9

4

INSTALLATION PROCEDURE

4.1 E

XISTING SYSTEM CHECK

It is necessary to check the existing system’s

functionality before installing the UC4+

Spray Height Control system

1 Drive your sprayer onto a flat piece of

land, with unobstructed boom movement

(e g no power lines)

2 Test that all boom functions operate

correctly As you test each function

check it off in Table 3

It is necessary to test the boom

functions in all directions

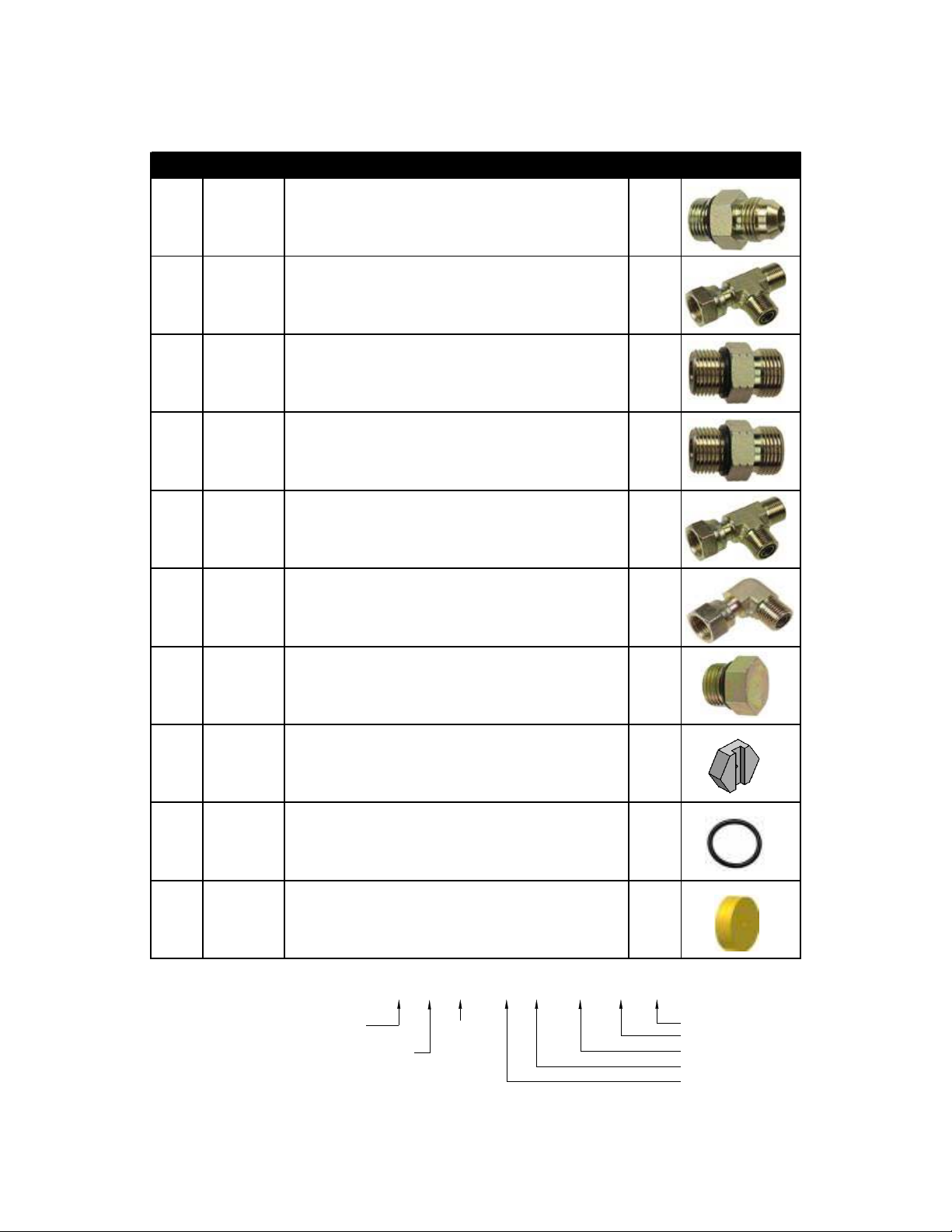

Table 3 – Hydraulic System Function

Check Sheet

BOOM

IN

OUT UP DOWN

LEFT

MAIN

RIGHT

*

Some sprayers may not have this function

4.2 B

OOM

S

PEED

T

EST

IMPORTANT:

Raise/lower all boom sections se eral

times to warm up the hydraulic system.

Grease all mo ing parts for consistent

results.

1 Lower each boom and main section as

close to the ground as possible

2 Set your sprayer at field working RPM

on the throttle and mark this value in

Table 4

You will need a stopwatch or a

watch that displays “seconds” for

the next step.

3 Raise the LEFT boom from its extreme

LOW position to the very TOP of its

travel Record the time this takes in

Table 4, “Trial #1” for “Left UP”

4 Lower the LEFT boom from its extreme

HIGH position to the BOTTOM of its

travel Record this time in Table 4,

Trial #1 for “Left DOWN”

Be careful when lowering the

booms so they don’t hit the

ground.

5 Similarly, record two more time trials

(Trial #2 & #3) for the LEFT boom and

record in Table 4.

6 Repeat Steps 1 through 5 for the RIGHT,

MAIN and ROLL functions

Your sprayer may not ha e a roll

feature.

7 Average the three trials recorded for

each boom movement and record this

calculation in the “Average Time” slot in

Table 4.

8 These “Average Times” now represent

how quickly your system can react to

manual control In Section 1.1, this

procedure is repeated with the UC4+

Spray Height Control system installed

for comparison and troubleshooting

purposes