

exit towards the right hand wing.

d) Make sure the temperature probe is

able to reach the side of the valve

block.

Figure 17 – Chassis Roll Sensor Mounting

2. Fasten the temperature probe to the

UC4+ valve block, using the supplied

3/8”x1/2” bolt as shown in Figure 18.

3. Cable-tie the temperature probe cable

and AMP (circular) connector securely

to a frame member.

Check that the roll sensors and

cables will not interfere with, or

come into contact with any parts of

the sprayer.

Figure 18 – Temperature Probe Attached

to the UC4+ Valve Block

15

4.4 H

YDRAULIC

I

NSTALLATION

WARNING!

The hydraulic system creates very high

pressure. Before disconnecting any

hydraulic lines ensure all pressure has

been bled from the system. When

changing the boom hydraulic hoses leave

the booms in TRANSPORT POSITION.

IMPORTANT:

Component failure due to oil

contamination is not covered under the

UC4+ Spray Height Control system

warranty. It is recommended that a

qualified technician does the hydraulic

installation.

4.4.1 Valve Assembly

1. On a clean surface remove all plastic

plugs from the NORAC hydraulic Valve

(V01) (Figure 19).

2. Install the 6MB-6MJ fittings (F07) on

the "P" and "T" ports and tighten to 18

ft-lbs.

Figure 19 – NORAC Valve Block

4. Install two orifices (F08) into the "B"

ports with the notch facing outward as

shown in Figure 20.

5. Install the remaining orifices (F08) into

the "A" ports with the notch facing

inward as shown in Figure 20.

6. Install the 6MB-4MJ fittings (F01) into

the "A" and "B" ports and tighten to 18

ft-lbs.

Figure 20 – Valve Block Assembly

4.4.2 Valve Mounting

1. Mount the NORAC valve (V01) on the

sprayer using the valve mounting

bracket (B10).

A common location for the valve

block is immediately to the right of

the sprayer’s valve block.

Figure 21 - Valve mounting location

NORAC

Valve

16

2. As shown in Figure 22, screw the short

side of the threaded rods into the bottom

of the valve block at least 3/8" (1 cm).

The valve mounting holes are drilled and

tapped 3/8 (1 cm) NC-1" (2.5 cm) deep.

3. Tighten the Hex nuts to hold the rods.

4. Put the mounting bracket on the other

side of the tube and tighten with the

spring washers and the Hex nuts.

5. Cut excess off of the rods, if necessary.

You must ensure no hydraulic

components will interfere with any

sprayer parts or be pulled tight at

any time.

Figure 22 – Valve Mounting Location

4.4.3 Hydraulic Plumbing

WARNING!

From this point in the installation the

booms will be inoperative until the

electronics are fully installed.

1. After the NORAC valves are mounted,

the hydraulic hoses and fittings can be

plumbed. The plumbing for the

hydraulic circuit is shown schematically

in Figure 3.

2. Connect the NORAC supplied hoses

(H01) to the Pressure (P) and Tank (T)

ports on the NORAC valve block (V01).

3. Remove the plugs from the spare

Pressure and Tank ports on the PLA

valve block.

4. Insert the 6MJ-8MB fittings (F03) into

the spare P and T ports on the PLA valve

block.

5. Connect hoses H01 (P and T lines), into

the ports on the sprayer valve block

where the 6MJ-6MB (F03) fittings are

located.

6. The existing hoses that run to the boom

tilt cylinders should be disconnected

from the sprayer valve block and

reconnected to the NORAC valve block.

7. The “raise” lines must be connected to

the "B" ports of the NORAC valve

block. The ports on the sprayer block

must then be capped with 4FJCN caps

(F02).

8. The "A" ports of the NORAC block

must be connected to the “lower” lines

of the cylinders. The ports on the sprayer

block must then be capped with F02.

It may be necessary to use the

supplied extension hoses (H02) and

4MJ-4MJ fittings (F04) to extend

the left tilt cylinder hoses.

17

ROP

4.5 E

LECTRICAL

I

NSTALLATION

1. Install the UC4+ Control Panel (E01) in

the cab of the sprayer. Mount the panel

where it will be clearly visible and

within easy reach of the operator.

A good spot to mount the UC4+ control

panel is on the right hand side of the cab

to the Roll Over Protection Bar. Four

pilot holes for the screws provided need

to be drilled to facilitate the control

panel mounting.

An alternate mounting bracket is

available from PLA. Figure 24 is an

example using the PLA mounting

bracket.

Figure 23 – Control Panel Mounting

Figure 24 – PLA Control Panel Mounting

ROP

18

Figure 25 – Cable Configurations: C10, C1 and C4

2. Connect the UC4+ power cable (C10) to

the UC4+ control panel in the sprayer

cab. Ensure both plugs (P16 and P4) are

connected to the panel.

3. Connect the 3-pin AMP plug (P3) on

C10 to the 3-pin AMP receptacle (R3)

on the power pigtail interface cable

(C14).

Ensure the UC4 control panel’s

power is OFF for the remaining

installation (Bottom of switch

pressed IN). Use caution when

handling the 12 V power line of the

existing wiring.

4. Connect the free ends of C14 to the

power and ground terminals in the PLA

fuse panel. The fuse panel is located

behind the sprayer’s seat.

5. Route the receptacle end (R16) of C10

out of the cab.

6. Connect the 16-pin AMP plug (P16) of

the valve extension cable (C11) to R16

of C10 on the outside of the cab (Figure

25).

Other manuals for UC4+

41

Table of contents

Other Norac Farm Equipment manuals

Norac

Norac UC4+ User manual

Norac

Norac UCB Sx275 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4 Total Control User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4+ User manual

Norac

Norac UC5 Sx275 User manual

Popular Farm Equipment manuals by other brands

Kemper

Kemper 300F Operator's manual

Ritchie

Ritchie CattleMaster Series installation instructions

Walinga

Walinga Grain-Vac 7614F Operator's manual

Zipper Mowers

Zipper Mowers ZI-MD500HST user manual

Amazone

Amazone Cirrus-Control Brief instructions

GREAT PLAINS

GREAT PLAINS Turbo Max VT1110-7.5M Operator's manual